Cast-aluminum rotor processing device

A technology for cast aluminum rotors and processing devices, applied in feeding devices, reaming devices, reaming devices, etc., can solve problems that affect the optimization of process flow, incoherent process connections, and affect the competitiveness of enterprises, so as to improve production and Processing efficiency, low cost, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

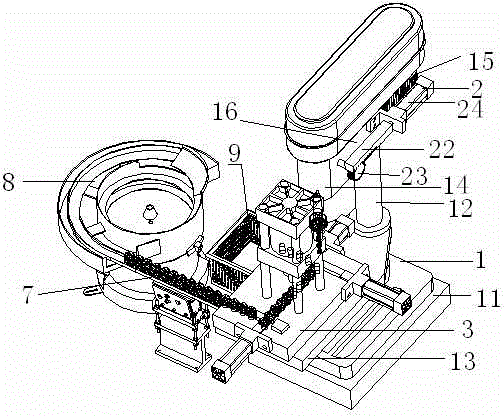

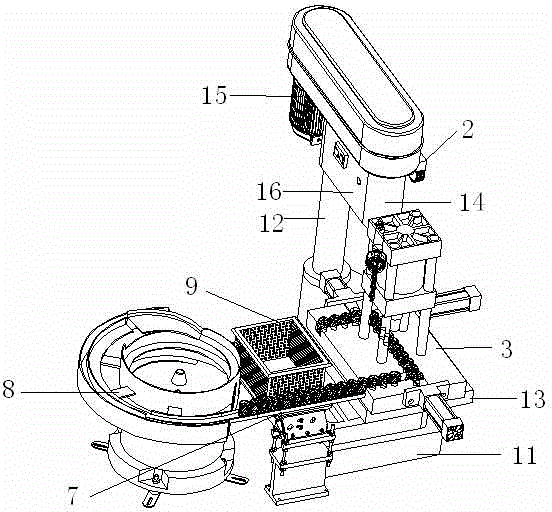

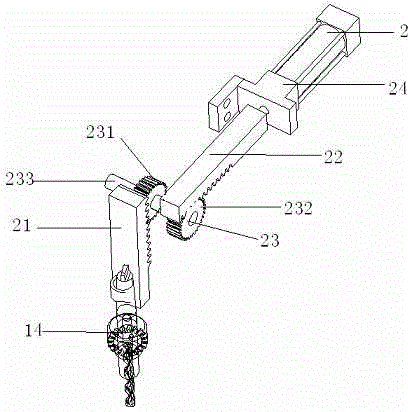

[0027] A cast aluminum rotor processing device, characterized in that it includes a bench-type drilling machine 1, including a base 11, a column 12, a support platform 13 and a drill bit 14, and is characterized in that the drill bit 14 is equipped with a telescopic device 2 that realizes the drill bit being stretched up and down , the drill bit 14 is driven by a motor 15 and is equipped with a protective case 16. The telescopic device 2 is fixedly arranged on the protective case 16. The telescopic device 2 includes a first rack 21, a second rack 22, a gear set 23 and a drill bit telescopic Cylinder 24, the first rack 21 is arranged on one side of the drill bit 14 and fixedly connected with the drill bit 14, the drill bit telescopic cylinder 24 is arranged on the outside of the protective shell 16 and arranged horizontally, and the second rack 22 is fixedly arranged on the drill bit telescopic The front end of the cylinder 24 expands and contracts with the telescopic cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com