Equipment for producing two-sided stainless steel composite thin strips by explosive composite rolling

A technology of production equipment and compound rolling, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low production efficiency and complicated process flow, and achieve high production efficiency, high processing precision and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

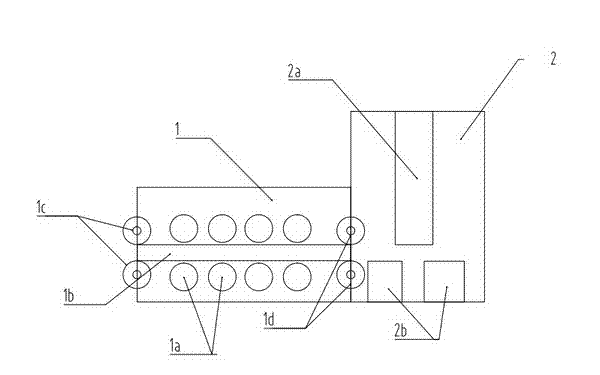

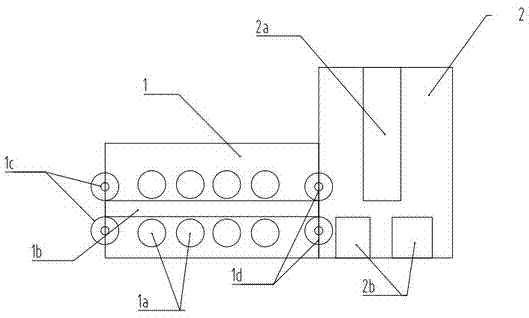

[0012] In order to gain an in-depth understanding of a production equipment for explosive clad rolling double-sided stainless steel clad thin strip, combined with figure 1 described as follows:

[0013] Explosive compound rolling double-sided stainless steel composite thin strip production equipment, the production equipment includes a grinding unit 1 and a straightening unit 2, the grinding unit 1 is a closed steel cuboid, and one end is designed with a roller 1c for clamping and transporting a steel plate 1b up and down. The roller 1c is connected to more than one pair of grinding rollers 1a in the horizontal advance direction, and then connected to the second roller 1d that clamps and transports the steel plate 1b up and down, and transports the steel plate 1b to the straightening unit 2; the straightening unit 2 has an upper apex 2a, two lower Vertex 2b. Grinding unit 1 is used for derusting and grinding process, and straightening unit 2 is used for straightening the blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com