Treatment method of distillation extraction waste liquid in fine chemical engineering production

A treatment method, distillation and extraction technology, applied in chemical instruments and methods, oxidized water/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems of high cost, long residence time, high pressure, etc., and achieve low cost and easy operation Convenience, easy management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

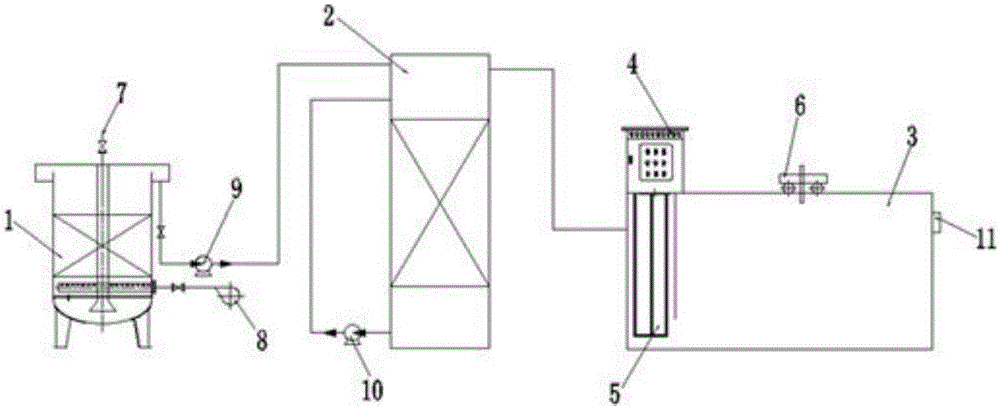

[0021] like figure 1 Shown, a kind of processing method of fine chemical industry production distillation extraction waste liquid comprises the following steps:

[0022] 1) Micro-electrolysis treatment: The waste water first enters from the water inlet 7 and passes through the micro-electrolysis equipment 1. The micro-electrolysis equipment 1 adopts a micro-electrical machine with a large anode and a small cathode, and fills the equipment with scrap iron chips and inert carbon particles in a special proportion. Under the pressurization of Roots blower 8, when iron filings and carbon particles are immersed in acidic wastewater, due to the electrode potential difference between iron and carbon, countless micro-primary batteries will be formed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com