Patents

Literature

76results about "Vibratory devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

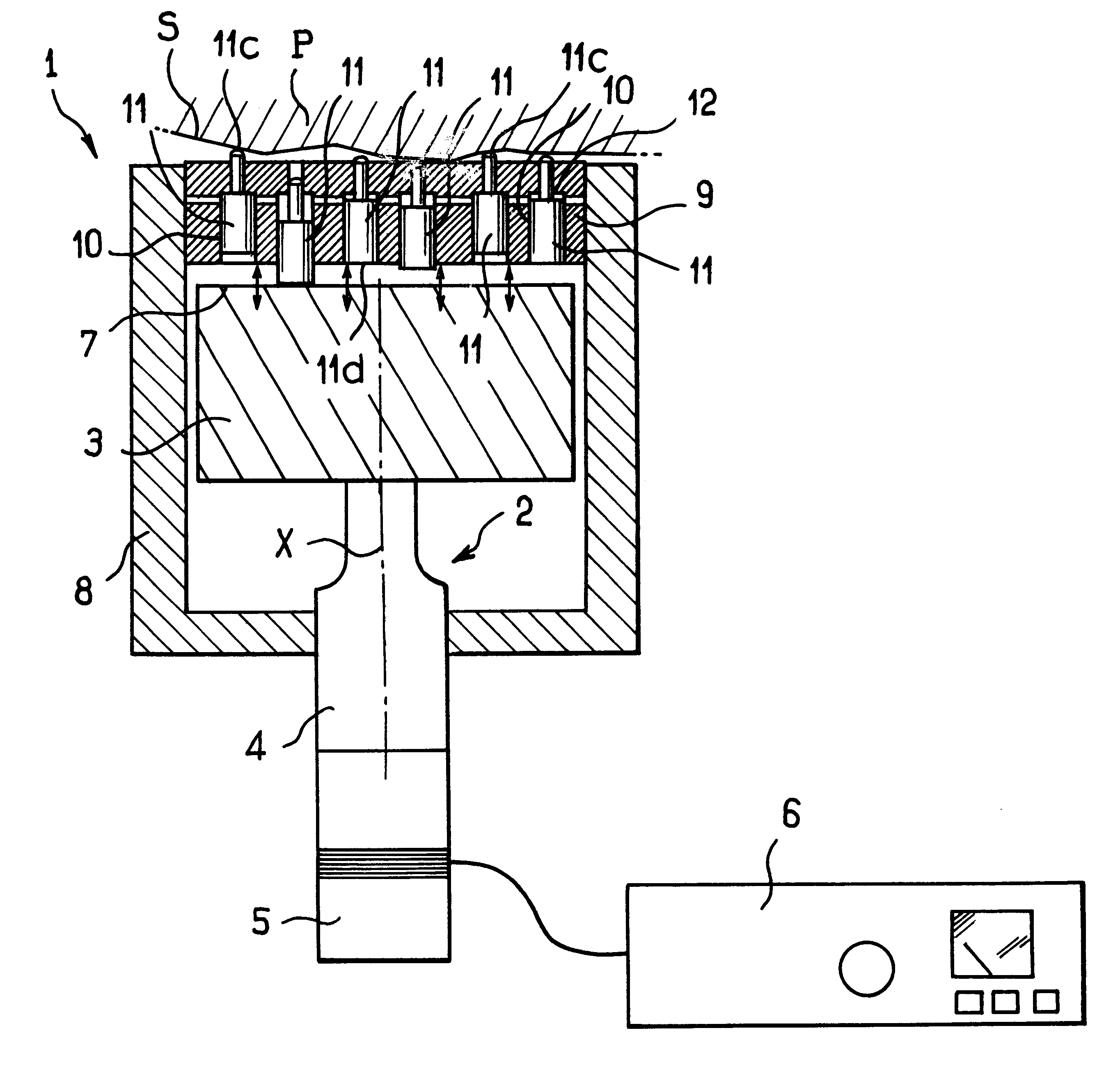

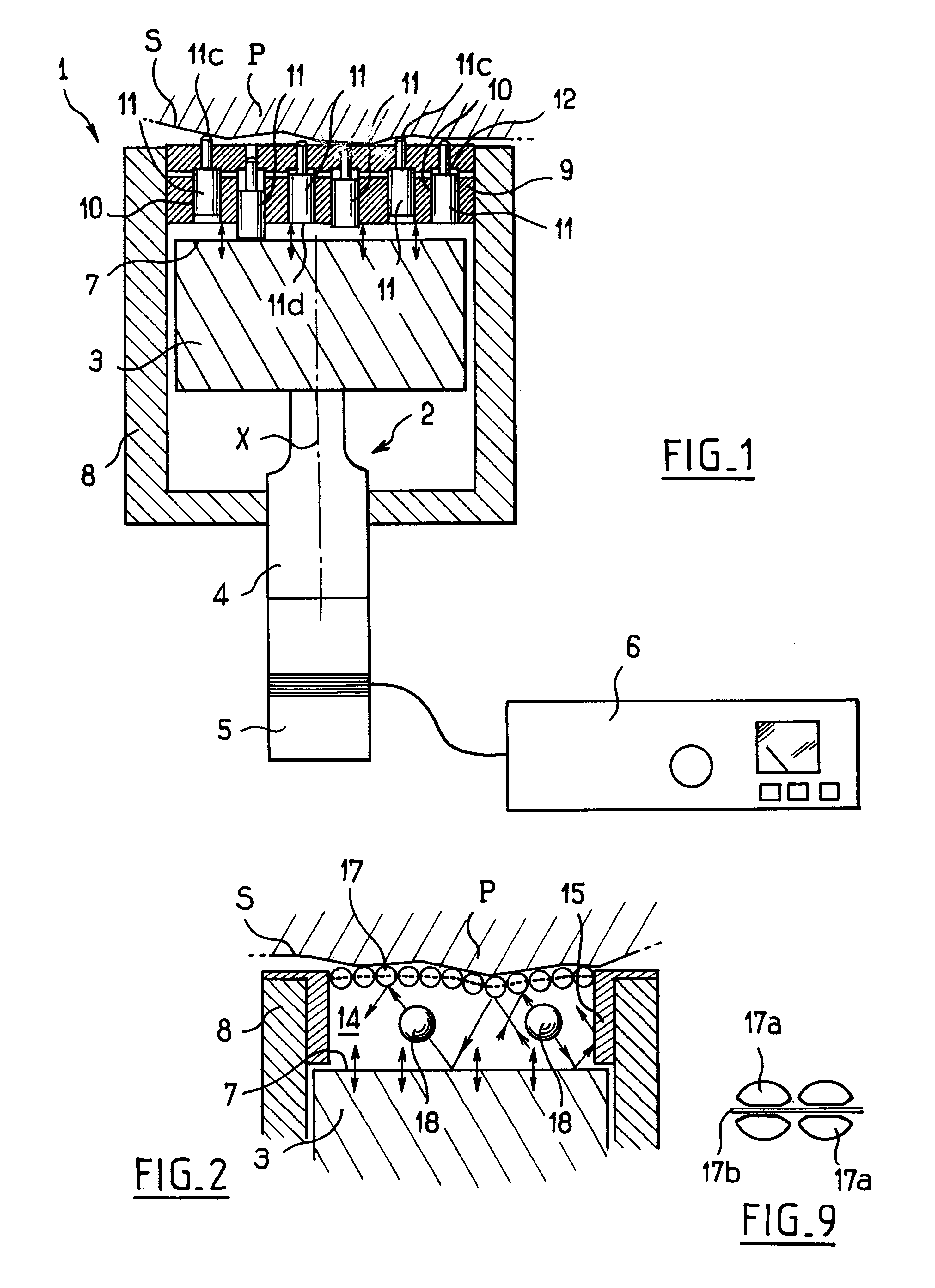

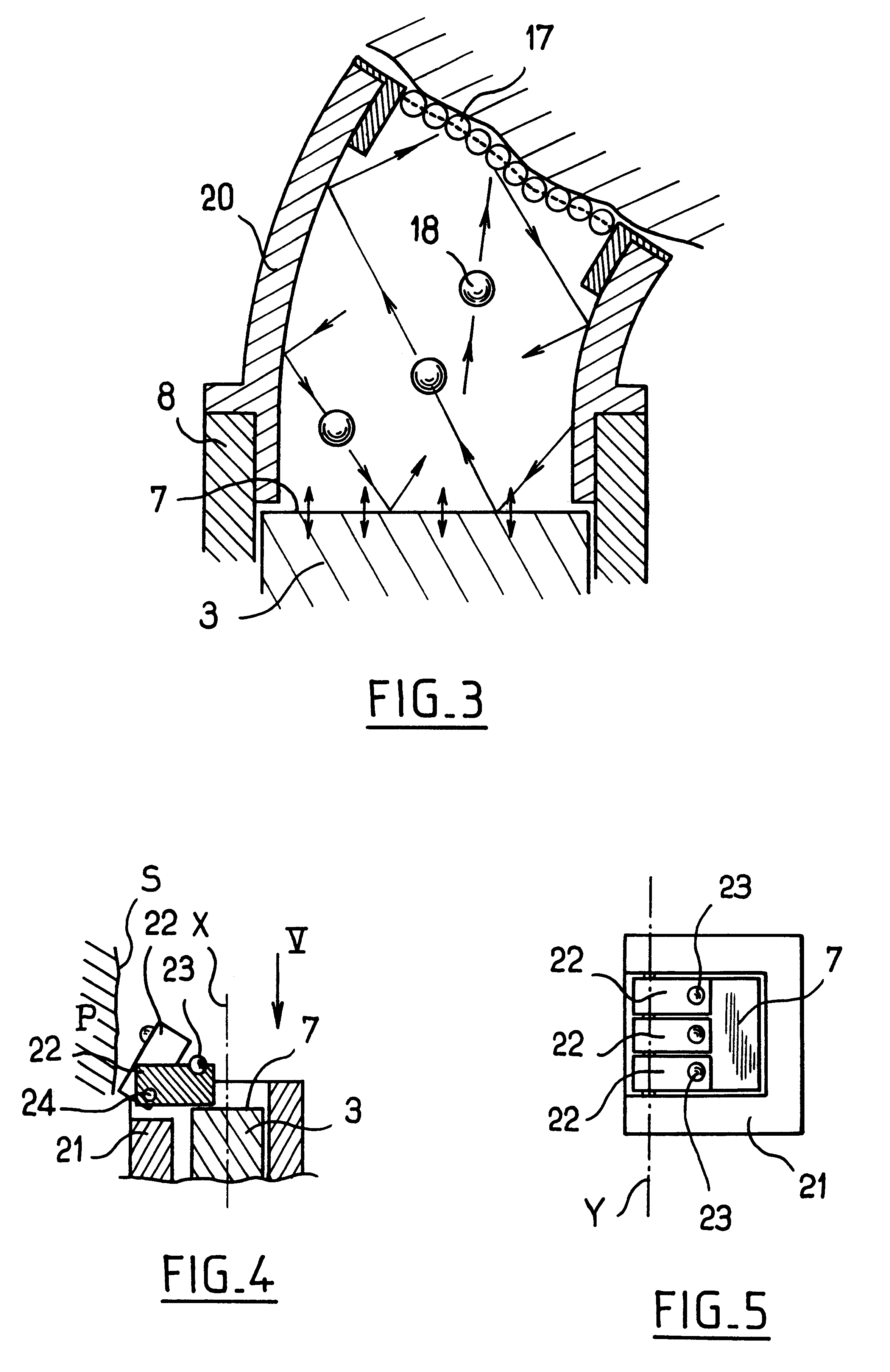

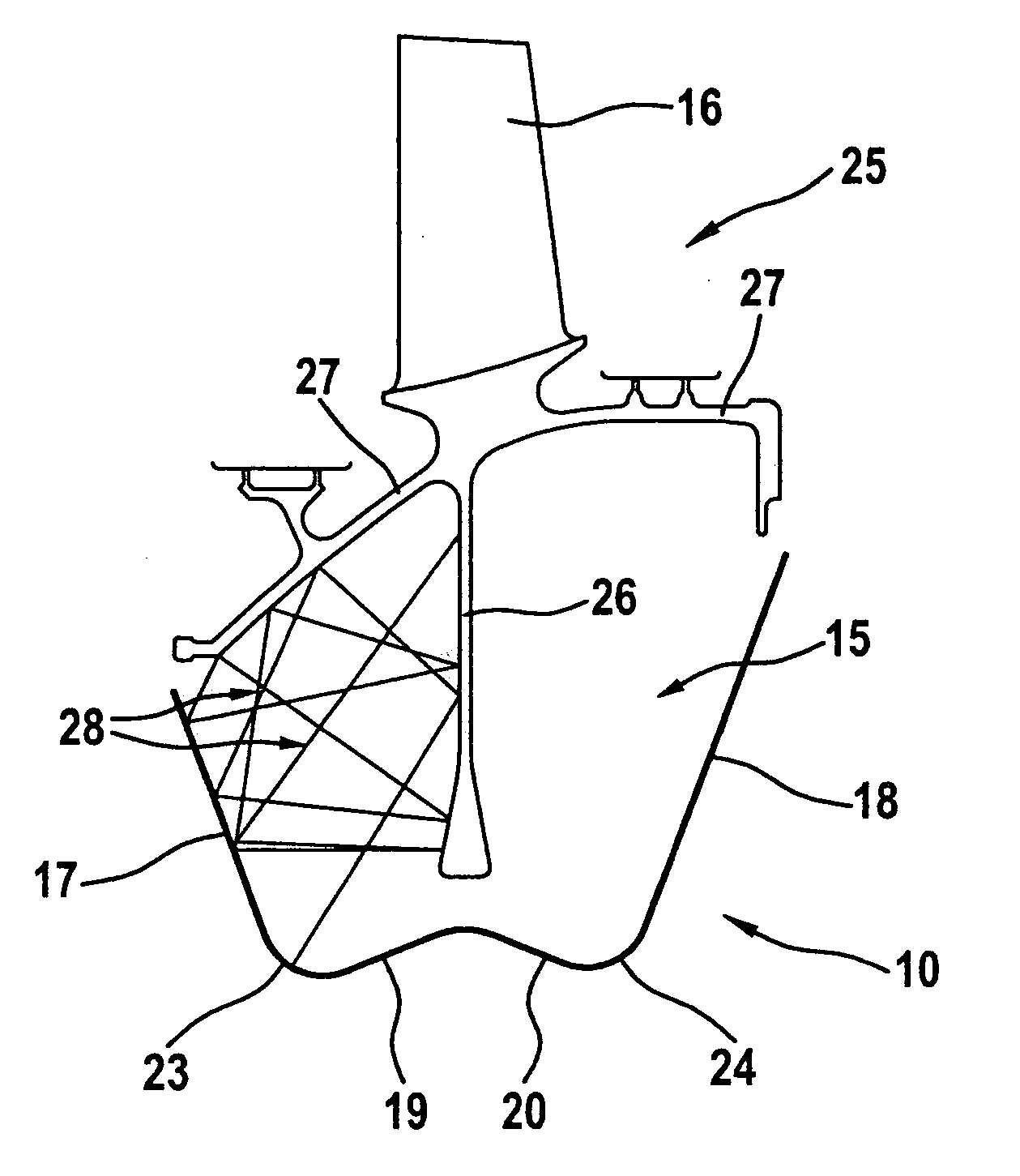

Apparatus for surface treatment by impact

InactiveUS6343495B1Quality improvementSimple treatmentNon-mechanical blast generatorsBurnishing machinesBiomedical engineeringProjectile

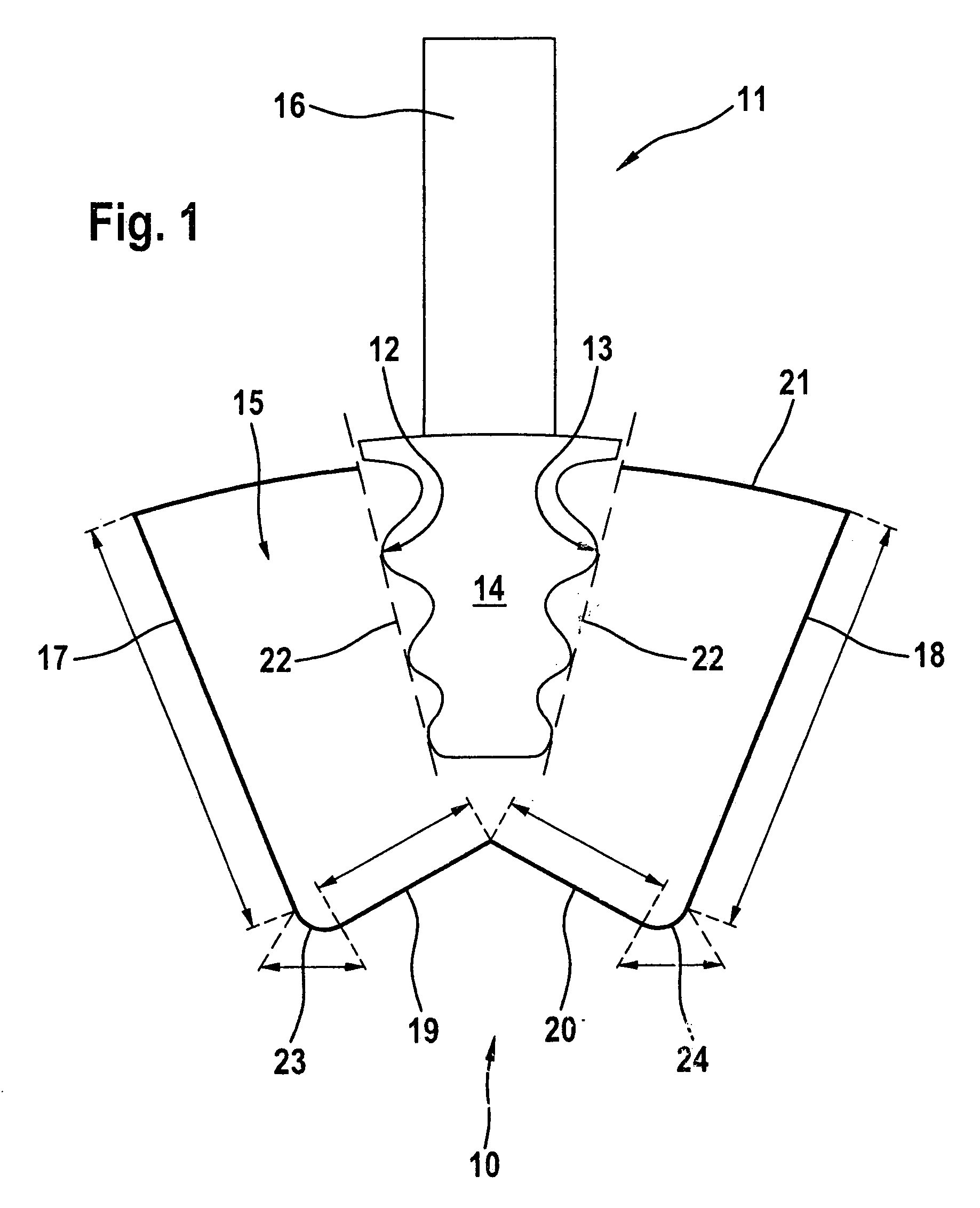

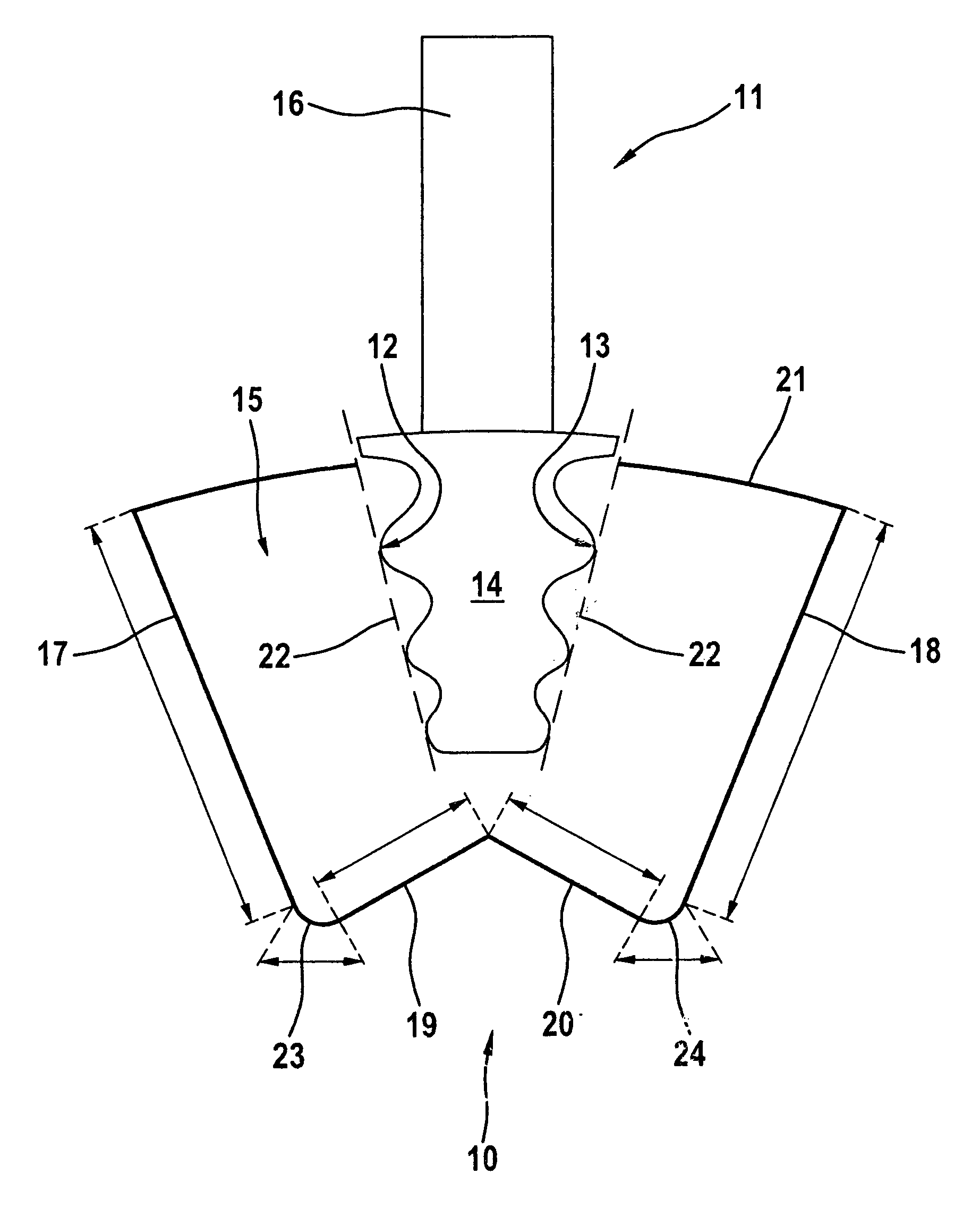

The invention relates to apparatus for surface treatment by impact, the apparatus comprising a vibrating surface and at least one projectile suitable for being projected towards the surface to be treated by said vibrating surface. The apparatus includes retaining means for keeping each projectile captive in the apparatus.

Owner:SONATS SOC DES NOUV APPL DES TECHN DE SURFACES

Method for the ultrasonic peening of large sized annular surfaces of thin parts

InactiveUS6289705B1Inhibits initiation and propagationImprove fatigue strengthBurnishing machinesVibratory devicesPeeningMaterials science

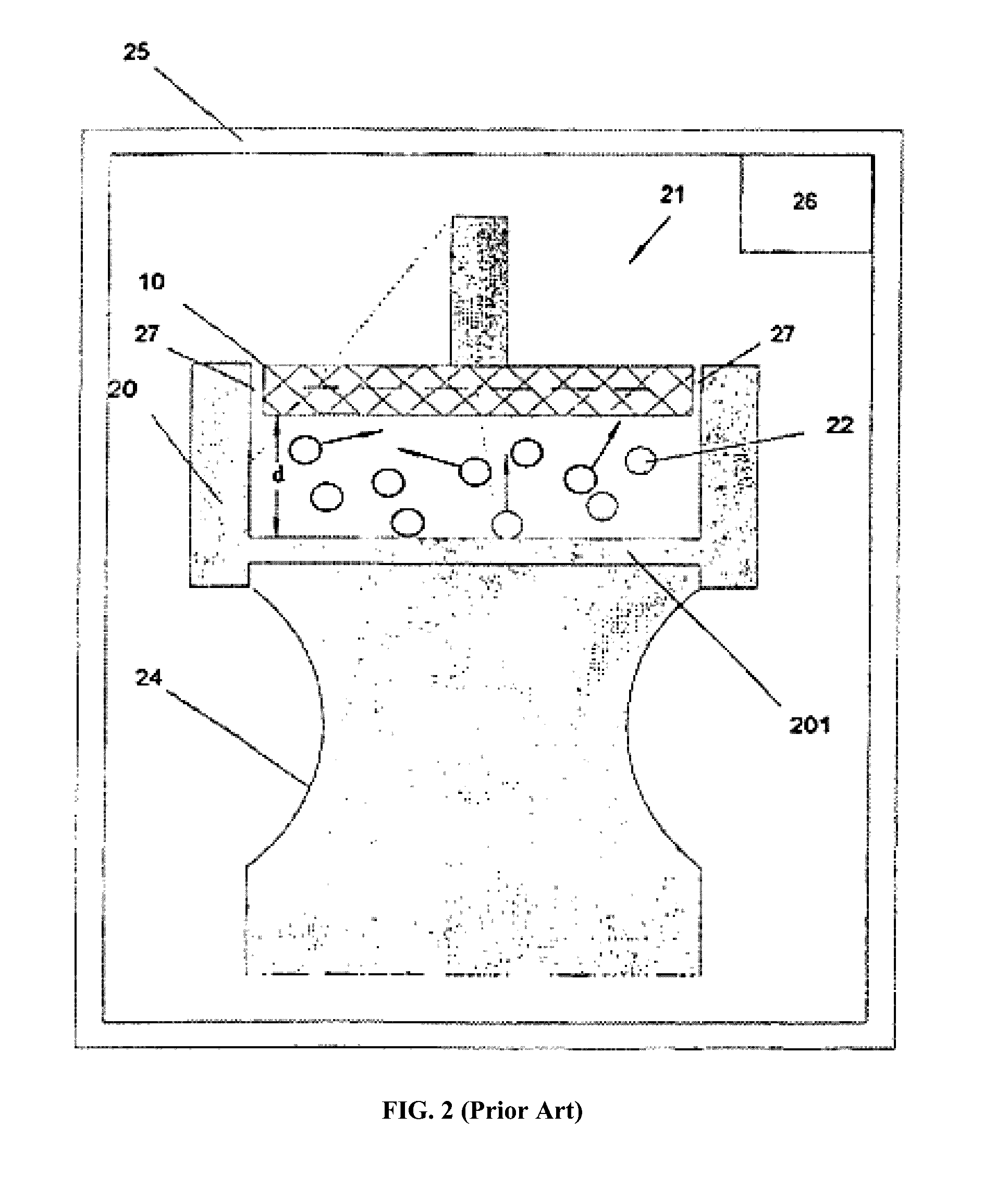

A method of so-called "ultrasonic" peening is described for peening large sized annular surfaces on thin parts. The method uses a microbead mist vibrated in a chamber with an opening so that the surface that is to be peened makes at least five movements past the opening of the peening chamber during peening so as to reduce deformation of the part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

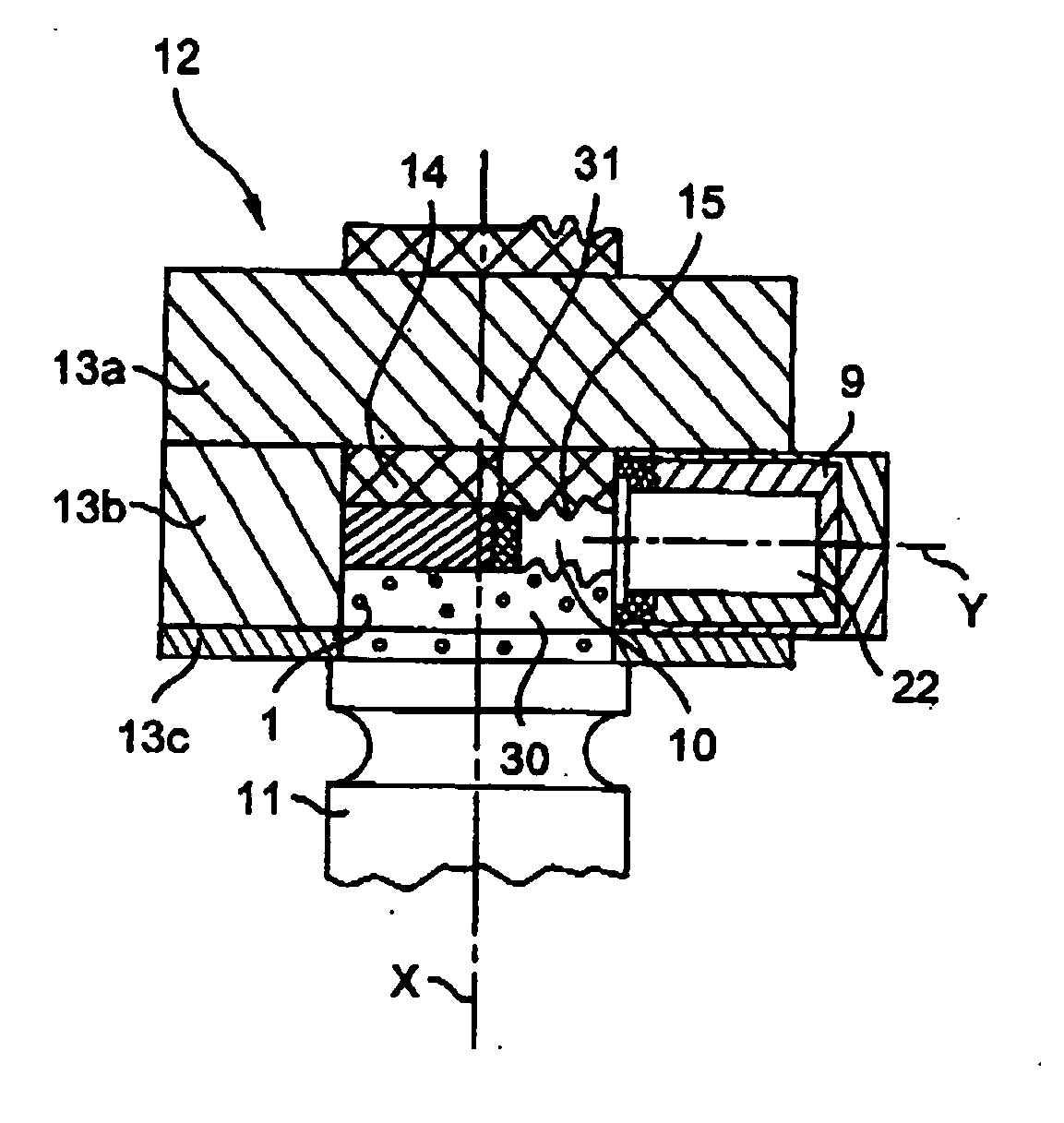

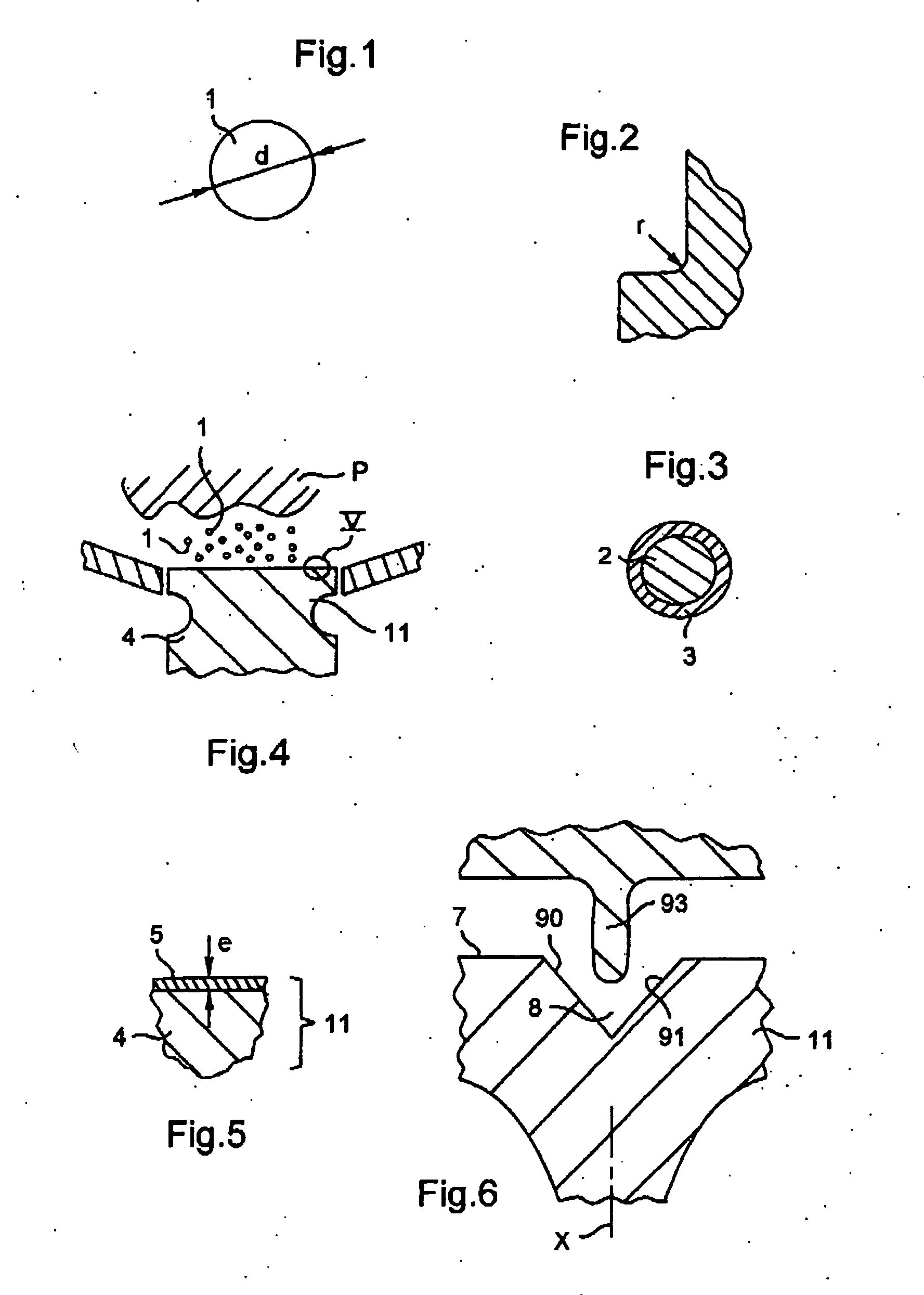

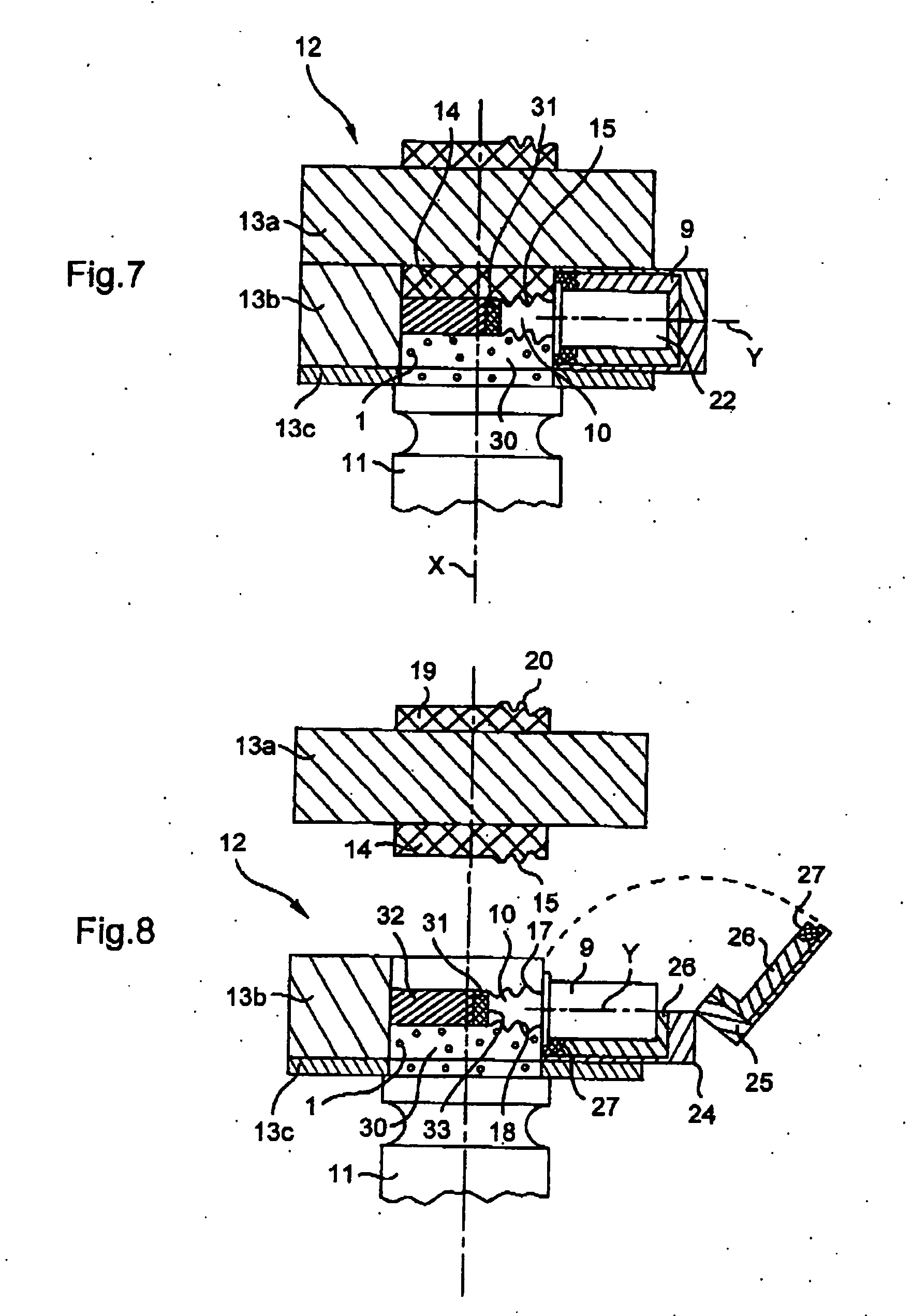

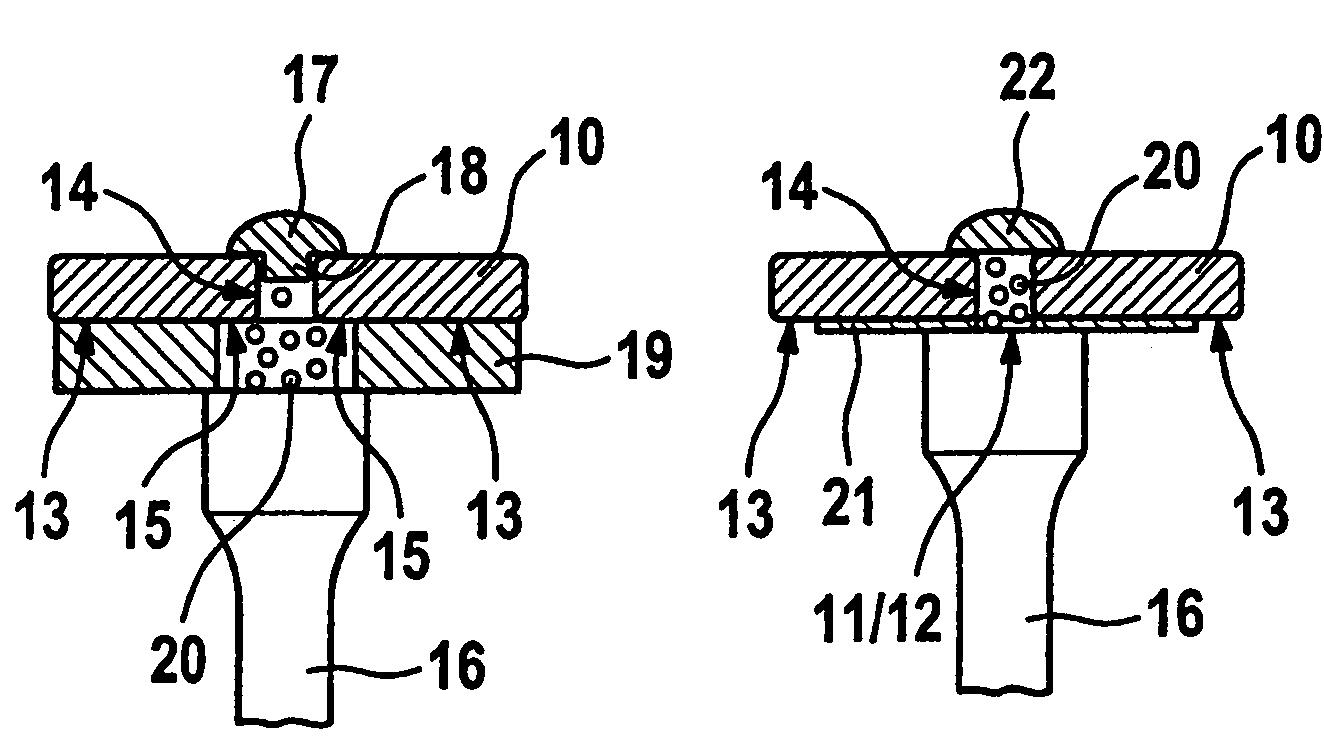

Shot, devices, and installations for ultrasonic peening, and parts treated thereby

InactiveUS20060021410A1Easy and quick to treatShorten treatment timeVibratory devicesMaximum dimensionMetallurgy

Shot for use in a peening installation, the shot having: hardness greater than or equal to 800 HV; density greater than or equal to 8 g / cm3; and pieces having a maximum dimension less than or equal to 1.5 mm.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

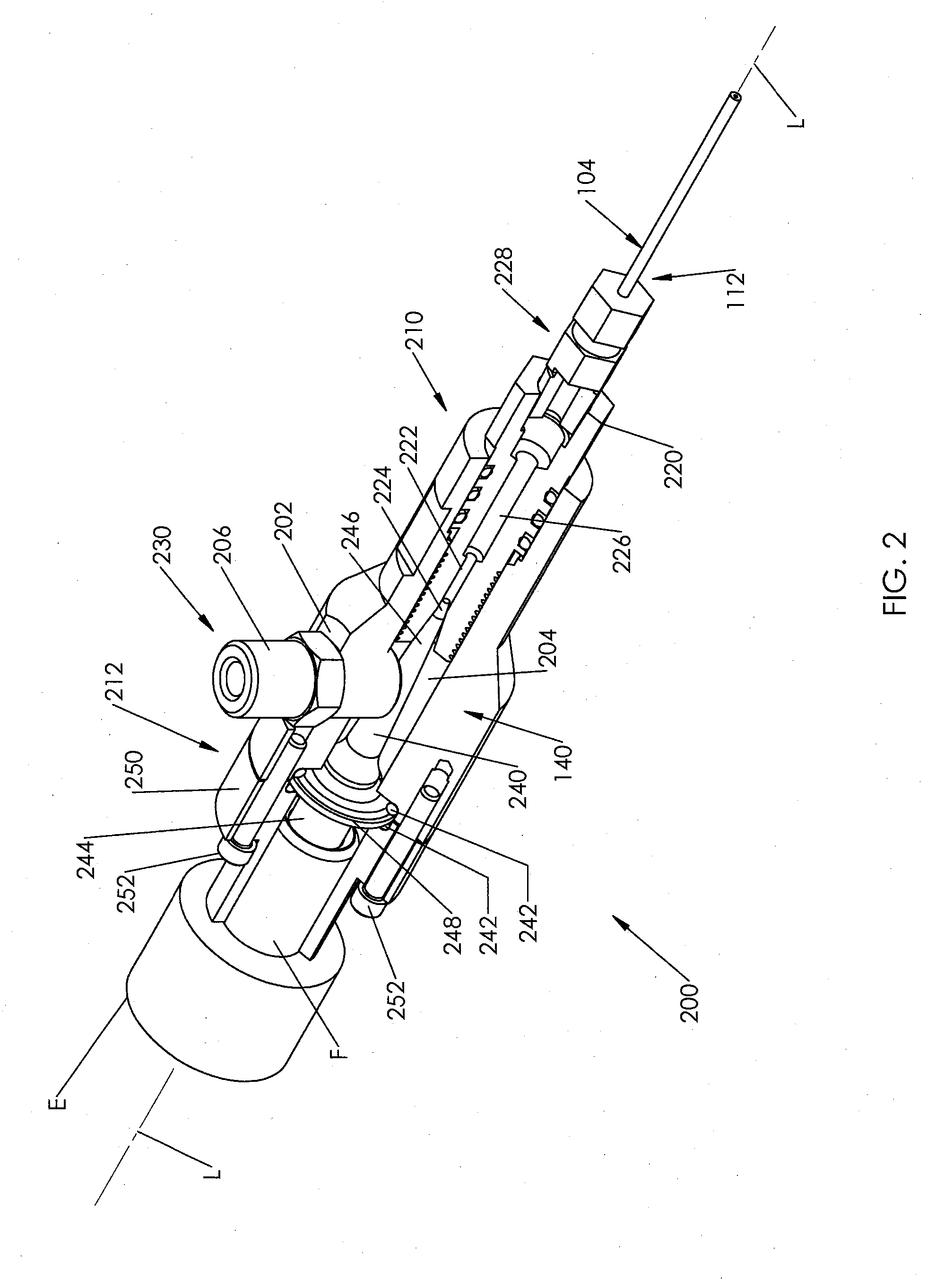

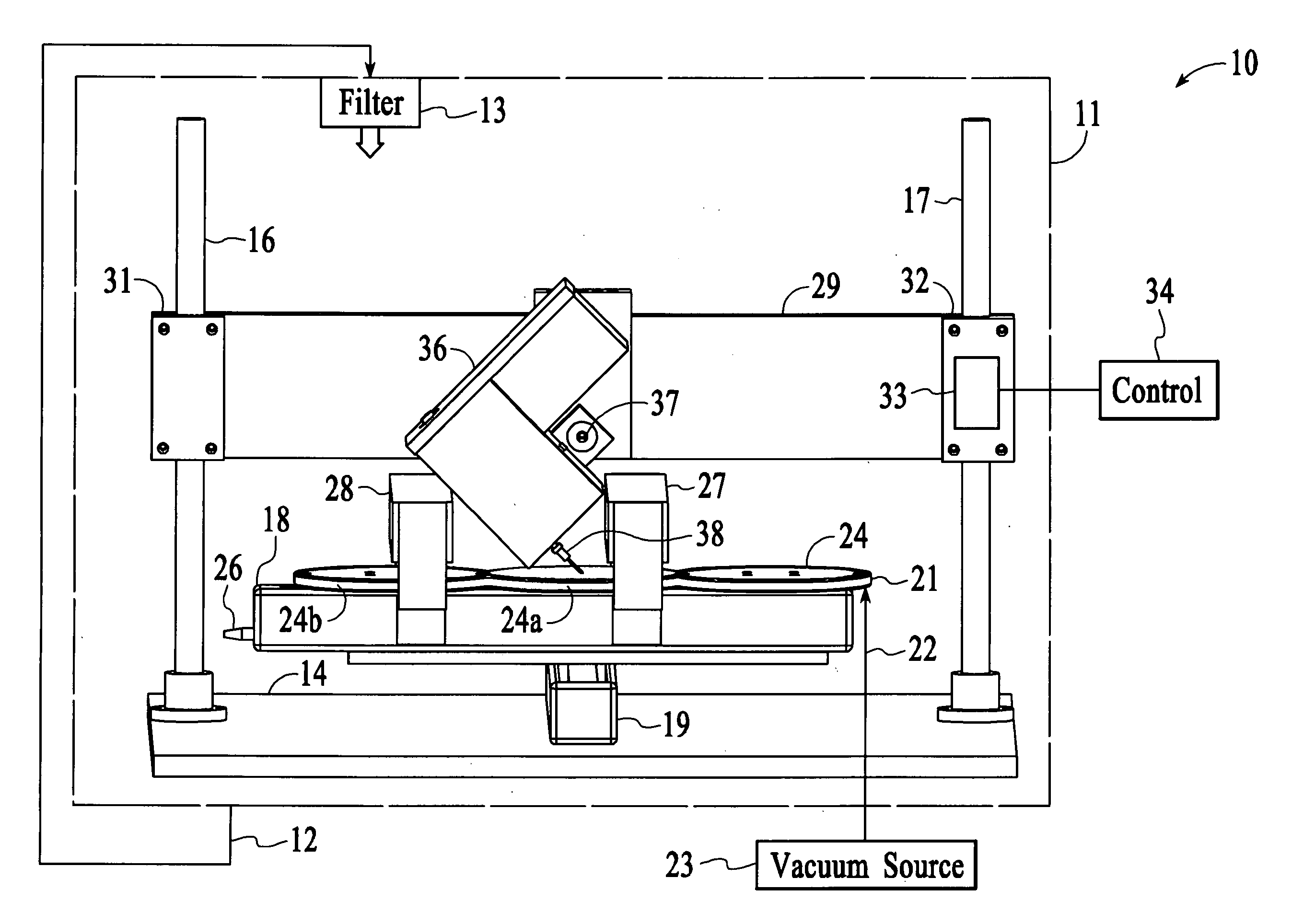

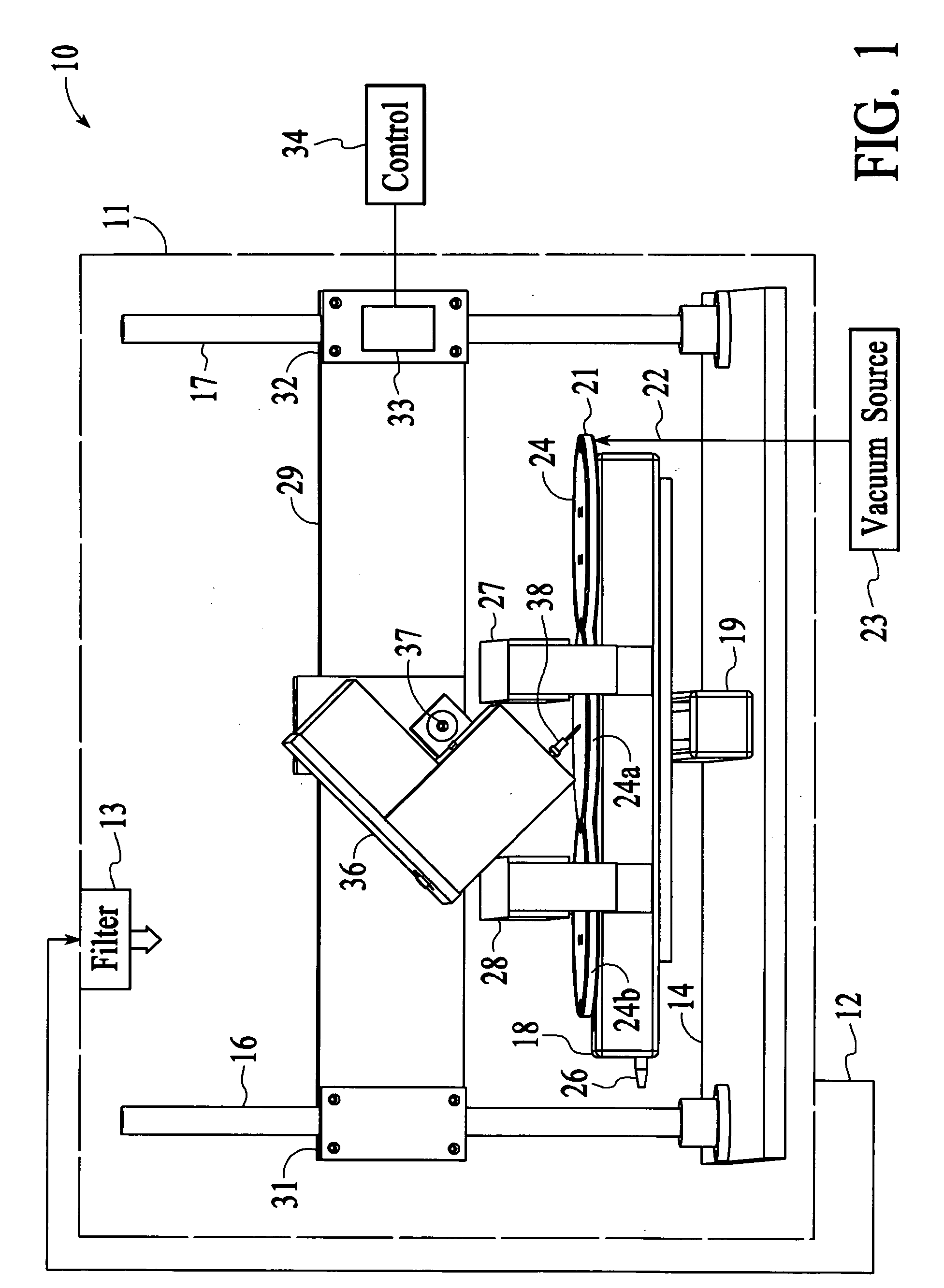

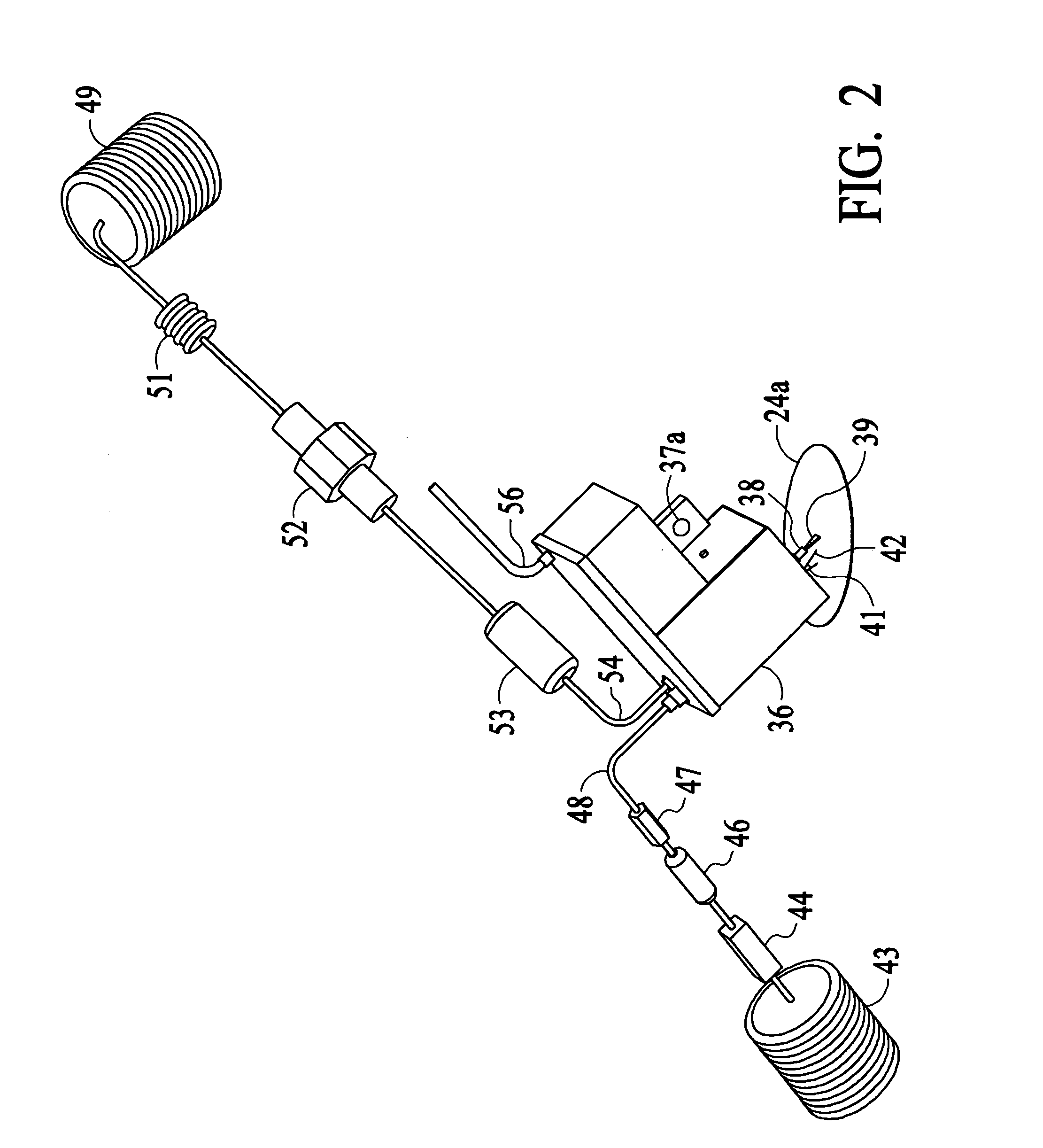

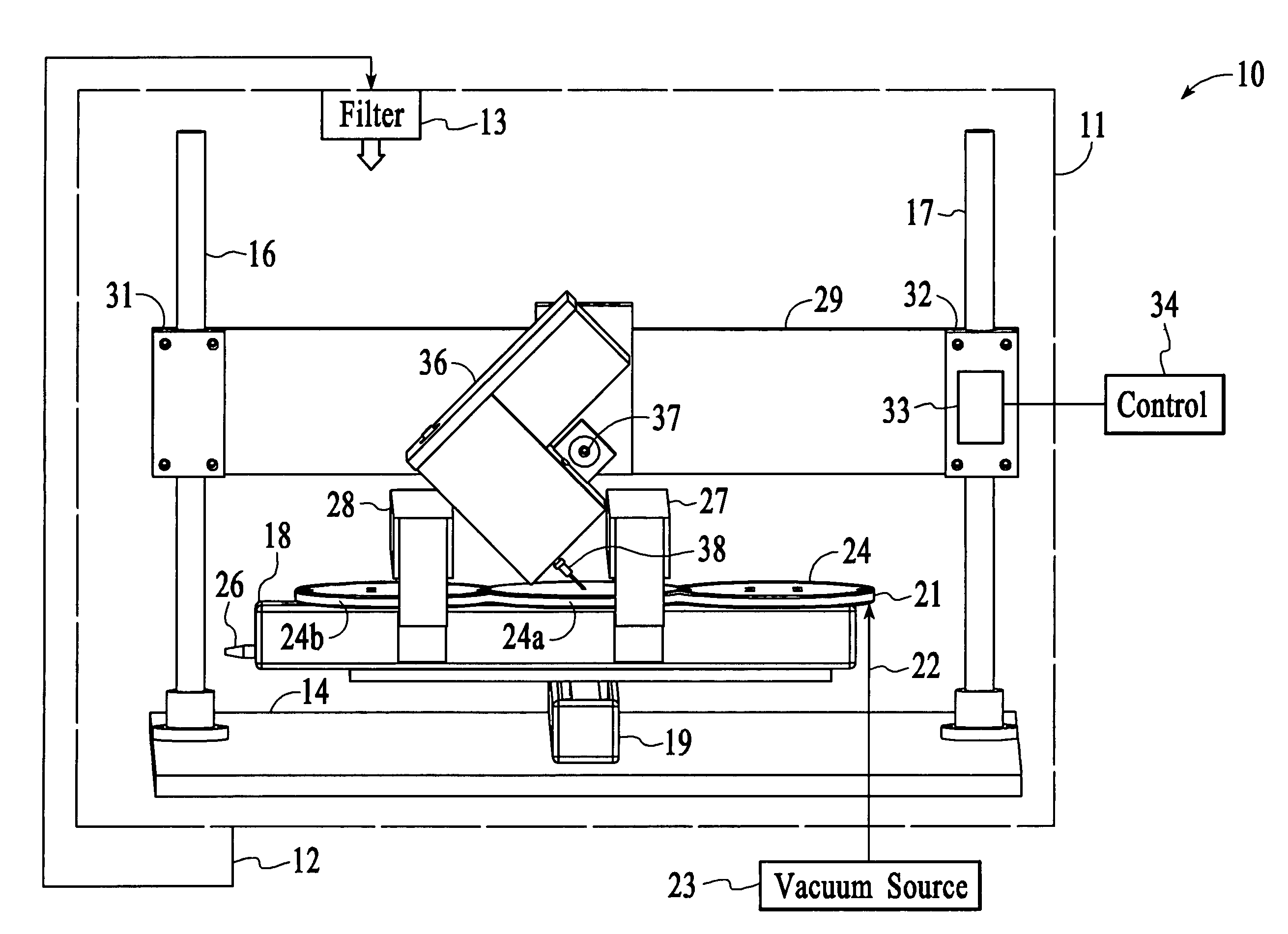

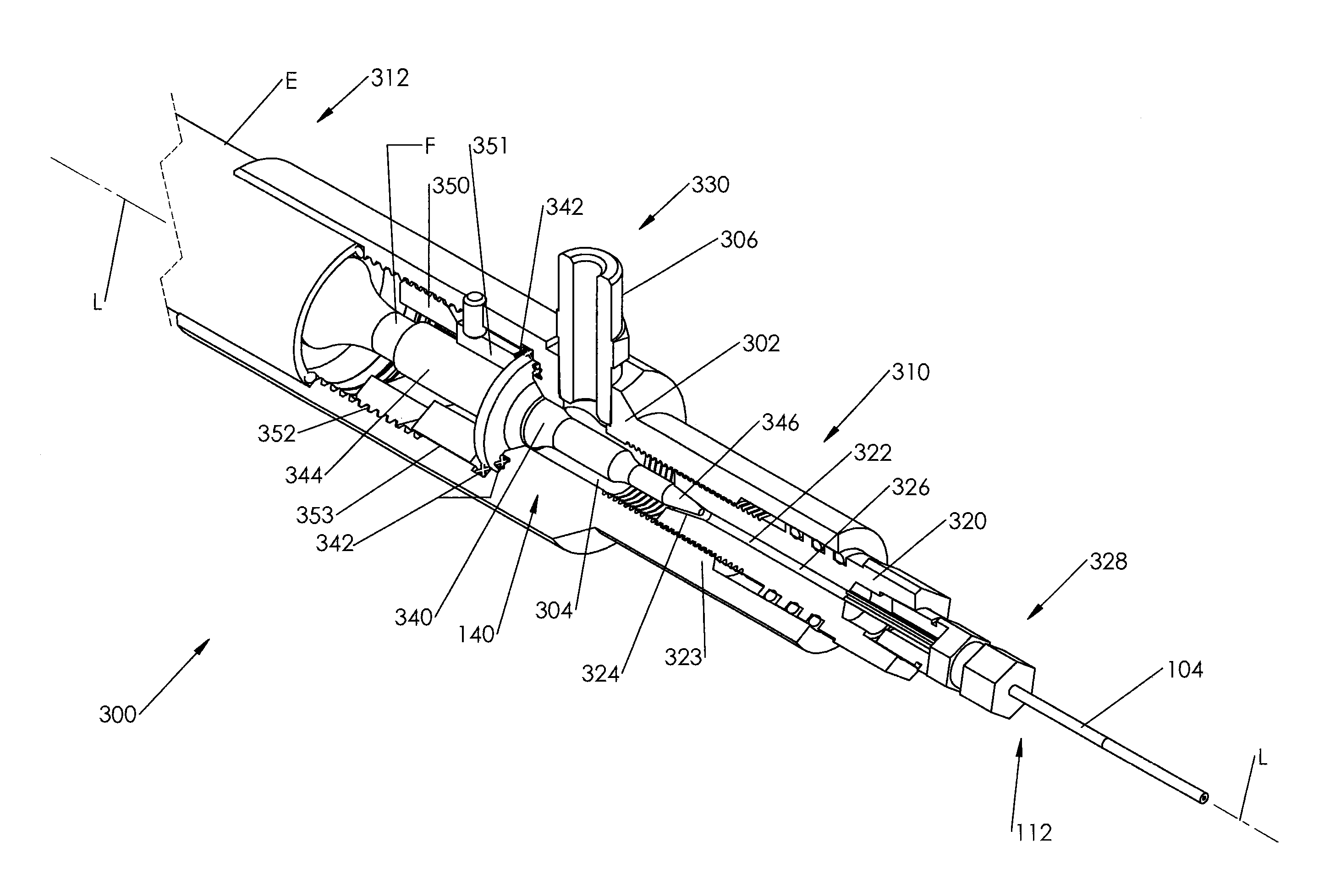

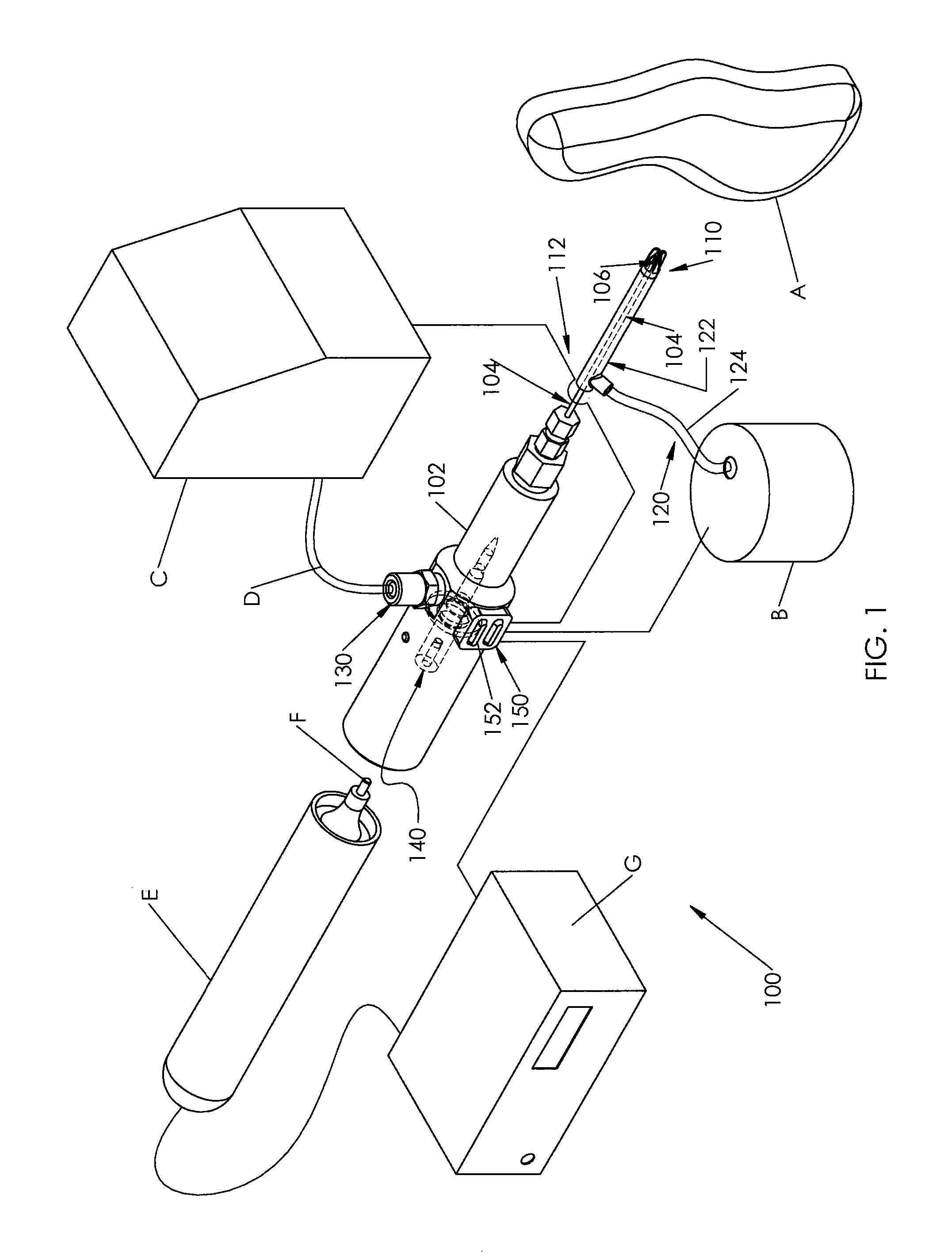

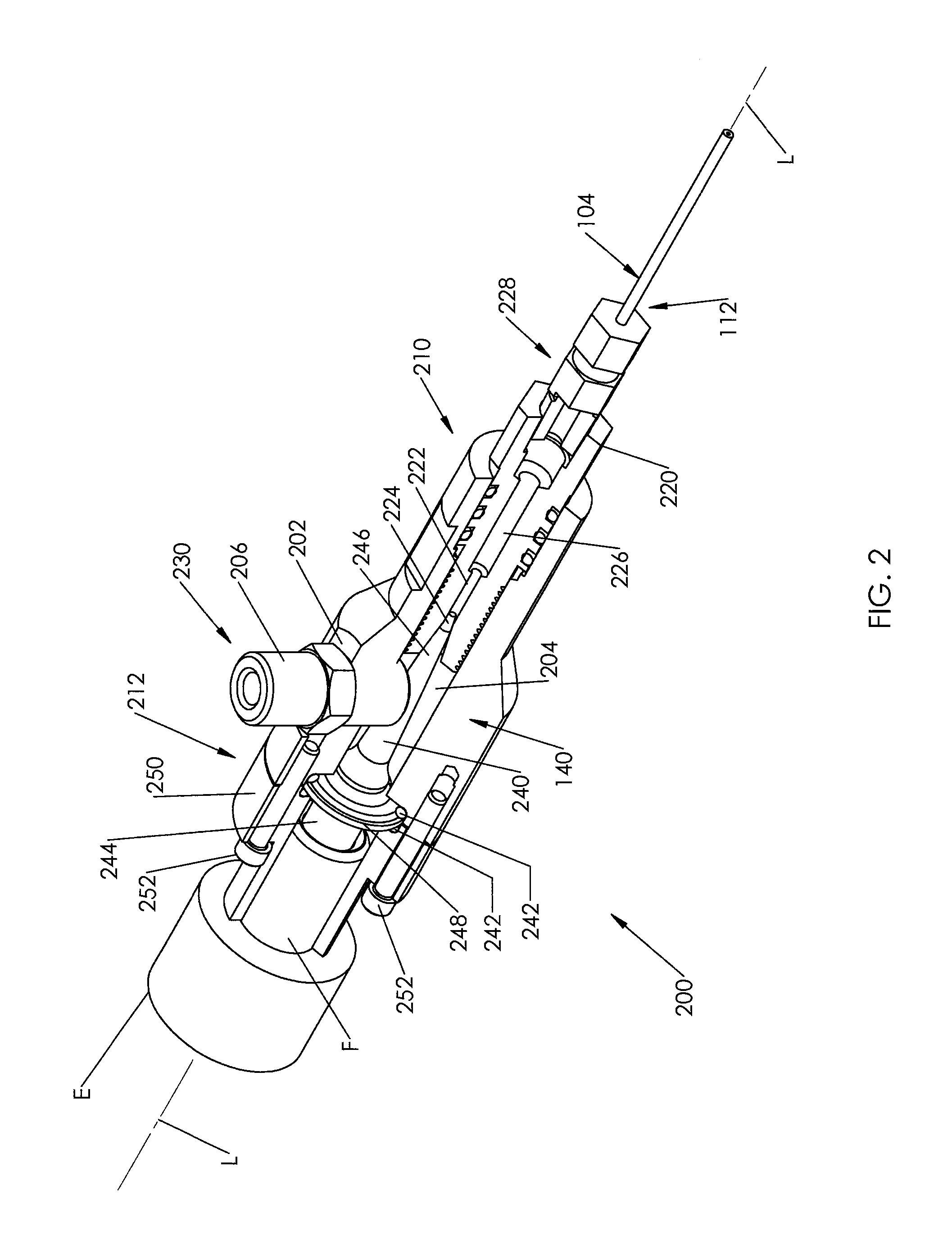

Fluid jet cell harvester and cellular delivery system

ActiveUS20140058361A1Improve matchEasy to operateIntravenous devicesFluid jet surgical cuttersHigh pressureTarget tissue

An ultrasonically pulsating high-pressure fluid jet coupled with a suction system serve as a tissue harvesting device. The pulsated fluid jet disrupts tissue, permitting both harvesting of cells for therapeutic delivery, and as a surgical dissector and aspirator, for liposuction, soft tissue dissection, etc. The jet is delivered to the target tissue through a cannula, coupled to an aspiration system. An ultrasonically actuated rod vibrates within the cannula engaging a nozzle, disrupting the fluid jet into droplets, permitting tuning of the jet to the resonant frequencies and impact pressures necessary to dissociate the target tissue. A suction recovery system may be separated or integrally formed with the fluid jet cannula, and is linked by a closed tubing system appropriate for sterilization and subsequent delivery of the harvested cells / tissues with or without growth factor or matrix addition for human re-implantation or for in vitro expansion for later re-implantation.

Owner:GORDON CHRISTOPHER BURNSIDE

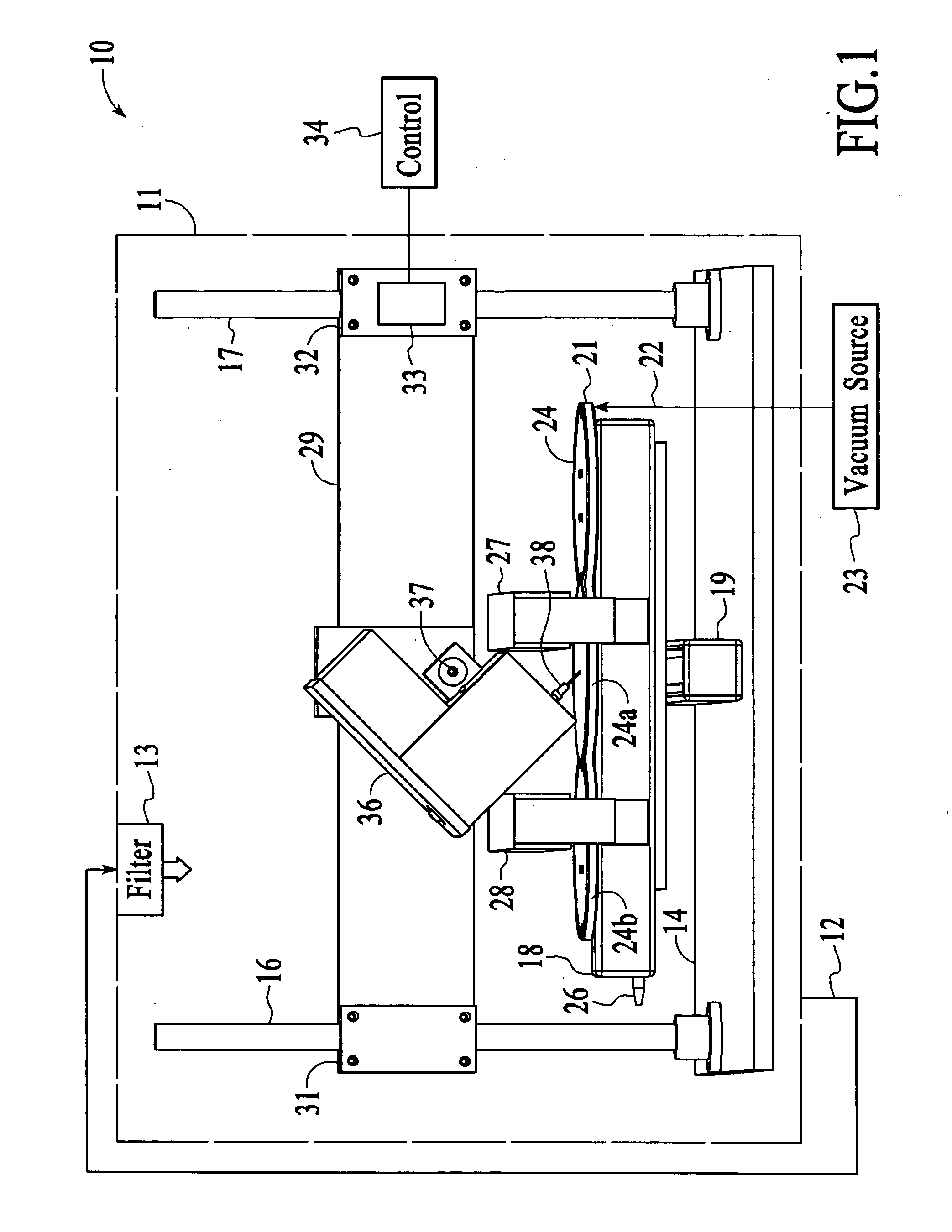

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

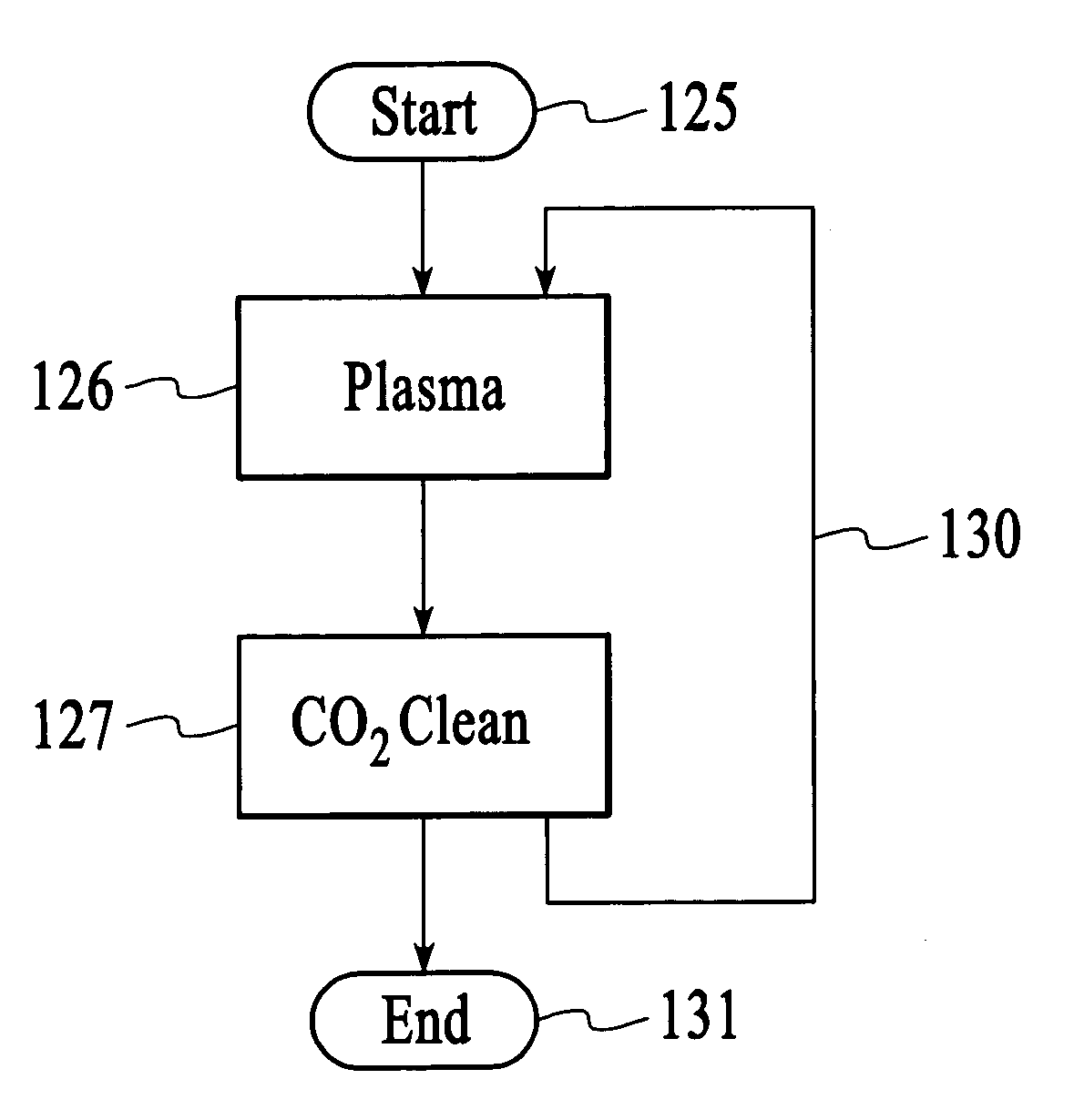

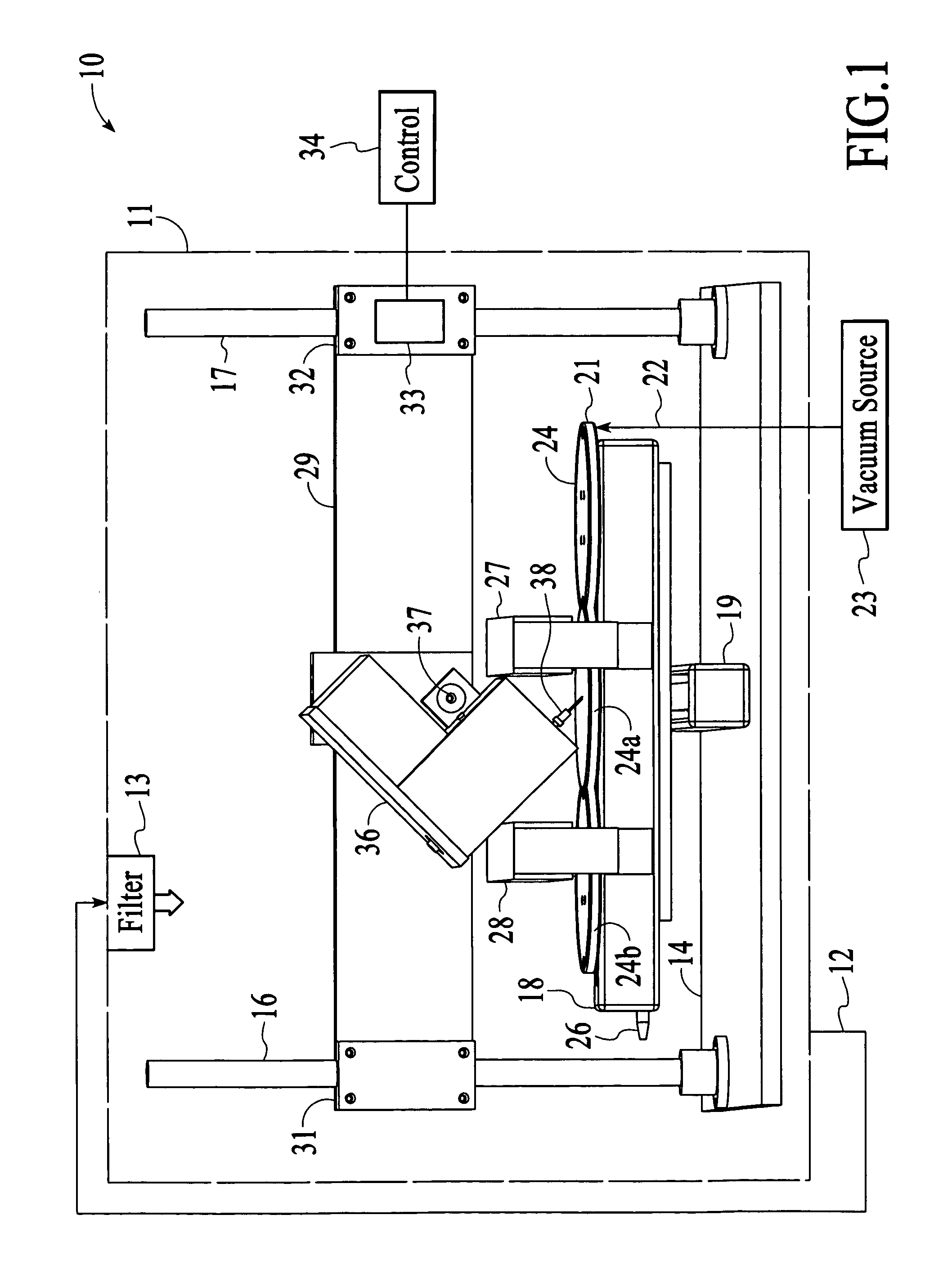

A method for manufacturing an article where the article has polymeric residue that is to be removed during the manufacture of the article. The article is introduced into a controlled environment of a processing tool that has at least first and second processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least the first processing chamber where they react with the polymeric residue. A cryogenic cleaning medium is supplied into the second processing chamber where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The first and second processing chambers may be dedicated to plasma processing or cryogenic processing or each may provide both plasma processing and cryogenic processing.

Owner:NANOCLEAN TECH

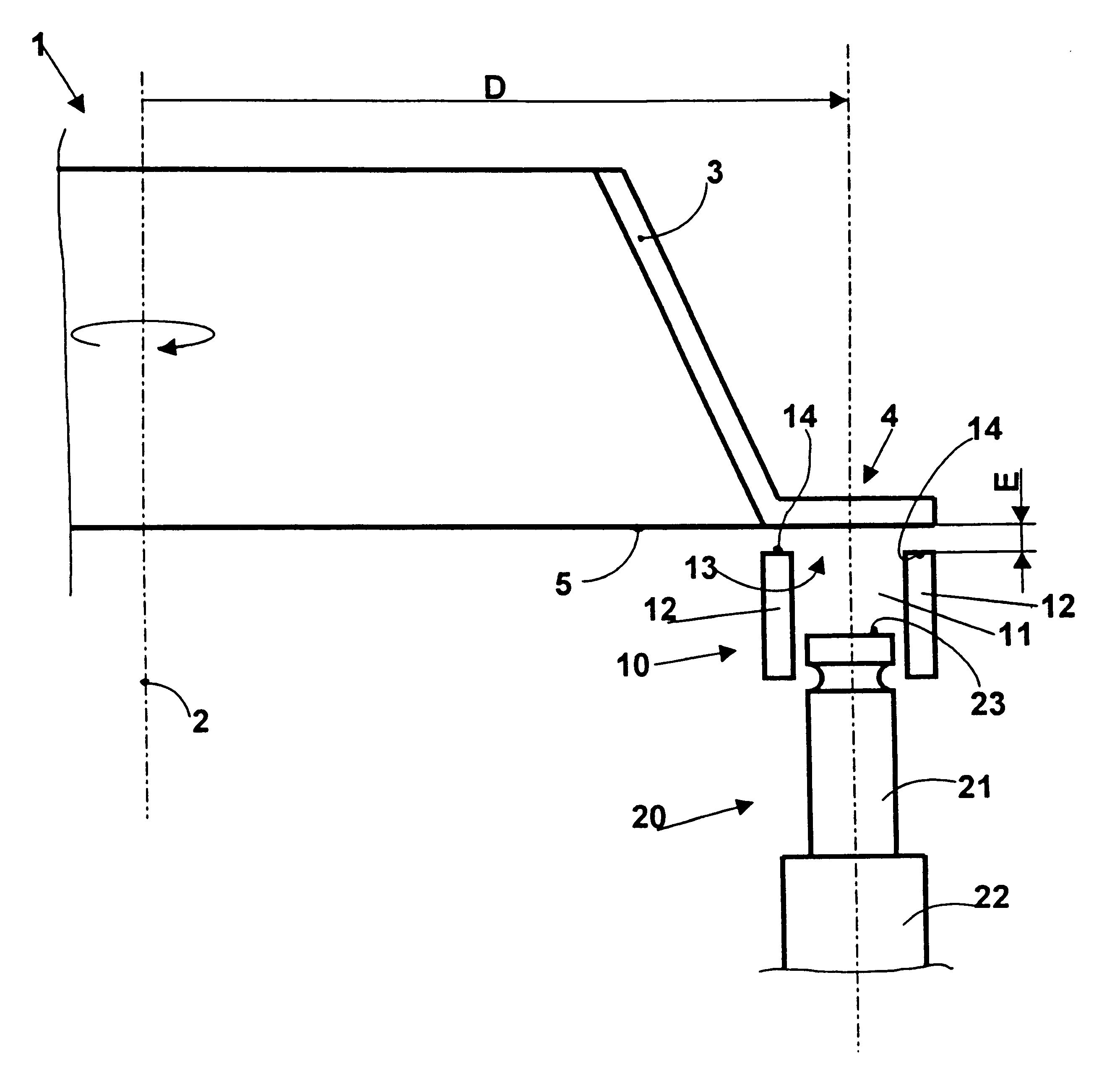

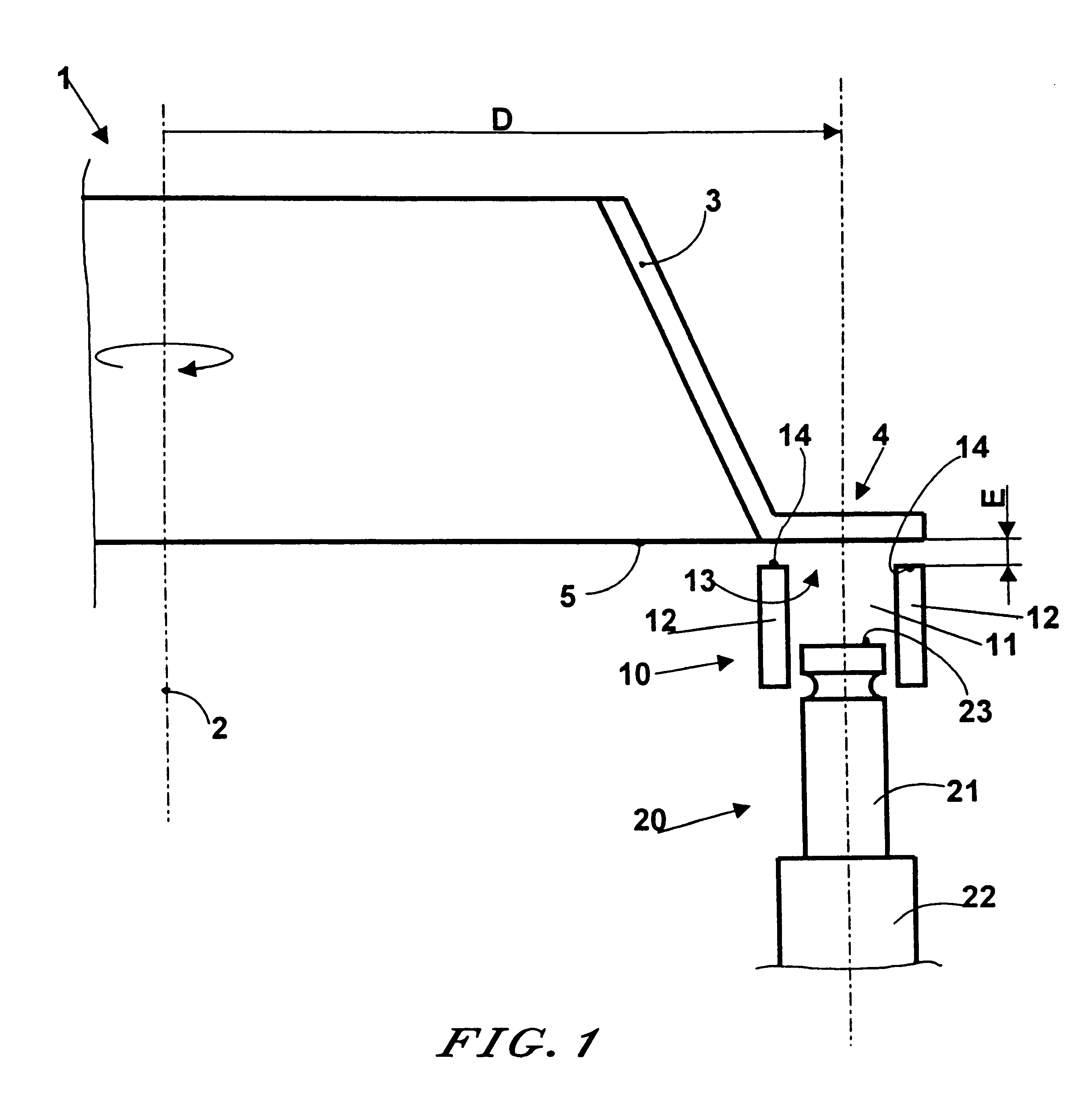

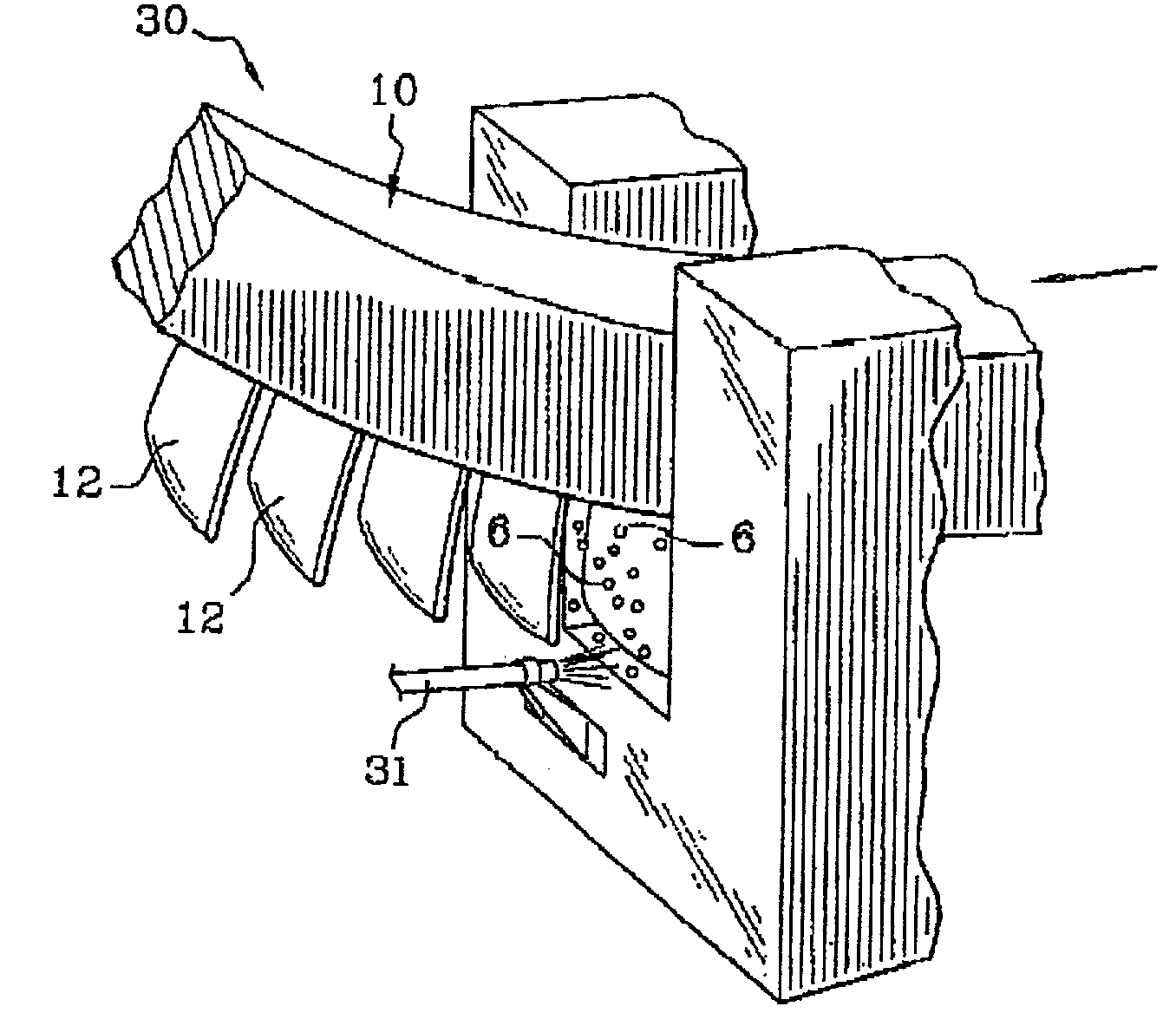

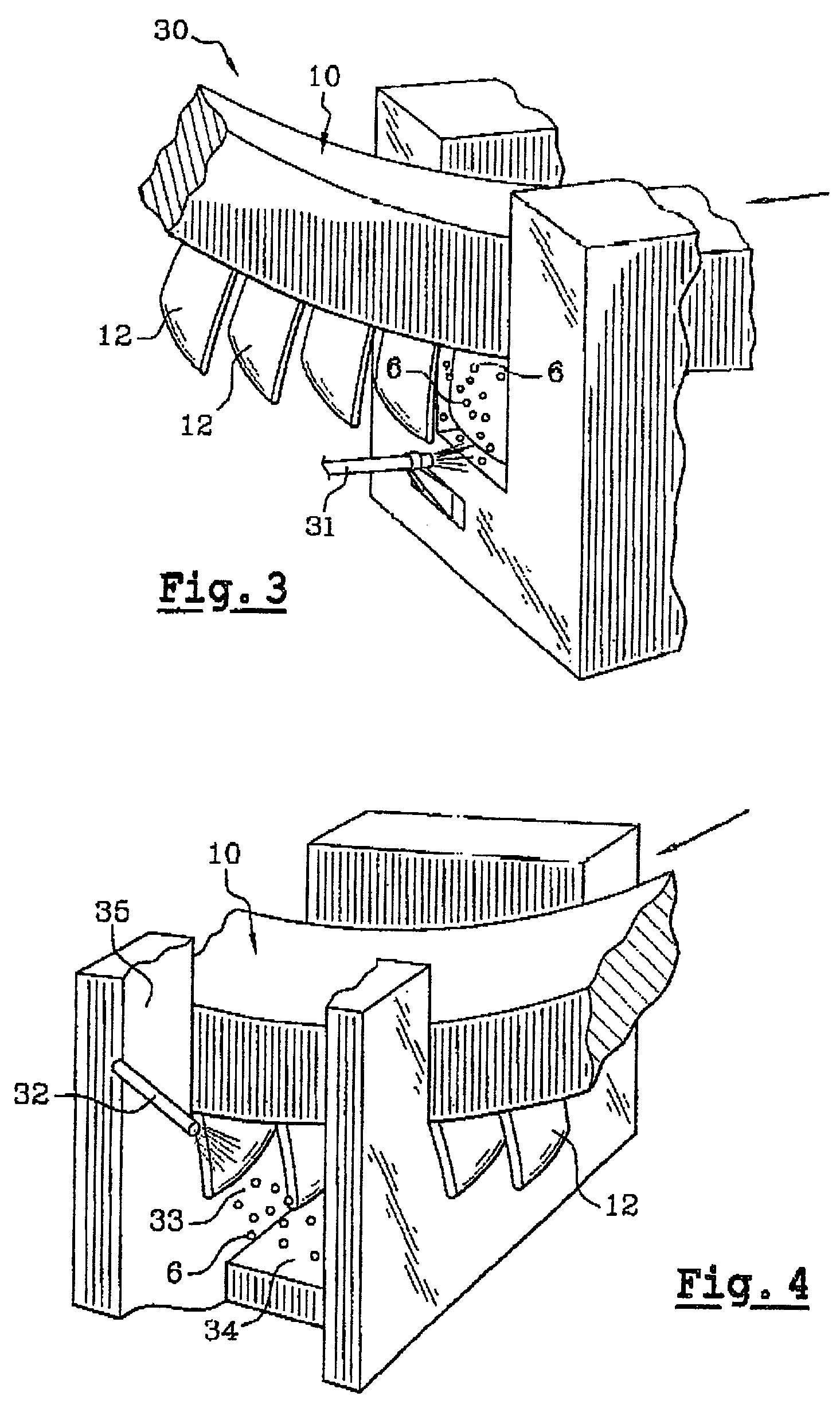

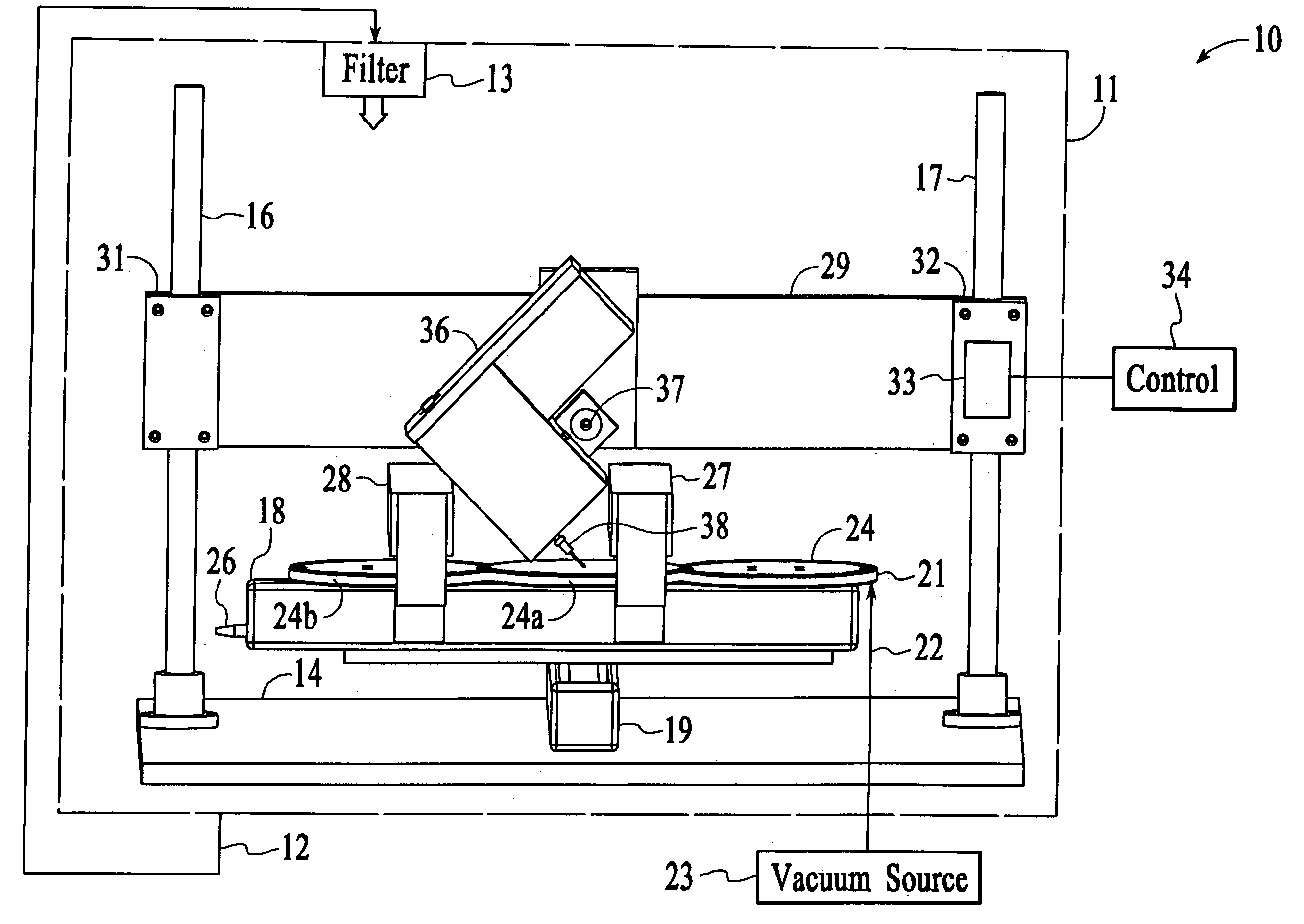

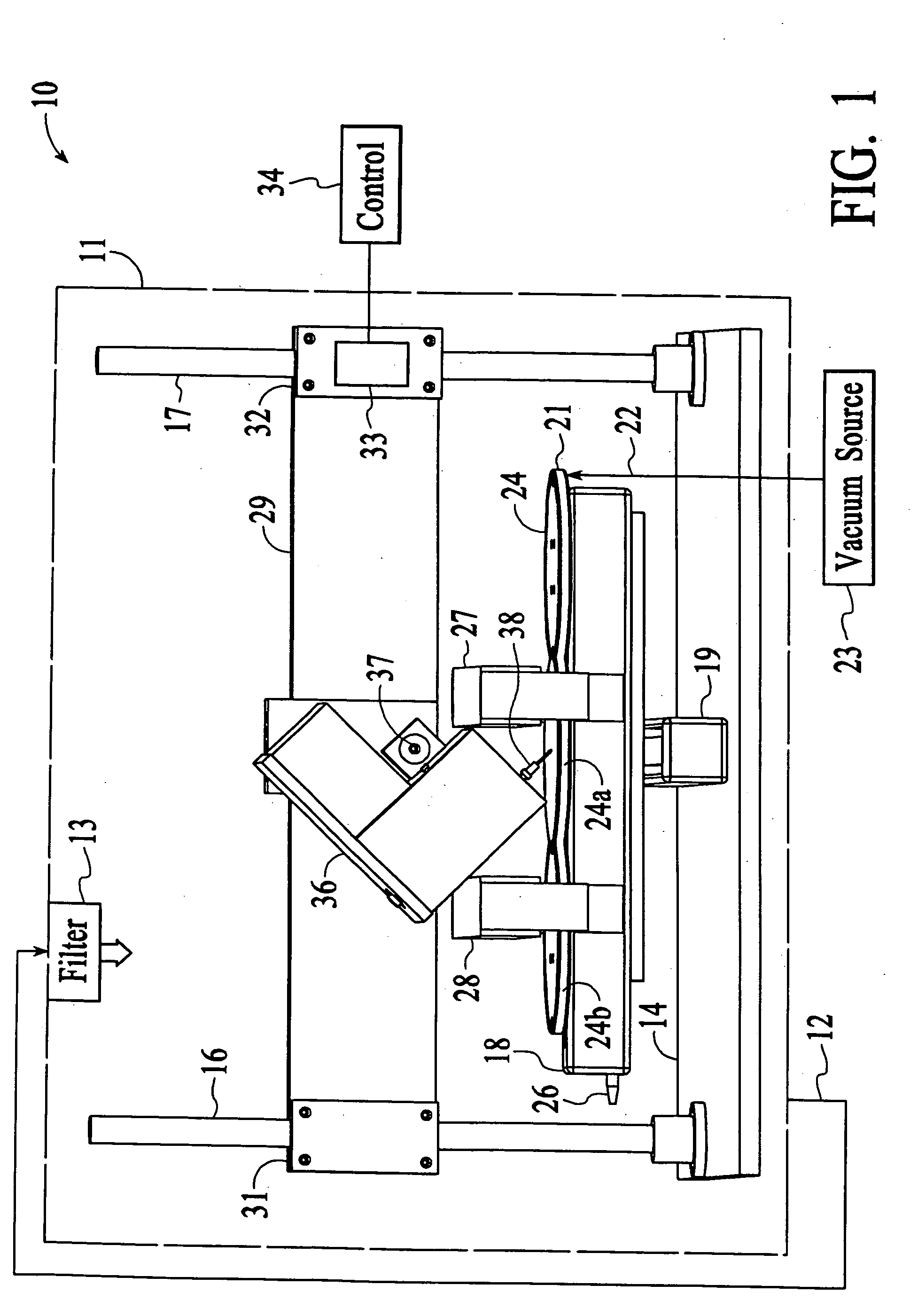

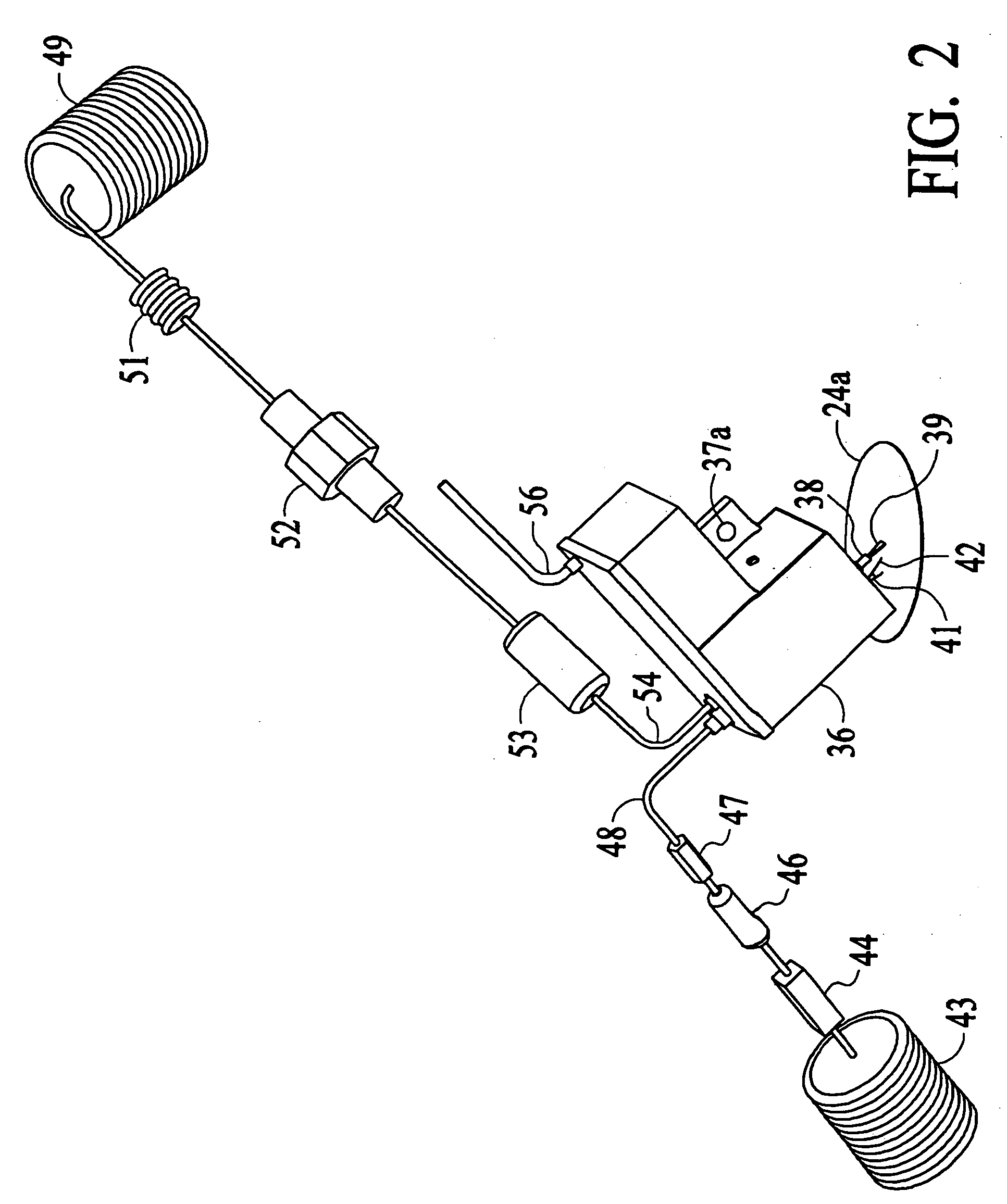

Method of shot blasting and a machine for implementing such a method

InactiveUS7028378B2Reduce usageHigh energyNon-mechanical blast generatorsBlade accessoriesEngineeringPeening

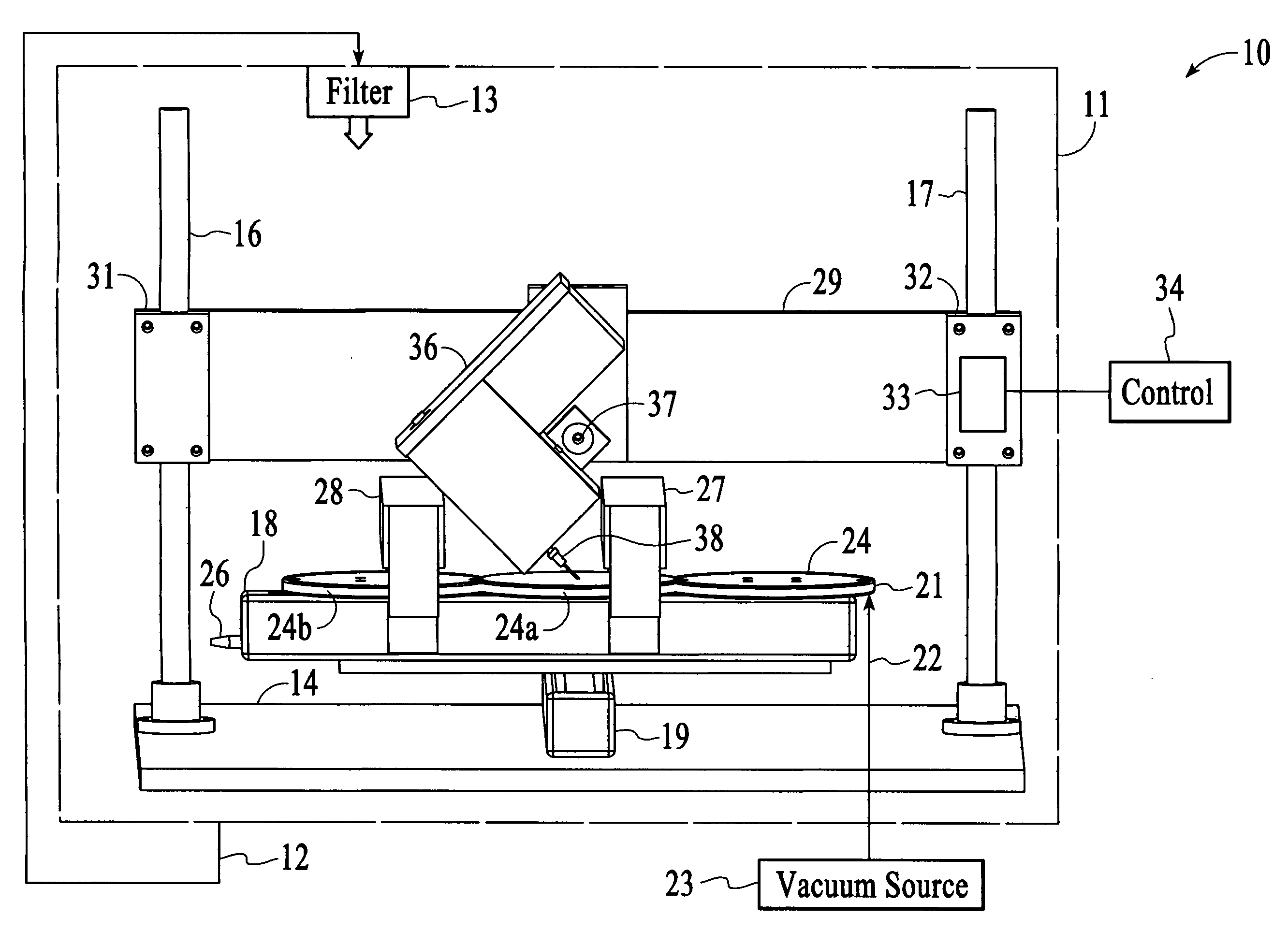

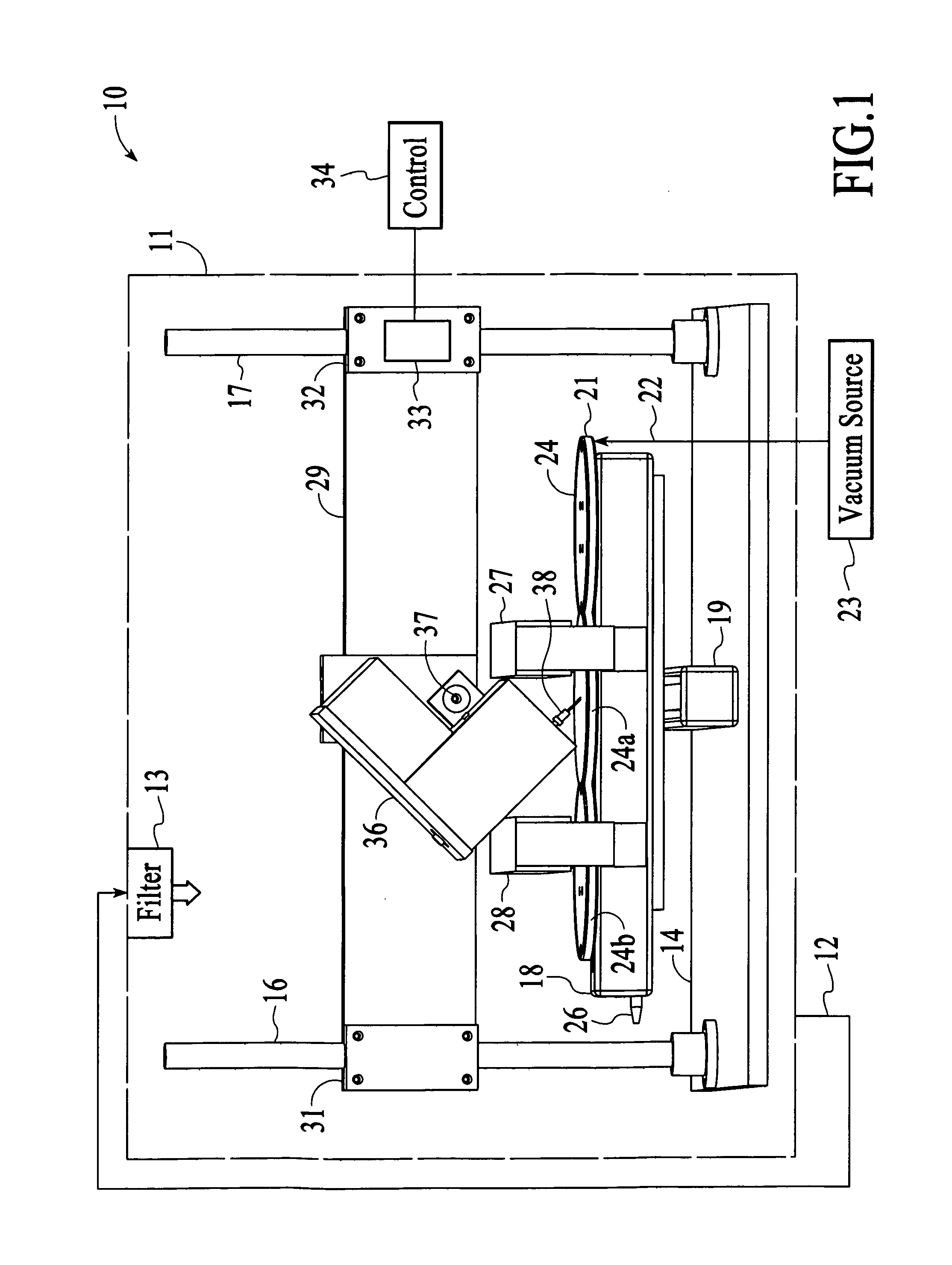

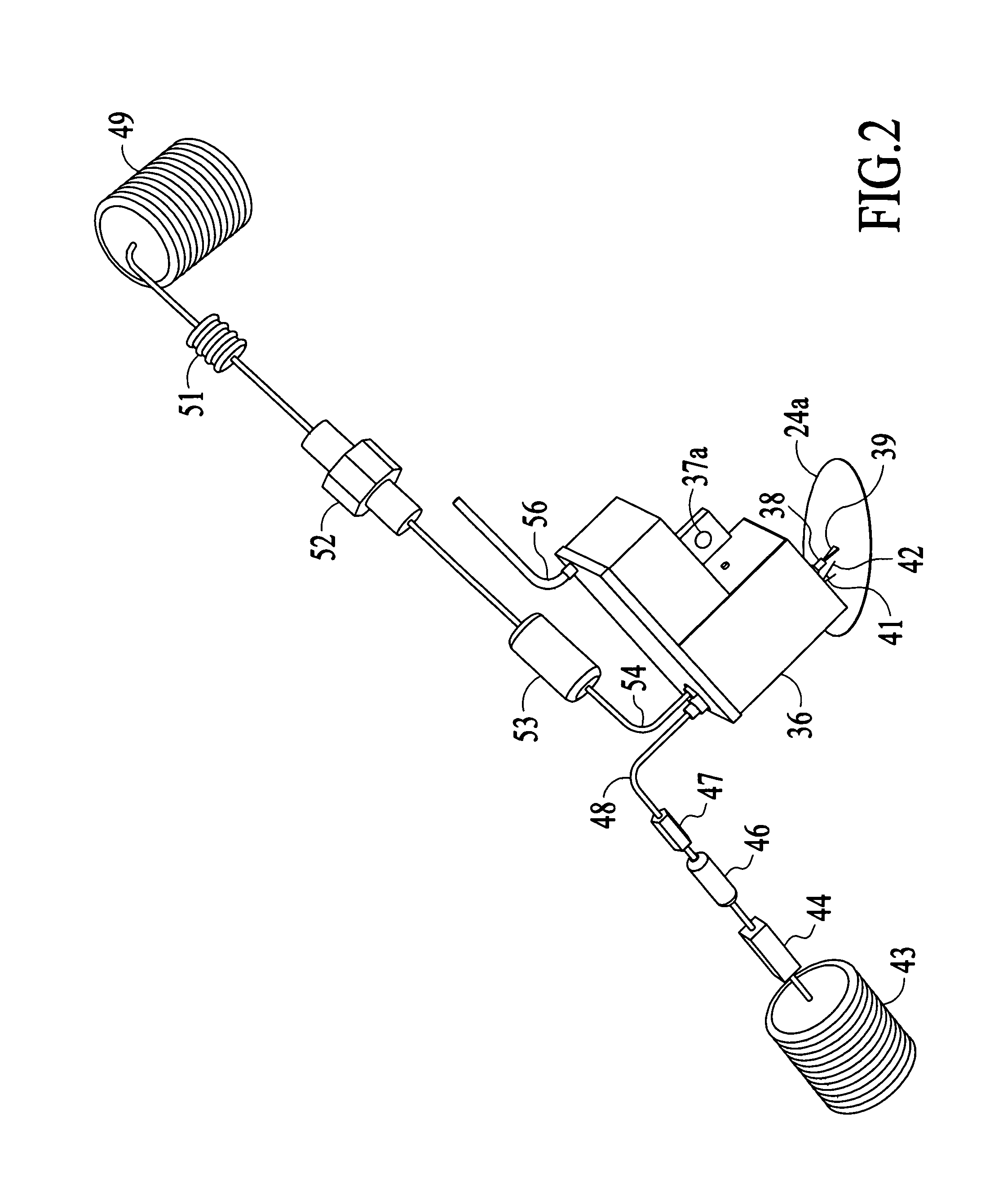

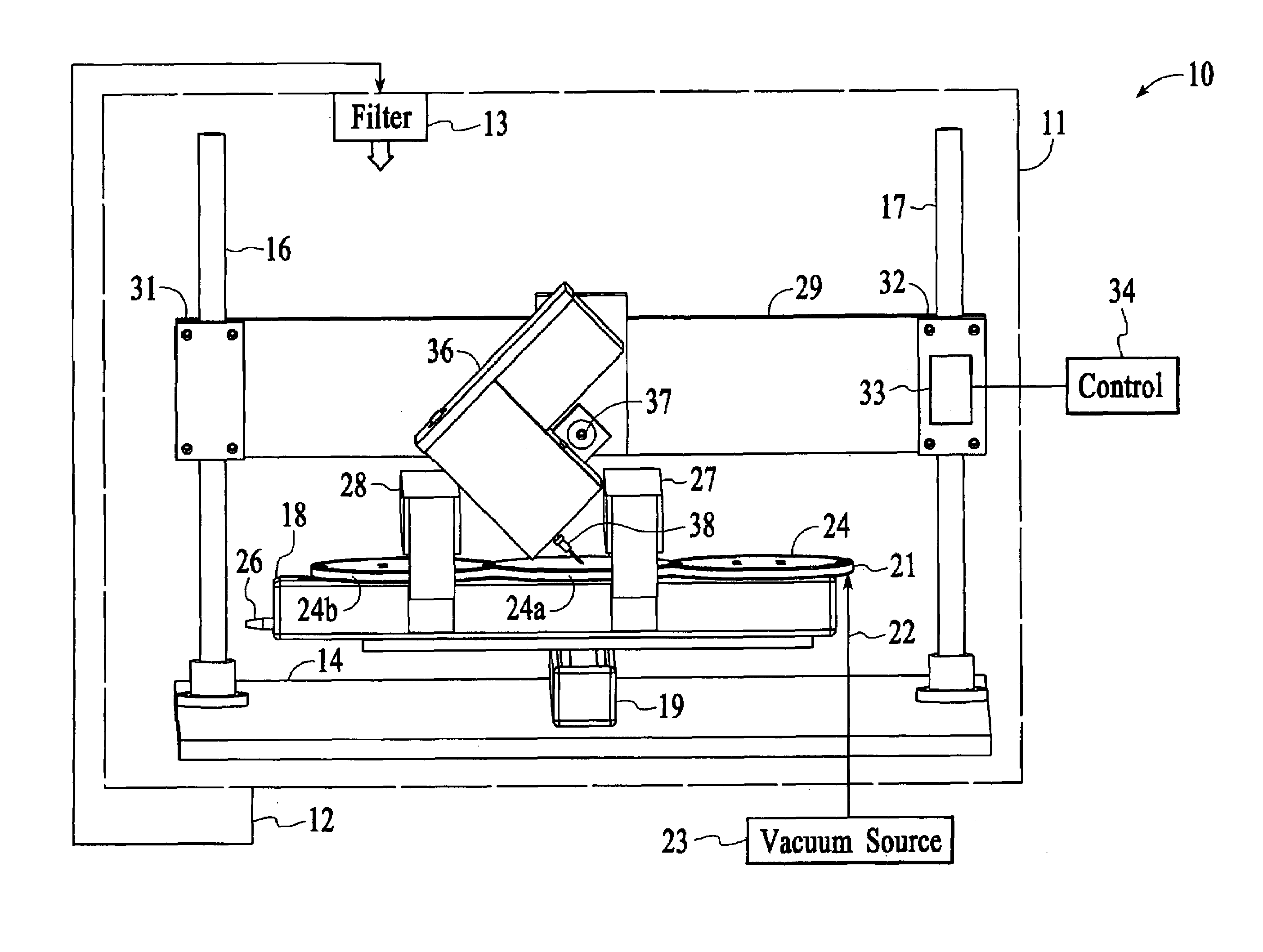

A part to be shot peened includes at least one thin wall (12″) defining two opposite main faces, the square root of the area of each face being greater than the mean distance between the two faces by a factor of at least five, and preferably by a factor of at least ten. According to the method, the part is caused to rotate at least intermittently relative to one or more vibrating surfaces, with at least one of the main faces being exposed to projectiles (6) set into motion by one or more of the vibrating surfaces, treatment taking place progressively on the face(s) so as to impart compression stresses thereto, with a portion only of the part being treated at any one time and with regions of the part preferably being exposed on several occasions to the projectiles, with relative rotation taking place between the exposures.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

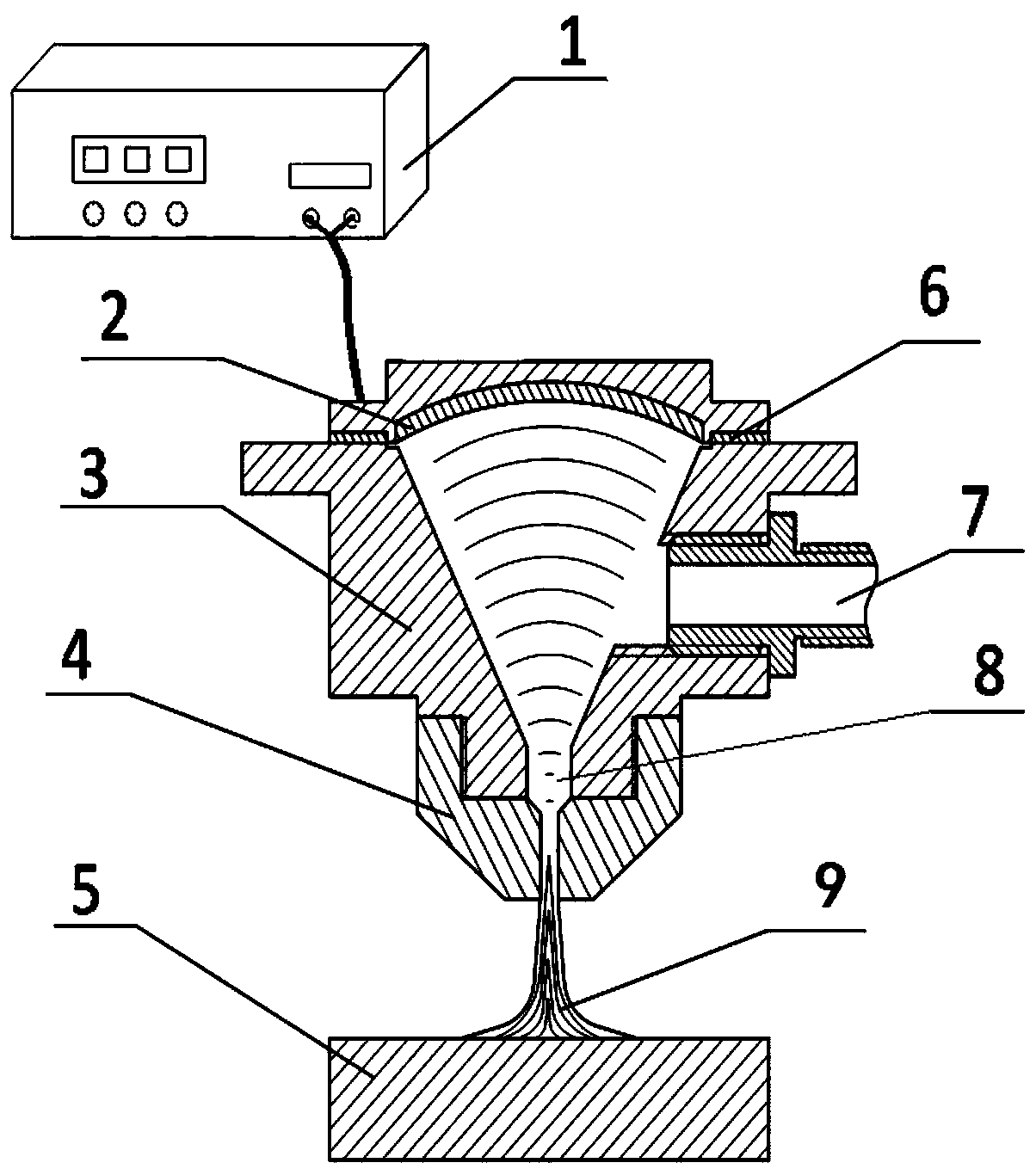

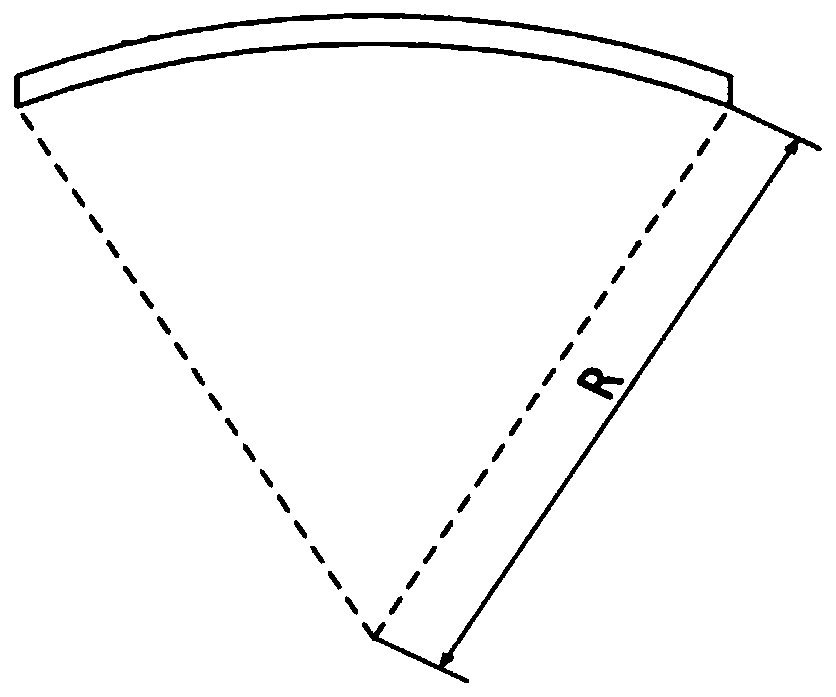

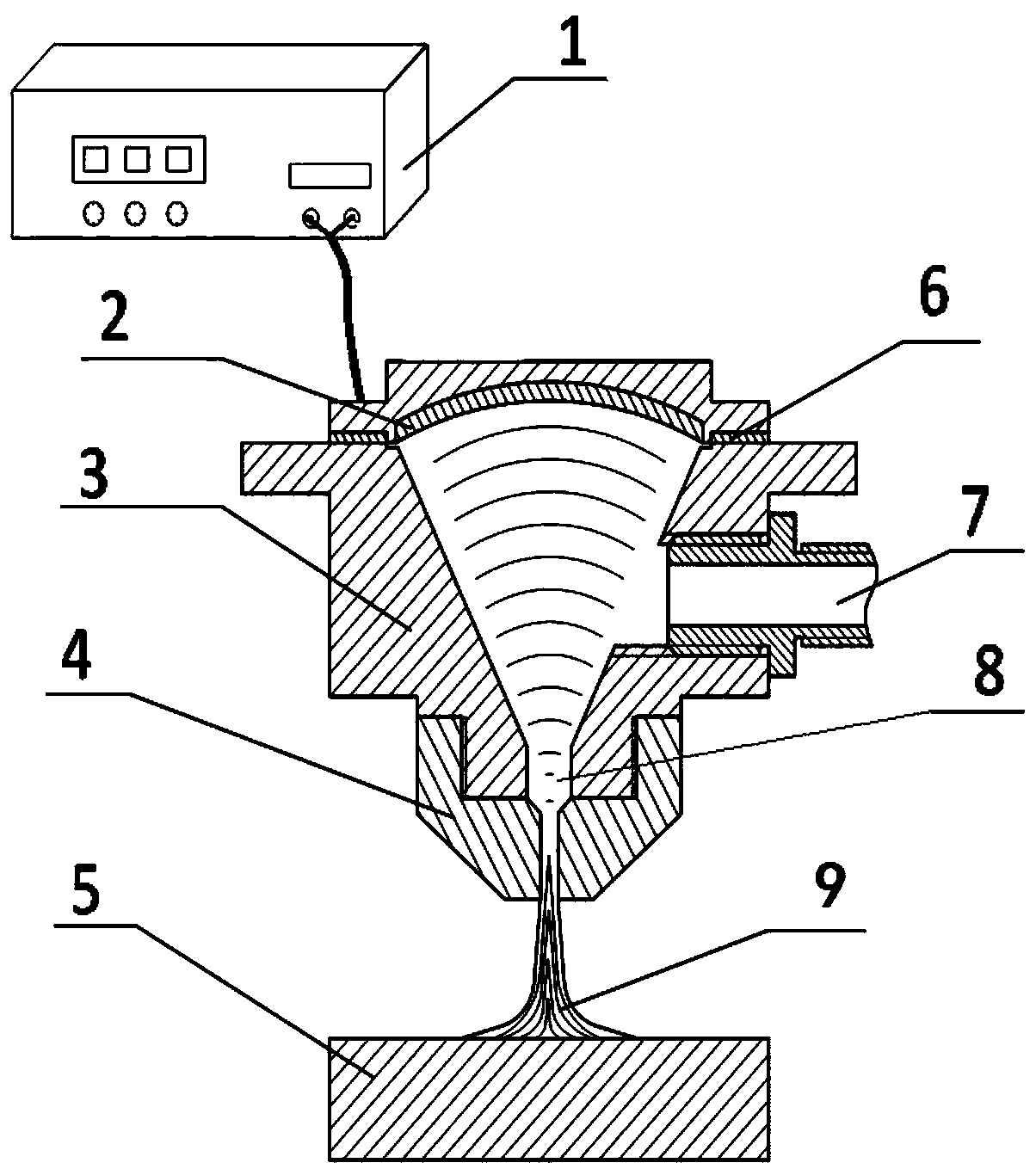

Ultrasonic cavitation assistant jet polishing system and polishing method

PendingCN110026908AImprove removal efficiencyPrecise control of removal volumeAbrasive machine appurtenancesAbrasive blasting machinesNumerical controlUltrasonic cavitation

The invention discloses an ultrasonic cavitation assistant jet polishing system which is characterized by comprising an ultrasonic transducer and a shell; the shell is internally provided with a containing cavity with an opening formed in the upper end; an ultrasonic transducer sealing cover is arranged on an opening formed in the upper end of the containing cavity in a sealing manner; the side surface of the shell is provided with a polishing solution supply hole; the lower side of the shell is provided with a jet nozzle; and the polishing solution supply hole and the jet nozzle communicateswith the containing cavity. The invention further provides an ultrasonic cavitation assistant jet polishing method. The ultrasonic cavitation assistant jet polishing system can be installed on a numerical control machine tool spindle box or an industrial robot mechanical arm, and the ultrasonic transducer is utilized to enable a polishing solution to generate high-frequency vibration and produce cavitation bubbles, and the high-pressure and high-speed polishing solution is sprayed to the surface of a workpiece, so that the material removal efficiency of an abrasive water jet is improved. The ultrasonic cavitation assistant jet polishing system and method provided by the invention can be suitable for surface type finishing of a super-smooth surface and is also suitable for surface processing and manufacturing of a microscopic special morphology.

Owner:TIANJIN UNIV

Methods for residue removal and corrosion prevention in a post-metal etch process

InactiveUS20050215445A1Improve throughputHigh selectivitySurface-active detergent compositionsNon-surface-active detergent compositionsHydrogenOxygen

A method of plasma assisted CO2 cleaning for dry removal of residual photoresist and sidewall polymer with an etch gas mixture comprising fluorine containing gas, oxygen and hydrogen in N2 or H2O. The process removes polymer residues present on a metal layer on a substrate and on the sidewalls of metal lines and inhibits chlorine-based corrosion while being very selective to exposed Ti, TiN, Al and SiO2. The invention is particularly suited for removing post metal etch polymer residue from top and sidewall of metal lines.

Owner:NANOCLEAN TECH

Device for surface blasting component

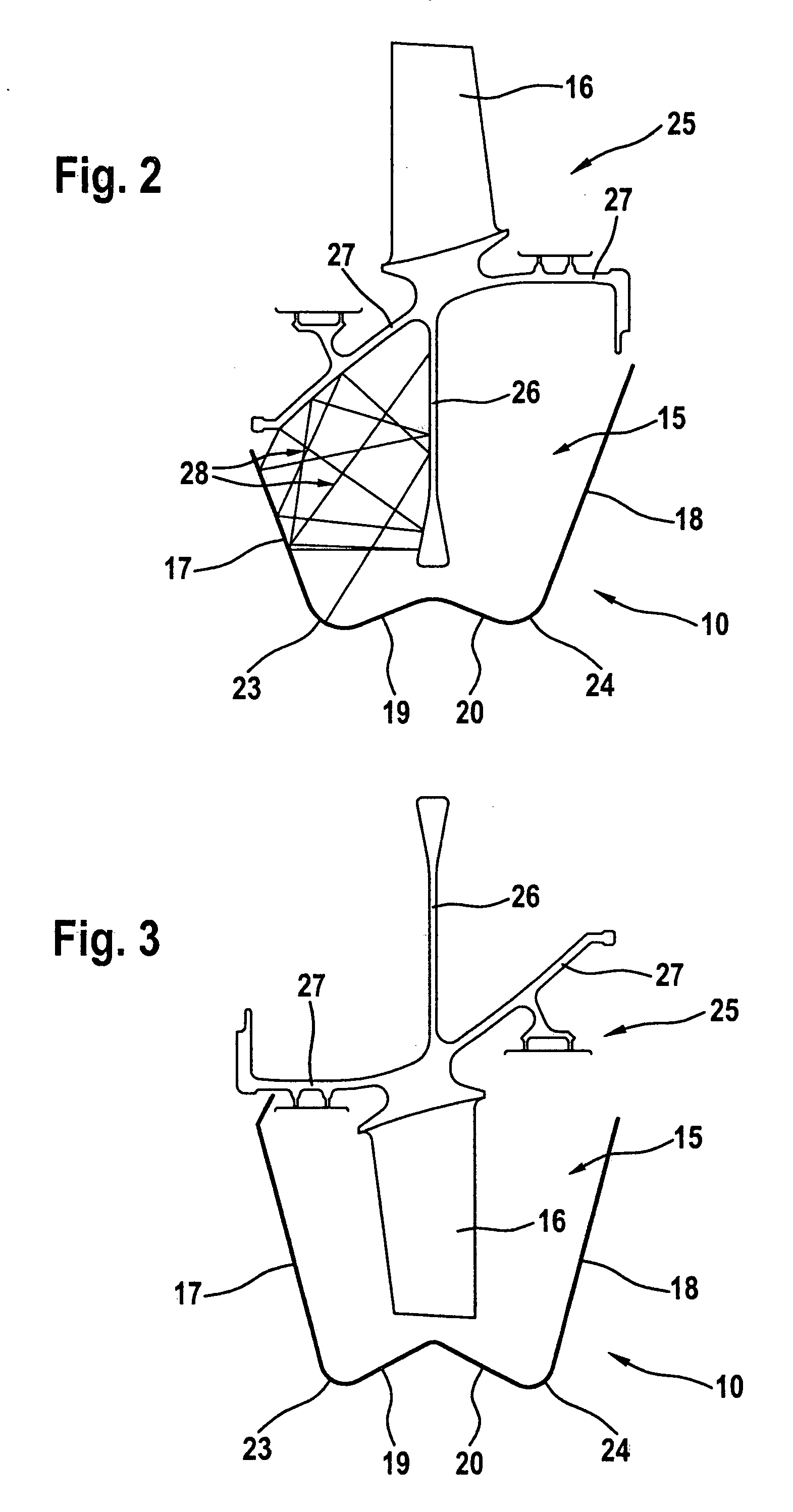

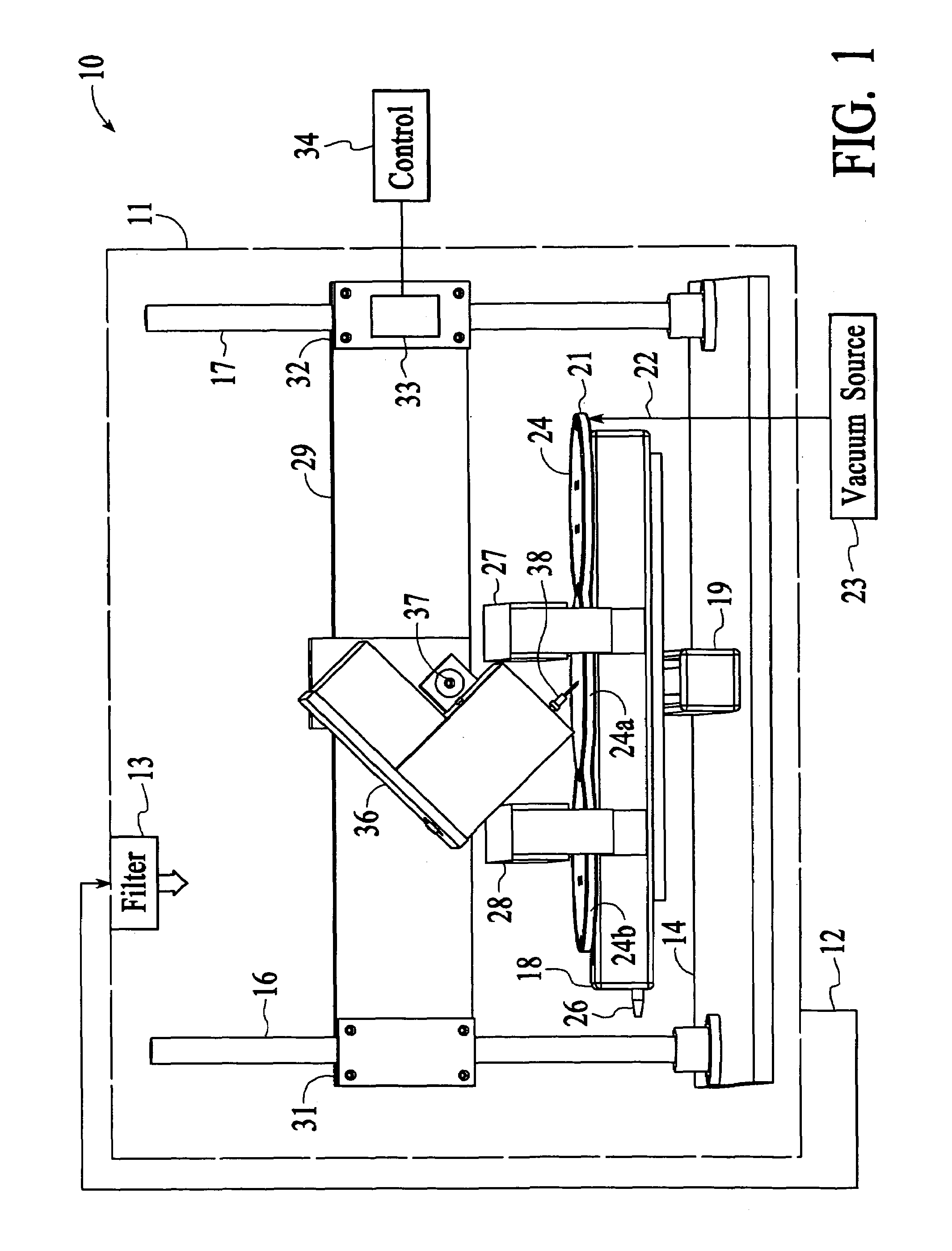

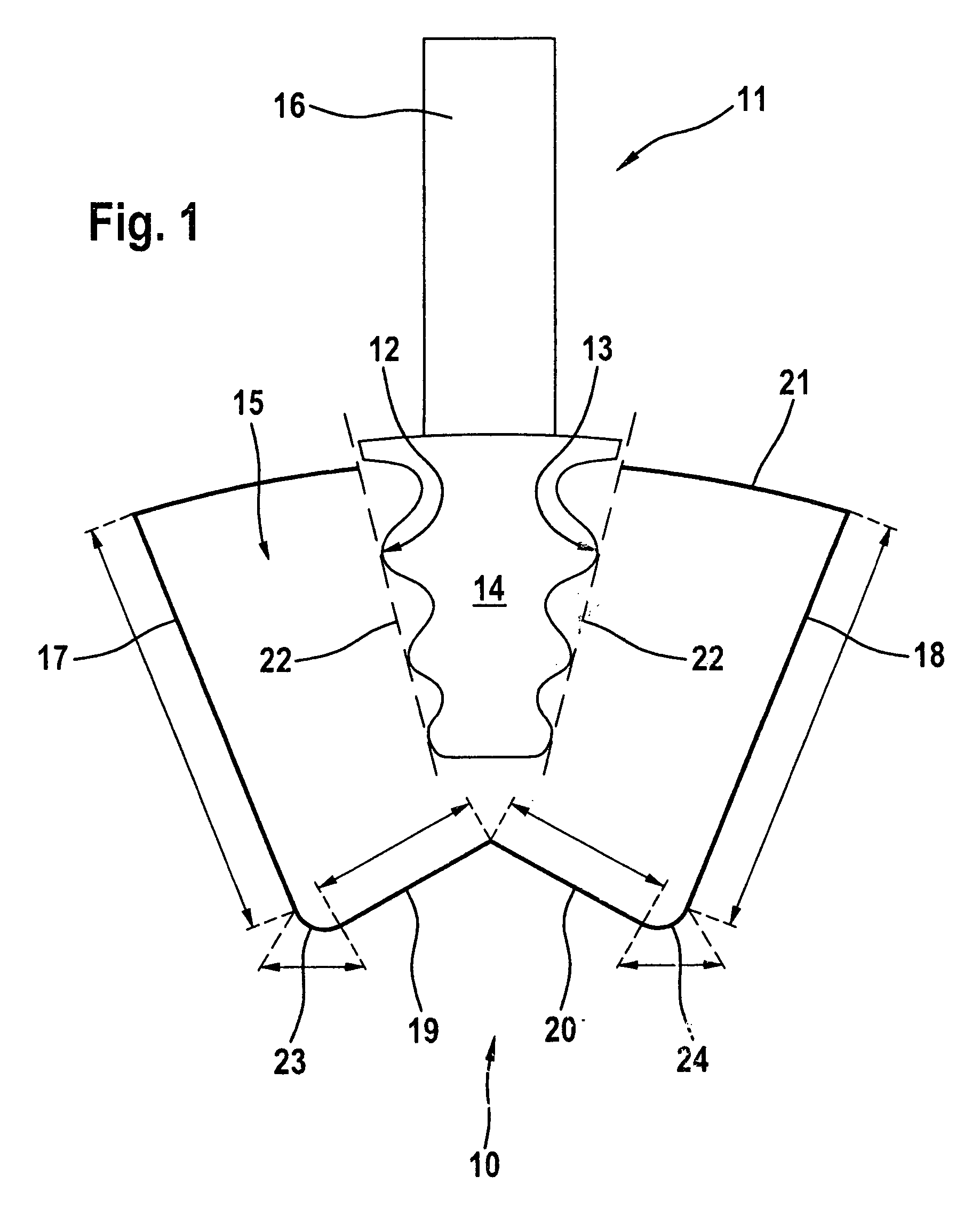

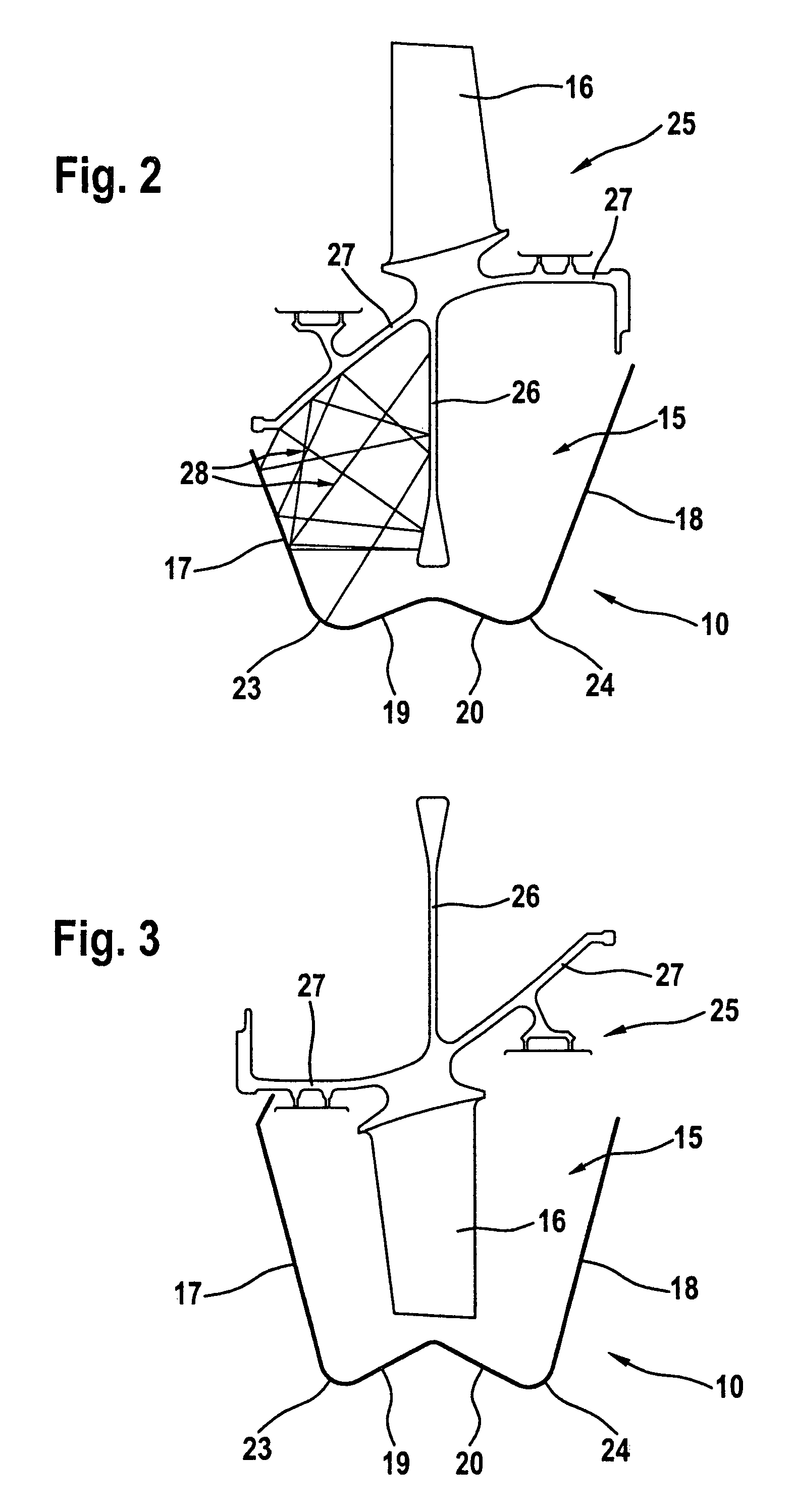

ActiveUS20060174483A1Improve efficiencyImprove machine qualityEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingEngineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

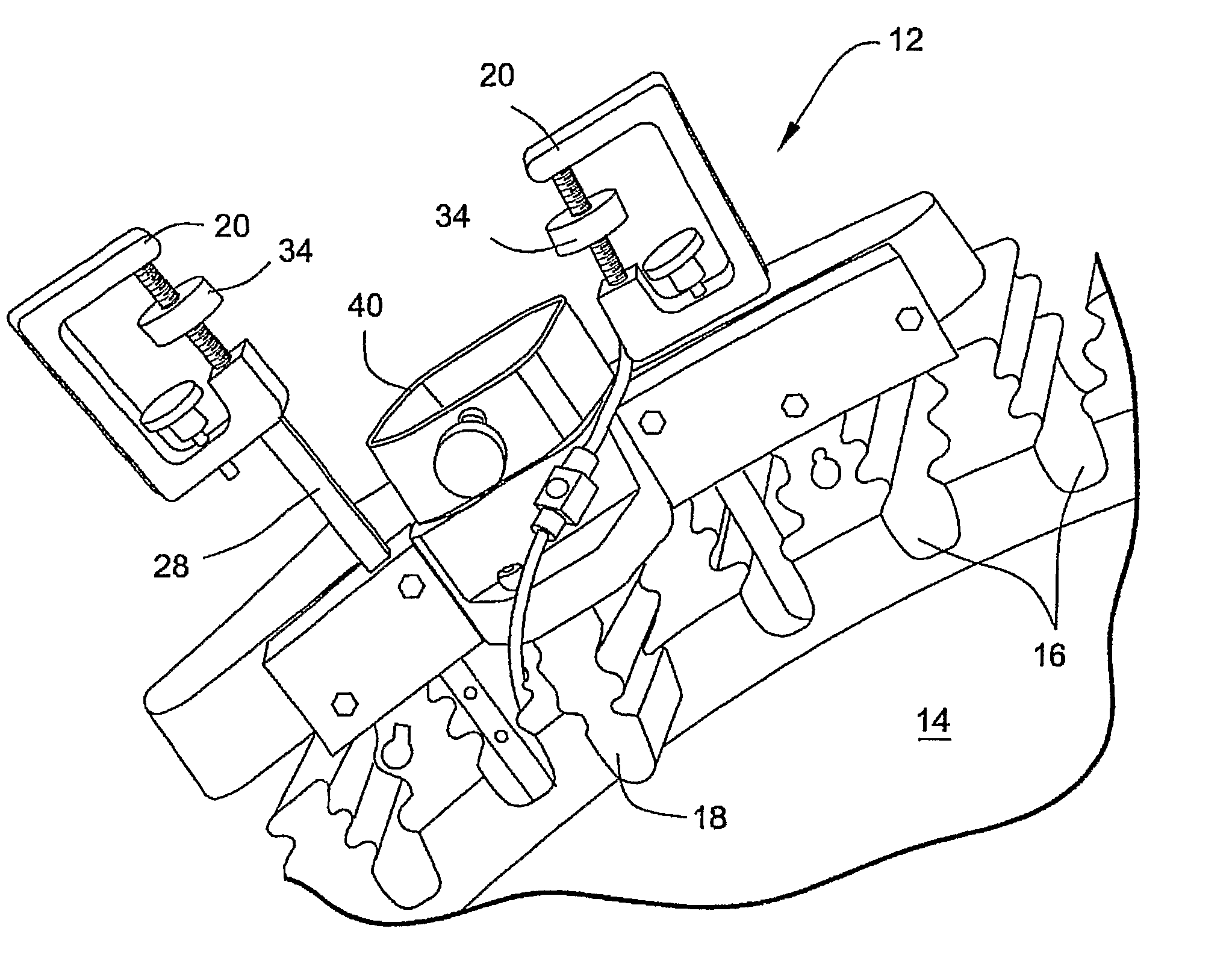

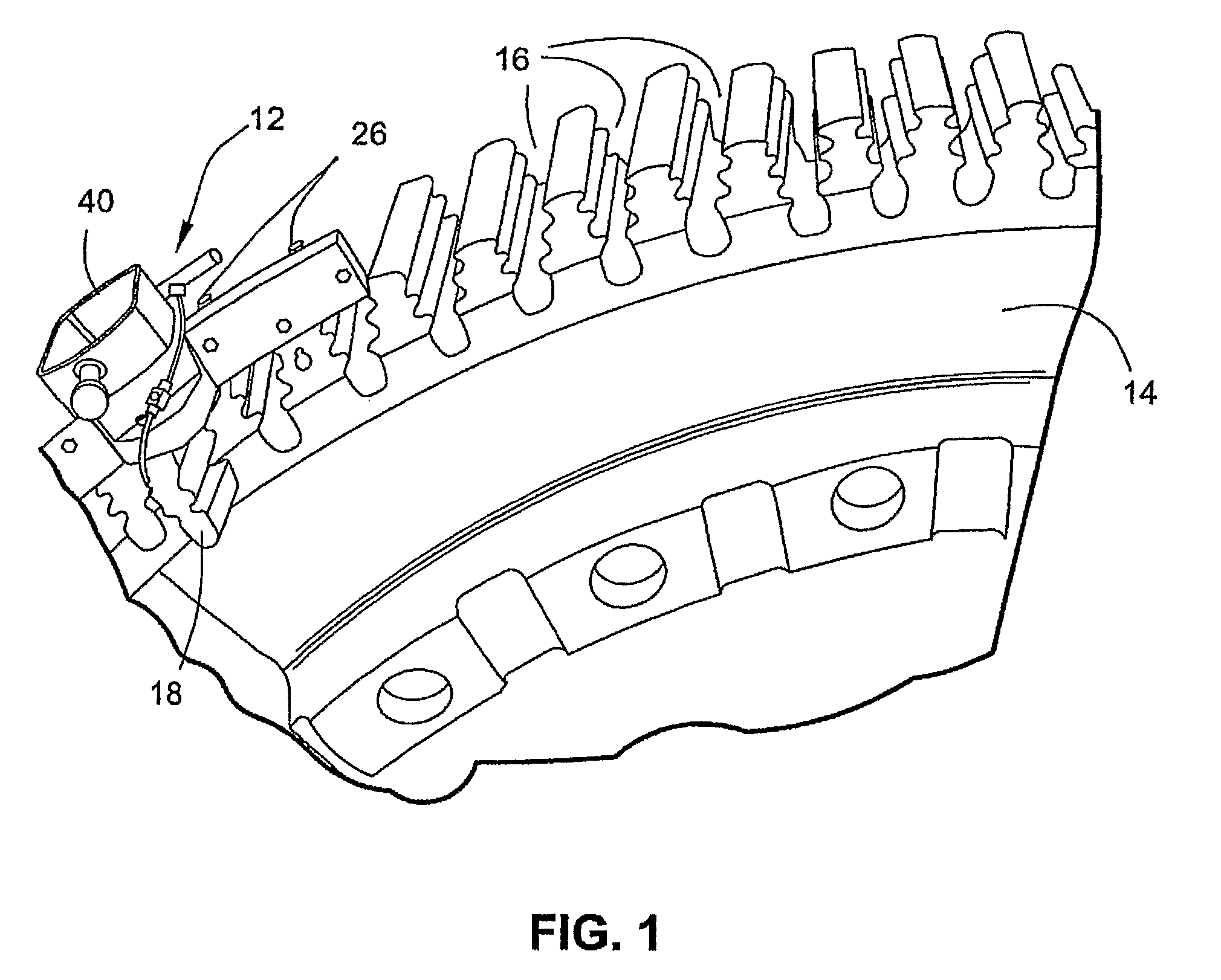

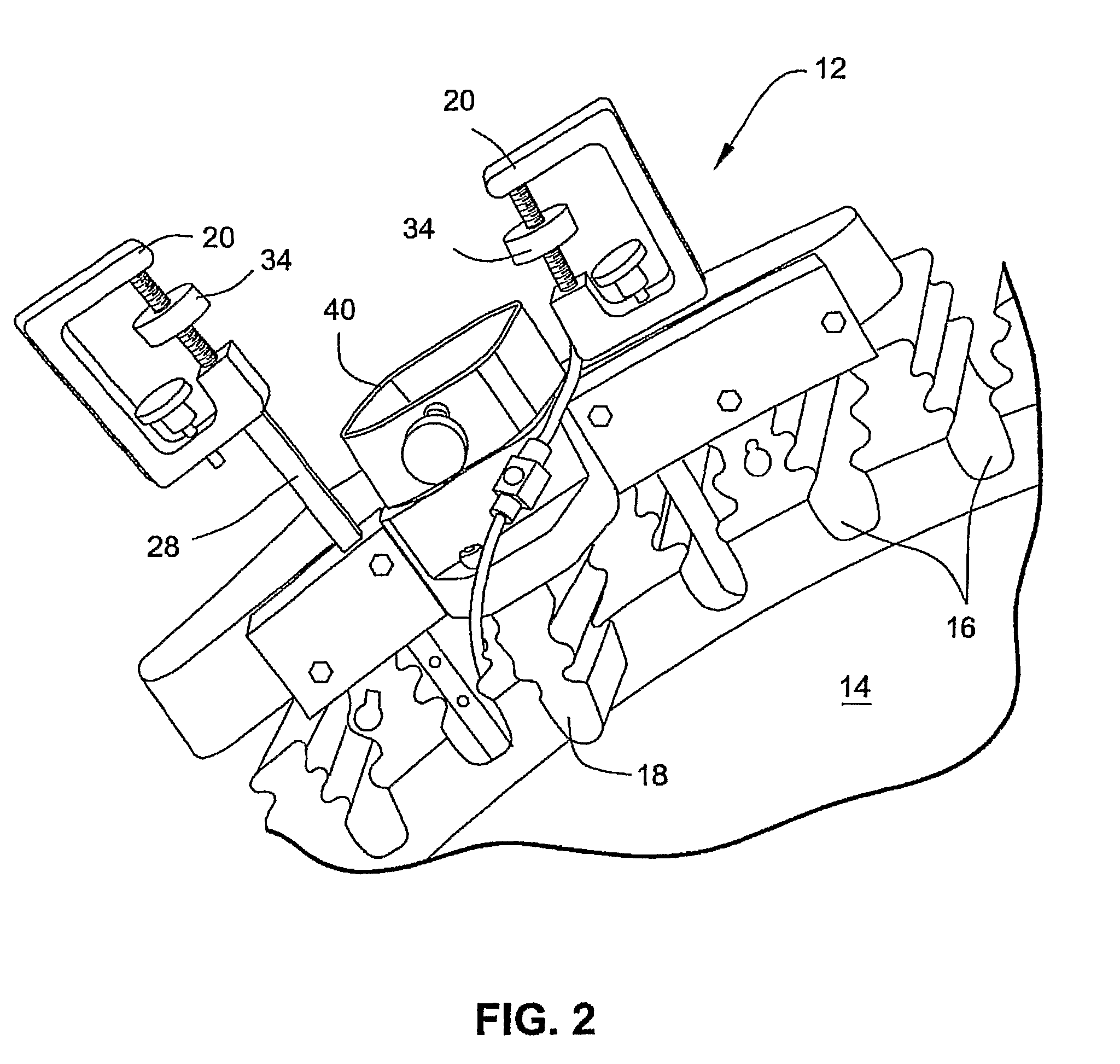

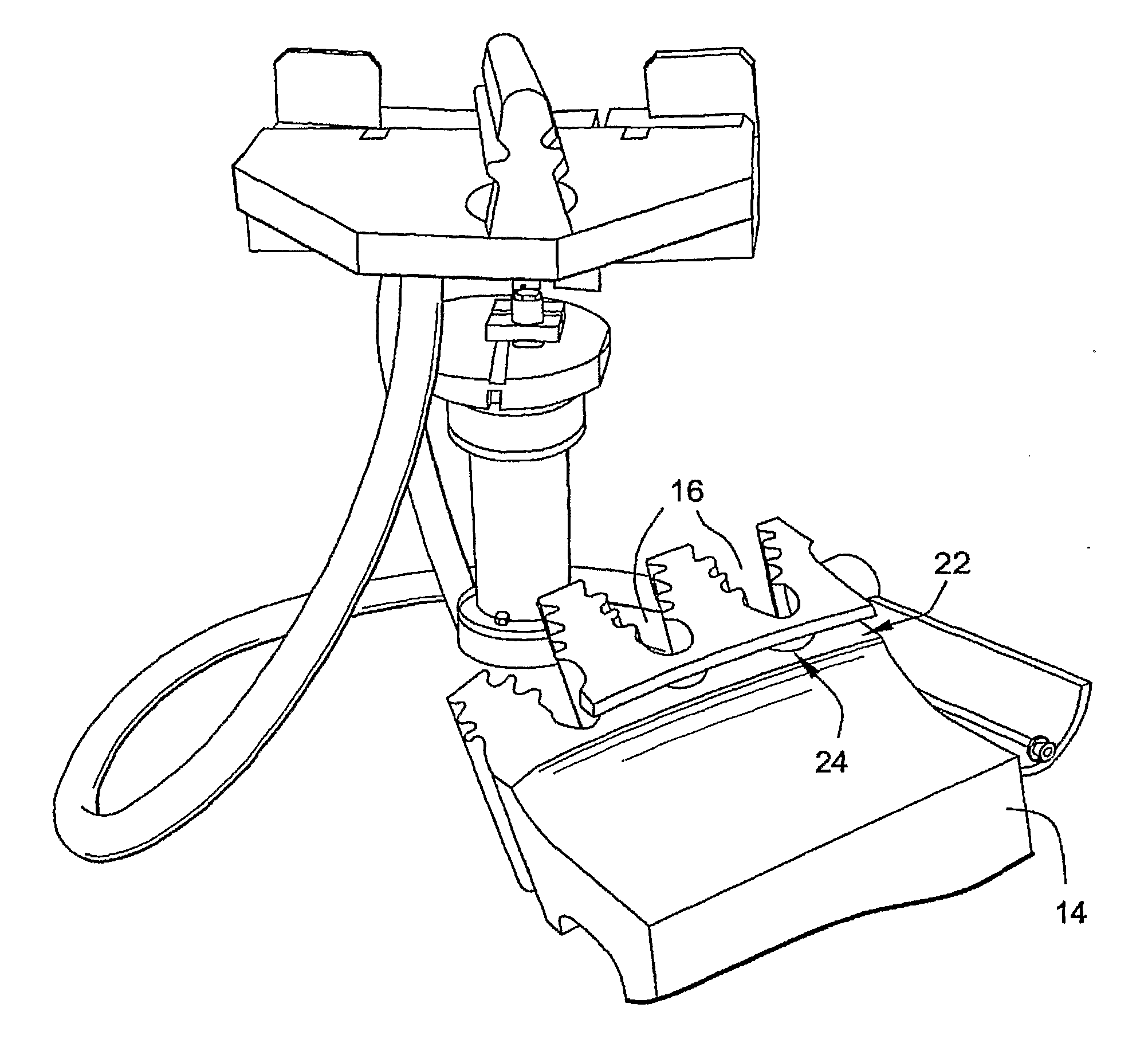

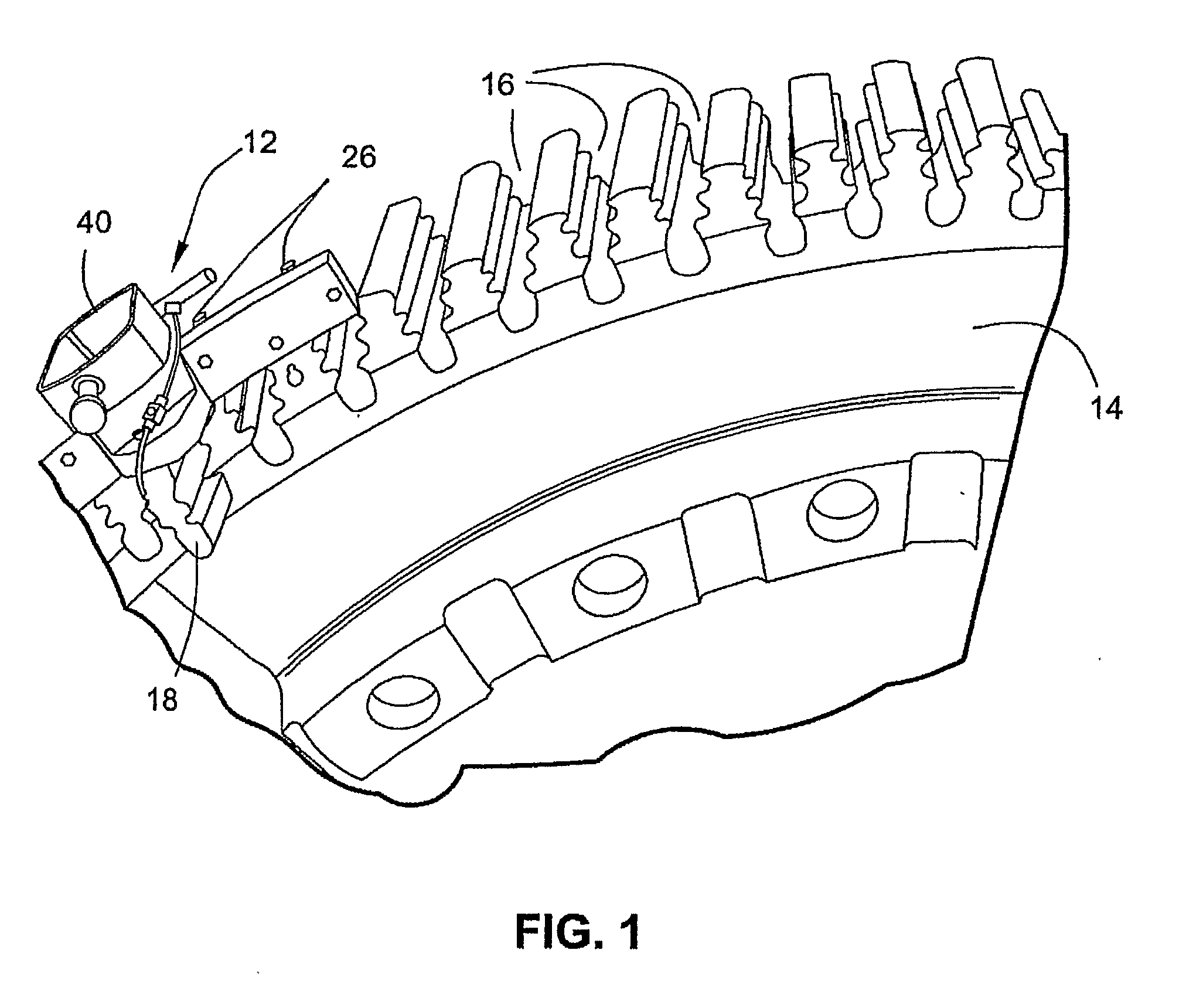

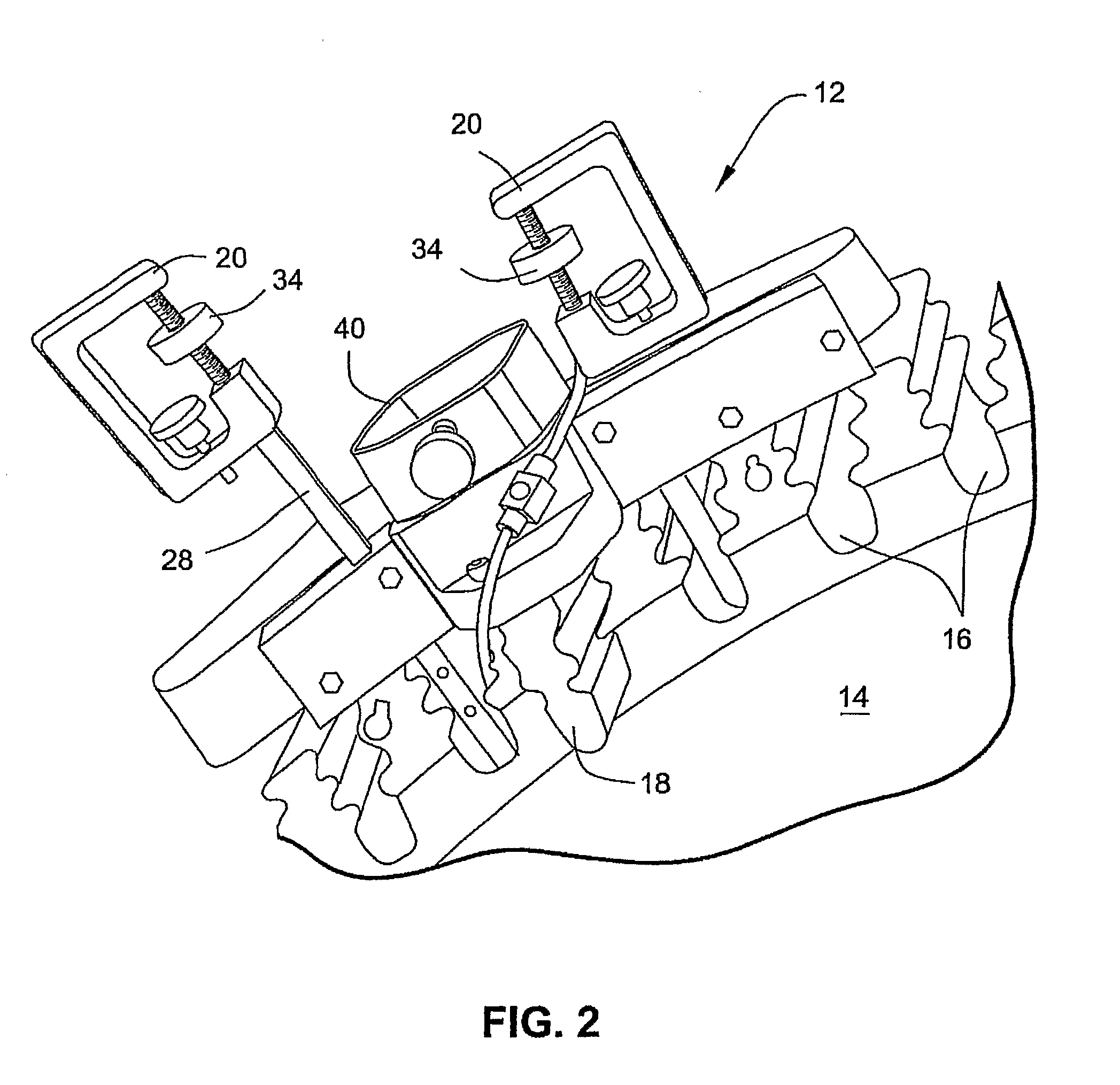

Ultrasonic peening treatment of assembled components

Ultrasonic peening treatment is desirable where an application of a compressive stress is helpful to reduce the incidence of crack formation on highly stressed parts. Ultrasonic peening treatment can be performed in field applications without requiring a rotor to be removed from the machine. The system includes an acoustic element that excites peening media within a peen chamber. A frame is attachable to an assembled turbine rotor component and includes support structure engageable with the acoustic element. The frame is cooperable with a chamber tooling that defines and encloses the peen chamber together with the turbine rotor component.

Owner:GE INFRASTRUCTURE TECH INT LLC

Method for surface blasting cavities, particularly cavities in gas turbines

InactiveUS7644599B2Minimizes deformation of materialReduce riskBurnishing machinesVibratory devicesAbrasive blastingEngineering

In a method for surface blasting hollow spaces or cavities, especially cavities of gas turbines, shot balls are accelerated with the aid of at least one vibrator, whereby the ultrasonically accelerated shot balls are directed onto surfaces of a cavity that is to be blasted. The vibrator is preferably positioned with a small spacing distance, preferably on the order of magnitude of the diameter of the shot balls utilized for the blasting, from the cavity to be blasted.

Owner:MTU AERO ENGINES GMBH +1

Methods for residue removal and corrosion prevention in a post-metal etch process

InactiveUS7134941B2Improve throughputHigh selectivityNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingHydrogenOxygen

A method of plasma assisted CO2 cleaning for dry removal of residual photoresist and sidewall polymer with an etch gas mixture comprising fluorine containing gas, oxygen and hydrogen in N2 or H2O. The process removes polymer residues present on a metal layer on a substrate and on the sidewalls of metal lines and inhibits chlorine-based corrosion while being very selective to exposed Ti, TiN, Al and SiO2. The invention is particularly suited for removing post metal etch polymer residue from top and sidewall of metal lines.

Owner:NANOCLEAN TECH

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7297286B2Small footprintEasy to cleanNon-mechanical blast generatorsDecorative surface effectsResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where the cryogenic cleaning medium removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied with a pulsating flow via a nozzle implement that sweeps across the article. The pulsating flow may be generated via a piezo device or a rotating shaft with a hole the periodically enables or interrupts flow through a flow channel.

Owner:NANOCLEAN TECH

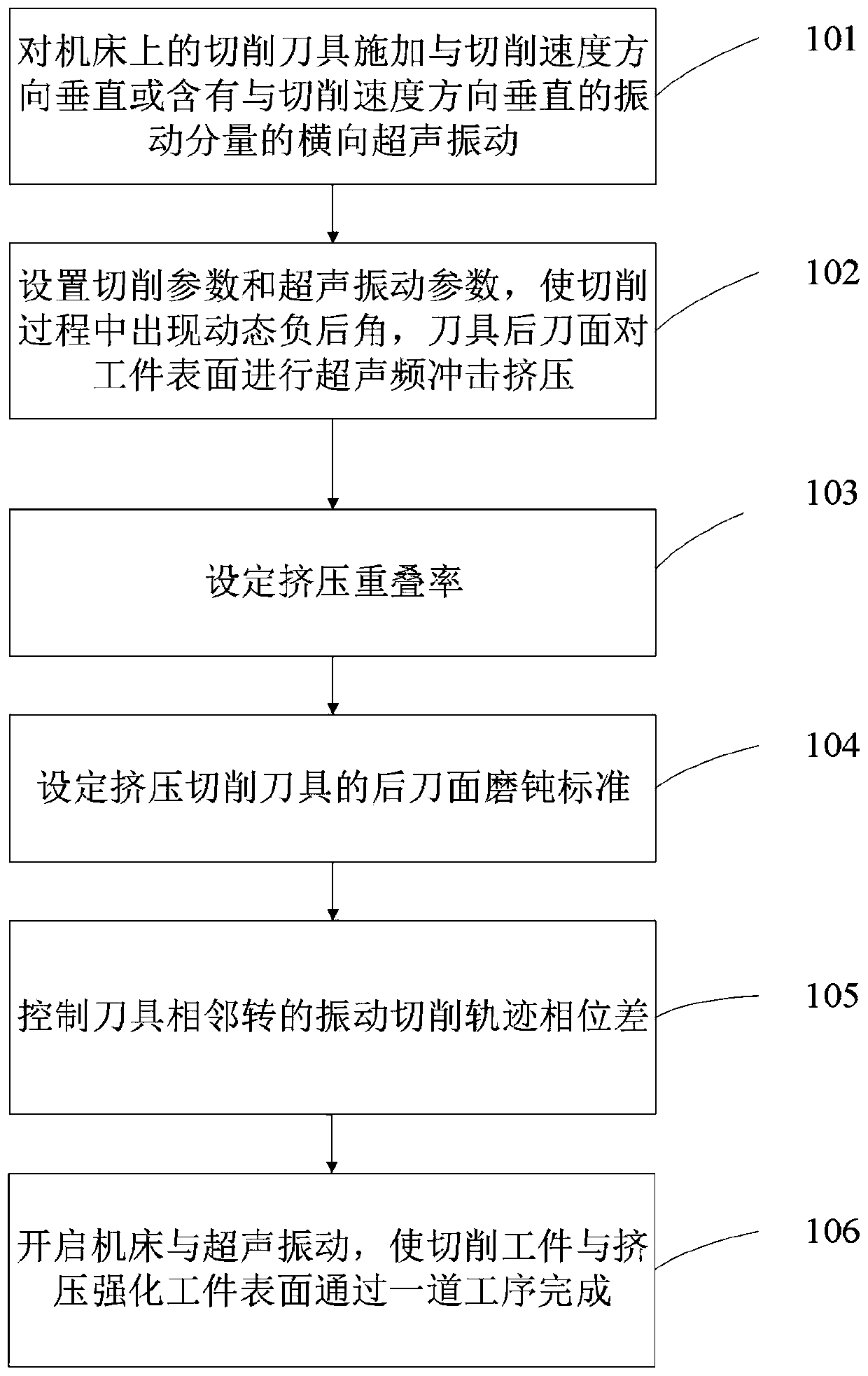

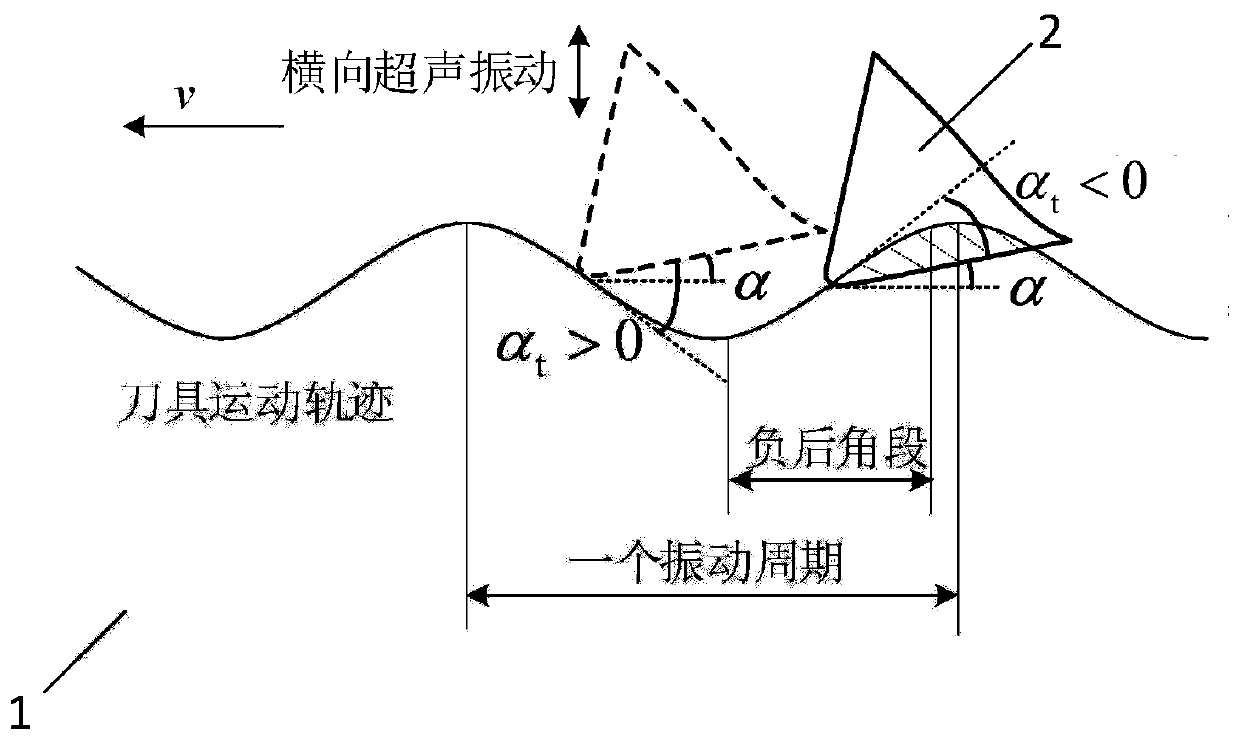

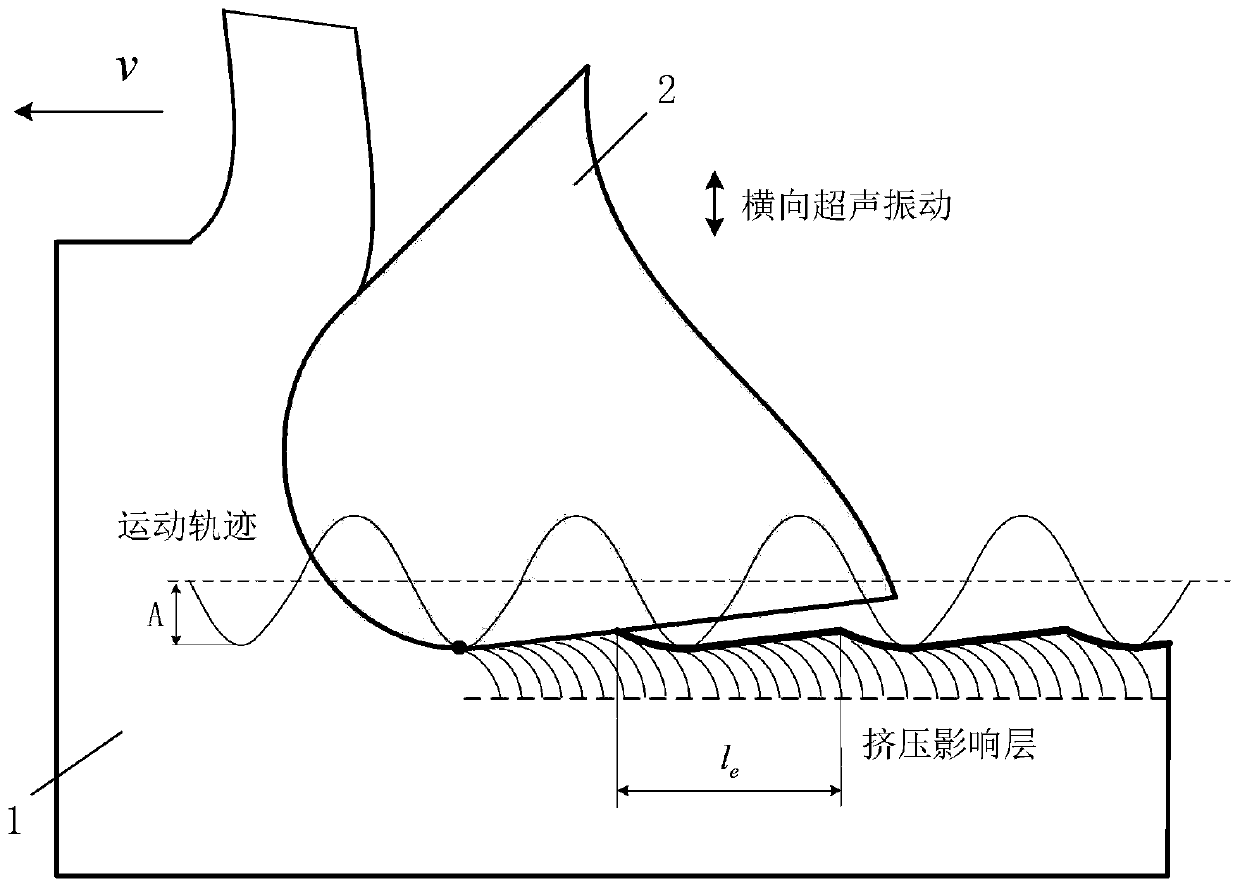

Ultrasonic stamping type cutting and extruding integrated machining method

ActiveCN110076350AImprove fatigue lifeIncreased surface microhardnessTurning machine accessoriesBurnishing machinesPhase differenceUltrasonic vibration

The invention discloses an ultrasonic stamping type cutting and extruding integrated machining method. The ultrasonic stamping type cutting and extruding integrated machining method comprises the following steps that transverse ultrasonic vibration which is perpendicular to the cutting speed direction or contains a vibration component perpendicular to the cutting speed direction is applied to a cutting tool on a machine tool; cutting parameters and ultrasonic vibration parameters are set, so that a dynamic negative rear angle is generated in the cutting process, and ultrasonic-frequency impactextrusion is performed on the surface of a workpiece by a rear tool face of the tool; the extrusion overlap ratio is set; a grinding dulling standard of a rear tool face of an extruding and cutting tool is set; the vibrating and cutting track phase difference of adjacent rotation of the tool is controlled; the machine tool and ultrasonic vibration are started, so that workpiece cutting and extrusion reinforcement of the surface of the workpiece are completed through one working procedure. According to the ultrasonic stamping type cutting and extruding integrated machining method, a reinforcing working procedure is not needed to be additionally provided, and the surface of the workpiece can undergo extrusion reinforcement while the workpiece is cut.

Owner:BEIHANG UNIV

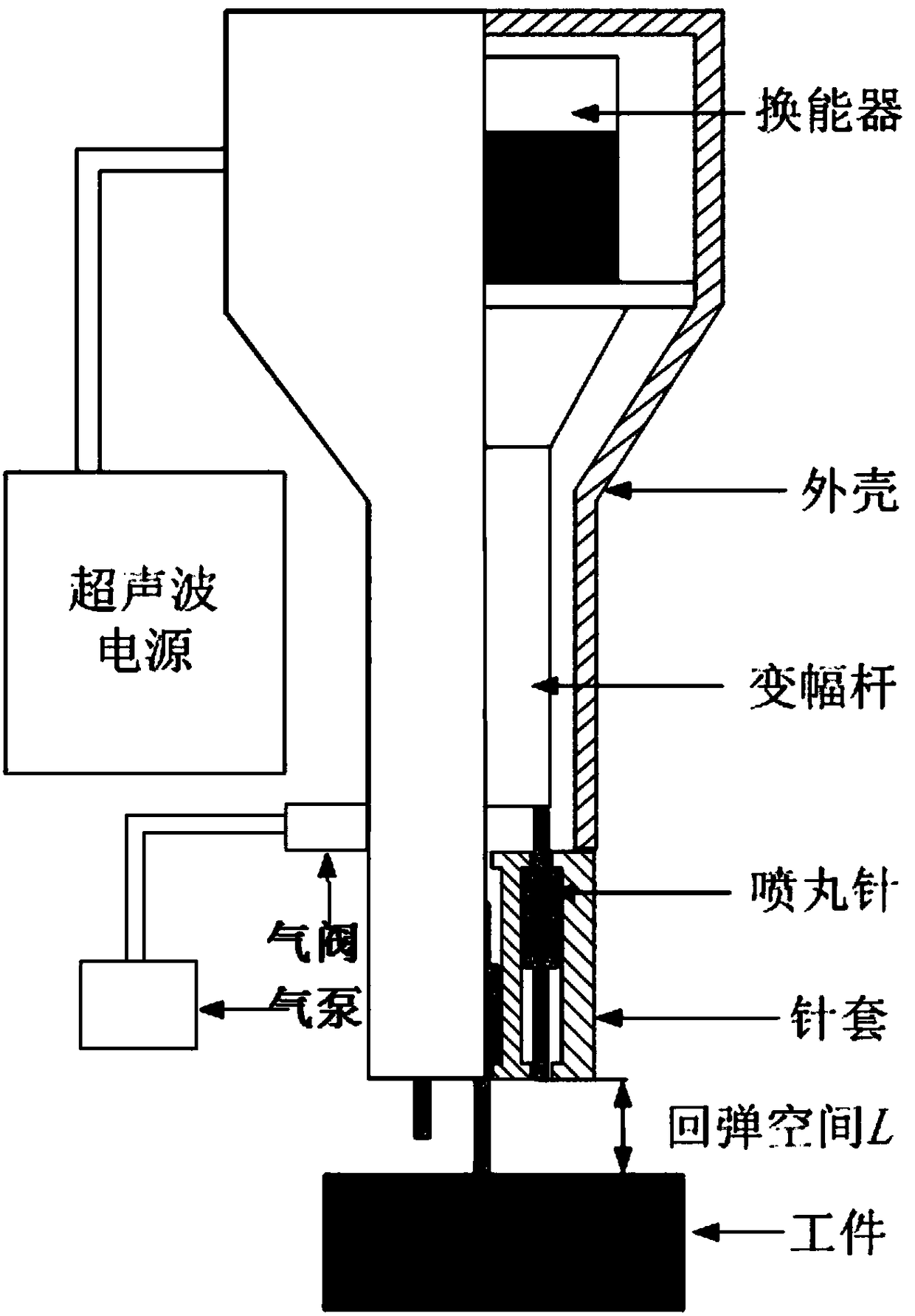

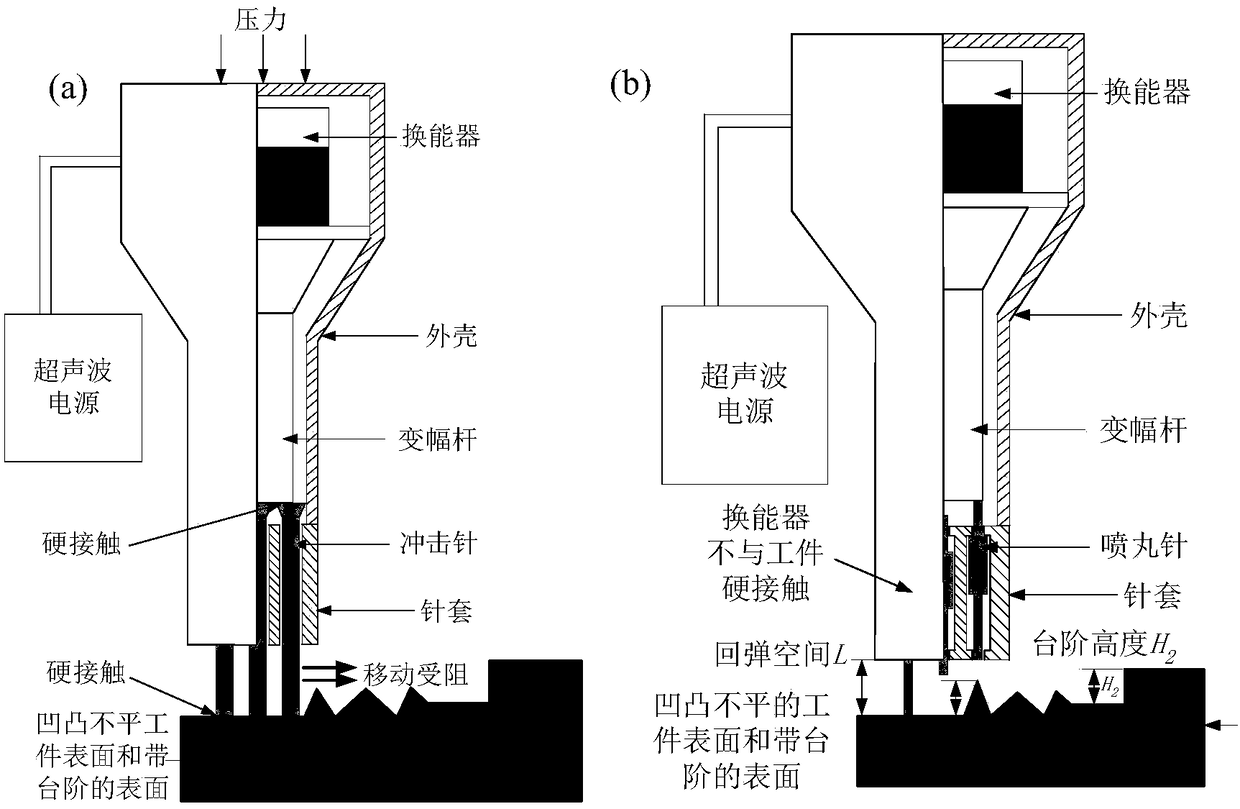

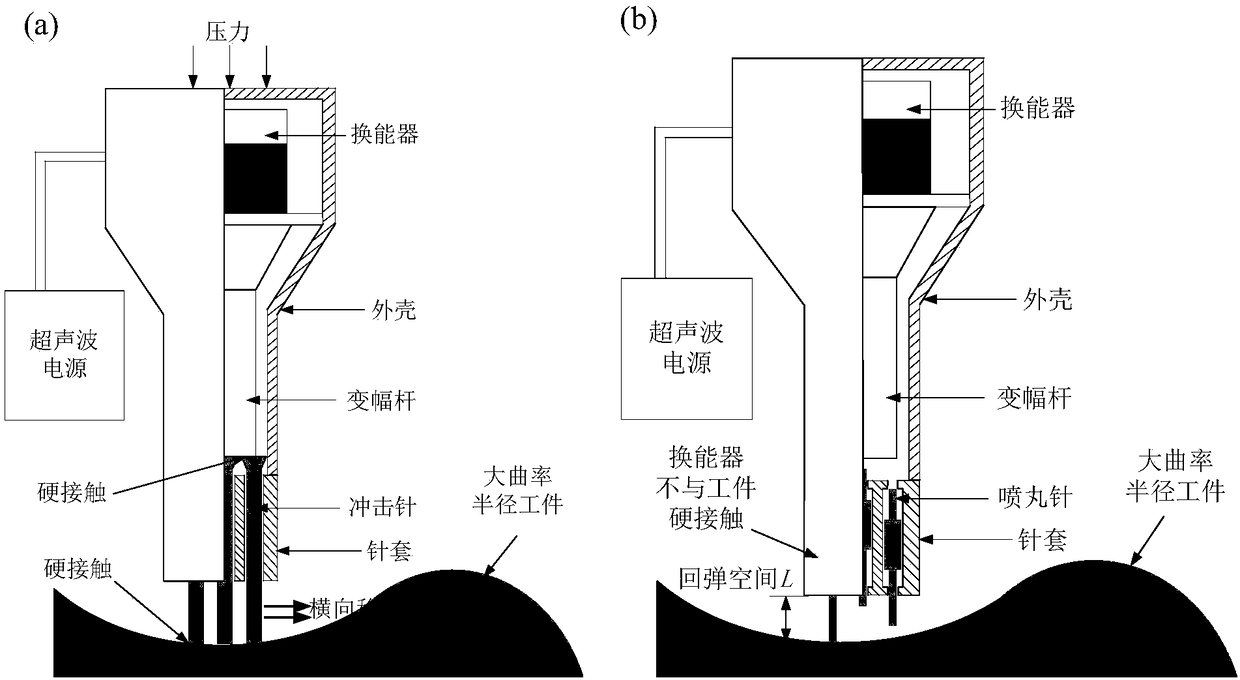

Full-angle flexible needle type ultrasonic shot blasting device

InactiveCN109420988AAchieving flexible contactVibratory devicesGrinding/polishing apparatusSuction forceTransducer

The invention discloses a full-angle flexible needle type ultrasonic shot blasting device. The full-angle flexible needle type ultrasonic shot blasting device is composed of an ultrasonic transducer,a shot blasting needle sleeve, a shot blasting needle and a suction device. The tail end of the shot blasting needle is adsorbed to the end face of the tail end of an amplitude-change pole of the transducer through suction force, and the shot blasting needle is popped out through ultrasonic vibration of the tail end of the amplitude-change pole. The shot blasting needle cannot be completely poppedout of the needle sleeve due to stop of the needle sleeve, and therefore the shot blasting needle can achieve constant reciprocating impacting between the amplitude-change pole of the ultrasonic transducer and a to-be-treated metal workpiece within a wide distance range, flexible contact between the shot blasting needle and the surface of the workpiece is achieved, the end of the shot blasting needle impacts on and is in contact with the surface of the to-be-treated metal workpiece only at the ultrasonic shot blasting moment, and the whole ultrasonic shot blasting device does not need to be in hard contact with the surface of the metal workpiece before shot blasting.

Owner:TIANJIN UNIV

Device for surface blasting component

ActiveUS8091192B2Improve machine qualityImprove efficiencyEdge grinding machinesNon-mechanical blast generatorsAbrasive blastingMechanical engineering

A device for surface blasting, e.g., for ultrasonic shot blasting, components, e.g., gas turbine components, includes at least one vibrator having an oscillating surface, e.g., having at least one ultrasonic sonotrode, the or each oscillating surface of the or each vibrator being adjoined by a machining chamber for receiving a section to be blasted of the component to be machined. The machining chamber is bounded in its cross-section by at least three sides, e.g., by at least two substantially vertical sides and by at least one substantially horizontal side. At least the substantially vertical sides of the machining chamber are formed by oscillating surfaces of in each case one vibrator.

Owner:MTU AERO ENGINES GMBH

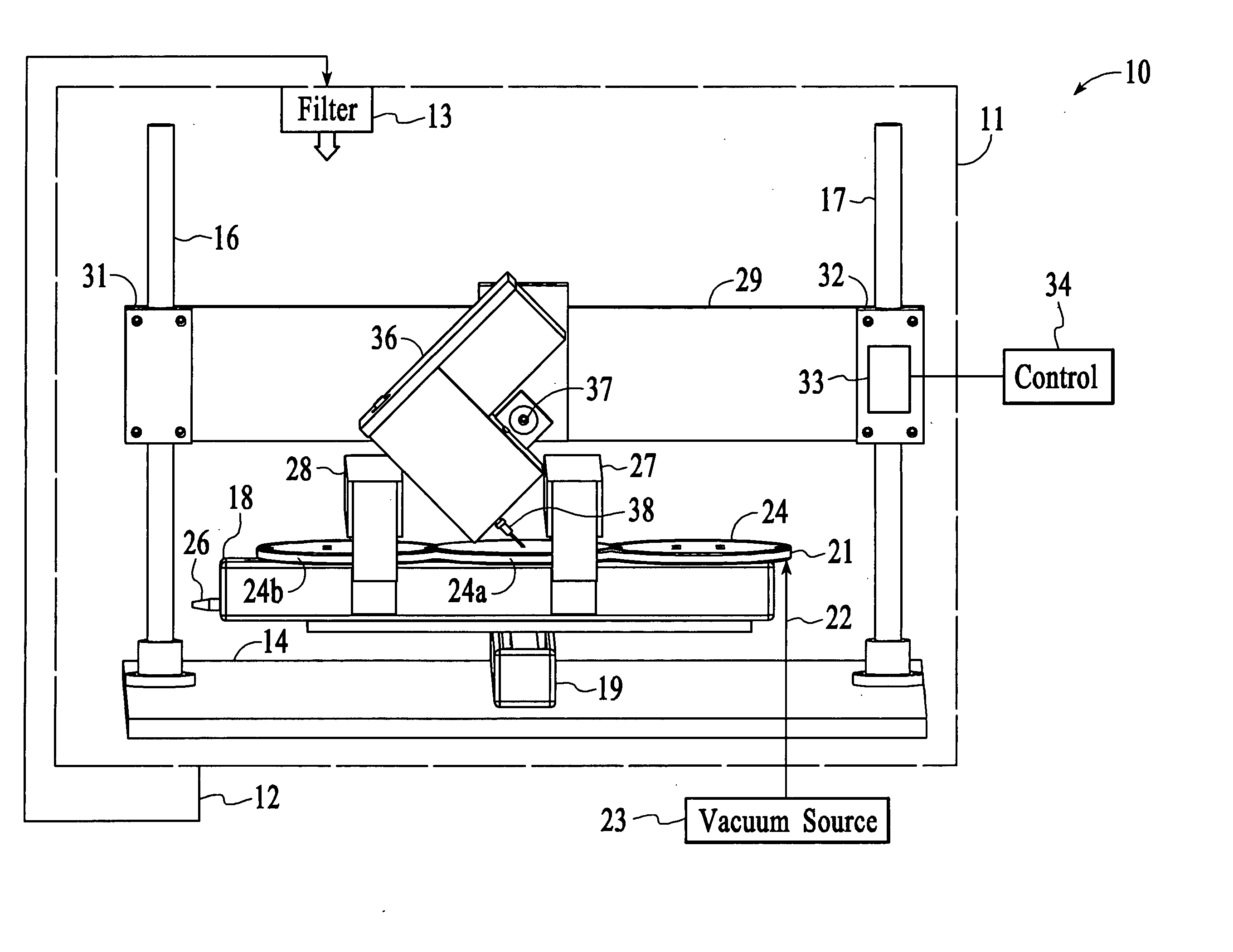

Application of the newly developed technology in stainless steel for biomedical implant

ActiveUS20160031063A1Desirable sizeDesirable weightMetal working apparatusVibratory devicesCytotoxicitySteel ball

The present invention pertains to a method of applying surface mechanical attrition treatment (SMAT) with a plurality of balls for treating surfaces of metallic alloys under a set of specific conditions in order to obtain a metal substrate with high yield strength and hardness, low cytotoxicity, high cytocompability and hemocompatibility suitable for medical implant. The plurality of balls used in the present invention comprises 316L stainless steel balls or zirconium oxide (ZrO2) balls.

Owner:NANO & ADVANCED MATERIALS INST

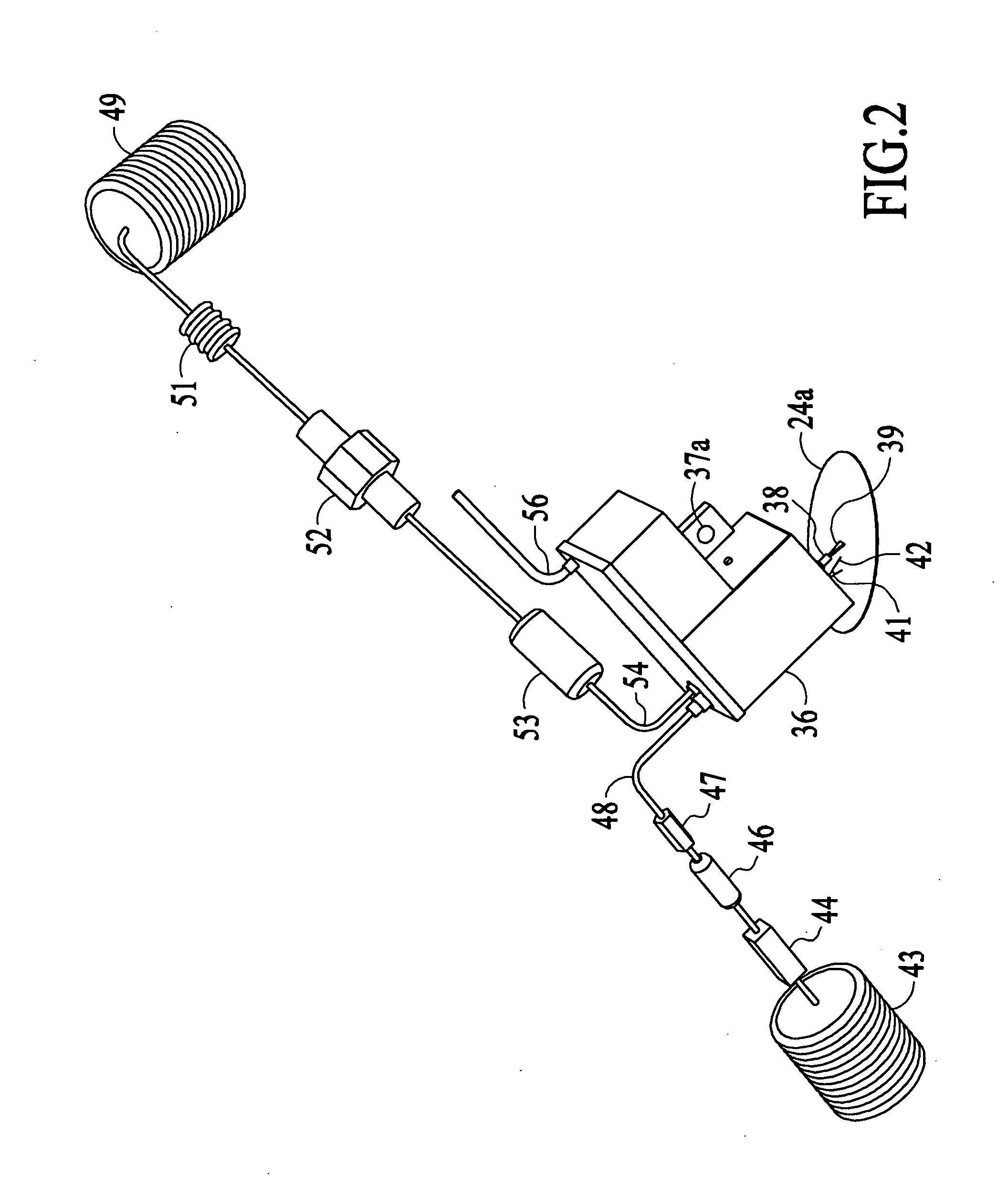

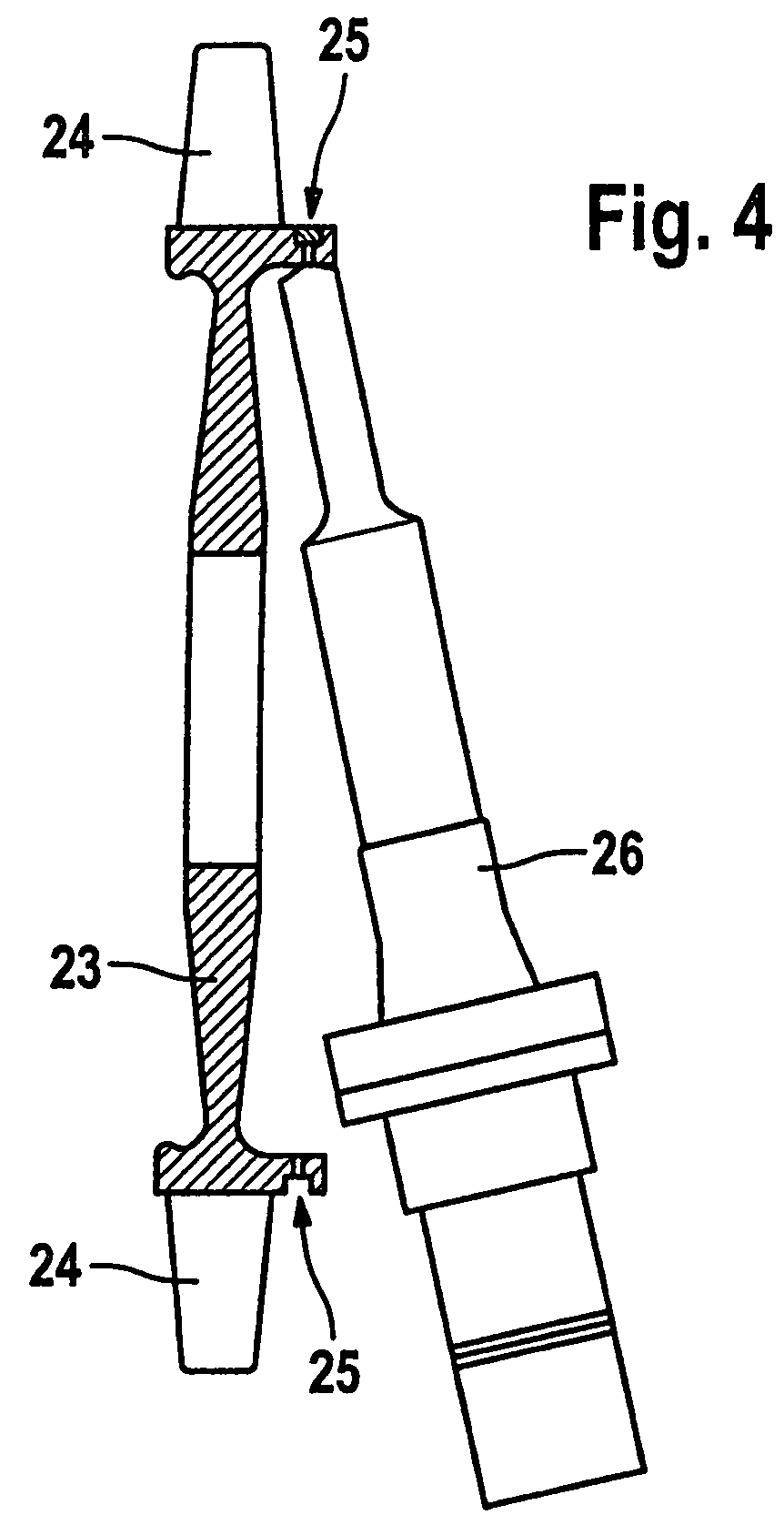

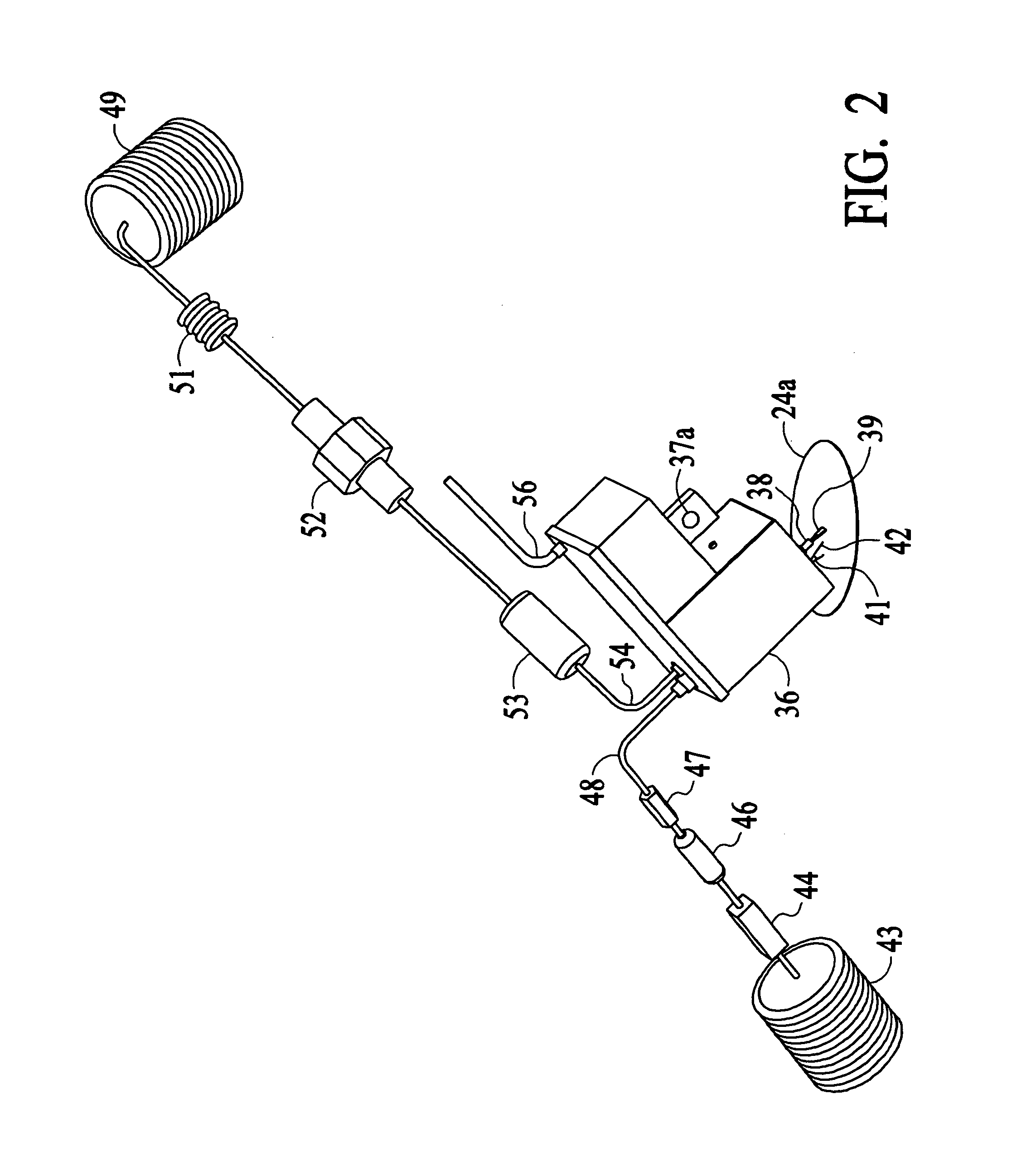

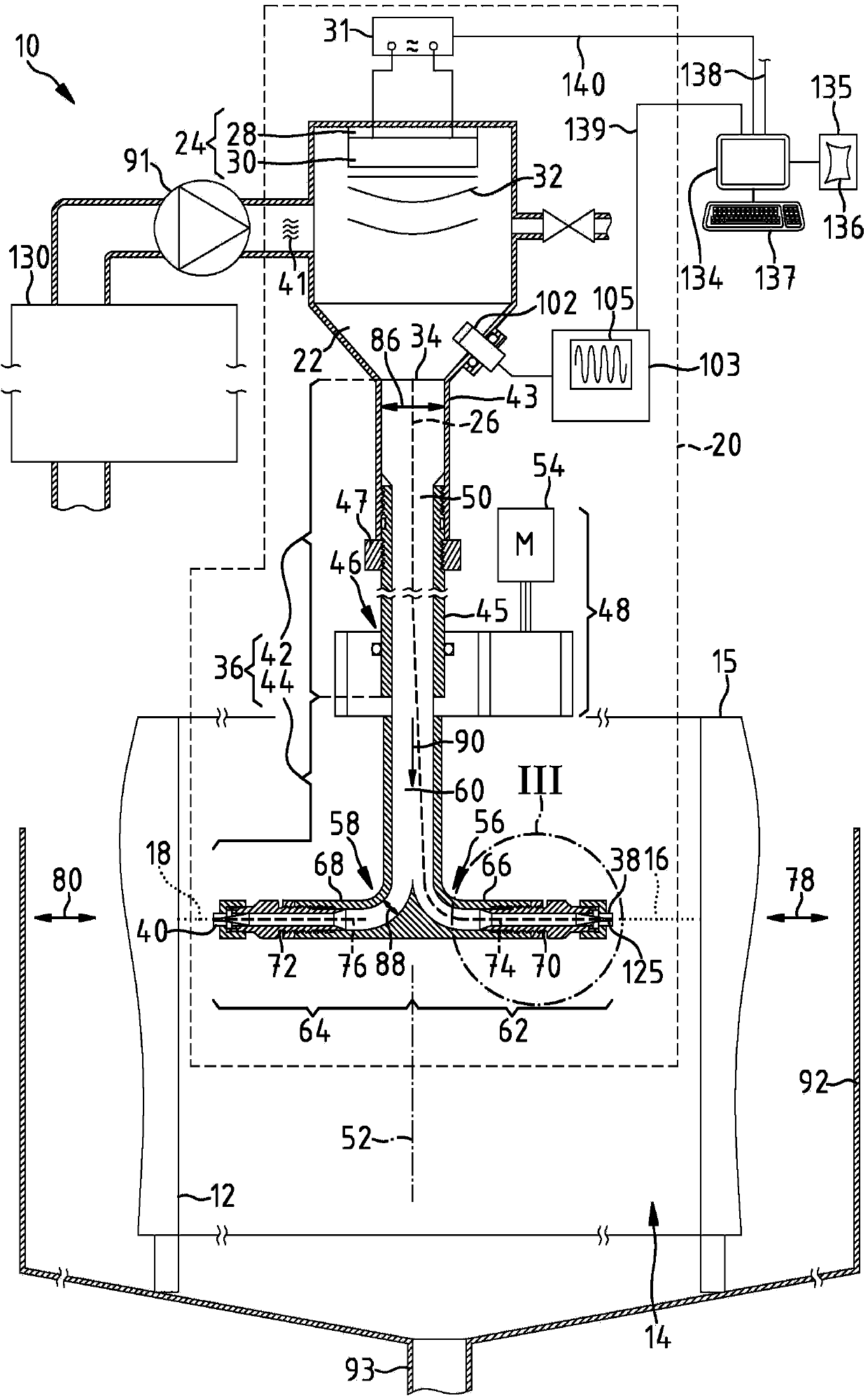

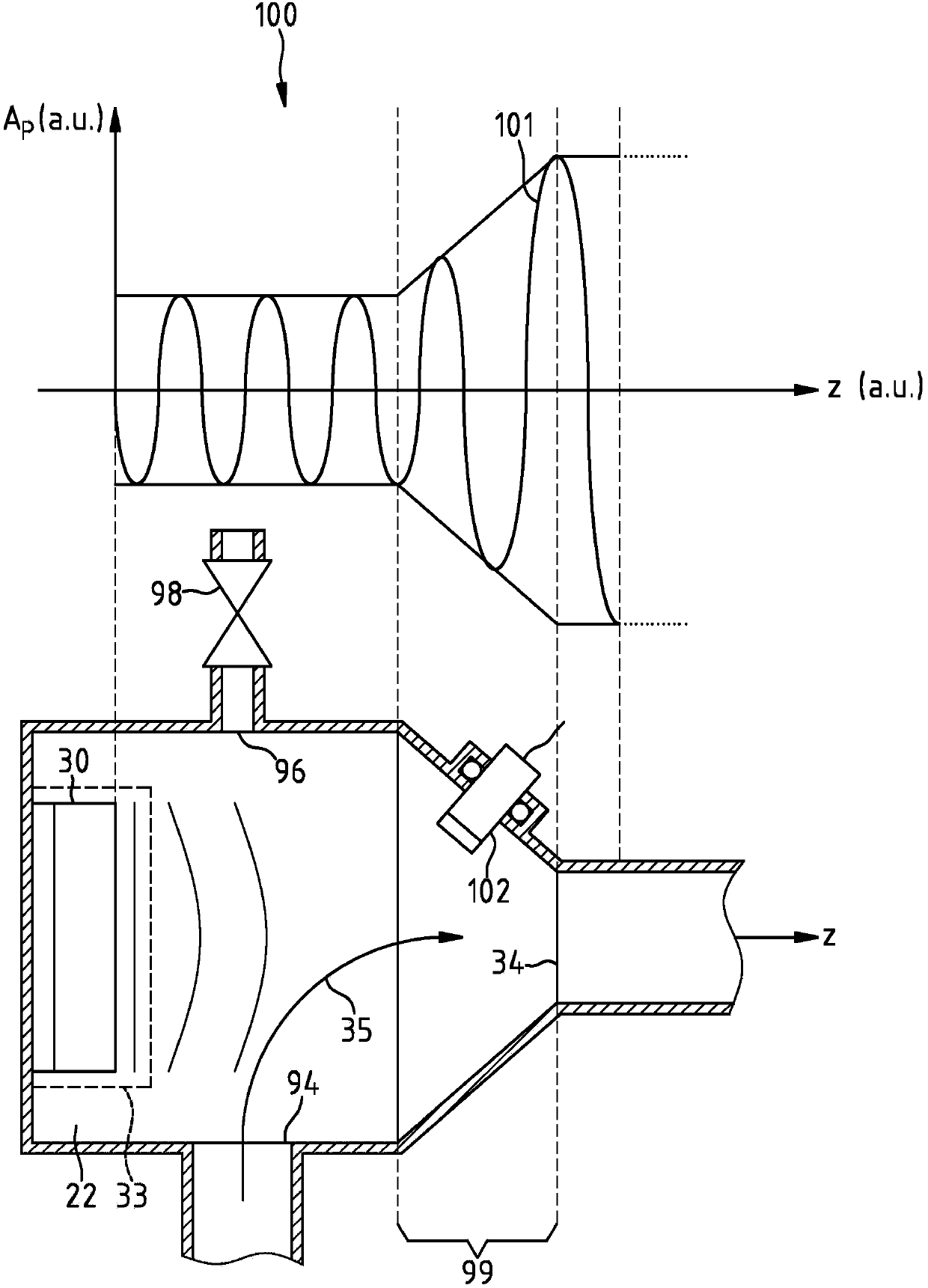

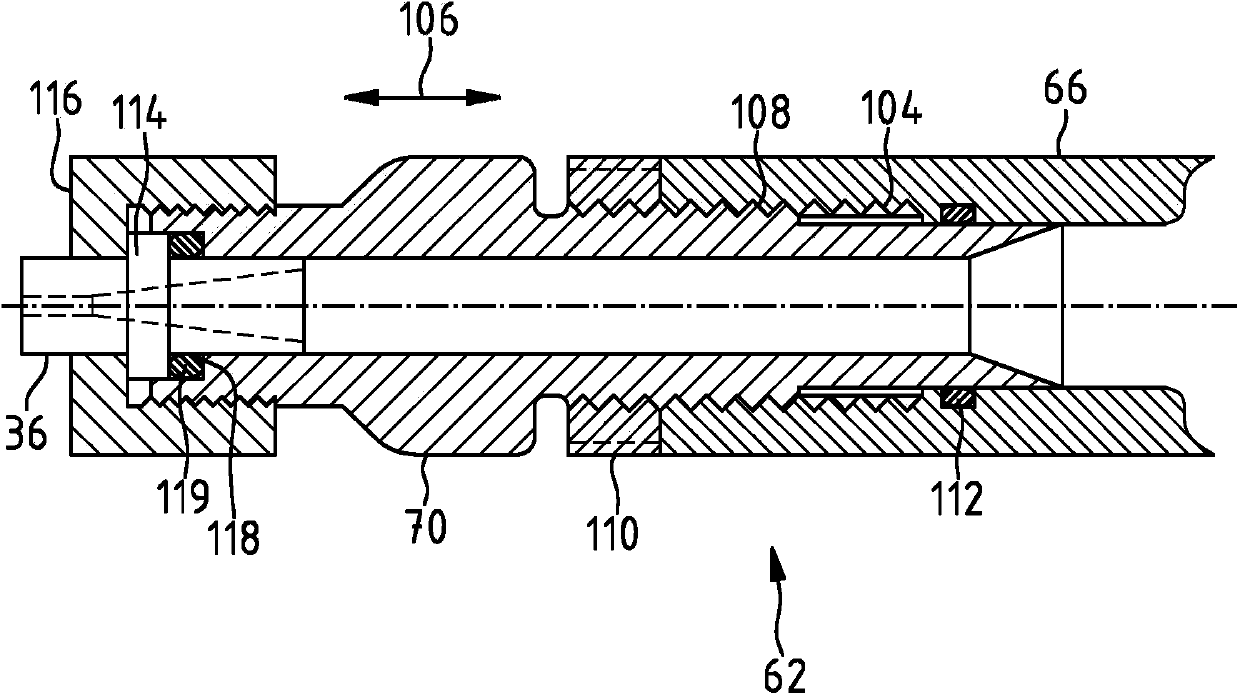

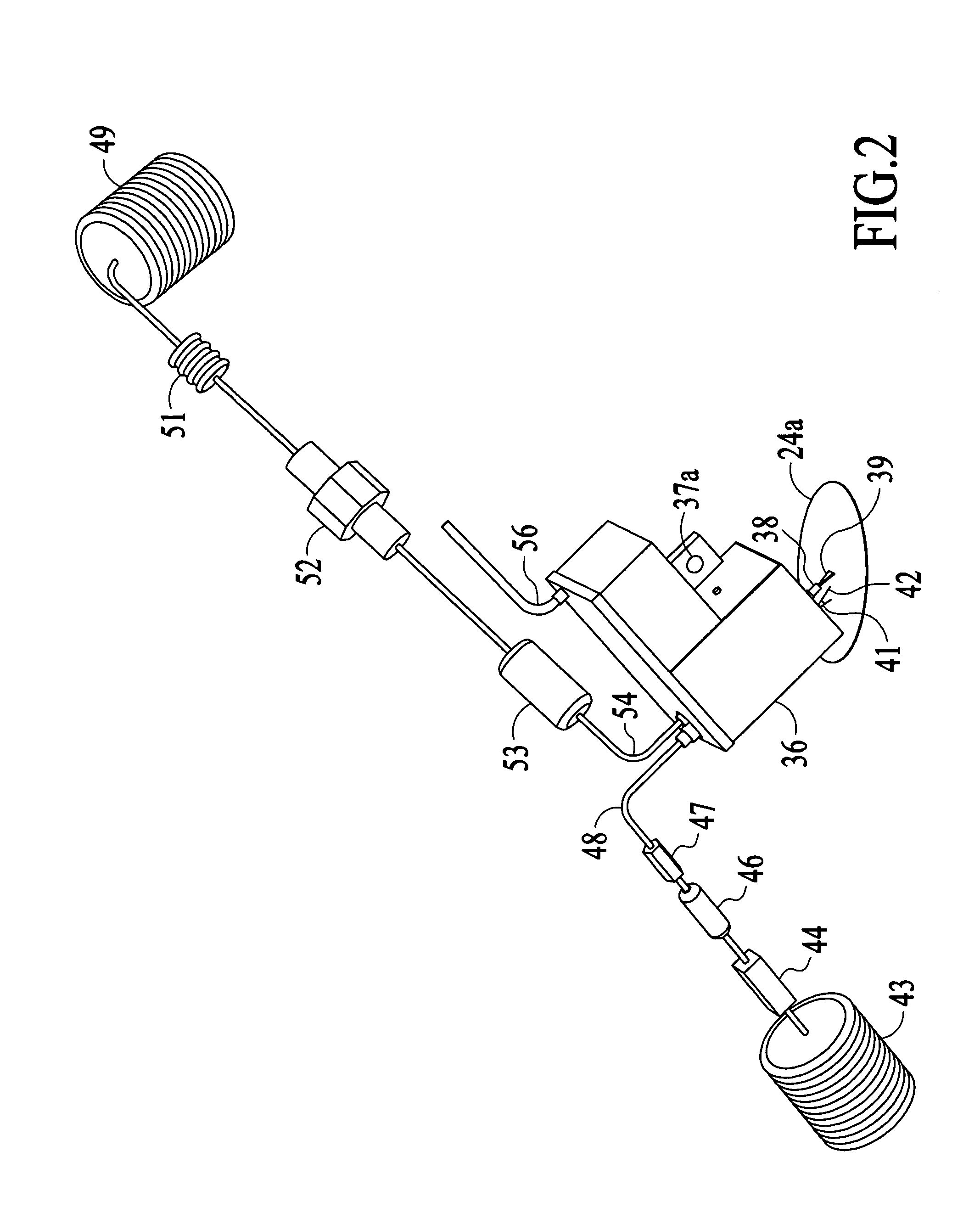

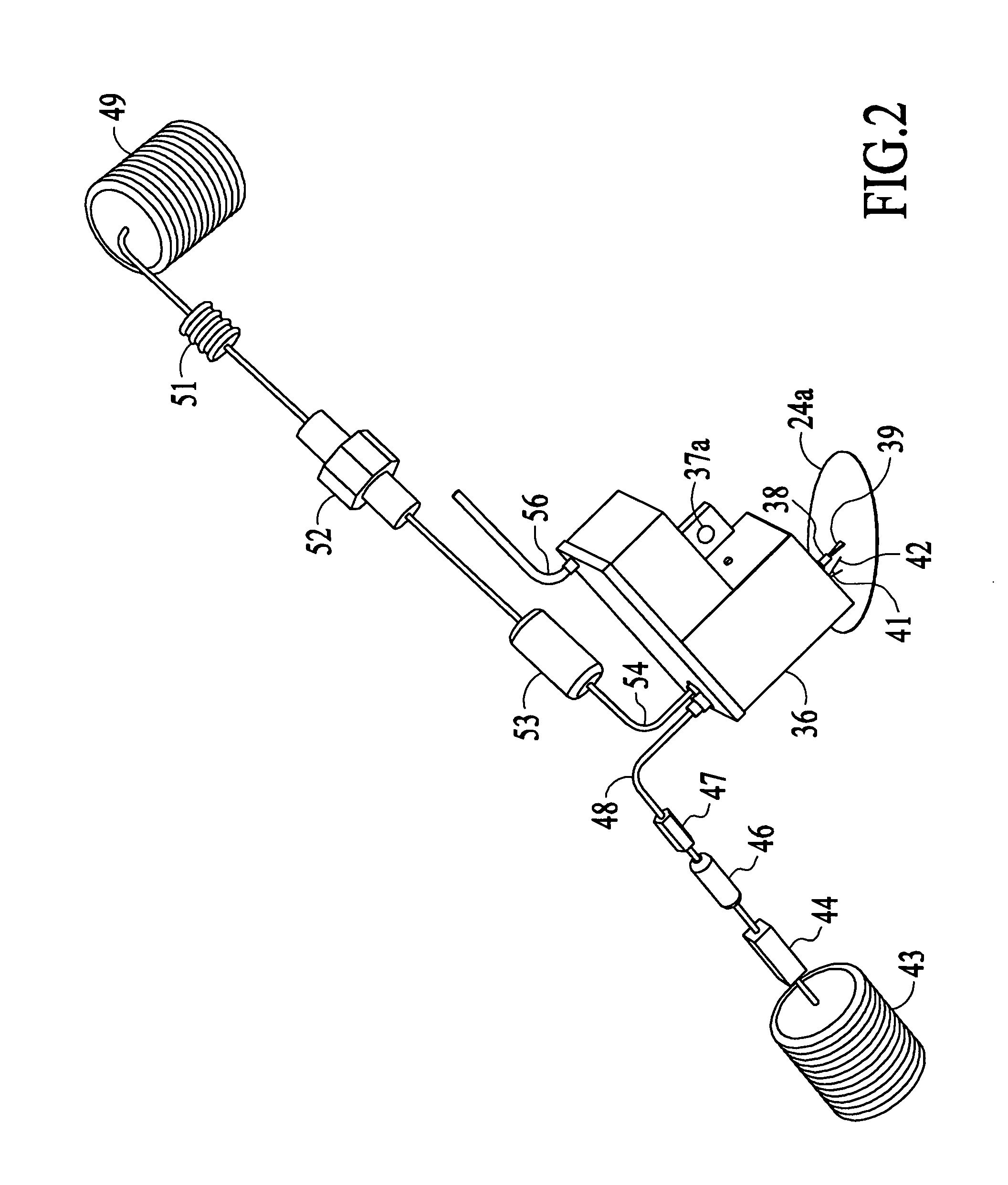

Device for generating a pulsating fluid jet subjected to pressure

The invention relates to a device for generating a pulsating fluid jet (16, 18) from fluid subjected to pressure. The device contains a line system (36) having at least one nozzle (38, 40), which has a nozzle orifice (125), from which a fluid jet (16) of fluid subjected to pressure can exit. The device (20) has a chamber (22), in which a pressure wave generation arrangement (24) for generating fluid pressure waves (32) is constructed. The chamber (22) communicates with the line system (36) through an exit opening (34) for the generated fluid pressure waves (32). According to the invention, the device (20) contains an adjusting arrangement (31, 47, 62, 64) for controlling the amplitude AP of the fluid pressure waves (22) in the line system (36) upstream of the at least one nozzle orifice (125). With the adjusting arrangement(31, 47, 62, 64), it is possible to adjust a Helmholtz number He:= L / Lambda formed from the quotient of the path length L for the fluid pressure waves(22) in the line system (36) between the exit opening (34) of the chamber (22) and the at least one nozzle orifice (125) of the at least one nozzle (38, 40), and the wavelength Lambda of the fluid pressure waves (22) formed in the line system (36).

Owner:DUERR ECOCLEAN GMBH

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS20050127038A1Avoid lostIncrease vacuumDecorative surface effectsSemiconductor/solid-state device manufacturingResistEngineering

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The cryogenic cleaning medium is supplied via a nozzle implement that sweeps across the article. A slide mechanism and drive motor may be supplied internal or external to the controlled environment.

Owner:MANOCLEAN TECH

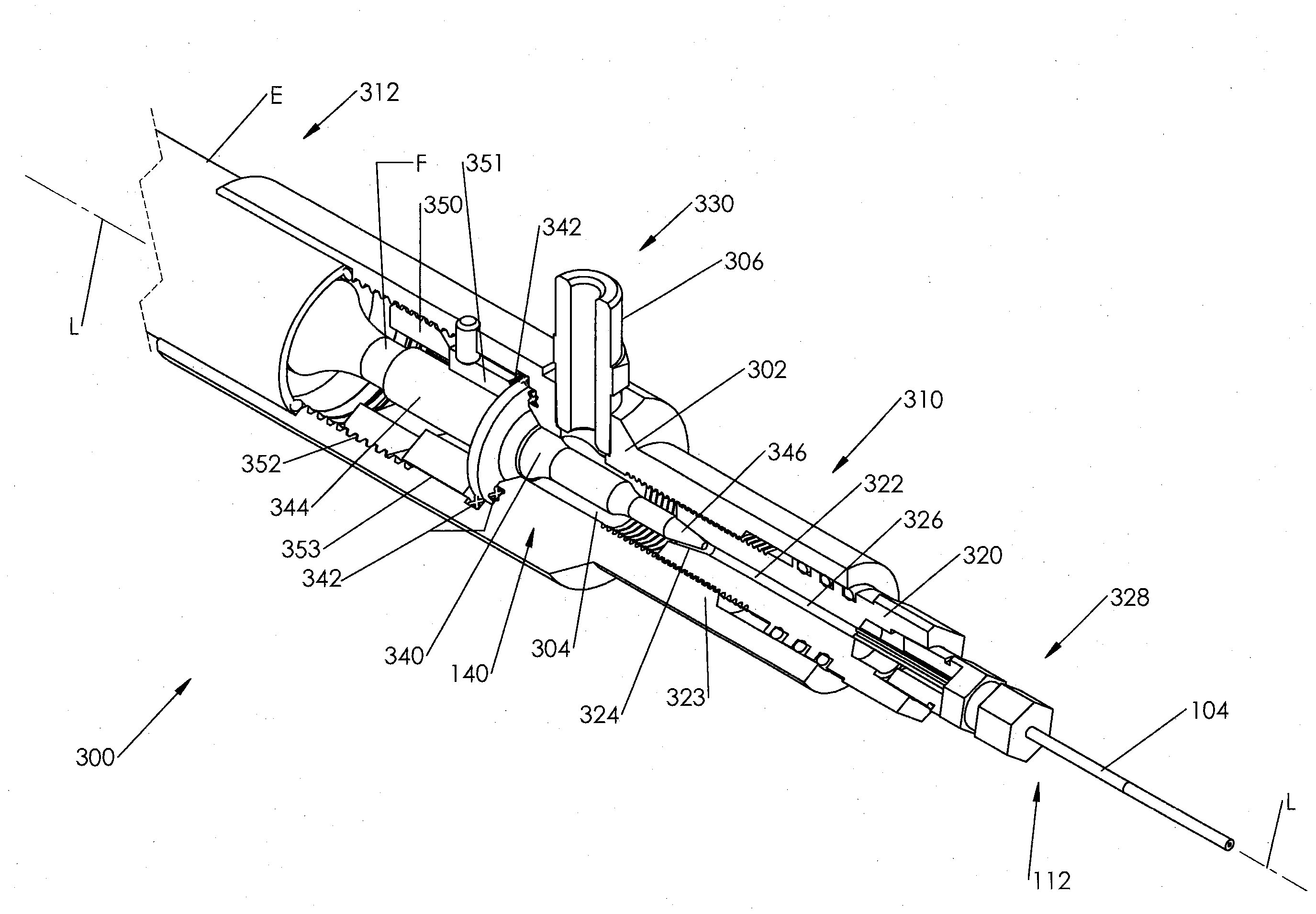

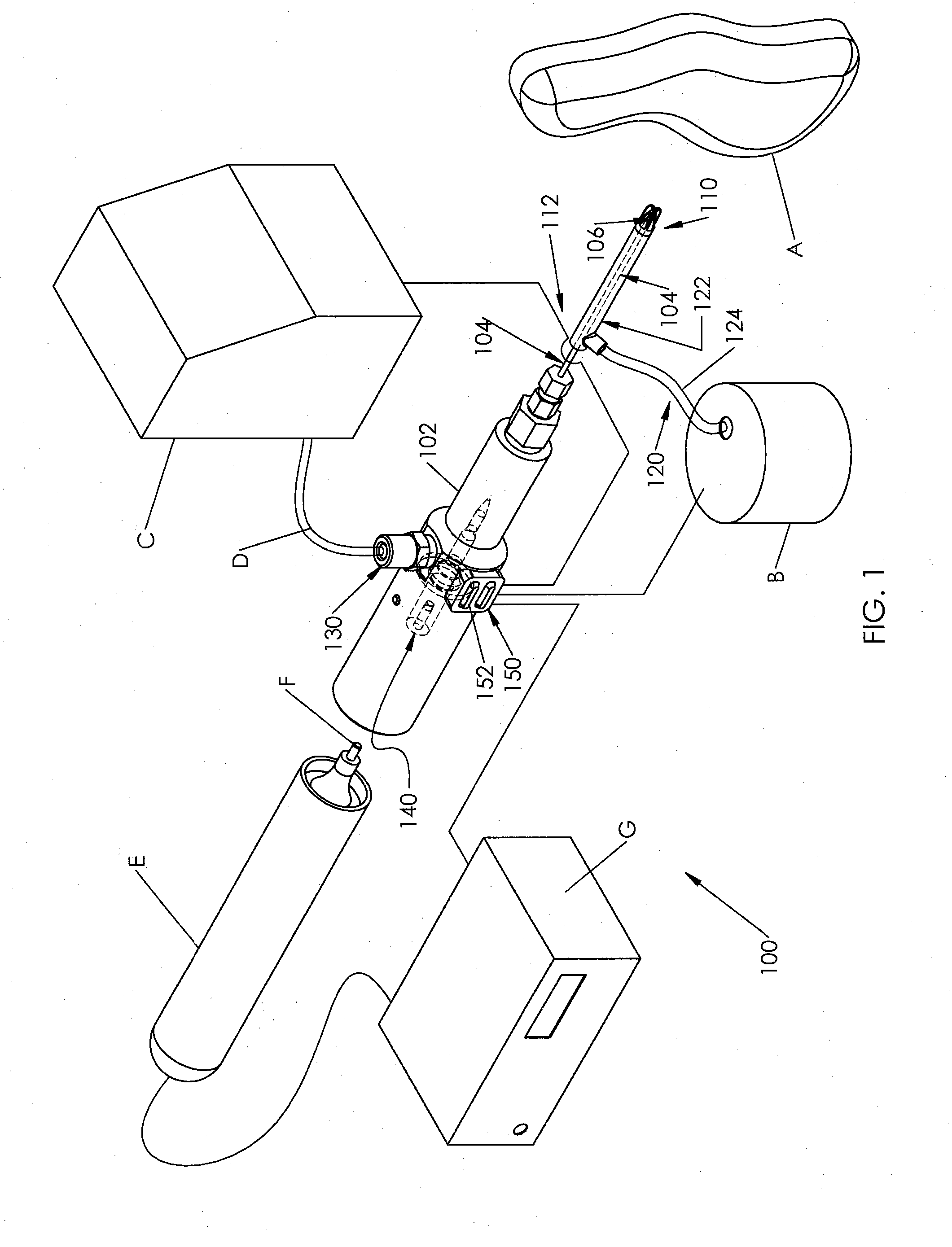

Ultrasonic Peening Treatment of Assembled Components

Ultrasonic peening treatment is desirable where an application of a compressive stress is helpful to reduce the incidence of crack formation on highly stressed parts. Ultrasonic peening treatment can be performed in field applications without requiring a rotor to be removed from the machine. The system includes an acoustic element that excites peening media within a peen chamber. A frame is attachable to an assembled turbine rotor component and includes support structure engageable with the acoustic element. The frame is cooperable with a chamber tooling that defines and encloses the peen chamber together with the turbine rotor component.

Owner:GENERAL ELECTRIC CO

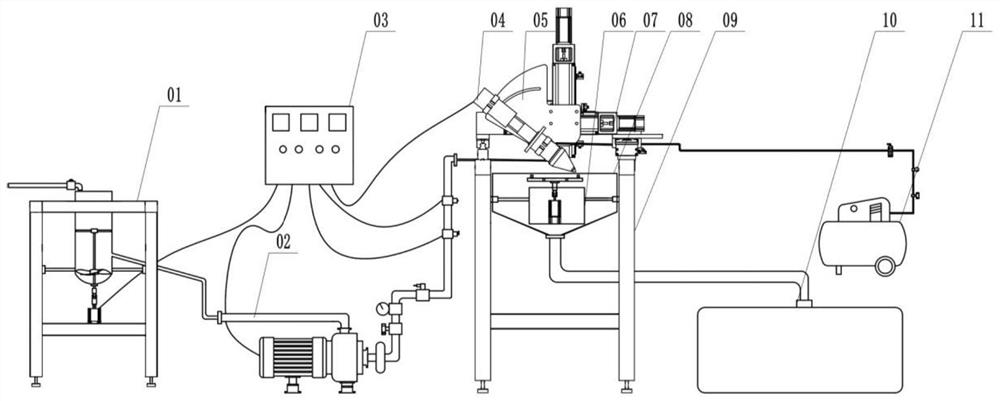

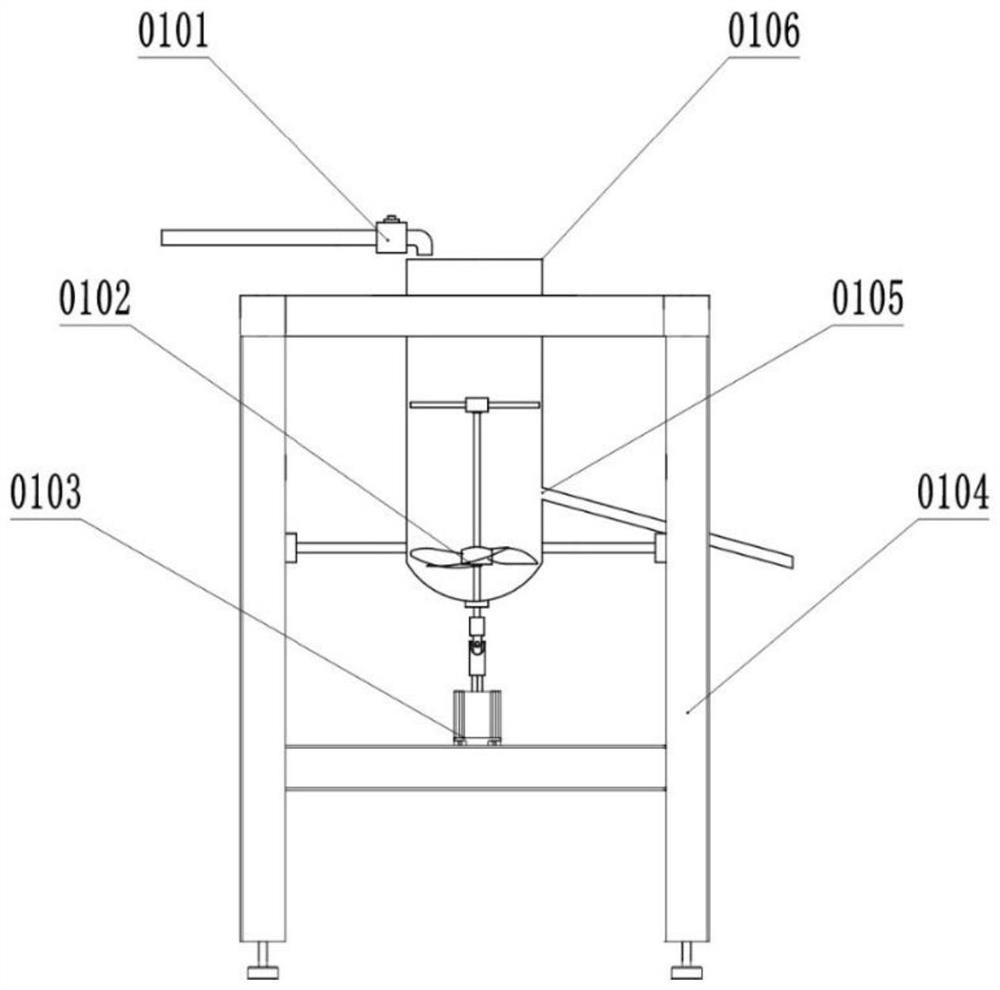

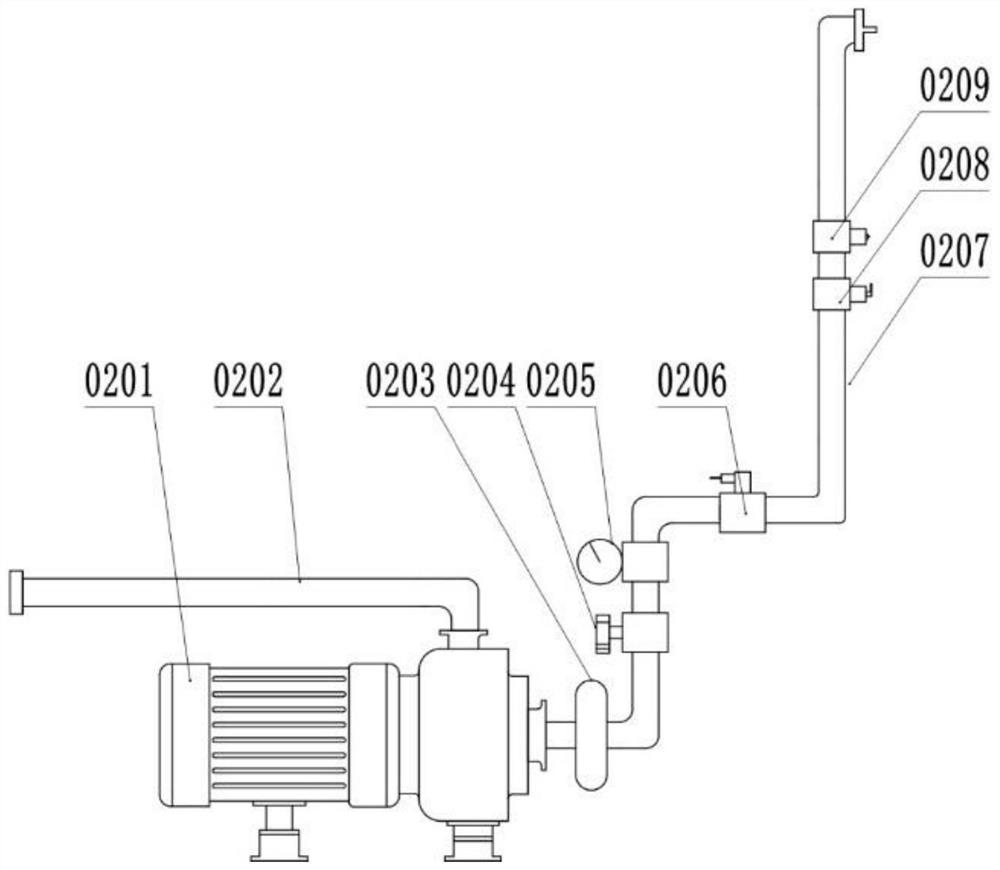

Ultrasonic vibration modulation pulse abrasive particle micro-jet polishing system

PendingCN112720273AImprove cycle efficiencyImprove mixing efficiencyBlast gunsRotary stirring mixersAir entrainmentEngineering

The invention discloses an ultrasonic vibration modulation pulse abrasive particle micro-jet polishing system. The system comprises an abrasive material mixing device, an abrasive material conveying device, a comprehensive control cabinet, a pulse jet polishing tool, an angle adjusting device, a workpiece rotating device, a three-axis moving module, a machining pool, a rack, a waste recovering device and a gas injection device. Pulse jet is formed according to the ultrasonic modulation principle, and the jet polishing efficiency is improved by means of the water hammer effect generated by fluid pulses; the intensity of the pulse jet is actively controlled through adjustment of the distance between the tail end of an amplitude-changing pole and the outlet of an inner cavity of a nozzle; the stability of the components of the abrasive particle flow is realized through monitoring of the concentration and viscosity of the abrasive particle flow; the pulse jet intensity is monitored in real time through an annular array sensor; cavitation erosion is avoided through an air entrainment cavitation reduction principle; and full-coverage precision polishing of the complex bent flow channel is achieved through cooperative movement of the three-axis moving module and the workpiece rotating device.

Owner:CHINA JILIANG UNIV

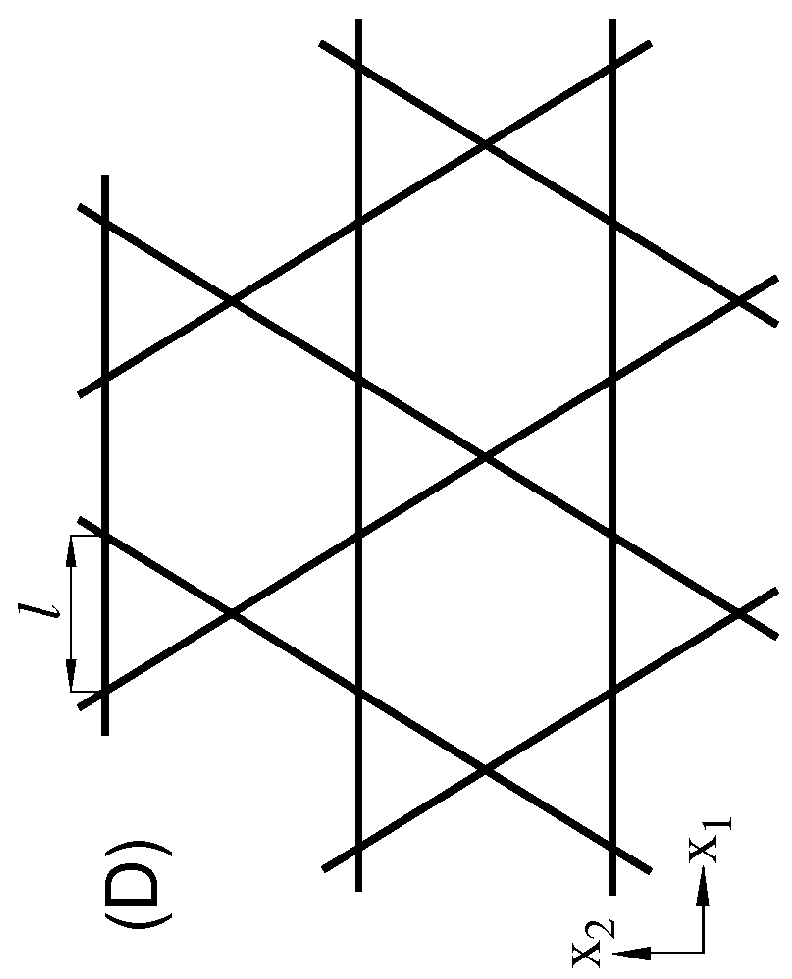

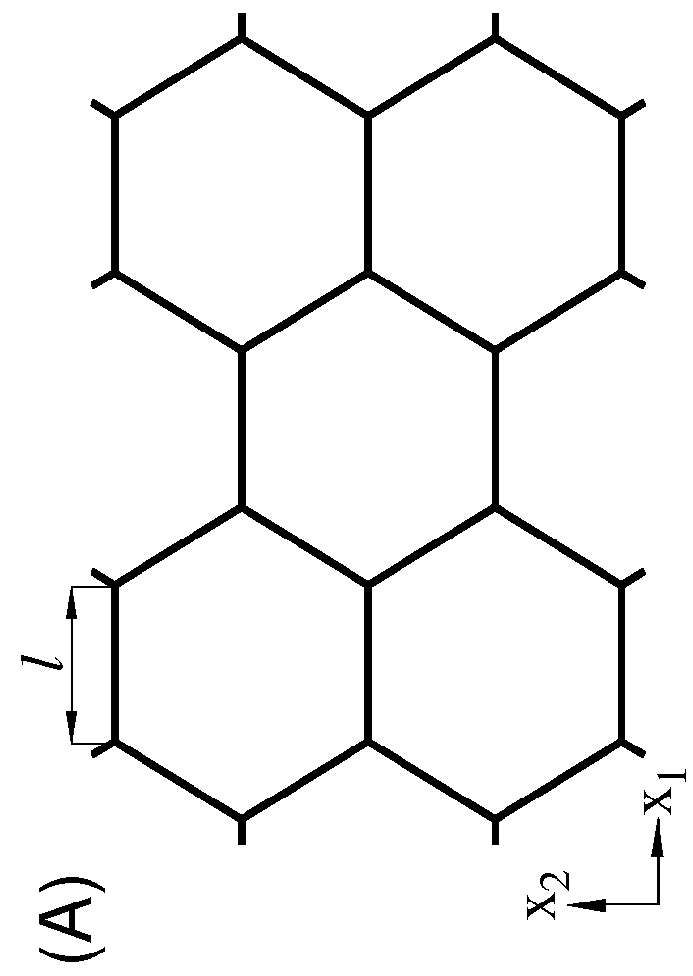

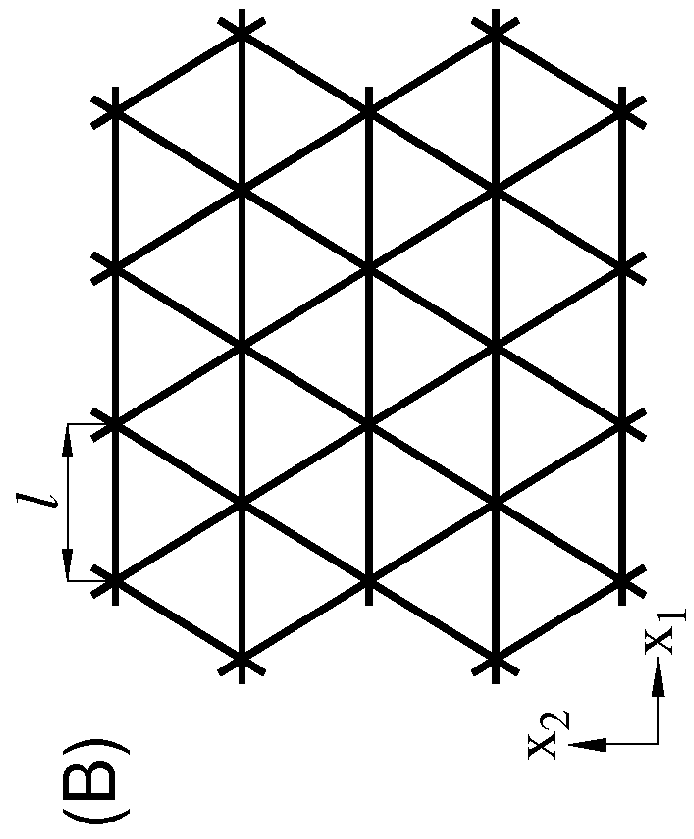

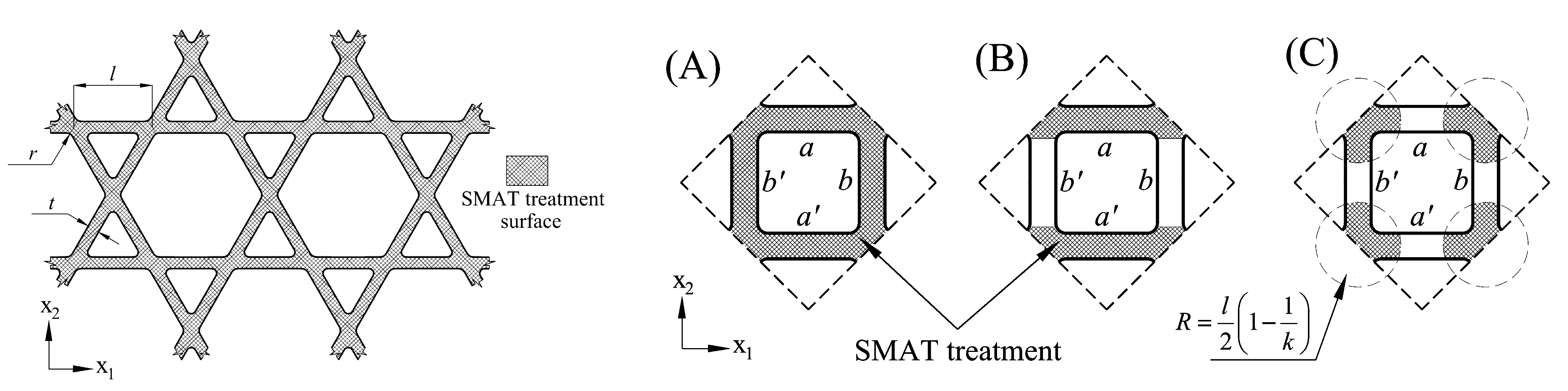

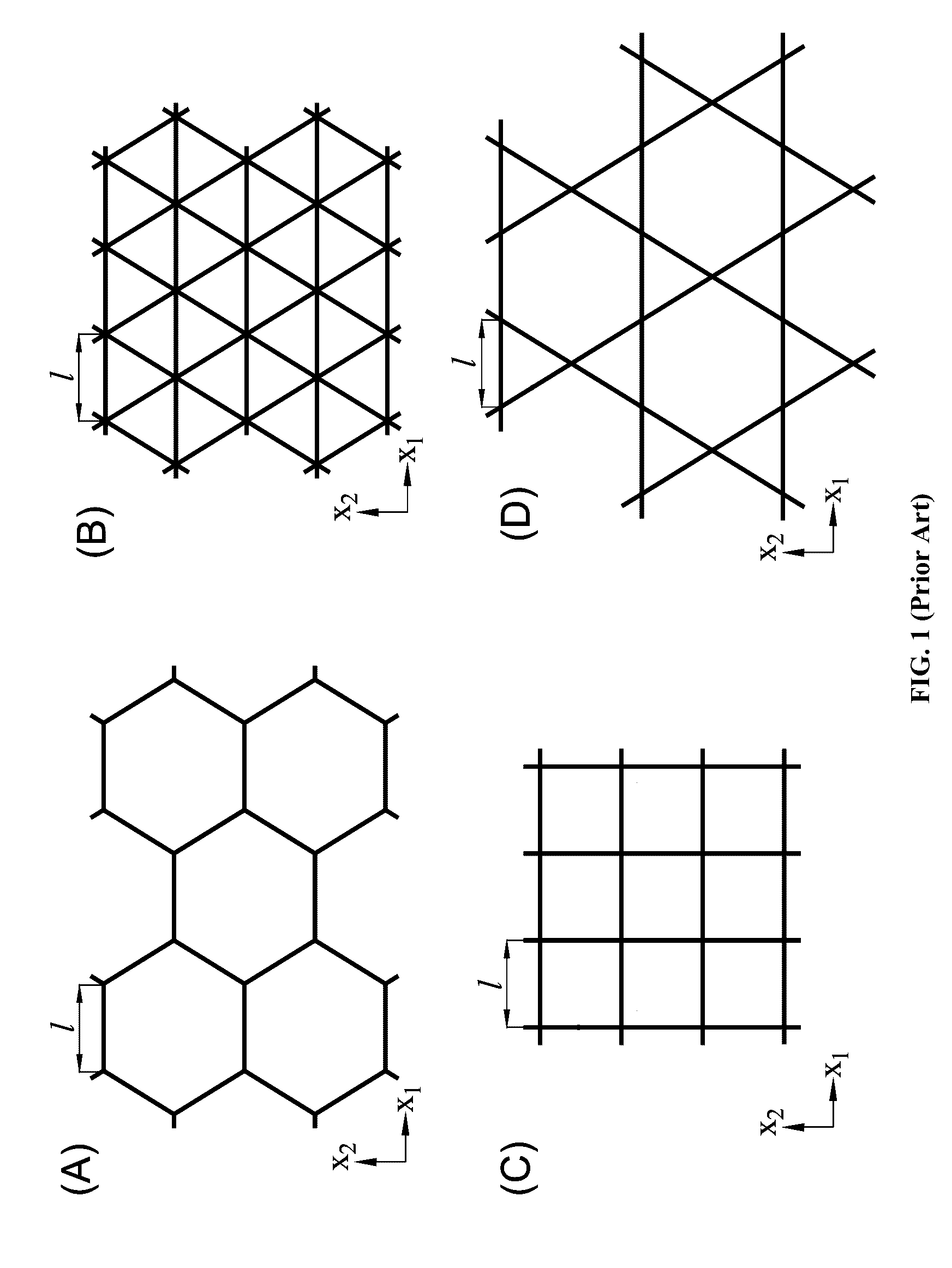

Nanostructured-lattices produced by surface mechanical attrition treatment method

ActiveUS9517545B2Light weightHigh strengthMetal working apparatusVibratory devicesNano structuringEngineering

Owner:NANO & ADVANCED MATERIALS INST

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7066789B2Small footprintEasy to cleanSemiconductor/solid-state device manufacturingAbrasive feedersResistDrive motor

A method for manufacturing an article having polymeric residue that is to be removed during the manufacture of the article is disclosed. The article is introduced into a controlled environment of a processing tool having one or more processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least one of the one or more processing chambers where they react with the polymeric residue. A cryogenic cleaning medium is supplied into at least one of the one or more processing chambers where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium. The cryogenic cleaning medium is supplied via a nozzle implement that sweeps across the article. A slide mechanism and drive motor may be supplied internal or external to the controlled environment.

Owner:MANOCLEAN TECH

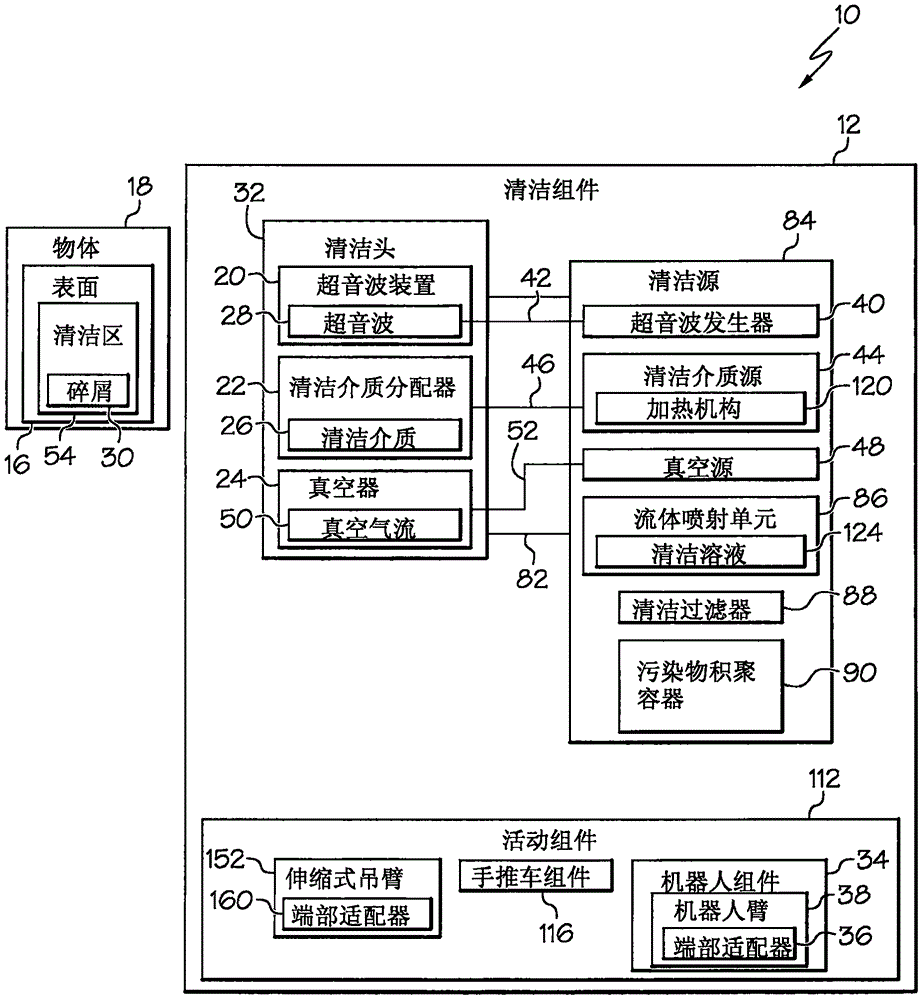

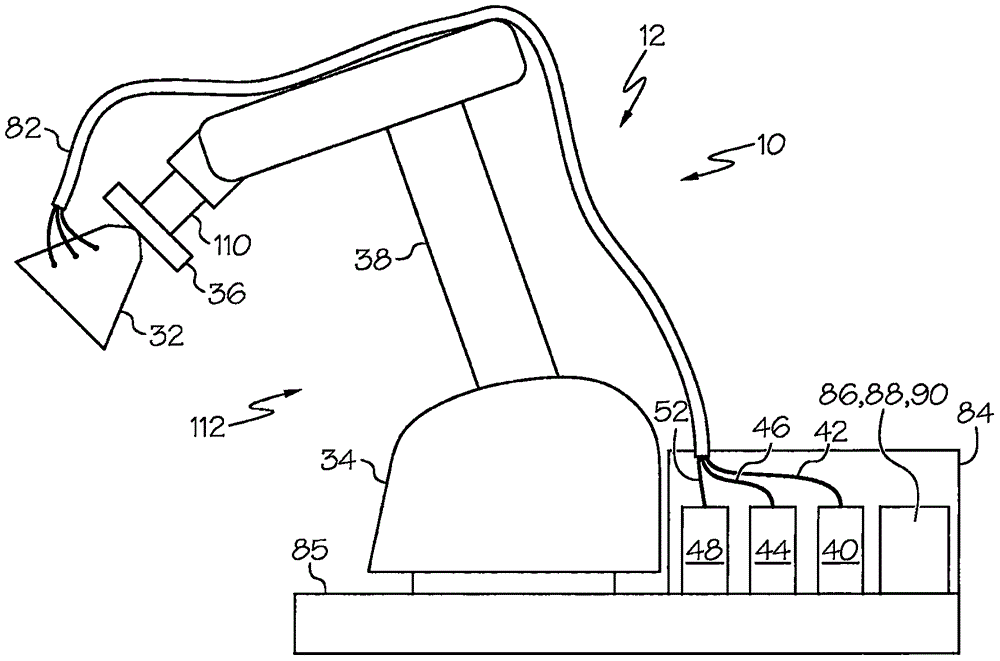

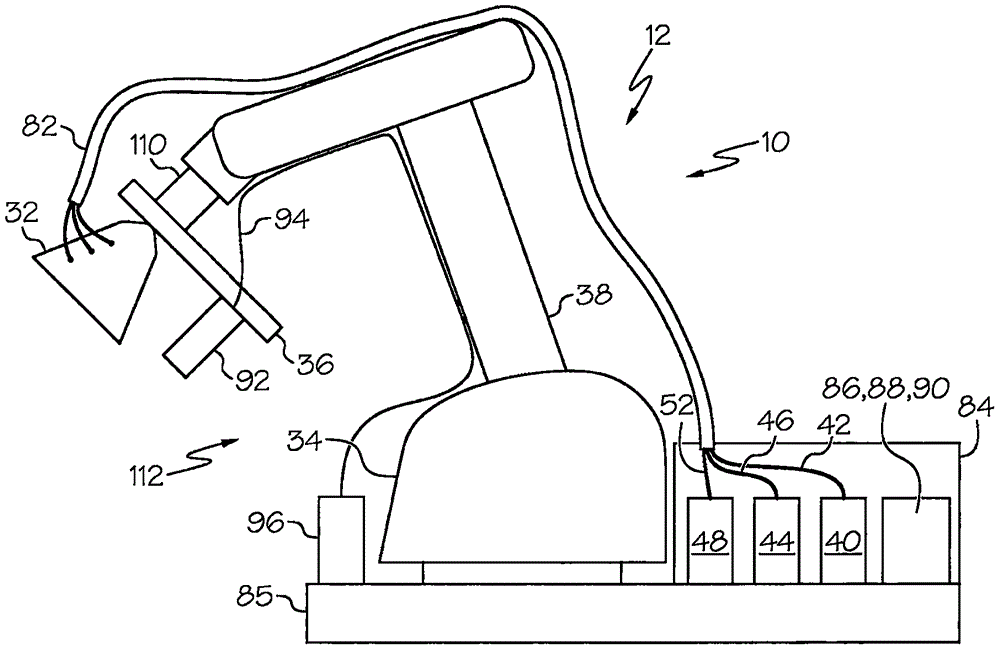

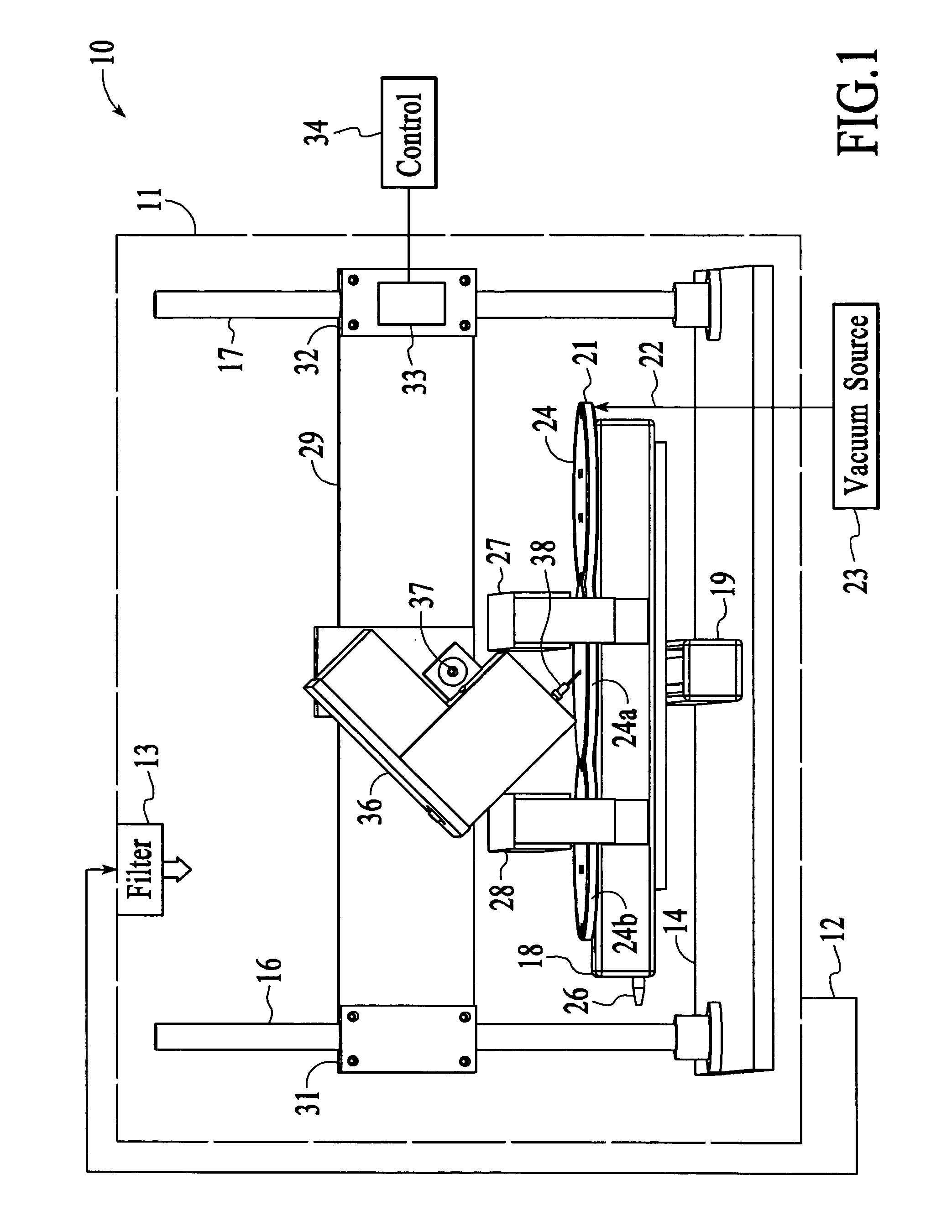

System and method for surface cleaning

ActiveCN106061632AReduce adhesionCleaning using gasesCleaning using liquidsSurface cleaningEngineering

A system for cleaning (10) an object (18) may include a cleaning medium dispenser (22) configured to deliver a cleaning medium (26) to a surface (16) of the object, wherein the cleaning medium dislodges and captures debris from the surface, an ultrasonic device (20) configured to deliver ultrasonic waves (28) to the object, wherein the ultrasonic waves generate ultrasonic vibrations in the object to atomize the cleaning medium from the surface and a vacuum (24) configured to provide a vacuum airflow, wherein the vacuum airflow collects atomized cleaning medium and debris from the surface.

Owner:THE BOEING CO

Methods for resist stripping and other processes for cleaning surfaces substantially free of contaminants

InactiveUS7101260B2Small footprintEasy to cleanElectrostatic cleaningSemiconductor/solid-state device manufacturingResistPlasma processing

A method for manufacturing an article where the article has polymeric residue that is to be removed during the manufacture of the article. The article is introduced into a controlled environment of a processing tool that has at least first and second processing chambers. Free radicals are generated from one or more reactant gases and introduced into at least the first processing chamber where they react with the polymeric residue. A cryogenic cleaning medium is supplied into the second processing chamber where it removes the polymeric residue present after the free radicals react with the polymeric residue. The reactant gases are selected to facilitate removal of the polymeric residue with the cryogenic cleaning medium The first and second processing chambers may be dedicated to plasma processing or cryogenic processing or each may provide both plasma processing and cryogenic processing.

Owner:NANOCLEAN TECH

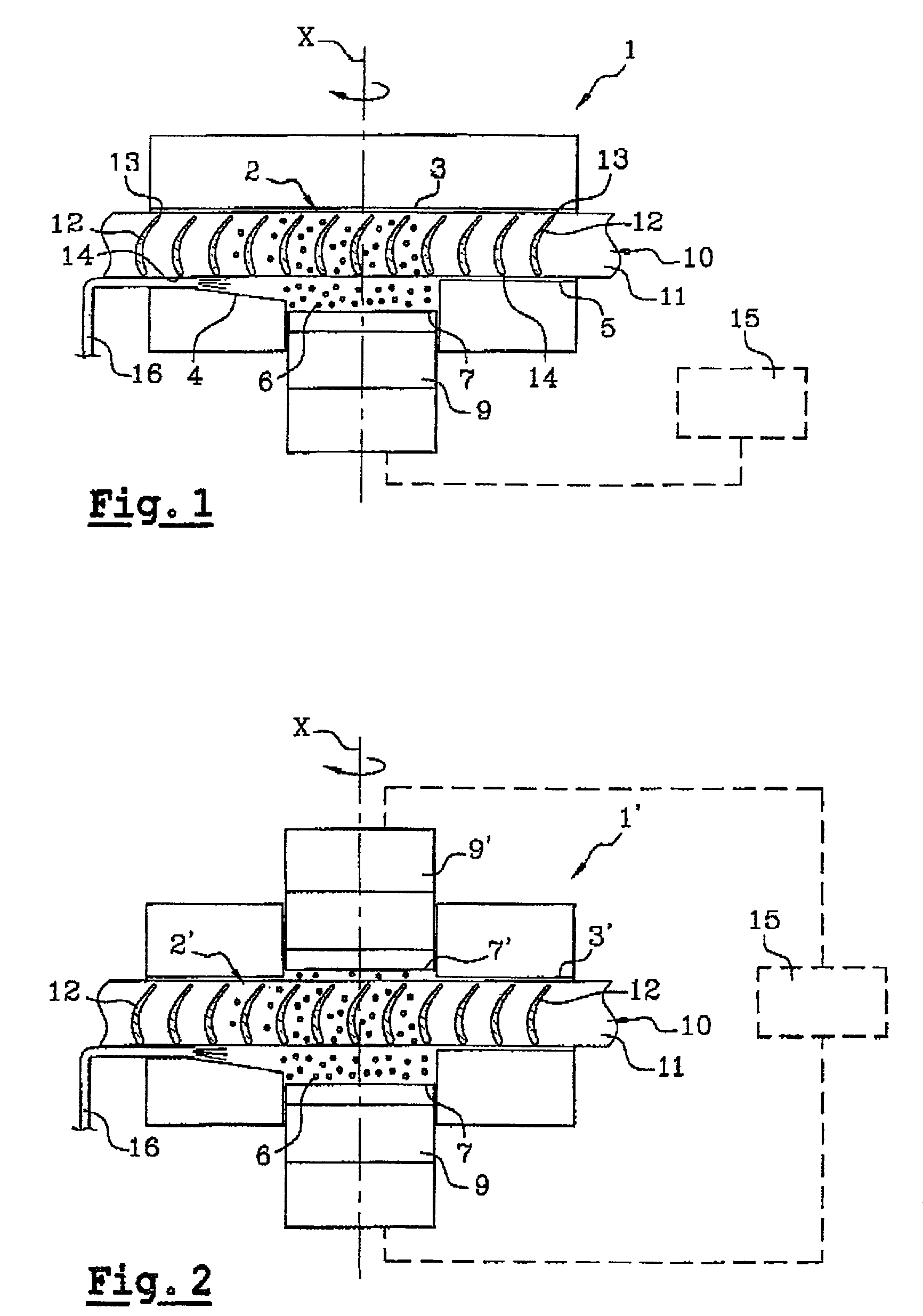

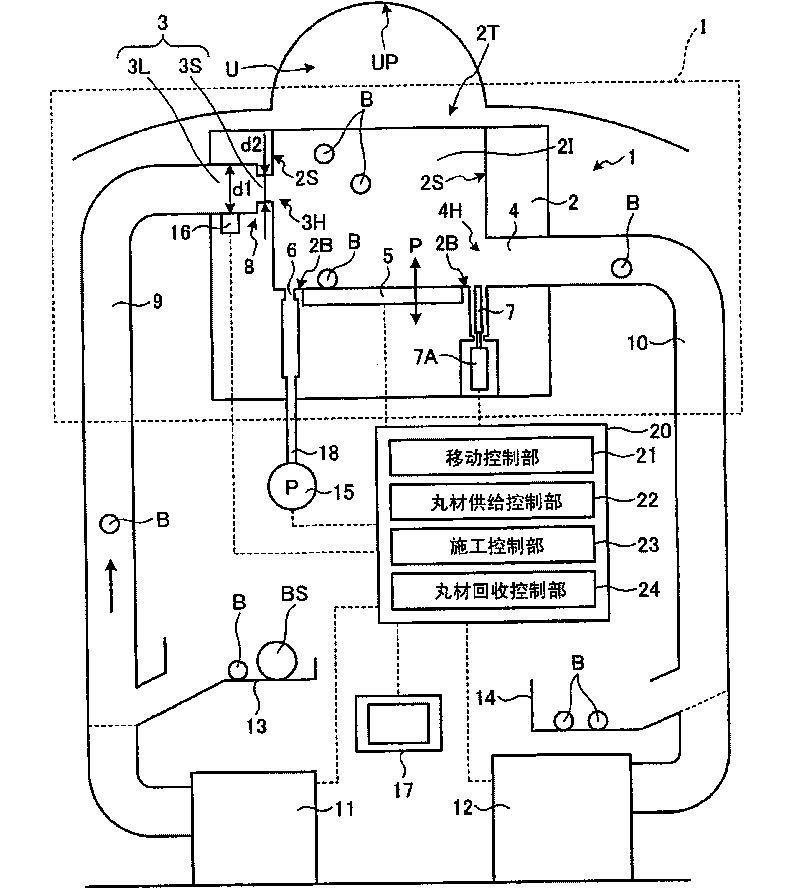

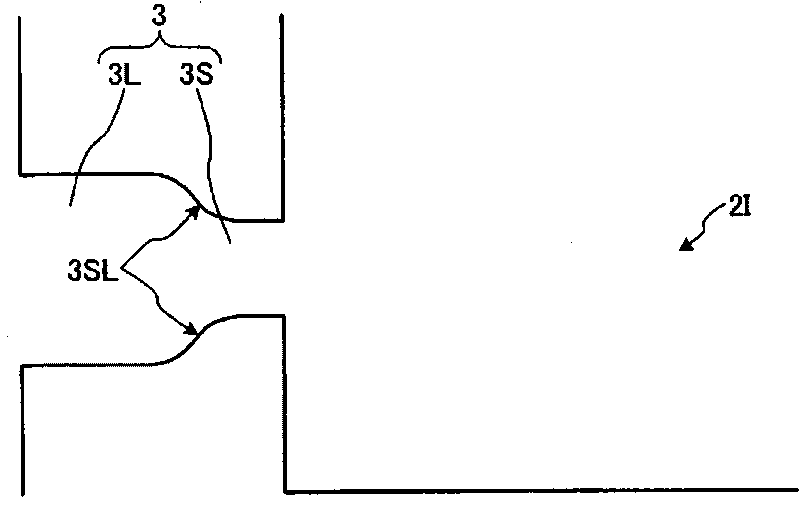

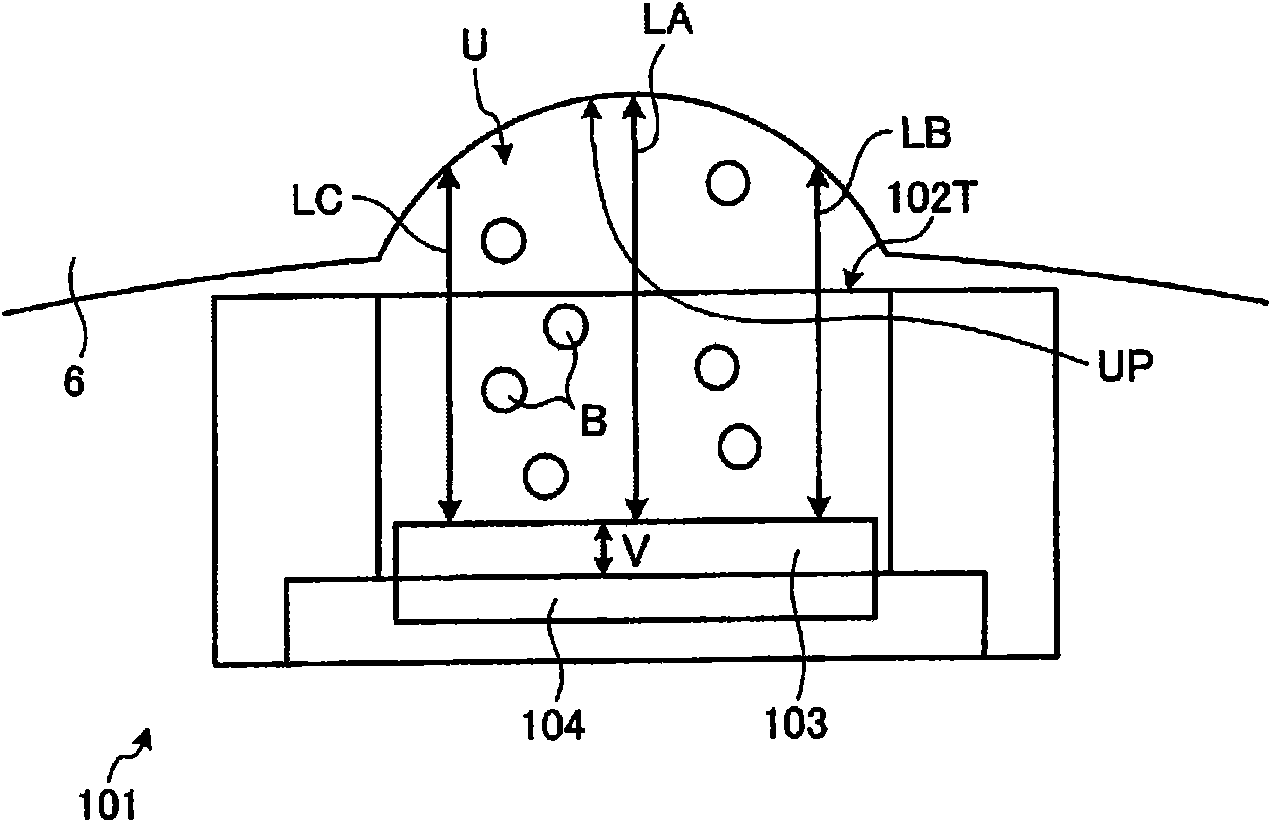

Shot-peening apparatus, and shot-peening execution method

Disclosed is a shot-peening apparatus (1) comprising a storage container (2) for storing shot members (B) to impinge on a shot-peening executed portion (U), an exciting device (5) for accelerating the shot members (B), a shot-member outlet (4) formed in the storage container (2) and connected to a shot-member recovery passage (10) to recover the shot members (B) from a container inside (2I), for extracting the shot members (B) in the container inside (2I) to the shot-member recovery passage (10), and a shot-member inlet (3) disposed in the storage container (2) and connected to a shot-member supply passage (9) to supply the shot members (B) to the container inside (2I), for supplying the shot members (B) from the shot-member supply passage (9) to the container inside (2I).

Owner:MITSUBISHI HEAVY IND LTD

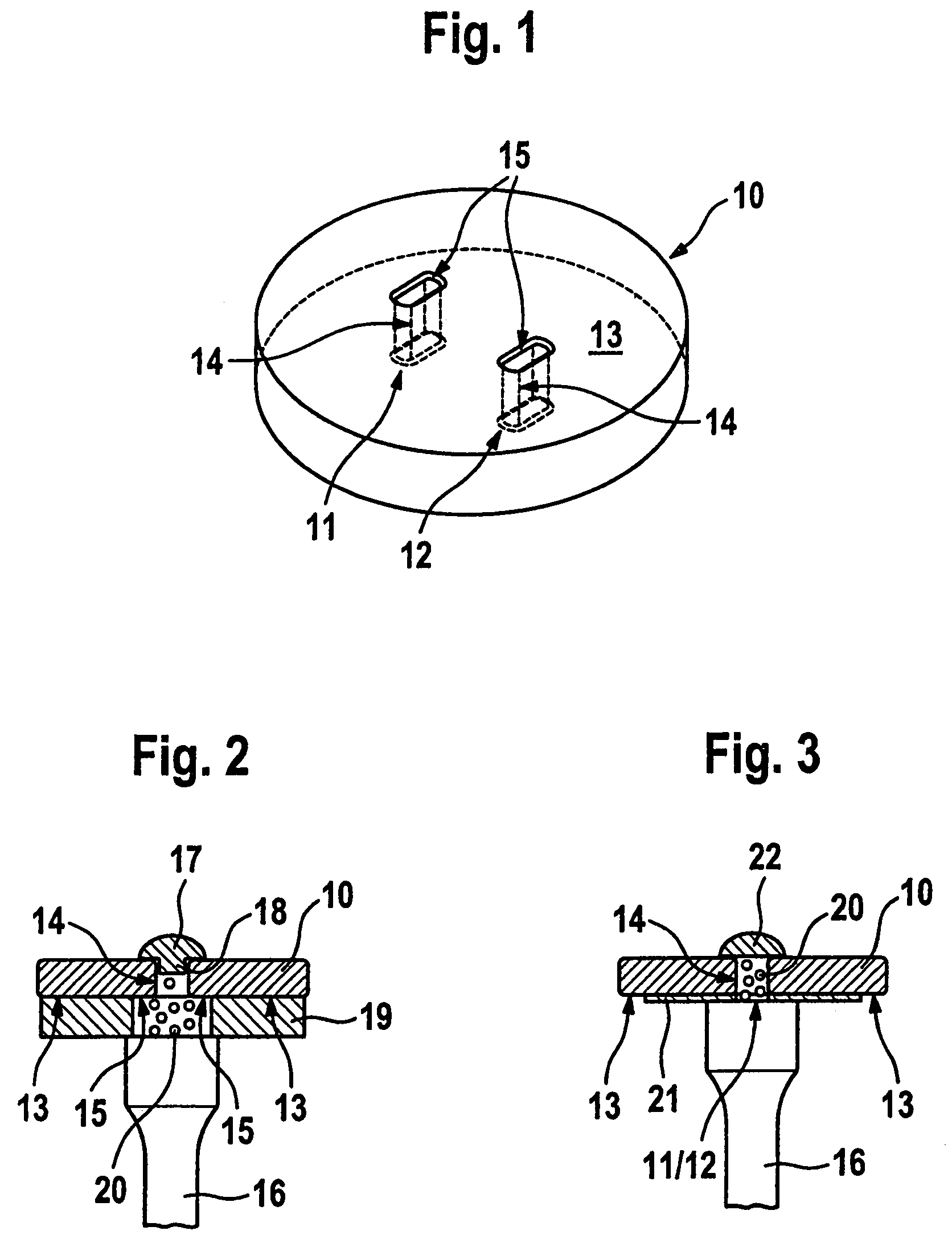

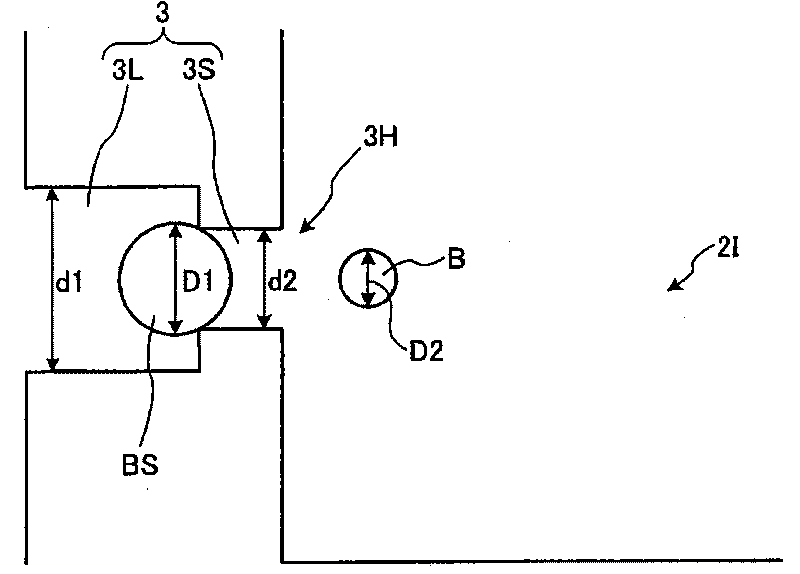

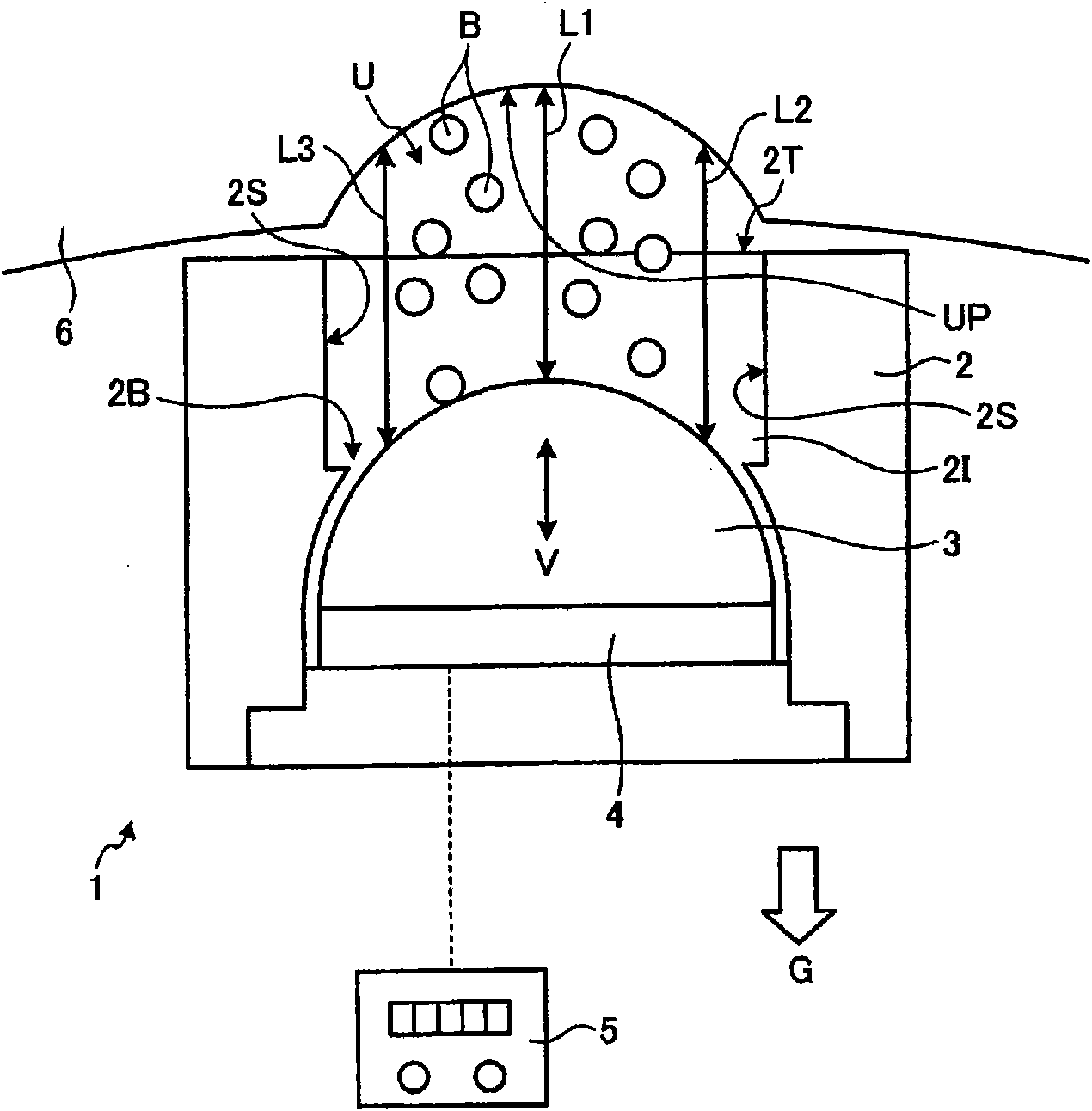

Shot peening device and oscillator for shot peening

InactiveCN101909821ACurb Construction InconsistenciesInhibition ConsistencyEdge grinding machinesImpeller wheelsPeeningMaterials science

A shot peening device (1) is equipped with a containment vessel (2) that stores shot material (B) used in shot peening, and performs shot peening of a worksite surface (UP) by the containment vessel (2) moving to the shot peening worksite (U). The shot peening device (1) is equipped with an oscillator (3). An oscillation means (4) that imparts kinetic energy to the shot material (B) in the container interior (2I) is mounted on the oscillator (3). The external shape of the oscillator (3) is formed into a shape matched to the shape of the worksite surface (UP) of the worksite (U).

Owner:MITSUBISHI HEAVY IND LTD

Fluid jet cell harvester and cellular delivery system

ActiveUS9549753B2Efficient dissociationHighly efficient emulsificationIntravenous devicesFluid jet surgical cuttersHigh pressureTarget tissue

An ultrasonically pulsating high-pressure fluid jet coupled with a suction system serve as a tissue harvesting device. The pulsated fluid jet disrupts tissue, permitting both harvesting of cells for therapeutic delivery, and as a surgical dissector and aspirator, for liposuction, soft tissue dissection, etc. The jet is delivered to the target tissue through a cannula, coupled to an aspiration system. An ultrasonically actuated rod vibrates within the cannula engaging a nozzle, disrupting the fluid jet into droplets, permitting tuning of the jet to the resonant frequencies and impact pressures necessary to dissociate the target tissue. A suction recovery system may be separated or integrally formed with the fluid jet cannula, and is linked by a closed tubing system appropriate for sterilization and subsequent delivery of the harvested cells / tissues with or without growth factor or matrix addition for human re-implantation or for in vitro expansion for later re-implantation.

Owner:GORDON CHRISTOPHER BURNSIDE

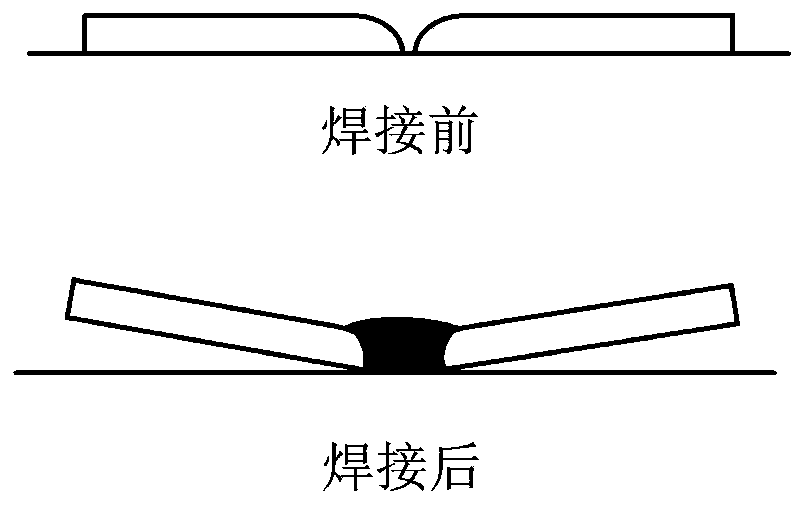

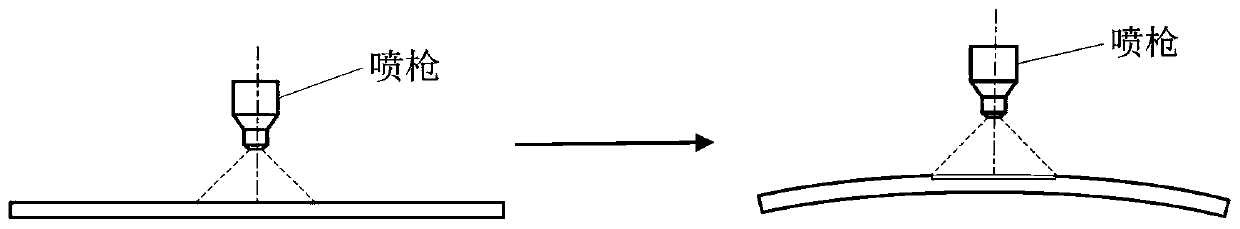

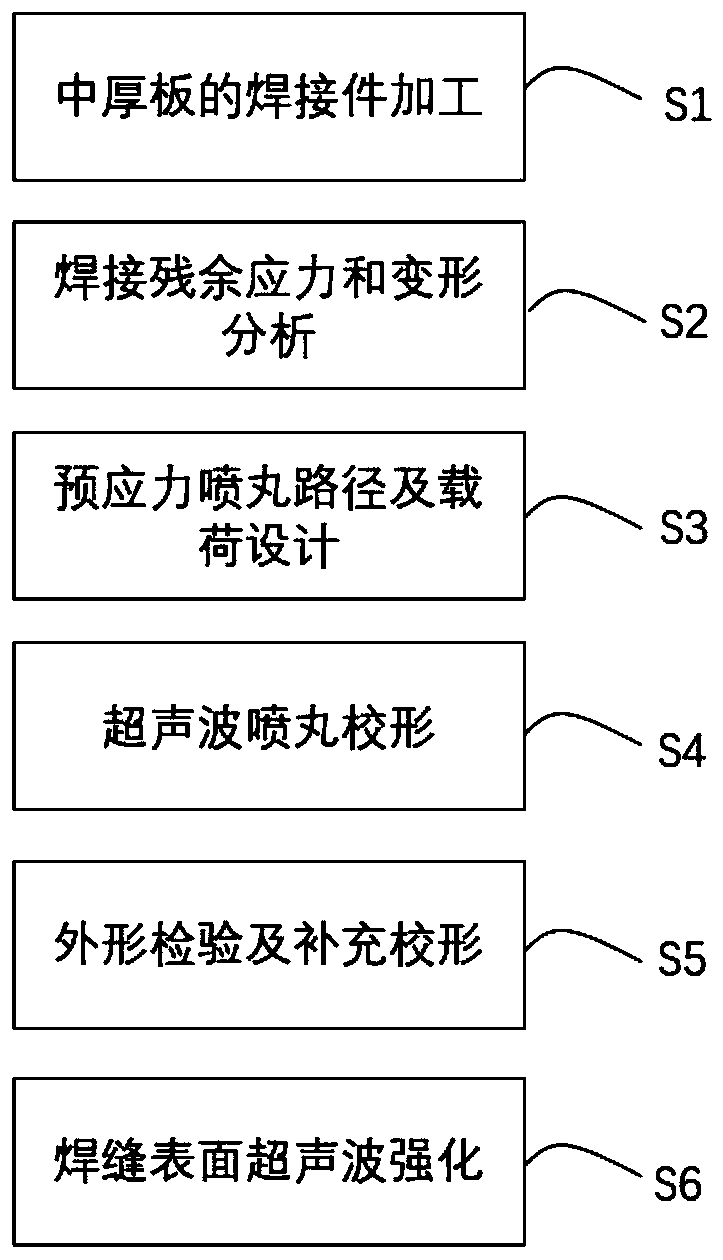

Shape correction and strengthening method for postwelding prestressing force of moderately thick light alloy plate

ActiveCN111546017ARealize the correctionRealize functionVibratory devicesGrinding/polishing apparatusWelding residual stressPre stress

The invention discloses a shape correction and strengthening method for postwelding prestressing force of a moderately thick light alloy plate. The method comprises steps as follows: S1), machining ofa welding part; S2), welding residual stress and deformation analysis; S3), design of a shot-blasting path and load of prestressing force; S4), ultrasonic shot-blasting shape correction; S5), outlineinspection and supplementary shape correction; and S6), ultrasonic strengthening for a weld surface. The method has main advantages as follows: an existing welding technology and process of a productare not changed, firing pin type ultrasonic shot-blasting equipment is utilized for shape correction and strengthening, shape correction and strengthening functions are realized by replacing workingheads of different sizes, and the operation is convenient and efficient. According to the method, after the welding part is cooled, residual stress which is not released is utilized as prestressing force load to be applied, so that energy required for shape correction can be greatly reduced, and meanwhile, damage of the material surface due to high-temperature-state shape correction is avoided. The method is particularly suitable for control treatment of welding deformation of a light high-strength material which is strengthened by heat treatment.

Owner:SHANGHAI UNIV OF ENG SCI

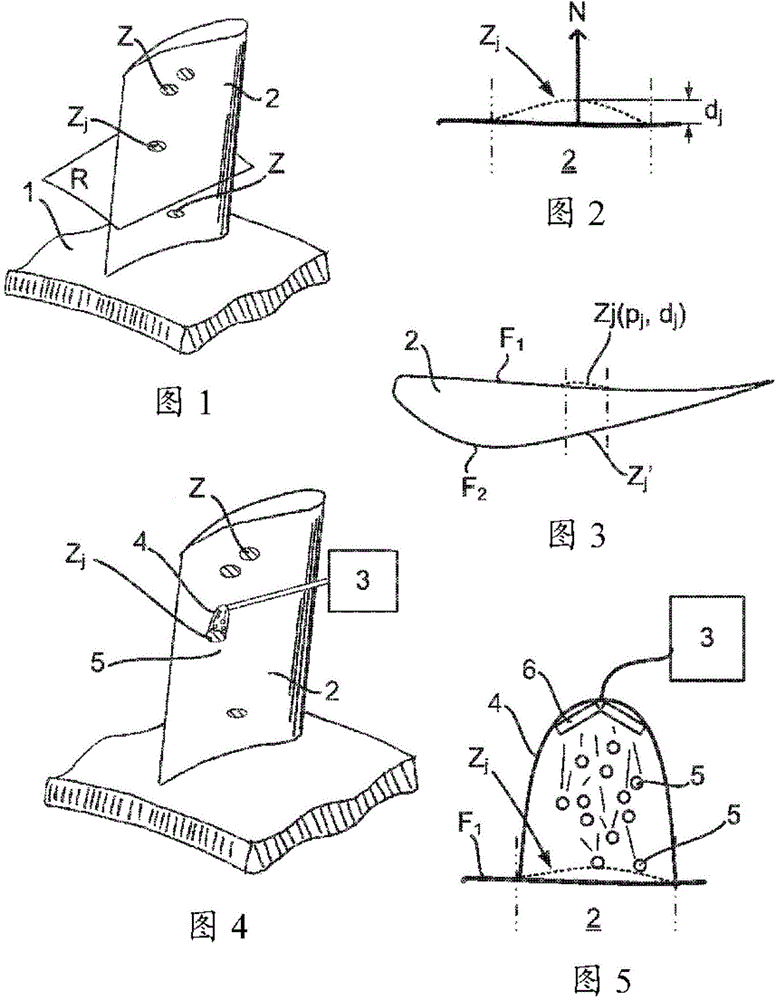

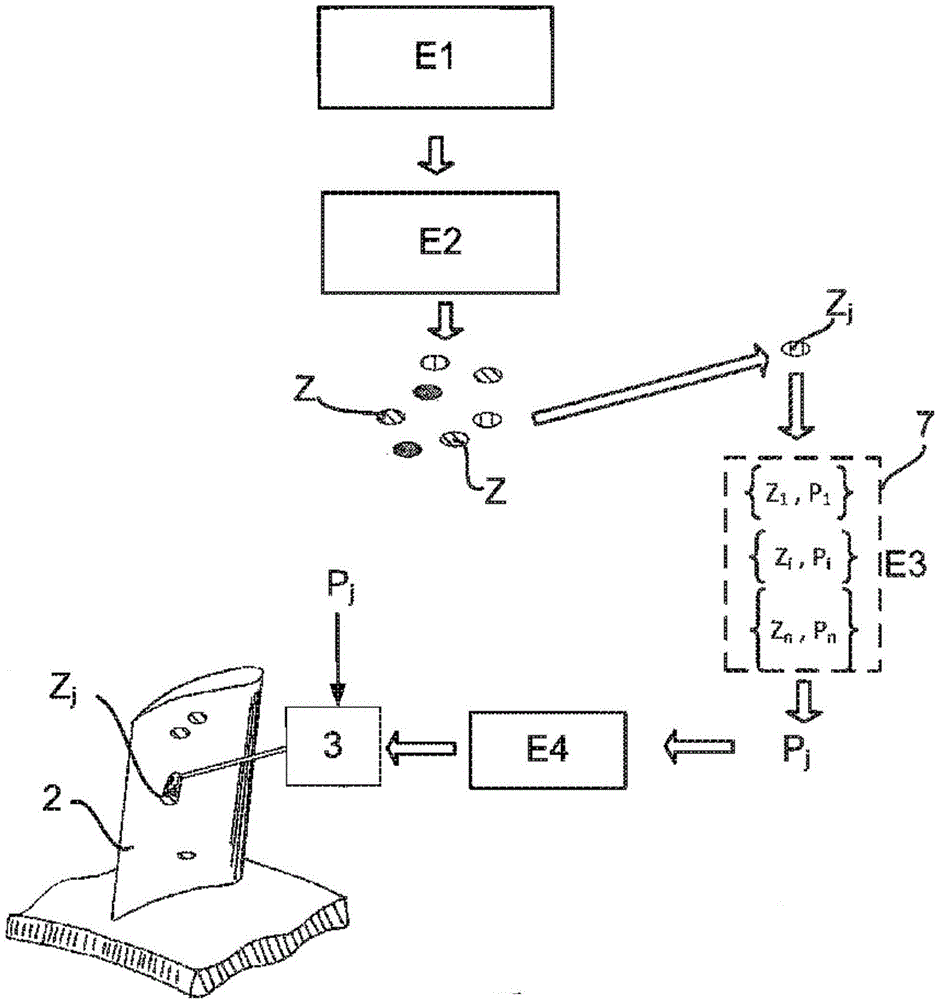

Method for reshaping a turbomachine blade that has at least one zone that has become deformed using peening

ActiveCN103958121ARegain shapeExtended service lifeAircraft componentsBlade accessoriesEngineeringPeening

Method for reshaping a turbomachine blade (2) comprising at least one deformed zone (Z), the method involving acquisition of a profile of said blade, comparing said profile against a reference profile in order therefrom to deduce at least one deformed zone (Zj) of the blade (2), comparing the deformed zone (Zj) against a deformation database (7) containing a plurality of deformed zones (Zj) each respectively associated with a plurality of settings (Pj) for a peening device (3), determining the setting (Pj) associated with said deformed zone (Zj) and peening the deformed zone (Zj) of the blade (2) using the peening device (3) on the basis of said determined setting (Pj) so as to restore said zone (Z) to the proper shape.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com