Ornithine production technology

A production process, ornithine technology, applied in the preparation of organic compounds, solid adsorbent liquid separation, organic chemistry, etc., can solve the problems of poor adsorption of ammonium resin, low product concentration, low adsorption capacity, etc., and achieve reduction The effect of wastewater discharge, high product concentration, and large adsorption capacity

Active Publication Date: 2014-07-16

XIAMEN STARMEM TECH

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

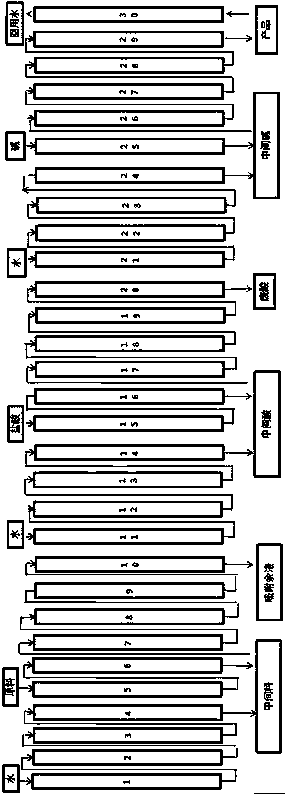

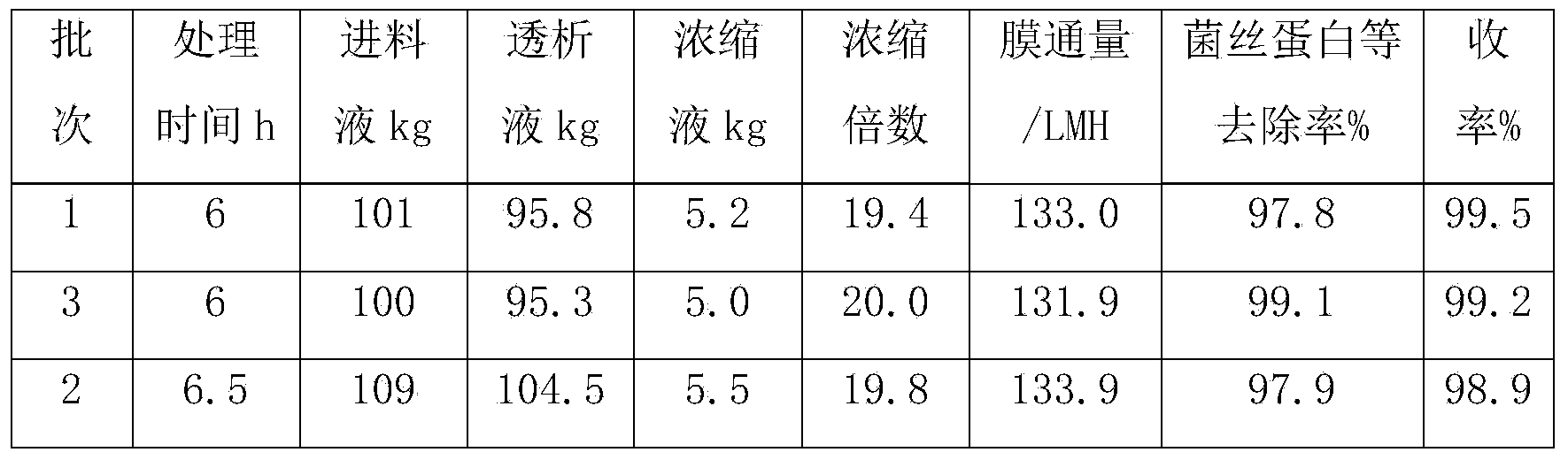

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] This example is used to illustrate the method for producing ornithine provided by the present invention.

[0036] 1) Ceramic membrane filtration

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Login to View More

Abstract

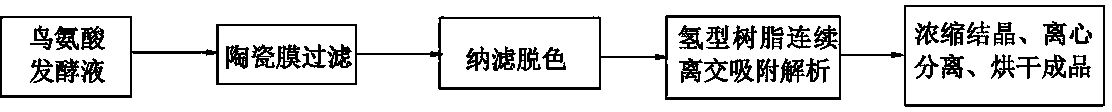

The invention discloses an ornithine production technology. The ornithine production technology is characterized by comprising the following steps: step one. filtering a ornithine fermentation liquid by using a ceramic membrane so as to obtain microfiltration dialysate; step two. carrying out nanofiltration decolorization on the microfiltration dialysate, and further purifying the microfiltration dialysate so as to obtain nanofiltration dialysate; step three. carrying out continuous ion exchange adsorption-desorption on the nanofiltration dialysate by filled hydrogen cation exchange resin so as to obtain ornithined liquor; and step four. concentrating, crystallizing and centrifugally separating the continuous ion exchange adsorption-desorption ornithined liquor, and drying a finished product so as to obtain a ornithine crystal. The ornithine production technology disclosed by the invention has the beneficial effects that the yield is high, the purification effect is good, the product concentration is stable, and the production cost is low.

Description

technical field [0001] The invention relates to the field of amino acid production, in particular to a production process of ornithine. Background technique [0002] The scientific name of Ornithine is α, δ-diaminovaleric acid, its molecular formula is C5H12N2O2, and its relative molecular mass is 132.16. It is an essential intermediate metabolite in human metabolism, mainly participates in the ornithine cycle (uric acid cycle, Krebs-Henseleit cycle), and plays an important role in the discharge of ammonia nitrogen. Its multifunctional health care function has made the development of ornithine products gradually heated up in recent years, and its application in the fields of medicine, health care and chemical industry is also becoming more and more extensive. [0003] The current production method of ornithine mainly includes the following steps: filtration, adsorption and analysis, ammonia removal, concentrated crystallization, centrifugal separation, and drying of the fin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C229/26C07C227/40B01D15/04

Inventor 张松北李振峰卢伯福孙洪贵

Owner XIAMEN STARMEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com