Automatic dried tofu marinating and spread cooling device

A dry tofu, automatic technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of long processing time, complex production process, waste of manpower, etc., and achieve the effect of saving energy, speeding up production time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

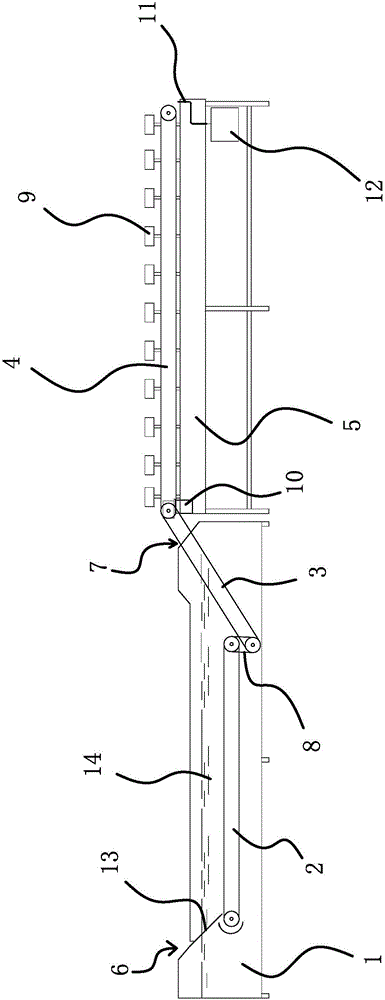

[0017] Such as figure 1 As shown, the dried tofu automatic marinating and cooling device includes a marinating box 1, a marinating conveyor belt 2, a lifting conveyor belt 3, a cooling conveyor belt 4 and a cooling steel frame 5, and the marinating box 1 is a rectangular box with a marinating liquid 14. One end of the case 1 is a feeding port 6 for dried tofu, and the other end is a discharge port 7, and the stewed conveyor belt 2 is arranged in the stewed case 1. The feeding port 6 of the stewed box 1 is provided with a slanted slide 13 that is inclined and extends to the stewed conveyor belt 2 , and dried beans enter the stewed conveyor belt 2 in the stewed box 1 along the slanted slide 13 .

[0018] The lifting conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com