Cylinder sleeve cleaning device and cylinder sleeve cleaning system

A cleaning device and a cleaning system technology, applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems that cylinder liners cannot be effectively cleaned, manpower is consumed, and cleaning efficiency cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

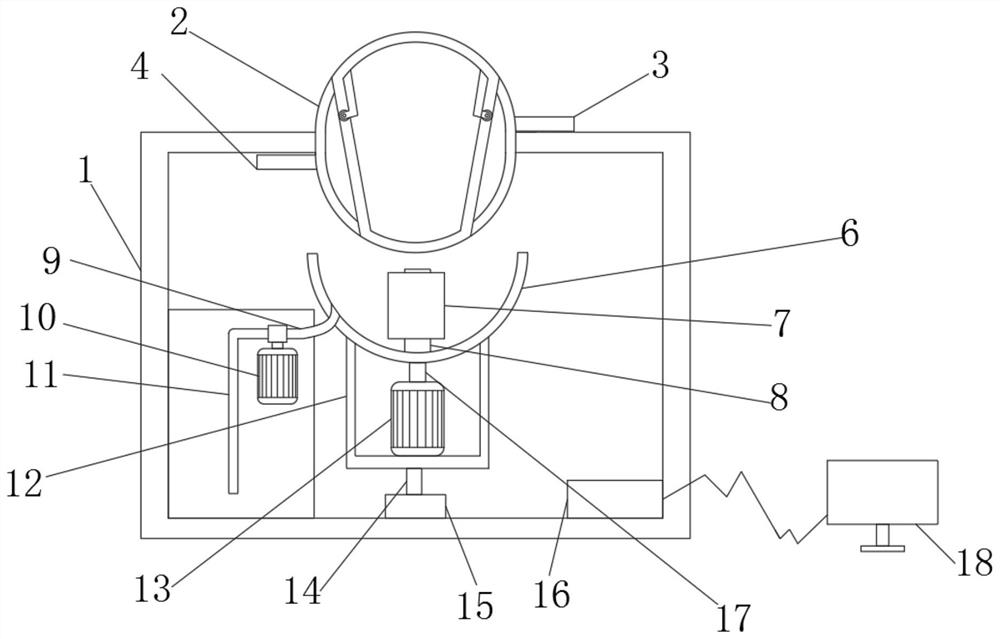

[0028] Such as Figure 1-2 As shown, a cylinder liner cleaning device includes a box body 1, a circular notch is opened on the upper end surface of the box body 1, and a spherical bin 2 is embedded in the circular notch, and the sides of the spherical bin 2 are arranged symmetrically. There is a connecting shaft, and a second servo motor is installed inside the upper end surface of the box body 1, and the output end of the second servo motor is connected with the connecting shaft.

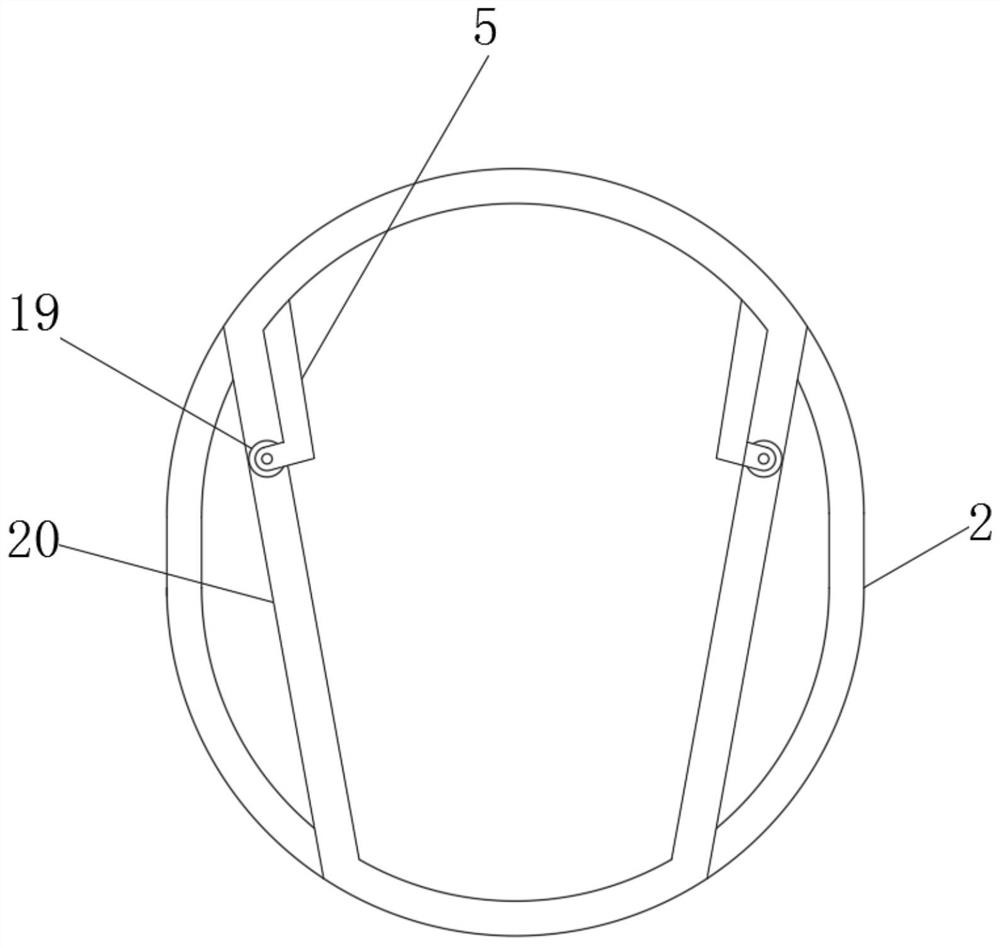

[0029] The interior of the spherical bin 2 is provided with a placement bin 20, the diameter of the upper port of the placement bin 20 is greater than the diameter of the lower port of the placement bin 20, and clamping devices are symmetrically arranged on both sides of the upper end of the placement bin 20, and the clamping device includes Press the plate 5 and the first servo motor 19, the first servo motor 19 is installed in the inner wall of the storage bin 20, one end of the press plate 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com