Patents

Literature

74results about How to "Regain shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Durable thermosets from reducing sugars and primary polyamines

ActiveUS20110262648A1Minimize formaldehyde contentFavorable cost/performanceOrganic detergent compounding agentsPretreated surfacesFiberCarboxylic acid

The present invention provides thermosetting aqueous binder compositions of one or more diprimary diamine, e.g. lysine, or poly(primary amine), e.g. polyethylenimine, and one or more reducing sugar in which the number of equivalents of primary amine relative to the number of equivalents of carbonyl groups in the reducing sugar ranges from 0.4:1 to 2:1, the binders being suitable for use on fiber, nonwoven, woven web and finely divided substrates. The binders are at least substantially formaldehyde free, need no polycarboxylic or polycarboxylate component, and yet provide excellent hot wet tensile strength when cured for as little time as a minute or less in use.

Owner:ROHM & HAAS CO +1

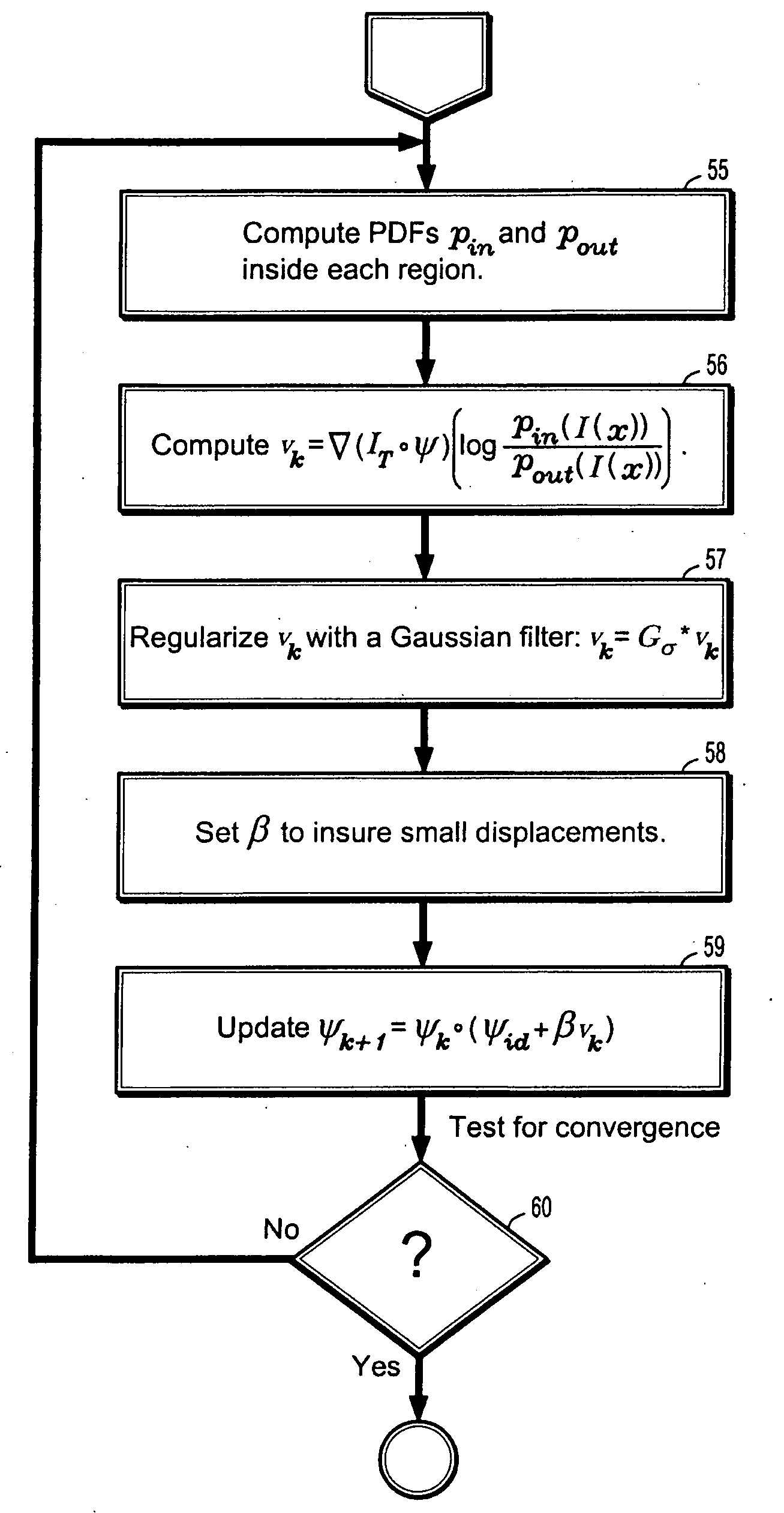

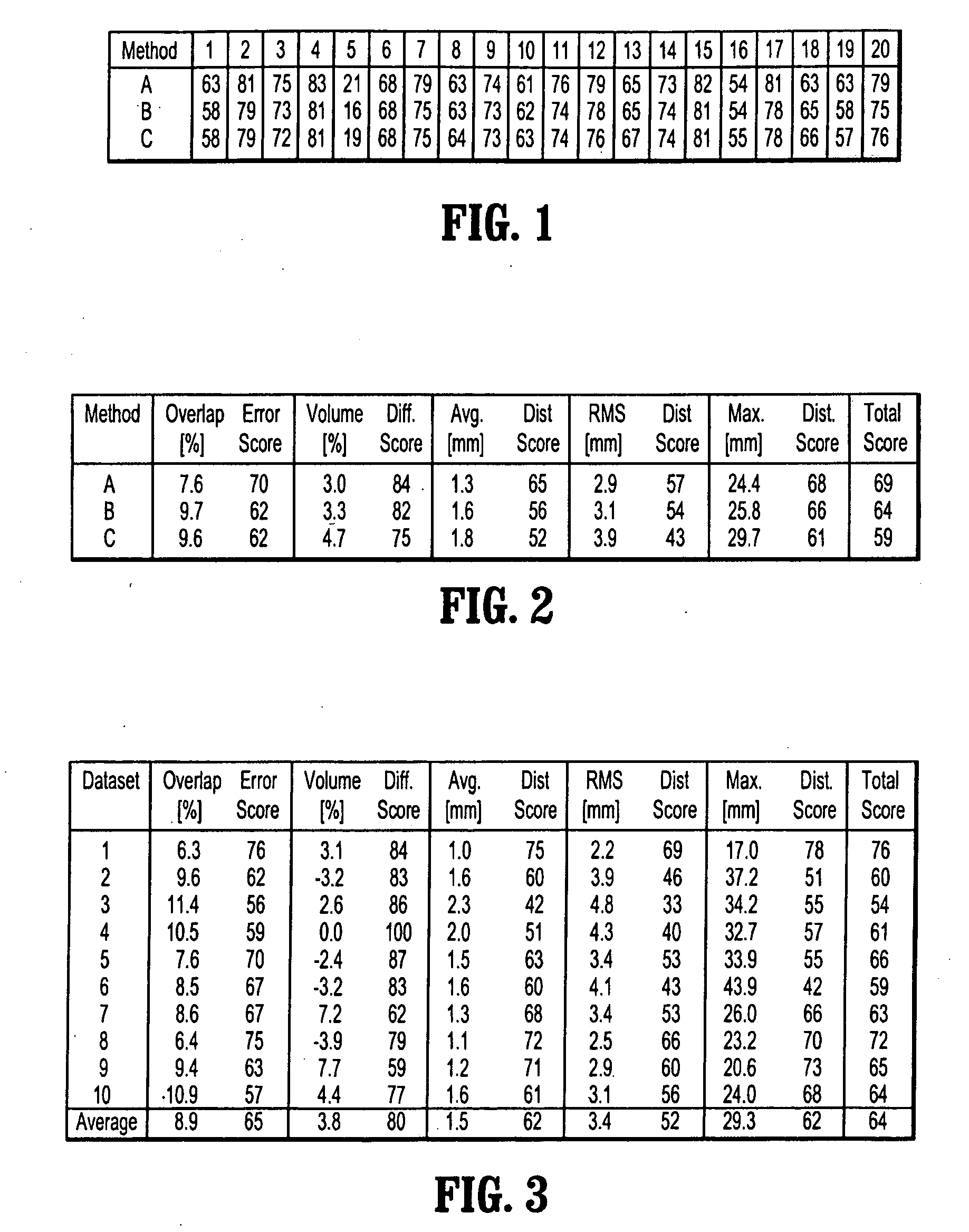

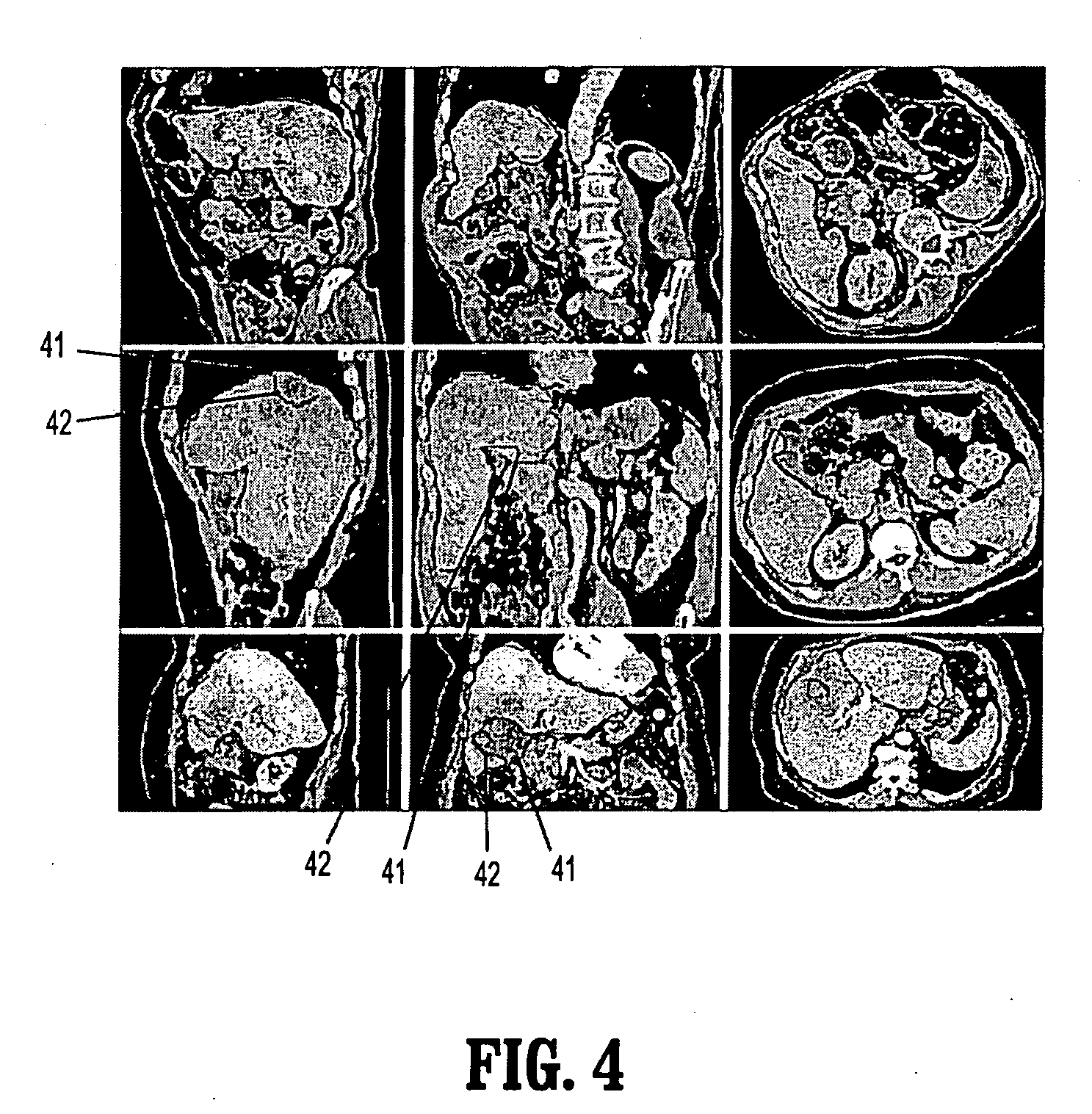

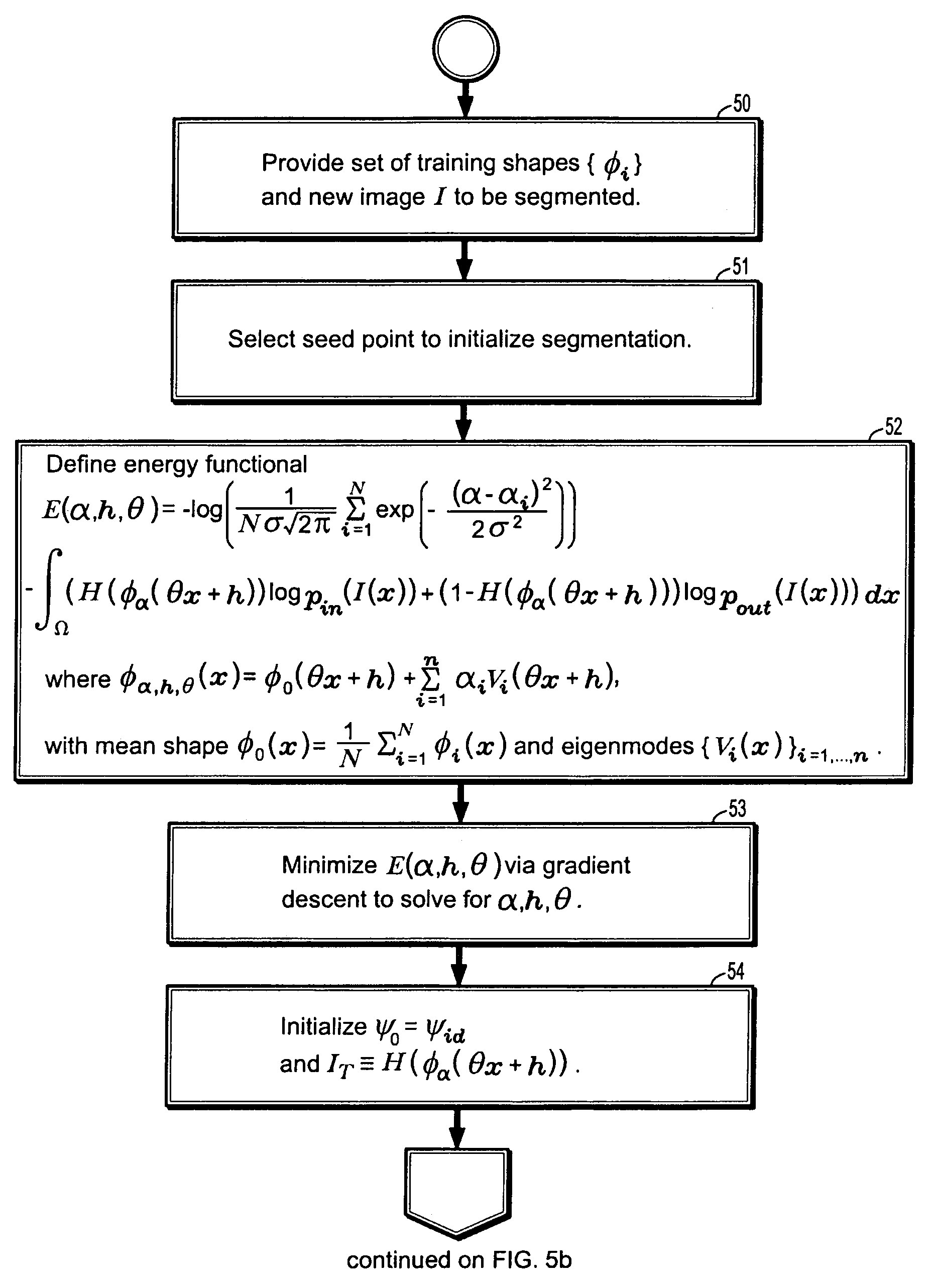

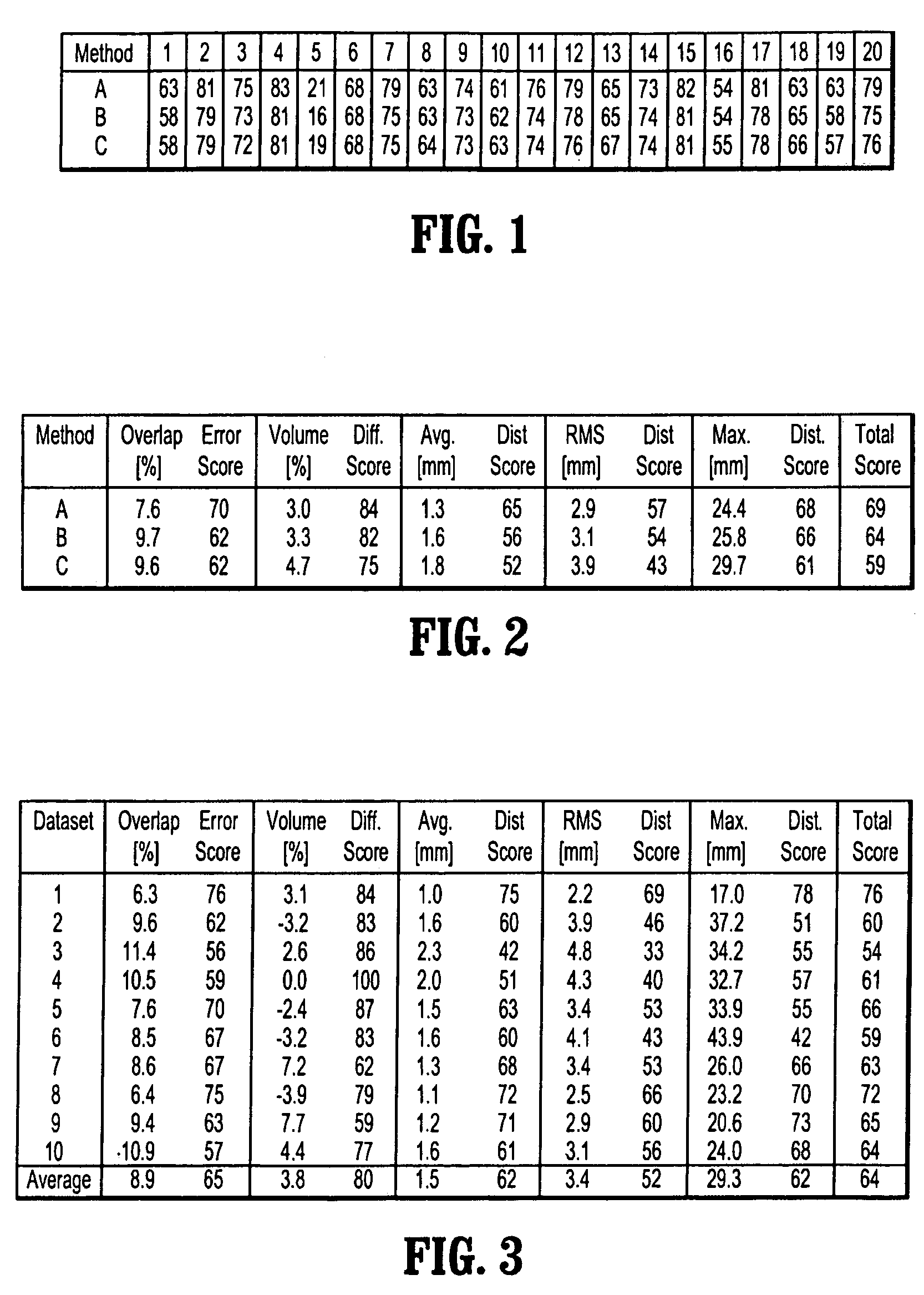

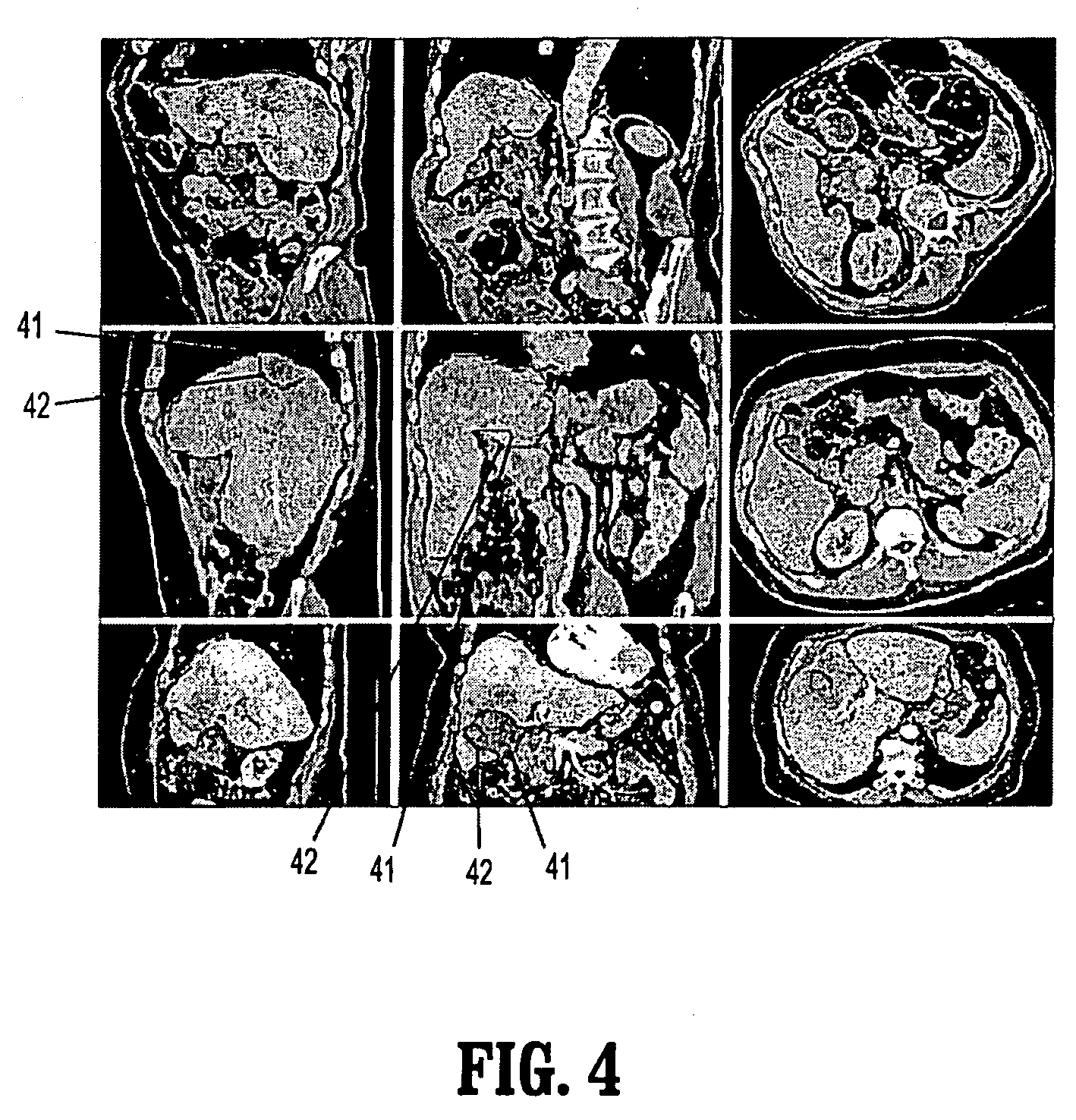

System and method for global-to-local shape matching for automatic liver segmentation in medical imaging

ActiveUS20090052756A1Improve robustnessPreserve topologyImage enhancementImage analysisIntensity histogramMedical imaging

A method for automatically segmenting a liver in digital medical images includes providing a 3-dimensional (3D) digital image I and a set of N training shapes {φi}i=1, . . . , N for a liver trained from a set of manually segmented images, selecting a seed point to initialize the segmentation, representing a level set function φα(θx+h) of a liver boundary Γ in the image asφα(x)=φ0+∑i=1nαiVi(x),whereφ0(x)=1N∑i=1Nφi(x)is a mean shape, {Vi(x)}i=1, . . . , n are eigenmodes where n<N, αi are shape parameters, and h ε R3 and θε [0,2π]3 are translation and rotation parameters that align the training shapes, minimizing a first energy functional to determine the shape, translation, and rotation parameters to determine a shape template for the liver segmentation, defining a second energy functional of the shape template and a registration mapping weighted by image intensity histogram functions inside and outside the boundary, and minimizing the second energy functional to determine the registration mapping, where the registration mapping recovers local deformations of the liver.

Owner:SIEMENS HEALTHCARE GMBH

Rapid cure thermosets from 5- and 6- membered cyclic enamine compounds made from dialdehydes

ActiveUS20110306726A1Favorable cost/performanceWide priceAldehyde/ketone condensation polymer adhesivesEnamineWater soluble

The present invention provides thermosetting aqueous binder compositions of one or more cyclic enamine, including bis-enamines and di- or higher functional enamines, optionally containing a water soluble or dispersible or dispersible primary amine compound. The binders are at least substantially formaldehyde free, need no polycarboxylic or polycarboxylate component, and yet provide excellent hot wet tensile strength when cured for as little time as a minute or less in use.

Owner:DOW GLOBAL TECH LLC +1

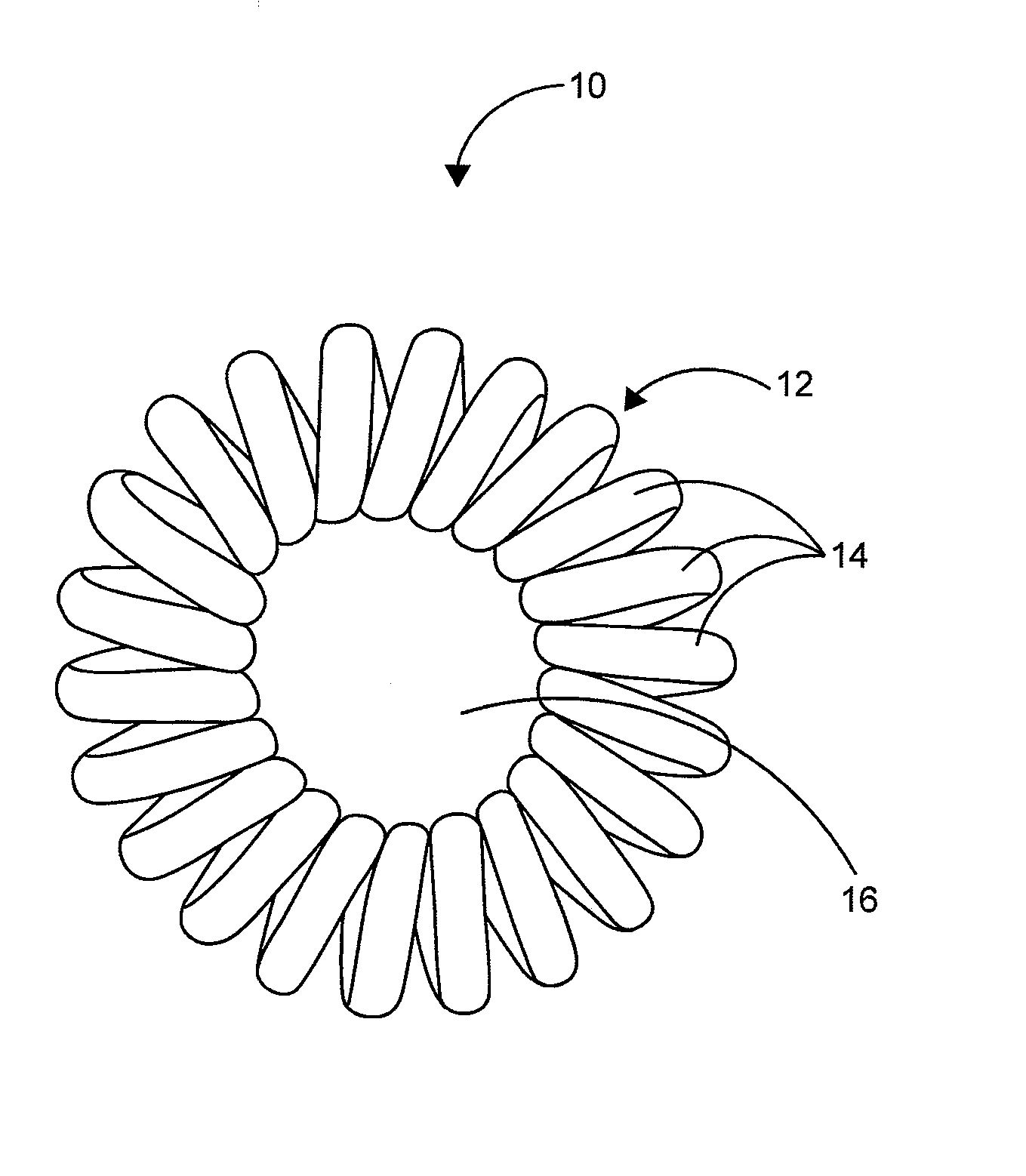

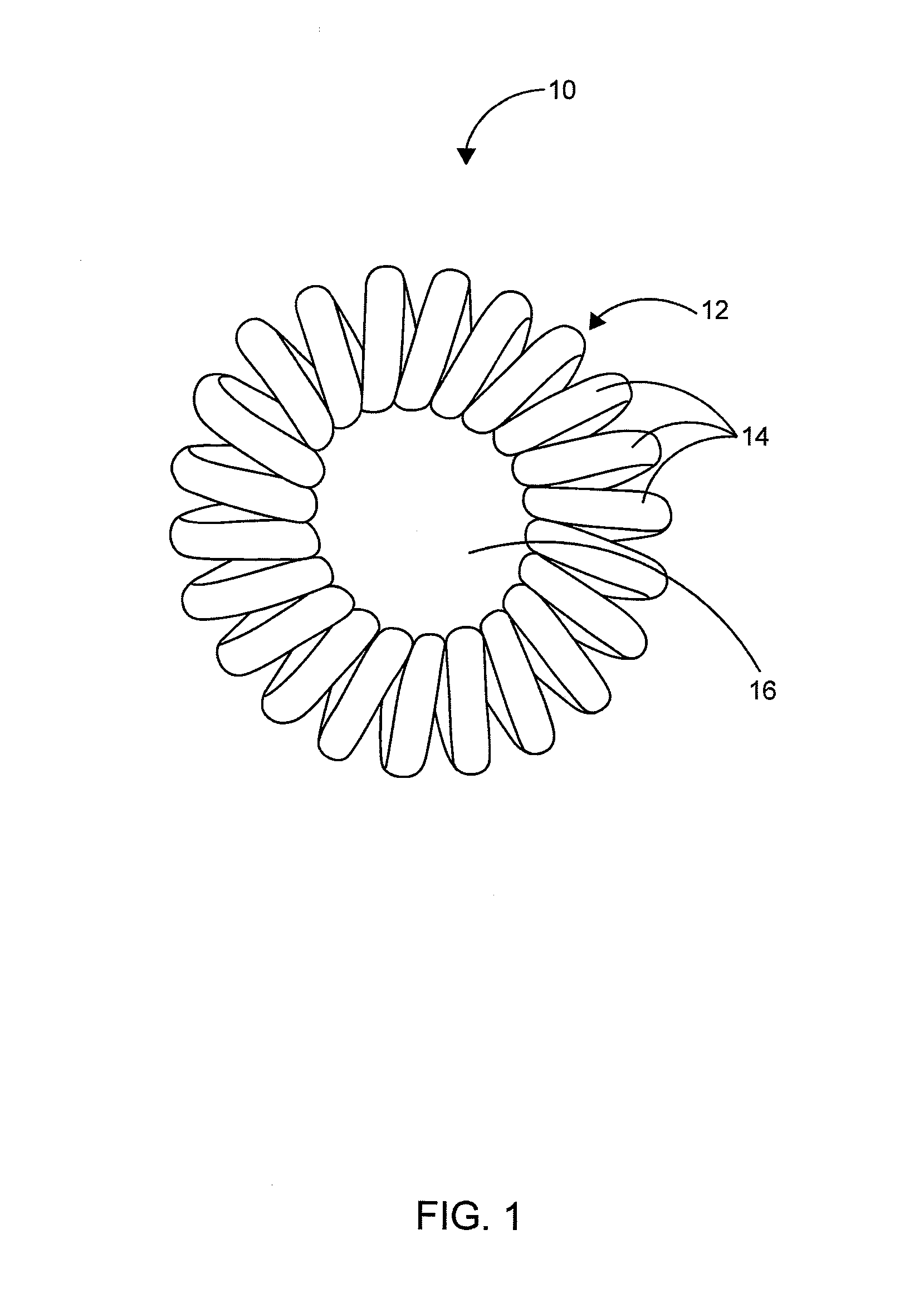

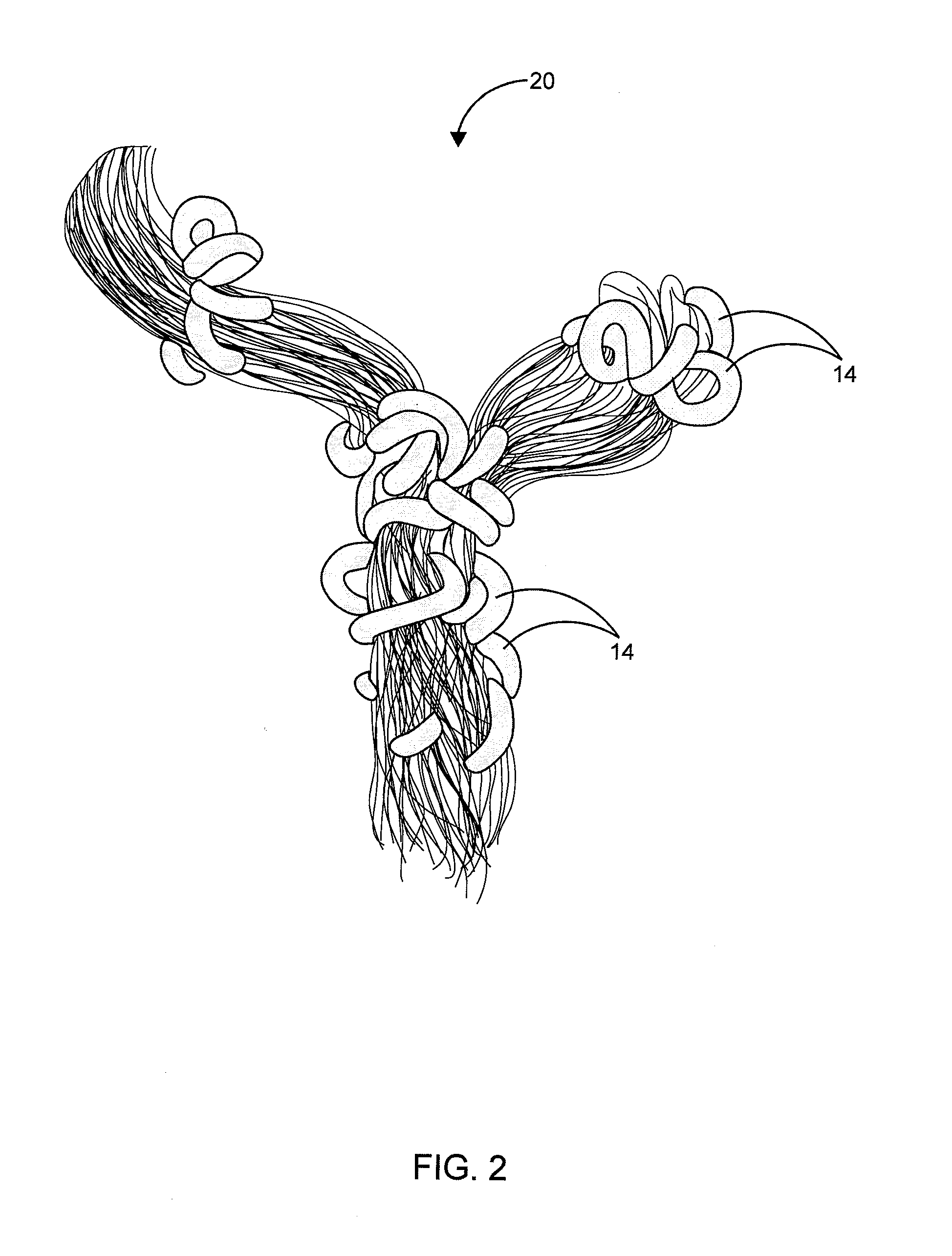

Hair Ties

InactiveUS20140096788A1Reduce frictionRegain shapeCurling devicesTravelling articlesEngineeringCoiled coil

The present invention is a hair accessory having a special coil design. The hair accessory comprising a substantially circular shaped member having a plurality of coiled coil structures, each of the plurality of coiled coil structures is arranged in a way to form a closed helical loop. When the coiled coil structure is twisted and folded for holding the hair, its special structure permits it to lock with itself so that the hair accessory remains in hair even if strenuous movement is performed by the wearer. The hardness of the material results in less friction with the hair thereby allowing easy gliding during pull out of hair. The twists around the hair act as anchors thereby not allowing the hair accessory to dislodge. The constant use of the hair accessory may tend to loose its shape and it can regain its shape by placing the hair accessory in boiling water.

Owner:KRASNIANSKY NOAM

System and method for global-to-local shape matching for automatic liver segmentation in medical imaging

ActiveUS8131038B2Improve robustnessPreserve topologyImage enhancementImage analysisIntensity histogramMedical imaging

A method for automatically segmenting a liver in digital medical images includes providing a 3-dimensional (3D) digital image I and a set of N training shapes {φi}i=1, . . . , N for a liver trained from a set of manually segmented images, selecting a seed point to initialize the segmentation, representing a level set function φα(θx+h) of a liver boundary Γ in the image asϕα(x)=ϕ0+∑i=1nαiVi(x),whereϕ0(x)=1N∑i=1Nϕi(x)is a mean shape, {Vi(x)}i=1, . . . , n are eigenmodes where n<N, αi are shape parameters, and h ε R3 and θε [0,2π]3 are translation and rotation parameters that align the training shapes, minimizing a first energy functional to determine the shape, translation, and rotation parameters to determine a shape template for the liver segmentation, defining a second energy functional of the shape template and a registration mapping weighted by image intensity histogram functions inside and outside the boundary, and minimizing the second energy functional to determine the registration mapping, where the registration mapping recovers local deformations of the liver.

Owner:SIEMENS HEALTHCARE GMBH

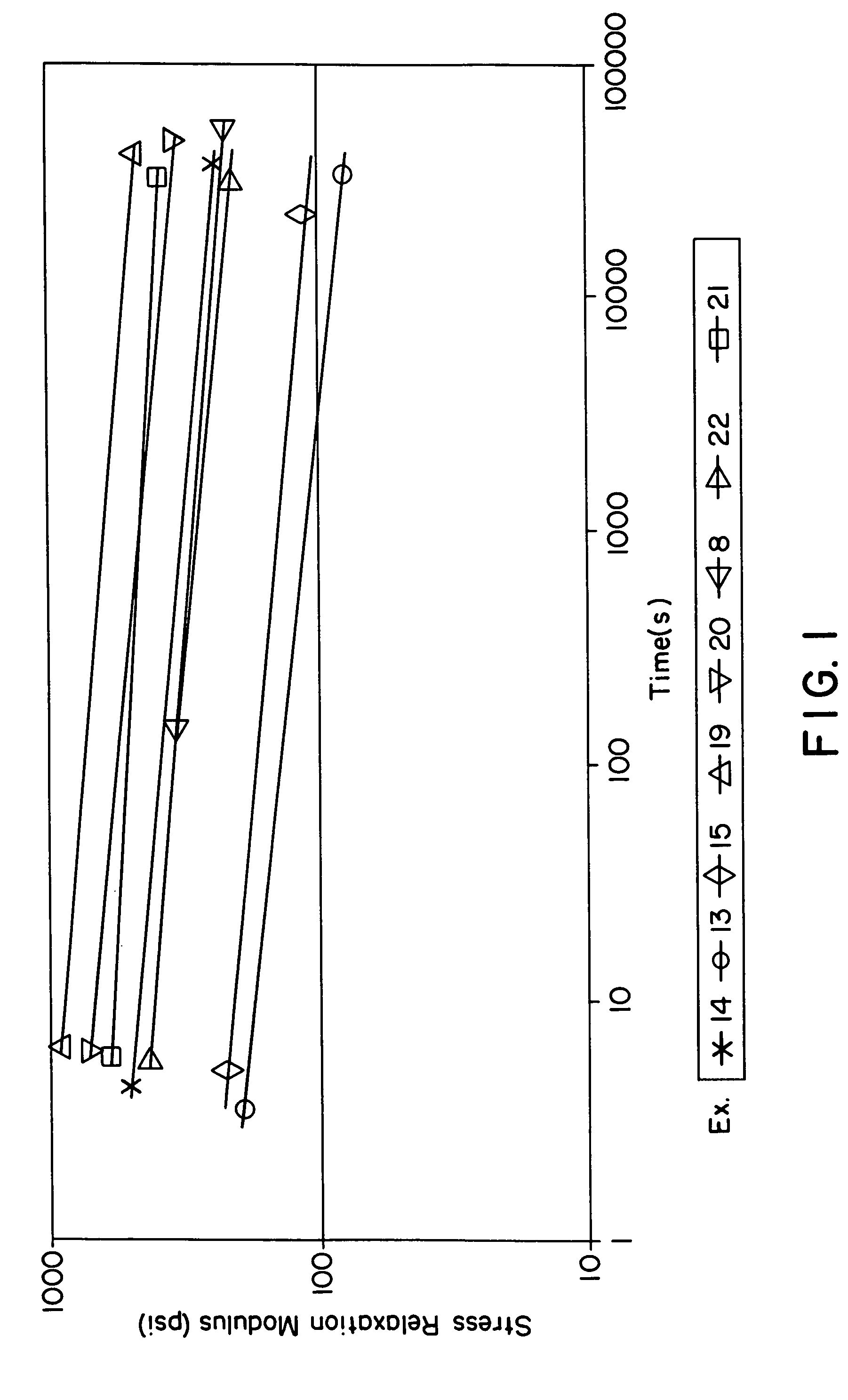

Elastomer compositions and method of making them

InactiveUS7247675B2Simple compositionImprove performanceSynthetic resin layered productsCellulosic plastic layered productsElastomerPersonal care

Compositions of high and low performance elastomer are formed using a process that chemically reacts some of the high and low performance elastomers together to form a graft copolymer. The elastomeric compositions provide intimately mixed elastomeric compositions which are thermodynamically stable and do not phase separate. The elastomeric compositions exhibit a variety of improved properties compared to simple blends of the same high and low performance elastomers in the same weight proportions. The elastomeric compositions are useful for producing films, fabrics, and laminates for use in a wide variety of personal care and medical articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

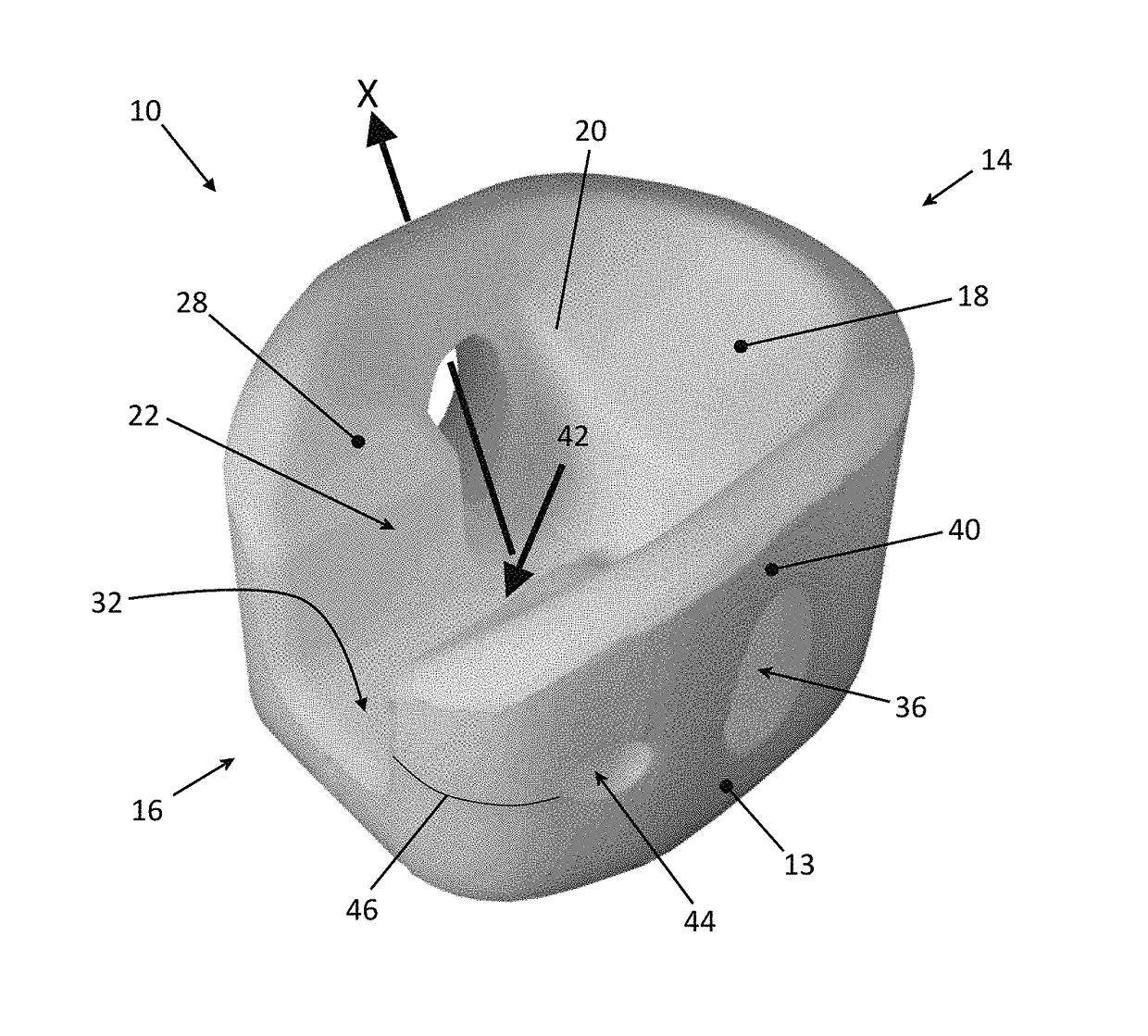

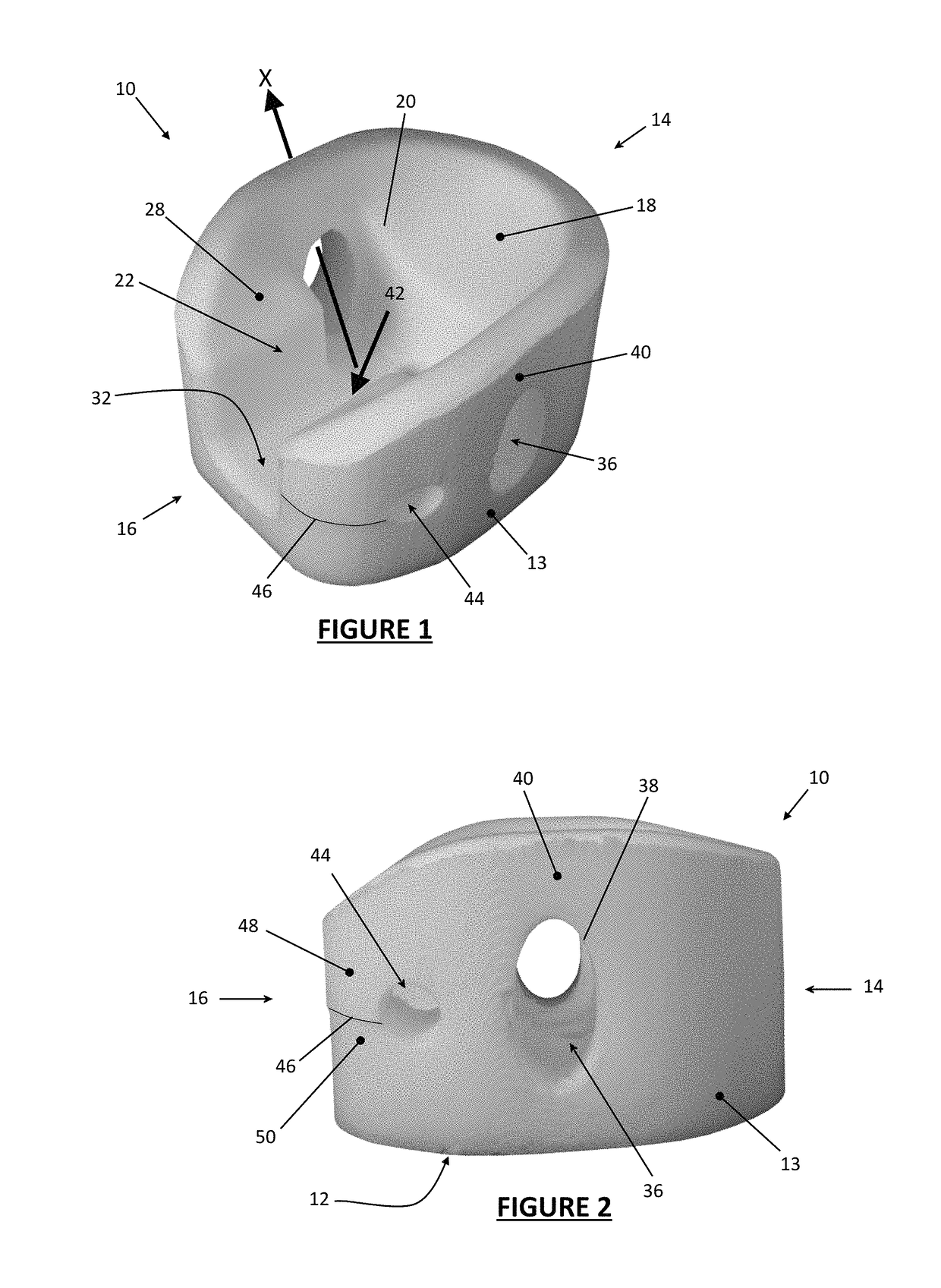

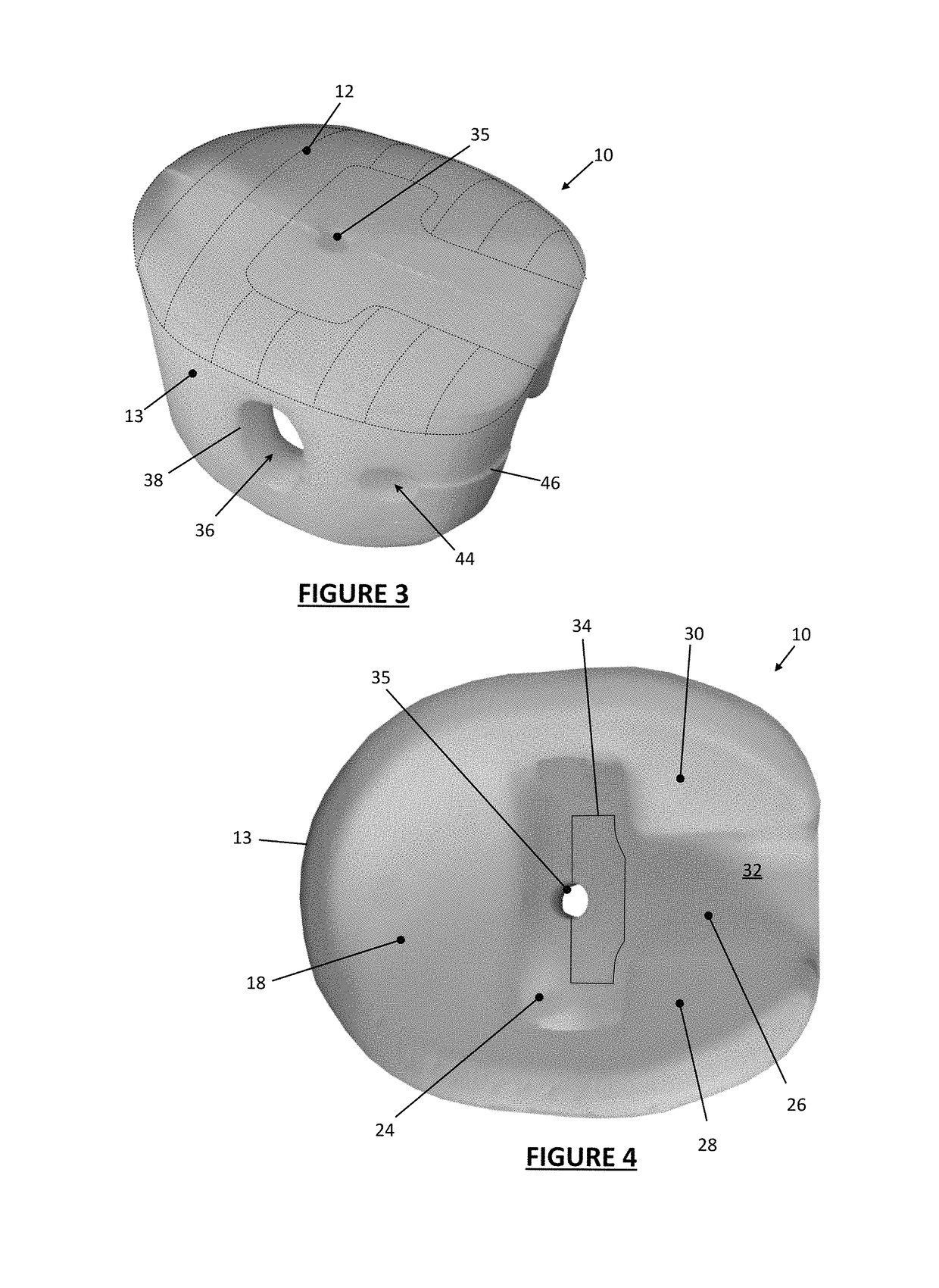

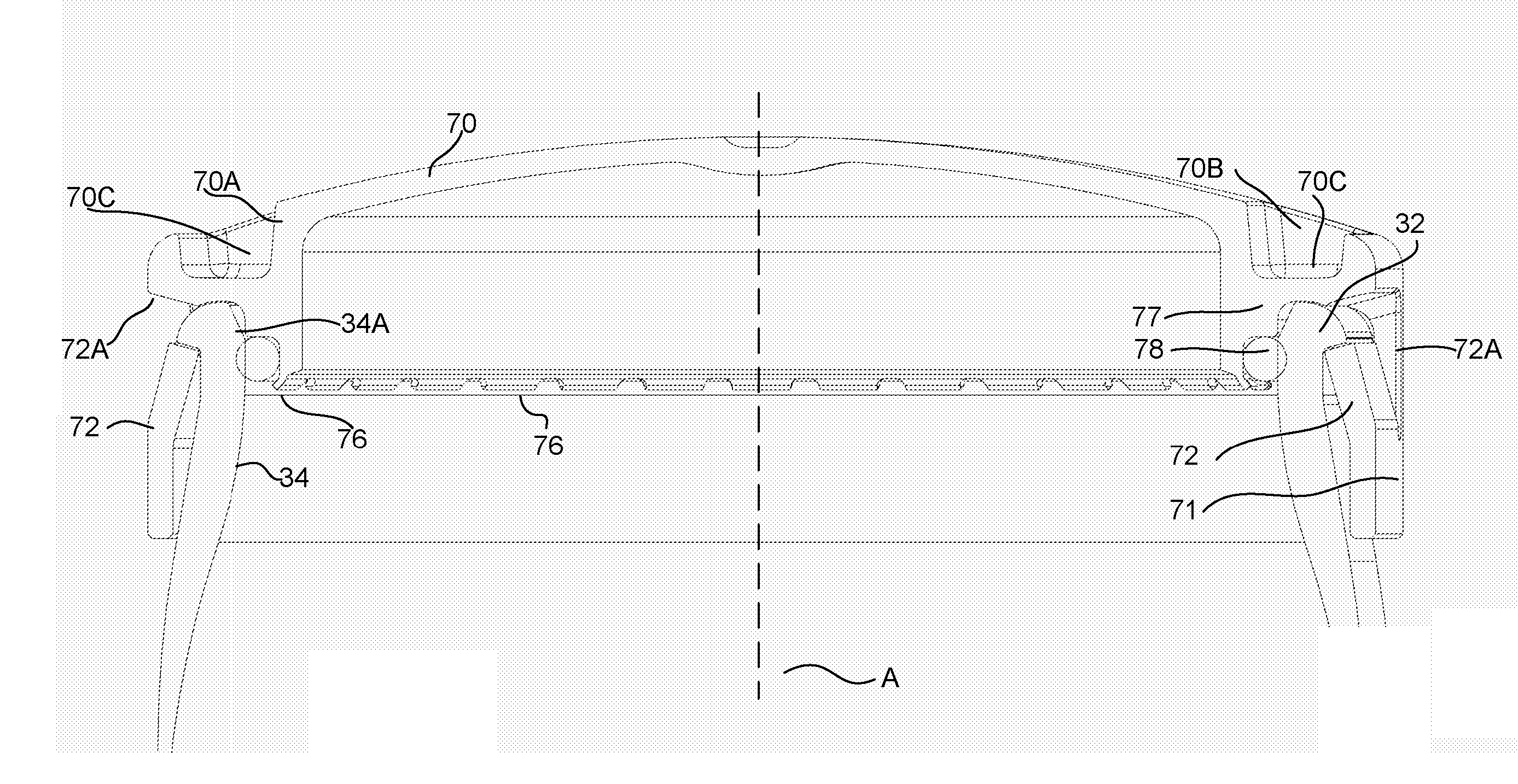

Head support

The present invention relates to a head support for supporting a patient's head while the patient is in a prone position. The head support comprises a body of compliant material whose shape provides a forehead support region, at least one further support region for supporting a lower portion of the patient's face, and a void which accommodates the patient's eyes, nose and mouth in use. According to one aspect of the invention, a viewing opening is provided which faces laterally and provides in use a line of sight from the exterior of the head support into the void, the viewing opening having a periphery which is an unbroken loop.

Owner:EC MEDICA

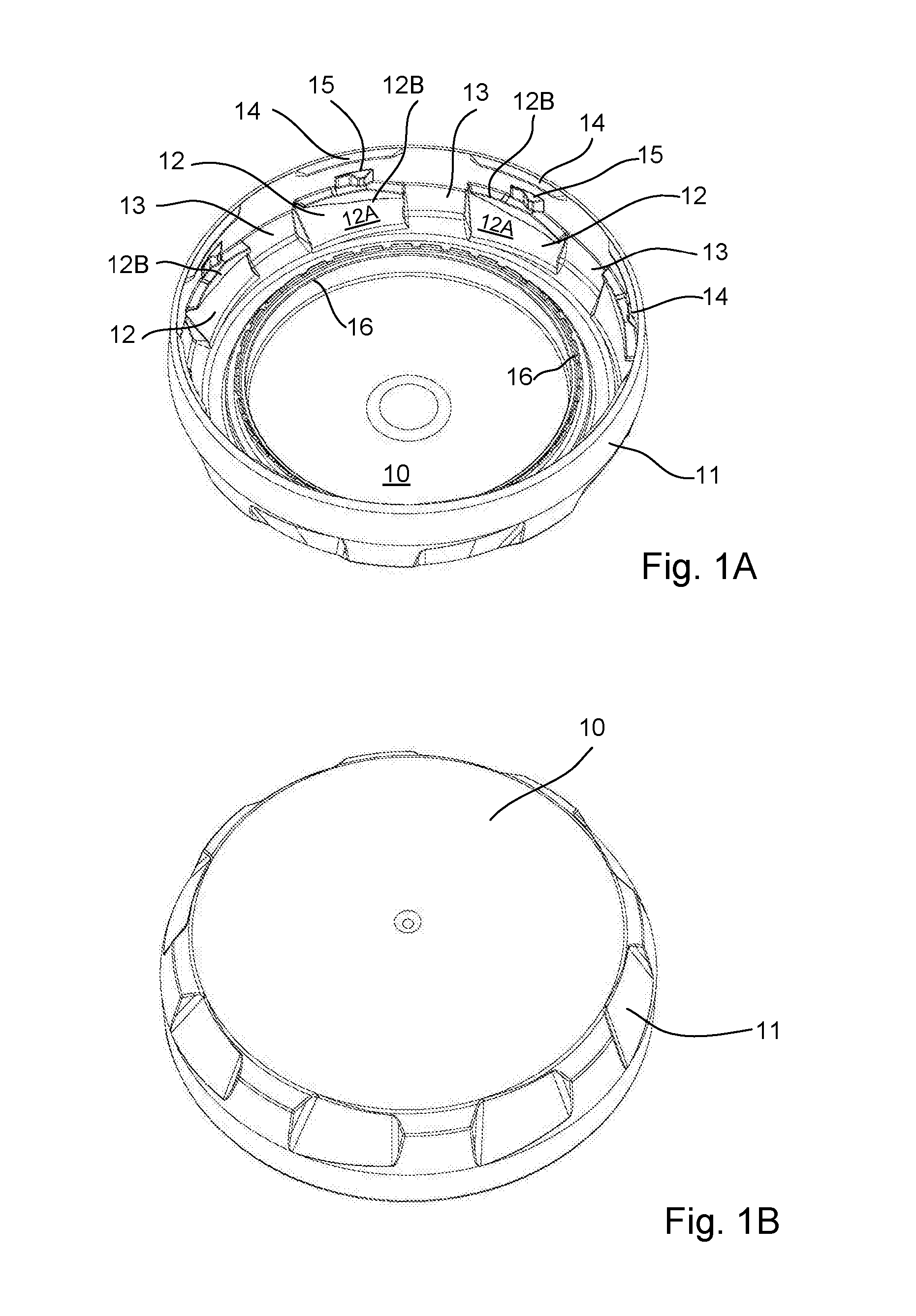

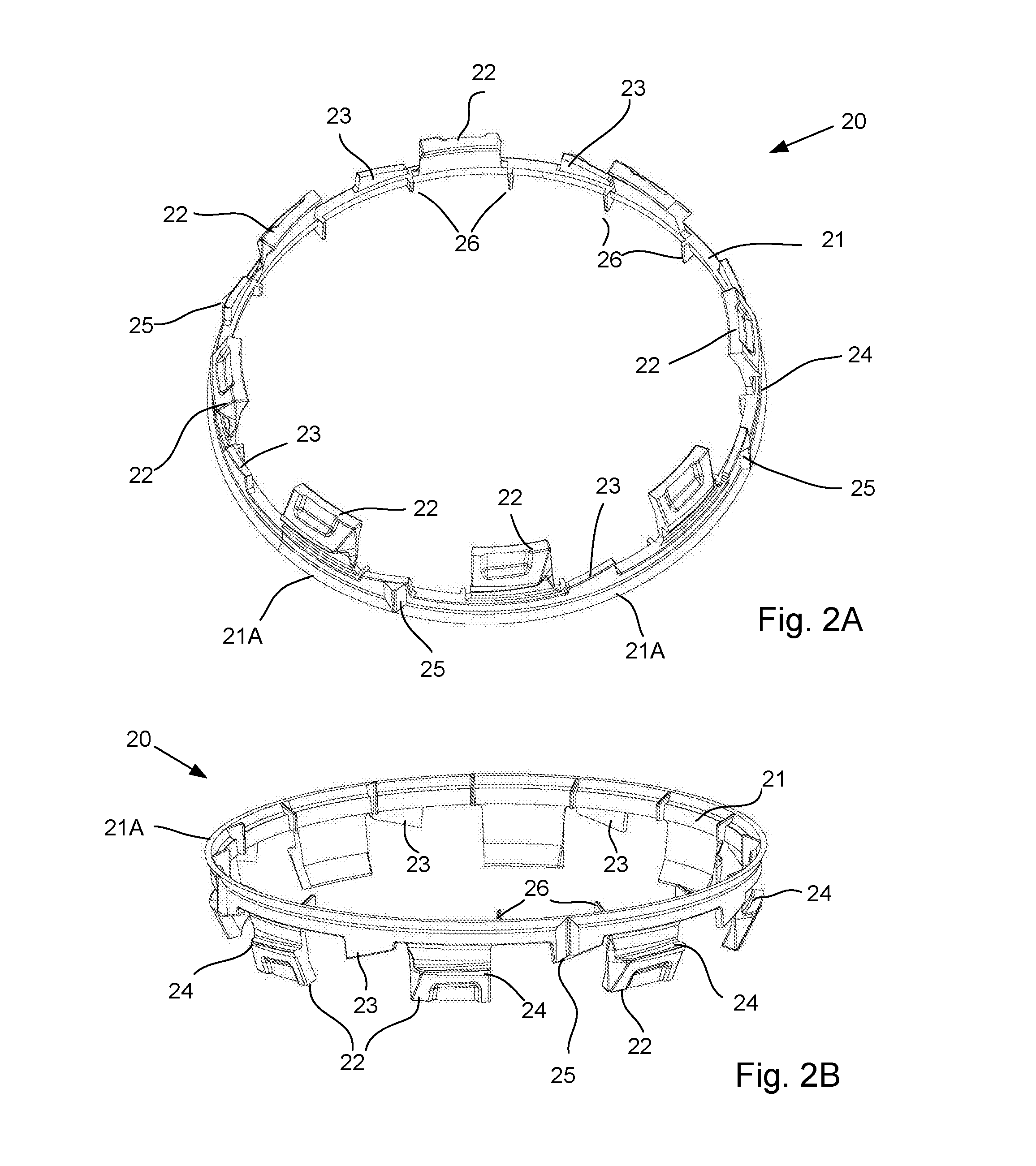

Closure for a container

InactiveUS20160107806A1Excellent gas barrier performanceResists compression setCapsDecorative coversElastomerPolyoxymethylene

A closure for releasably securing to a container adapted for storing foodstuff or a beverage, the closure comprising closing means (14) for closing a mouth of the container and securing means (22,23) for securing it in a closed position, the closing means and the securing means being formed of a plastics material comprising polyoxymethylene so as to provide a substantial gas barrier to the passage of oxygen and / or carbon dioxide therethrough, The closure may have a sealing member (18) formed of resilient material (compared to the rigid material of the remainder of the closure) for providing a seal between the closure and the container. The sealing member may be provided on a bore component which projects into the container so that, in use, it seals against an internal surface of the container. The sealing member may be an o-ring (18) formed of an elastomer, e.g. nitrile butadiene rubber. A foodstuff or beverage container, e.g. in the shape of a wine glass or the shape of a beer glass, having such a closure is also described. The use of a plastics material comprising polyoxymethylene for closing a container provides a barrier to the ingress of oxygen and / or to the egress of carbon dioxide to improve the shelf life of the product is also described.

Owner:KEMIRA OY +1

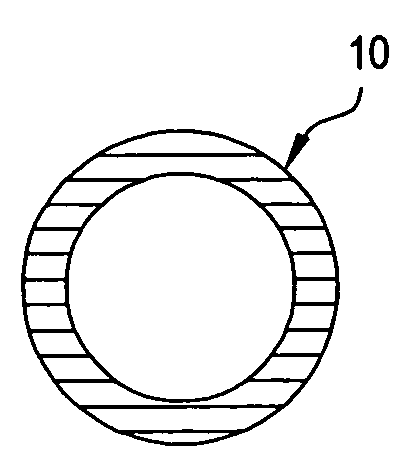

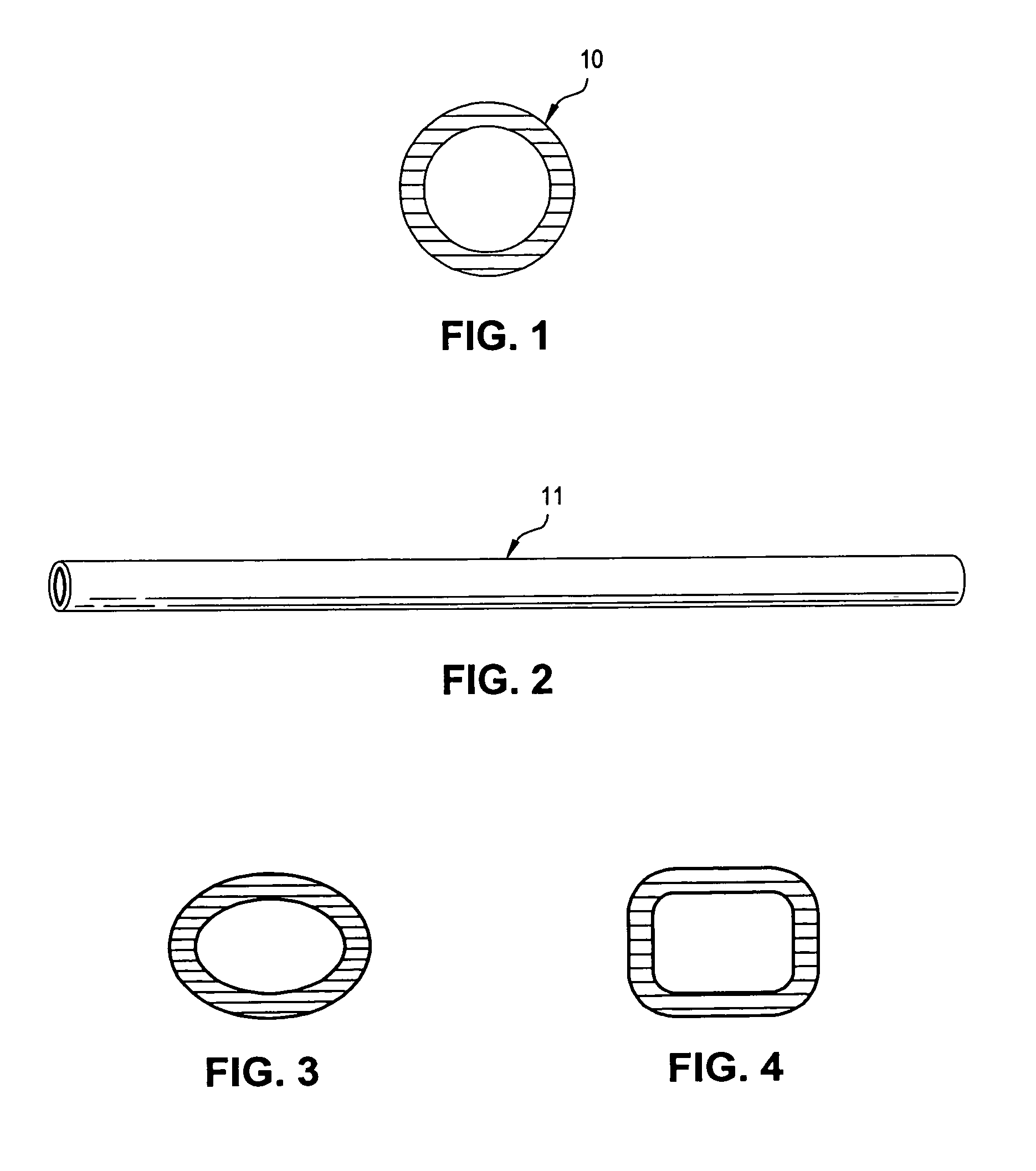

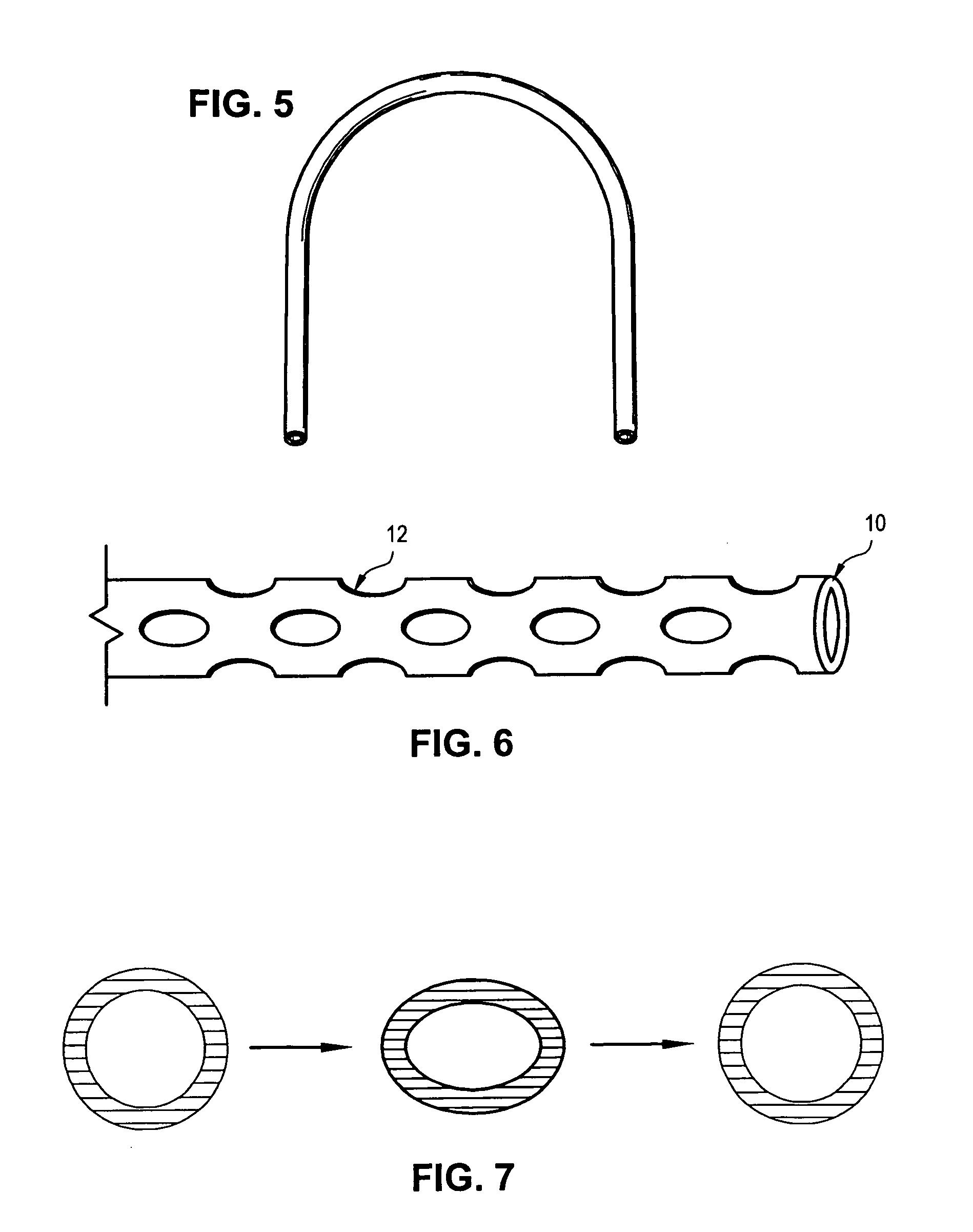

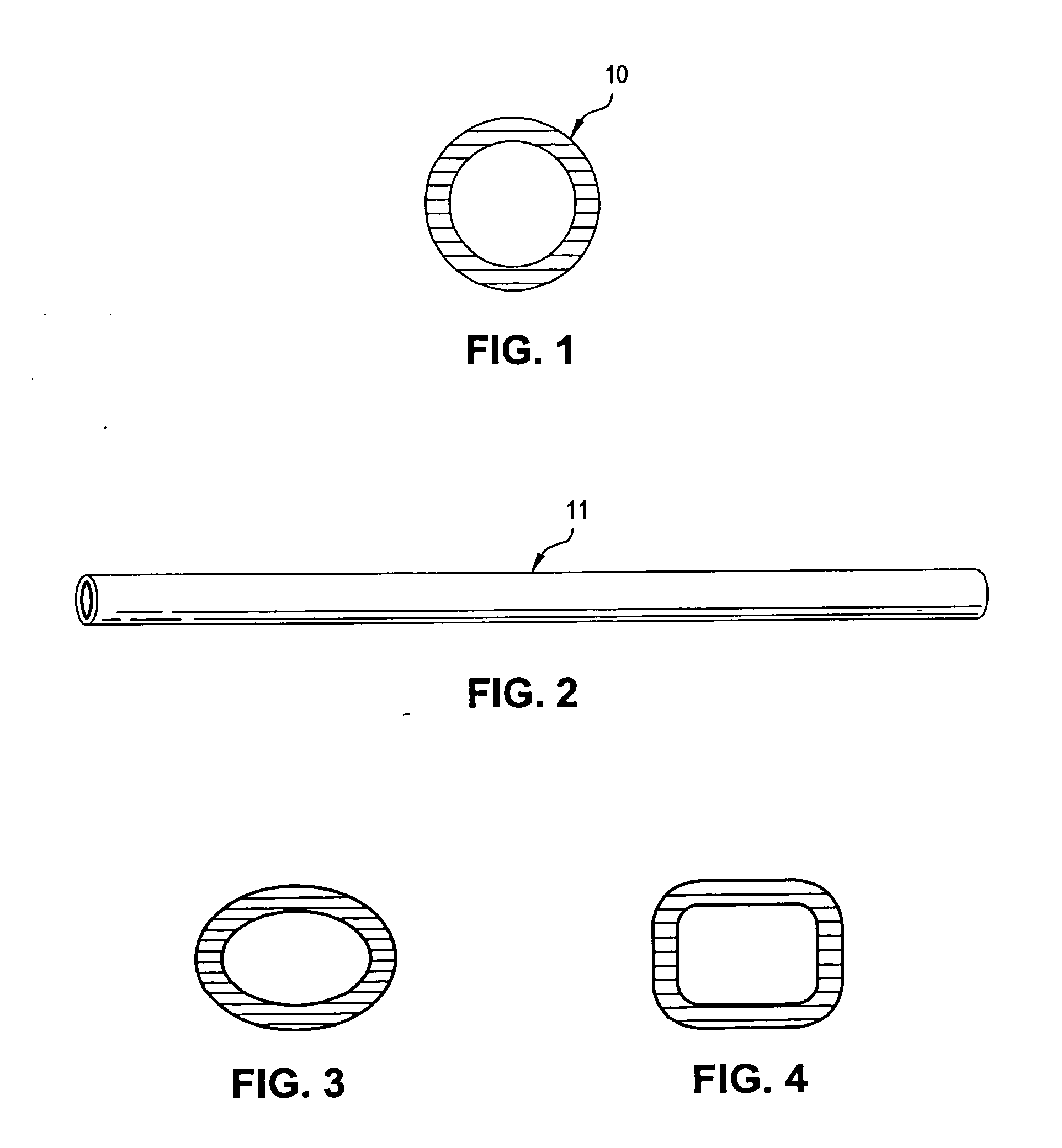

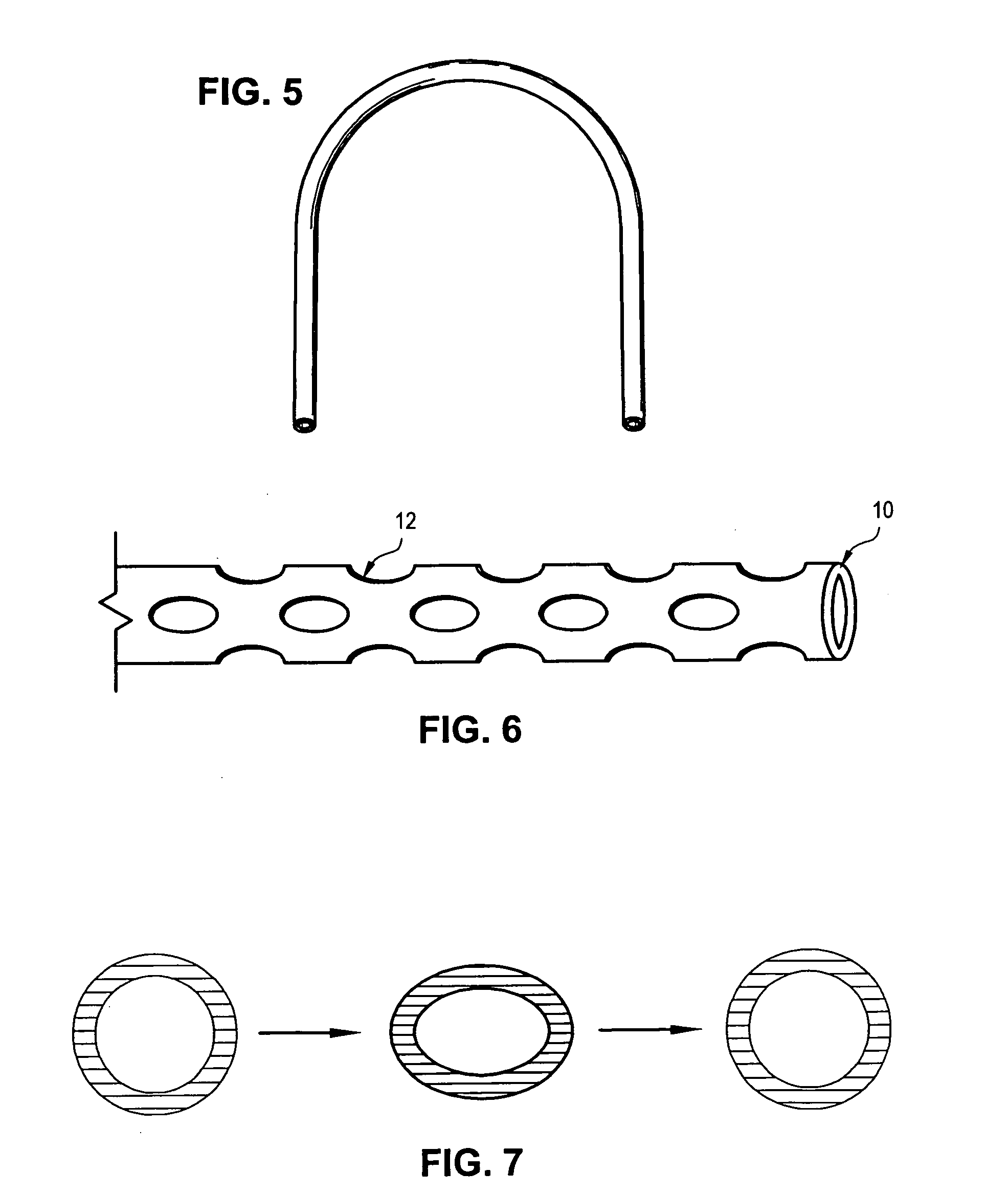

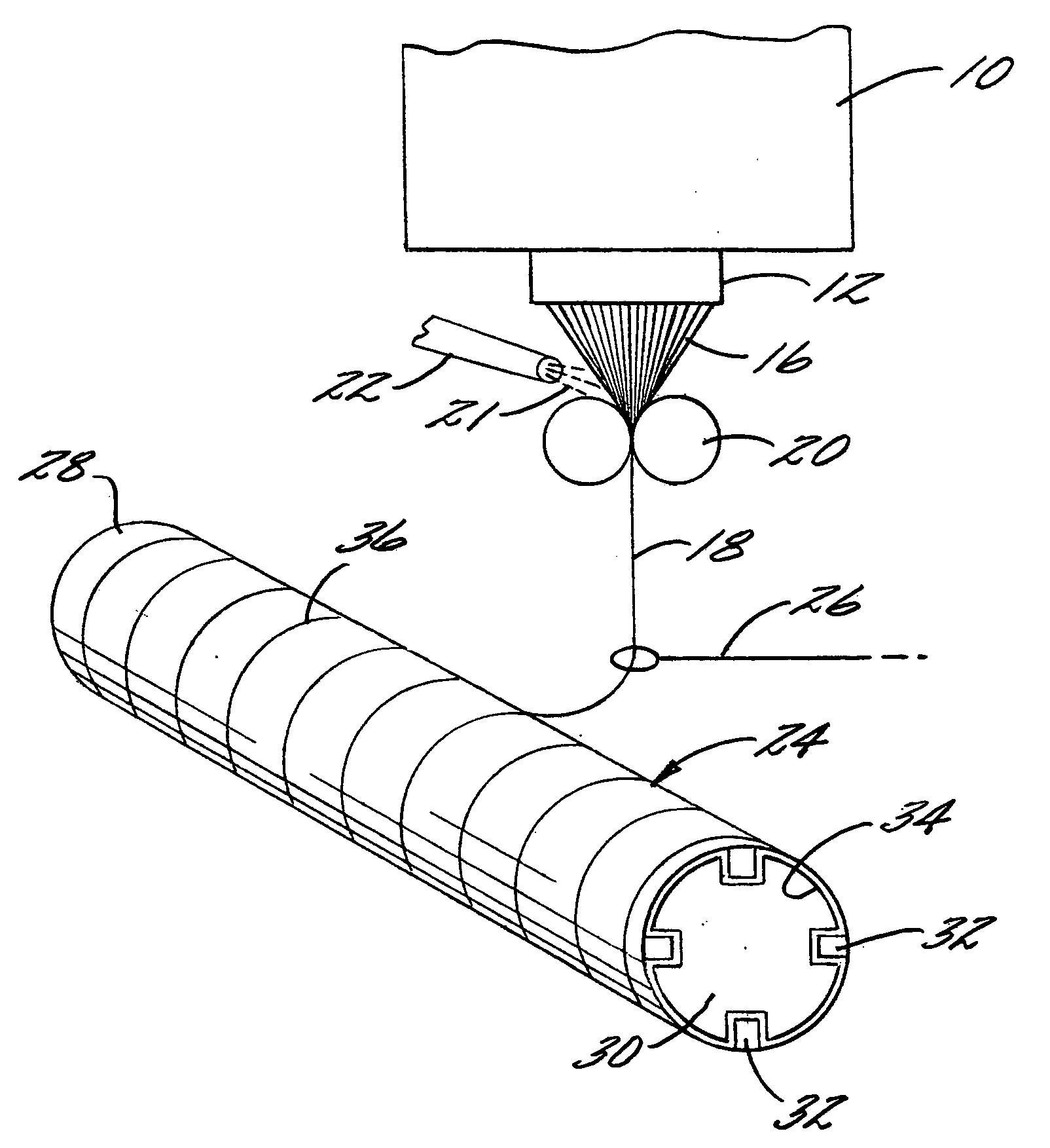

Tubular orthodontic arch wire

InactiveUS7354267B2Decreasing force levelReduce amountArch wiresDental toolsArch wiresTitanium alloy

A length of tubular material of unitary construction is formed into the approximate shape of a human dental arch for use as an orthodontic arch wire. The tubular material is composed of a super-elastic nickel titanium alloy which may also have shape memory. The cross-sectional shape of the arch wire tube can be round, oval, square, or rectangular. The preferred thickness of the tube is preferably 20 percent of its outside diameter and the tube may be perforated to alter its performance.

Owner:VOGT WILLIAM

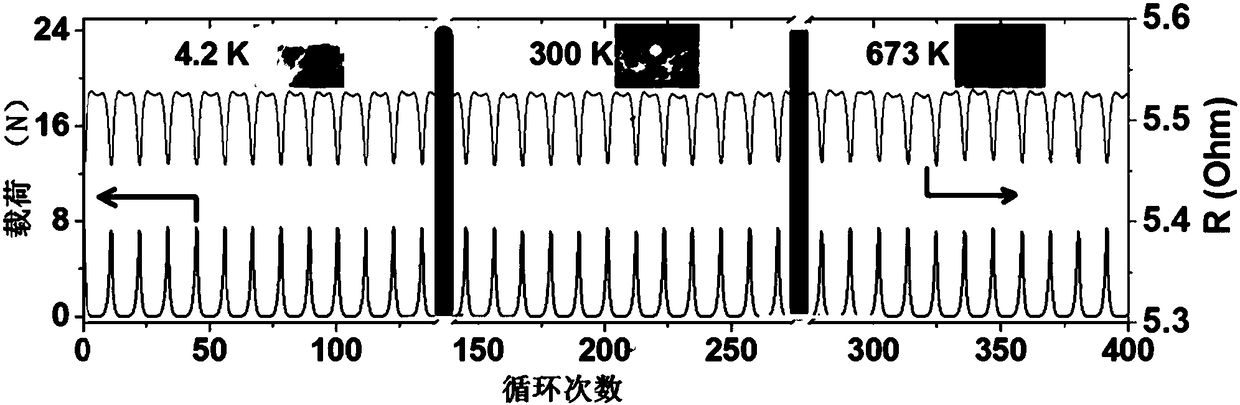

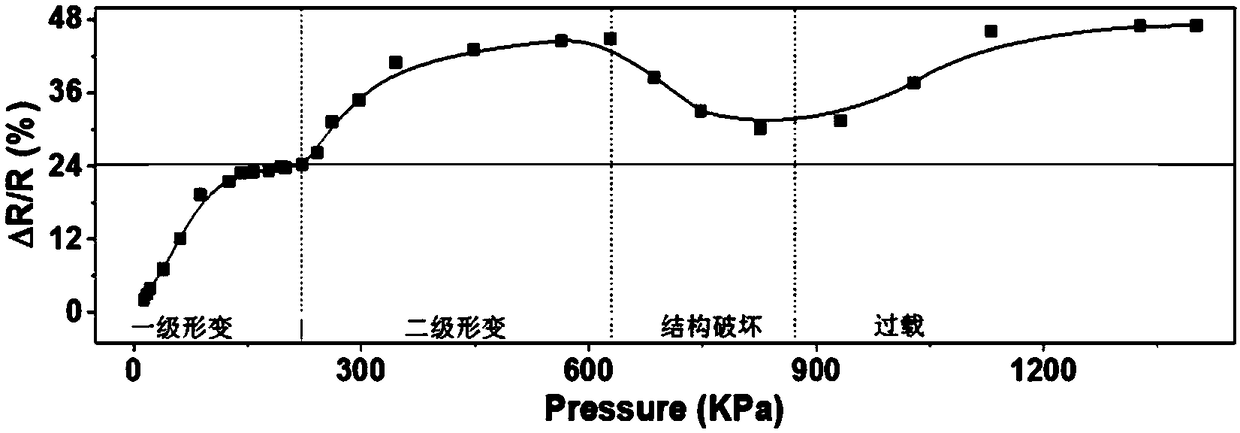

Pressure-sensitive graphene film preparation method

The invention discloses a pressure-sensitive graphene film preparation method. Graphene oxide is subjected to solution film formation, chemical steam reduction, high-temperature sintering and the liketo obtain a graphene film. The graphene film is high in flexibility and free of marks after being repeatedly folded by more than 100 thousands of times and is quick in shape recovery (50ms). The high-flexibility elastic graphene film is resistant to repeated folding of more than 100 thousands of times, the horizontal elastic elongation at break is 12-24%, the elastic vertical compression rate is80-90%, and the electric conductivity is 400-700S / cm. The high-flexibility elastic graphene film is highly sensitive to pressure and can be used as a high-fatigue-resistance pressure sensor.

Owner:ZHEJIANG UNIV

Biodegradable particle and method for producing the same

InactiveUS20090311337A1Reduce intensitySmoothly degradedPowder deliverySurgical adhesivesCatheterGuide tube

The present invention aims to provide a biodegradable particle capable of being molded without an aggregation or cohesion of the particles, capable of being carried or injected without clogging by an aggregation in a micro diameter tube such as of a catheter, needle or syringe mainly used in pharmaceutical and medical applications of which inner diameter is smaller than the particle size or in a blood vessel and capable of being smoothly degraded in a specified period of time so that degraded component can finally be absorbed or discharged in vitro. As means for solving the problem, the present invention provides a biodegradable particle characterized in that a compressive modulus of the particle in water saturated state is 10 MPa or less.

Owner:TORAY IND INC

Method for remedying water-eroded defects on finished surface of engine cylinder block

ActiveCN103192226ANo thermal deformationGuaranteed dimensional accuracyManufacturing technologyEngineering

The invention discloses a method for remedying water-eroded defects on the finished surface of an engine cylinder block and belongs to the technical field of engine cylinder block refabrication. The method includes: polishing the defective surface to expose a cylinder block body; polishing sharp corners or edges on the cylinder block body; removing oil at defective positions; re-polishing; cleaning the defective positions; remedying the defective positions by electric spark ionic microwelding to make the welded positions level to the finished surface of the cylinder block; polishing the welded positions to make the welded positions lower than the finished surface of the cylinder block; remedying the welded positions by pulse cold welding to make the welded positions higher than the finished surface of the cylinder block; and polishing the welded positions to make the welded positions level to the finished surface of the cylinder block. The method effectively guarantees fine bonding of welding material and substrate during welding. The electric spark ionic microwelding is reasonably combined with the pulse cold welding, so that efficiency is increased and the remedied texture is kept dense and non-defective.

Owner:WEICHAI POWER CO LTD

Chromium carbide ceramic thermal-spraying flux-cored wire

InactiveCN102400083AHigh hardnessHigh bonding strengthMolten spray coatingWelding/cutting media/materialsChromium carbideCarbon steel

The invention provides a chromium carbide ceramic thermal-spraying flux-cored wire. The weight percentages of chemical compositions of the flux-cored wire are that 75 to 85 wt% of Cr2C3, 10 to 15 wt% of NiCr, 1 to 3 wt% of La2O3 and 4 to 7 wt% of graphite; and the powder size is minus 120 to plus 80 meshes. The raw materials are put into an agitator to be evenly mixed, a H08 low-carbon steel belt is adopted by a scarfskin, flux-cored wire production equipment is adopted, and the ceramic flux-cored wire of which the outer diameter is F4 to F6 is formed through curliness and extraction. When the flux-cored wire is used, the spraying distance is controlled within a range of 80 to 120mm and the coating thickness is 0.1 to 0.3mm. The flux-cored wire has the advantages that the cost is low, a large bonding strength reaching 15 to 20MPa exists between a sprayed coating and a low-carbon steel substrate, the sprayed coating has higher hardness reaching 600 to 1000HV within a certain spraying distance range and has higher wear resistance.

Owner:YANSHAN UNIV

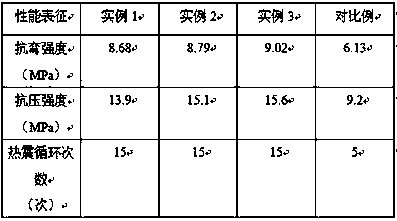

Method for preparing composite foam ceramic

InactiveCN109734476AInhibit aging phenomenonImprove antioxidant capacityCeramicwareSlurryMechanical property

The invention relates to a preparation method of a composite foam ceramic, and belongs to the technical field of materials. According to the invention, zirconium oxide and aluminum oxide are used as raw materials to prepare the composite foam ceramic, and the aluminum oxide is added to generate obvious crack bifurcation and bending to lengthen a crack path, so that the phase change effect of the zirconium oxide is strengthened; and meanwhile, by thermal mismatch of the aluminum oxide and the zirconium oxide, the aluminum oxide is compressed in a matrix, a semi-coherent interface and carbonitriding structure is not easily formed at a crystal boundary, and quite high mechanical strength of the material is maintained. A composite foam ceramic is prepared by taking the polyurethane foam as a foam matrix, the polyurethane foam has an open network structure, it can be ensured that ceramic slurry freely permeates and mutually adheres, the polyurethane foam modified by a surfactant has certainhydrophilicity, the mechanical property of a final product is improved, by the sufficient resilience of the final product, it can be ensured that the shape can be quickly restored after excess slurryis extruded, and the polyurethane foam can be completely gasified without residues during high-temperature sintering.

Owner:常州兆威不锈钢有限公司

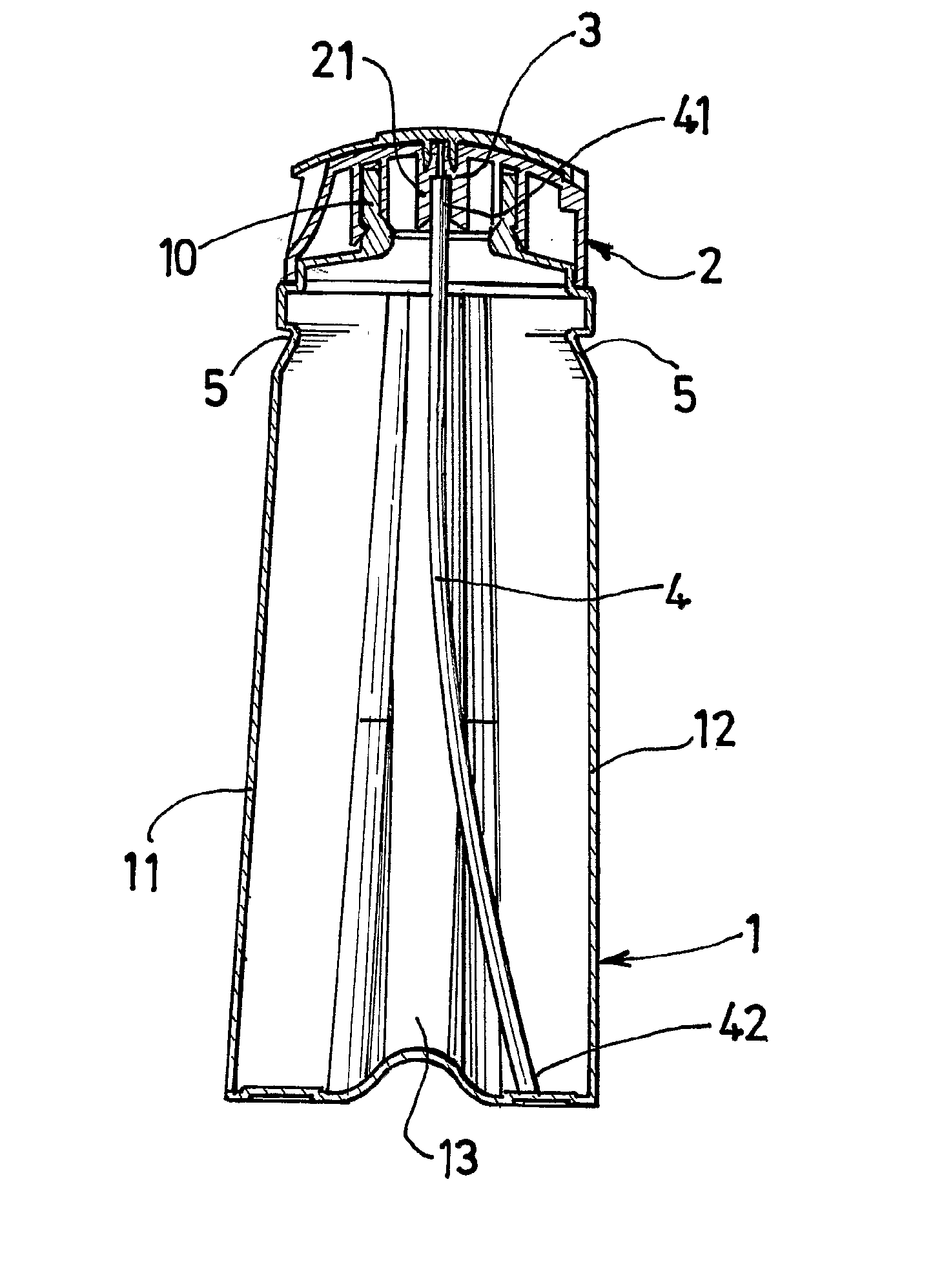

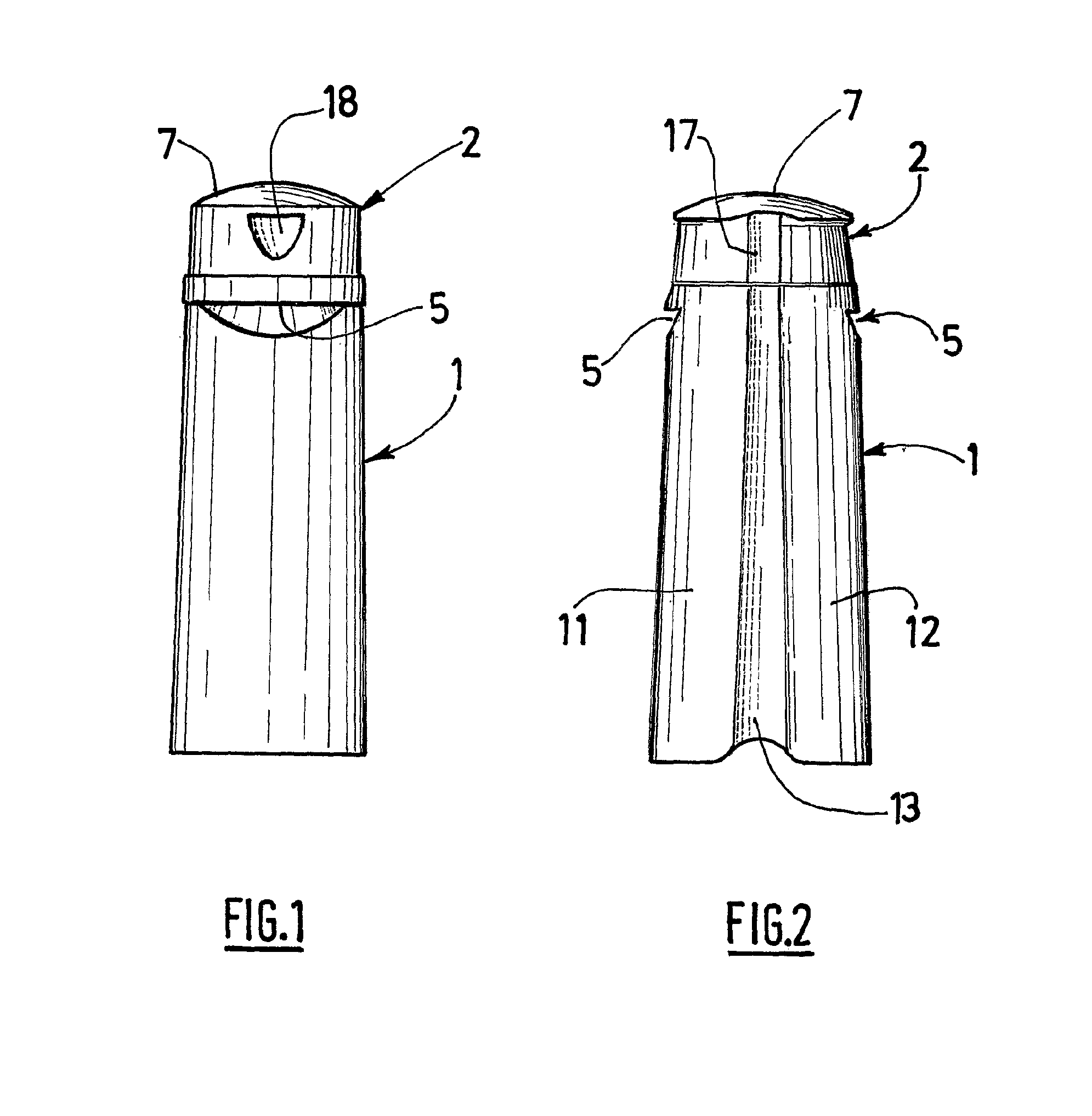

Device For Packaging And Delivering A Liquid Product

InactiveUS20080011783A1Promote recoveryEven air distributionPortable flexible containersFlexible containersLiquid productEngineering

The invention concerns a device for packaging and delivering a liquid product, comprising a container deformable by pressure applied on its side walls, wherein said liquid to be delivered is stored, said container being closed by a head for dispensing the liquid product which is traversed by an outlet for the liquid product. The device also comprises a liquid drawing tube whereof one end is fixed proximate the outlet for the liquid, the tube being of such length that its other end is proximate the base of the container. The wall of the container comprises cavities partly delimiting the outline of the dispensing head. The invention is characterized in that at least one passage is provided proximate the dispensing head to ensure an air intake into the container after the liquid is dispensed, so as to allow the container to recover its initial shape by replacing by volume the dose of liquid delivered.

Owner:REXAM DISPENSING SYST S

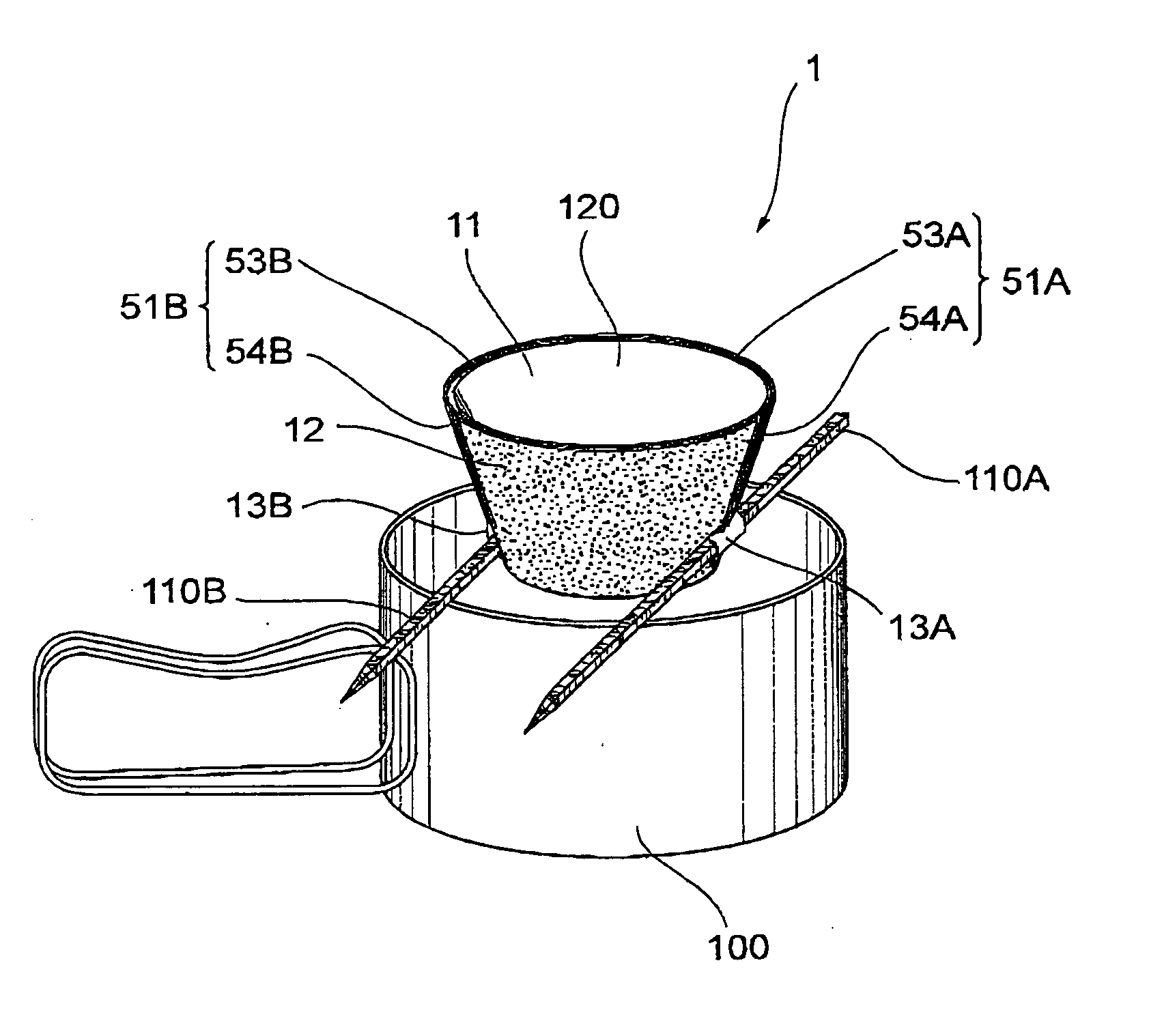

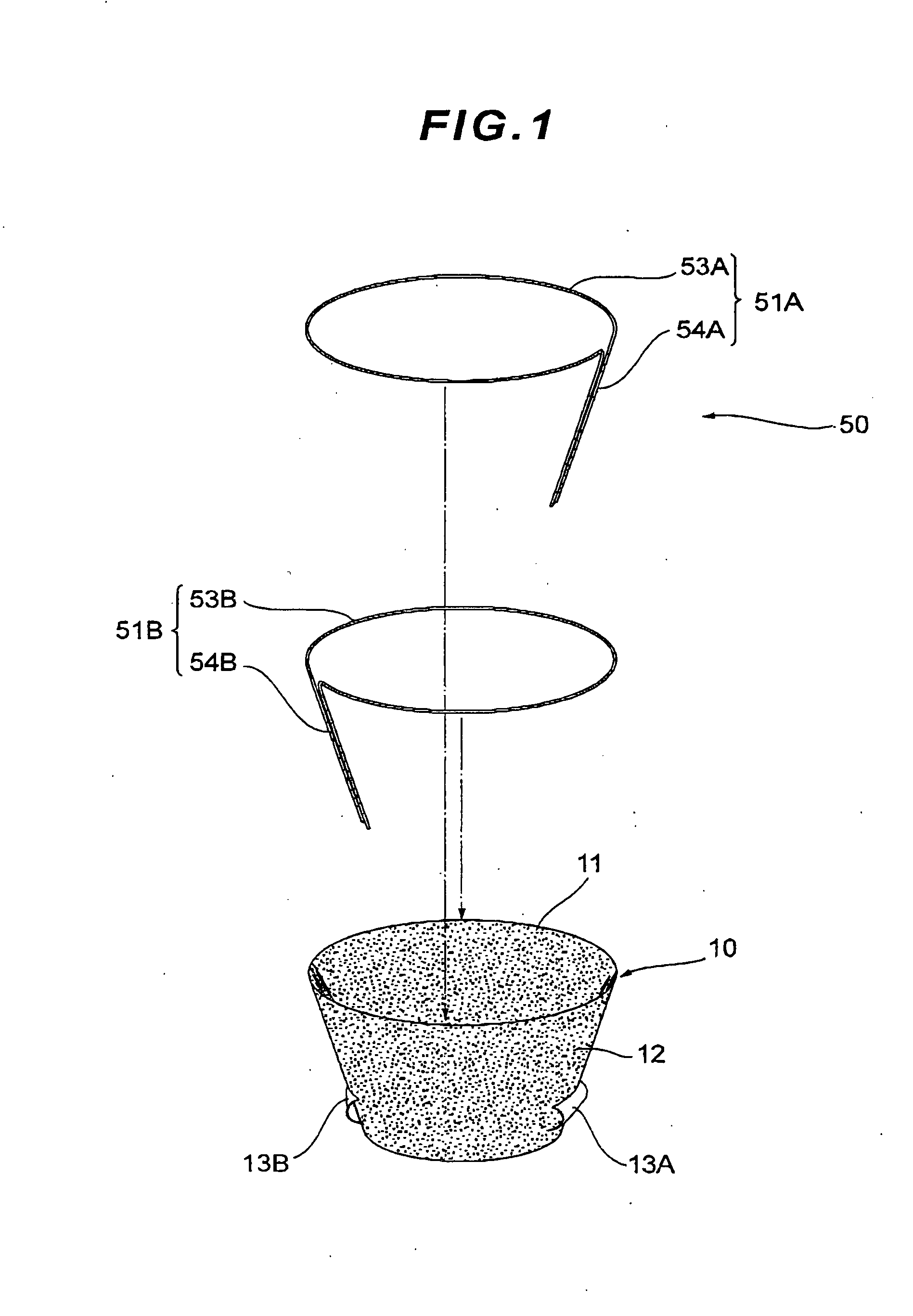

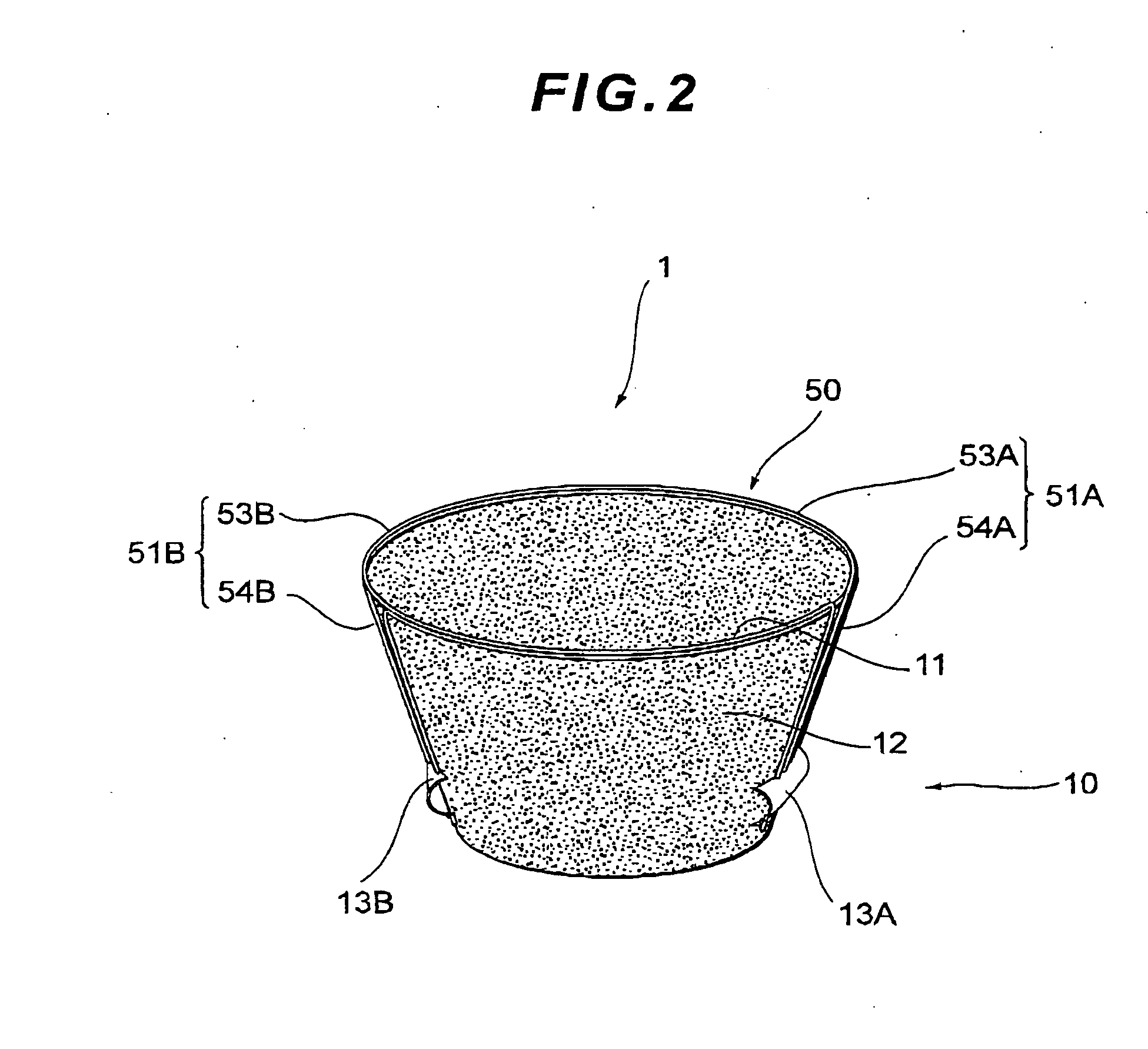

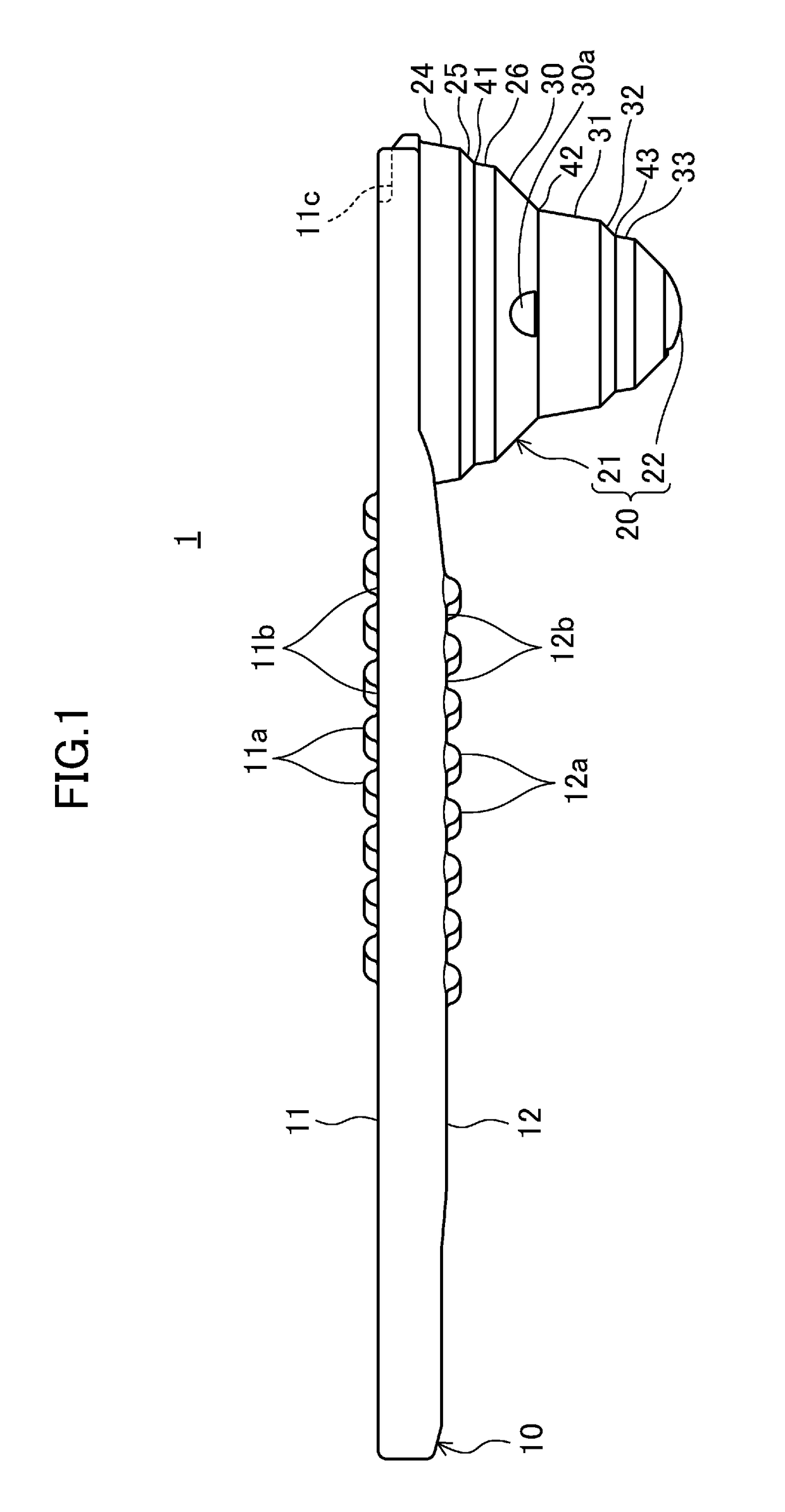

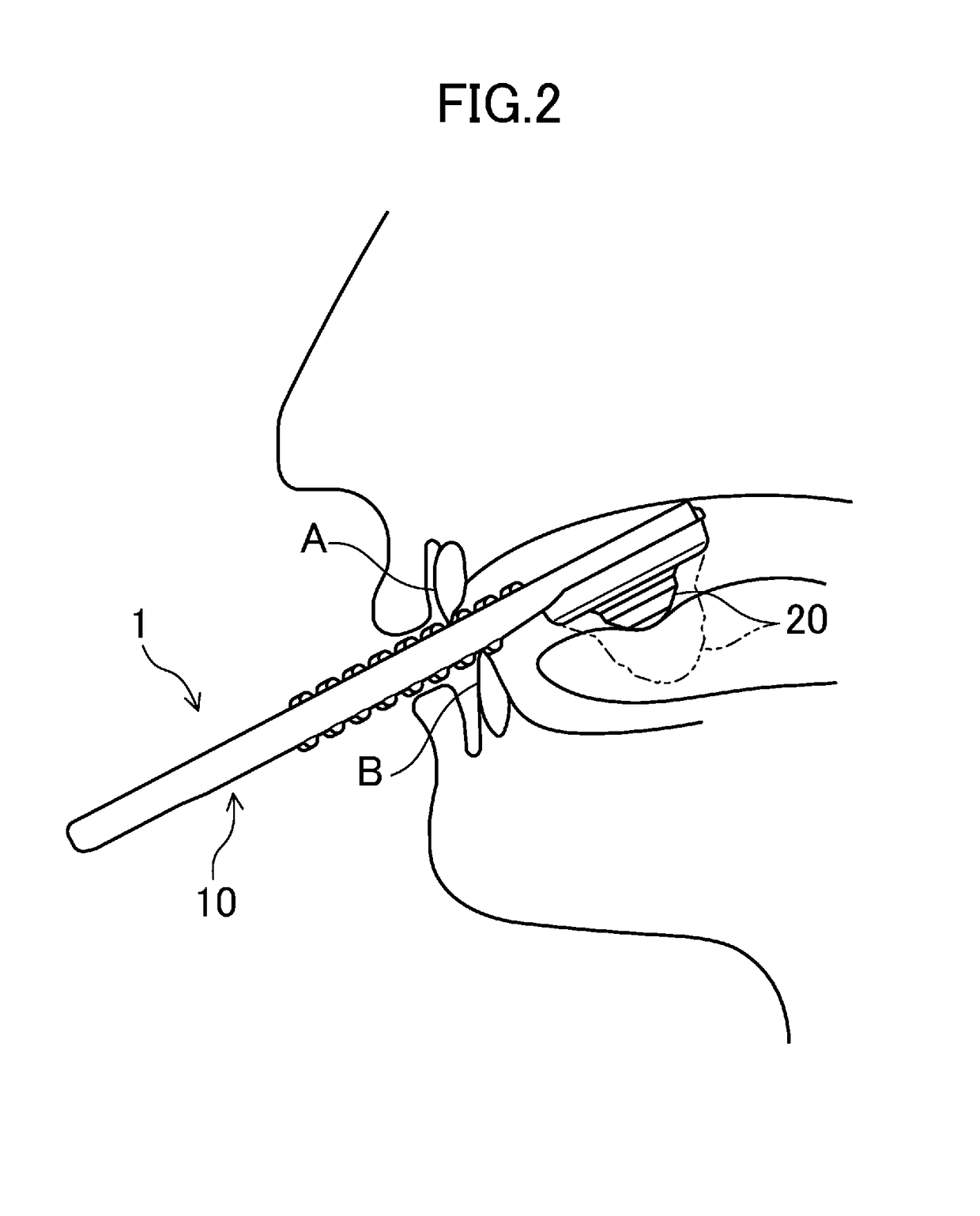

Dripper

Provided is a dripper that is light-weight and deformable into an arbitrary shape to be stored compactly and that enables coffee extraction irrespective of the existence of a filter. Provided is a dripper 1 for extracting coffee, including: a filter portion 10 that is formed from fabric with permeability and that includes an opening 11 through which coffee powder can be added and a receiving portion 12 that receives the coffee powder added through the opening 11; and a frame 50 that is made of an super-elastic alloy and can define the respective shapes of the opening 11 and the receiving portion 12 in the filter portion 10.

Owner:MONT BELL

Tubular orthodontic arch wire

A length of tubular material of unitary construction is formed into the approximate shape of a human dental arch for use as an orthodontic arch wire. The tubular material is composed of a super-elastic nickel titanium alloy which may also have shape memory. The cross-sectional shape of the arch wire tube can be round, oval, square, or rectangular. The preferred thickness of the tube is preferably 20 percent of its outside diameter and the tube may be perforated to alter its performance.

Owner:VOGT WILLIAM

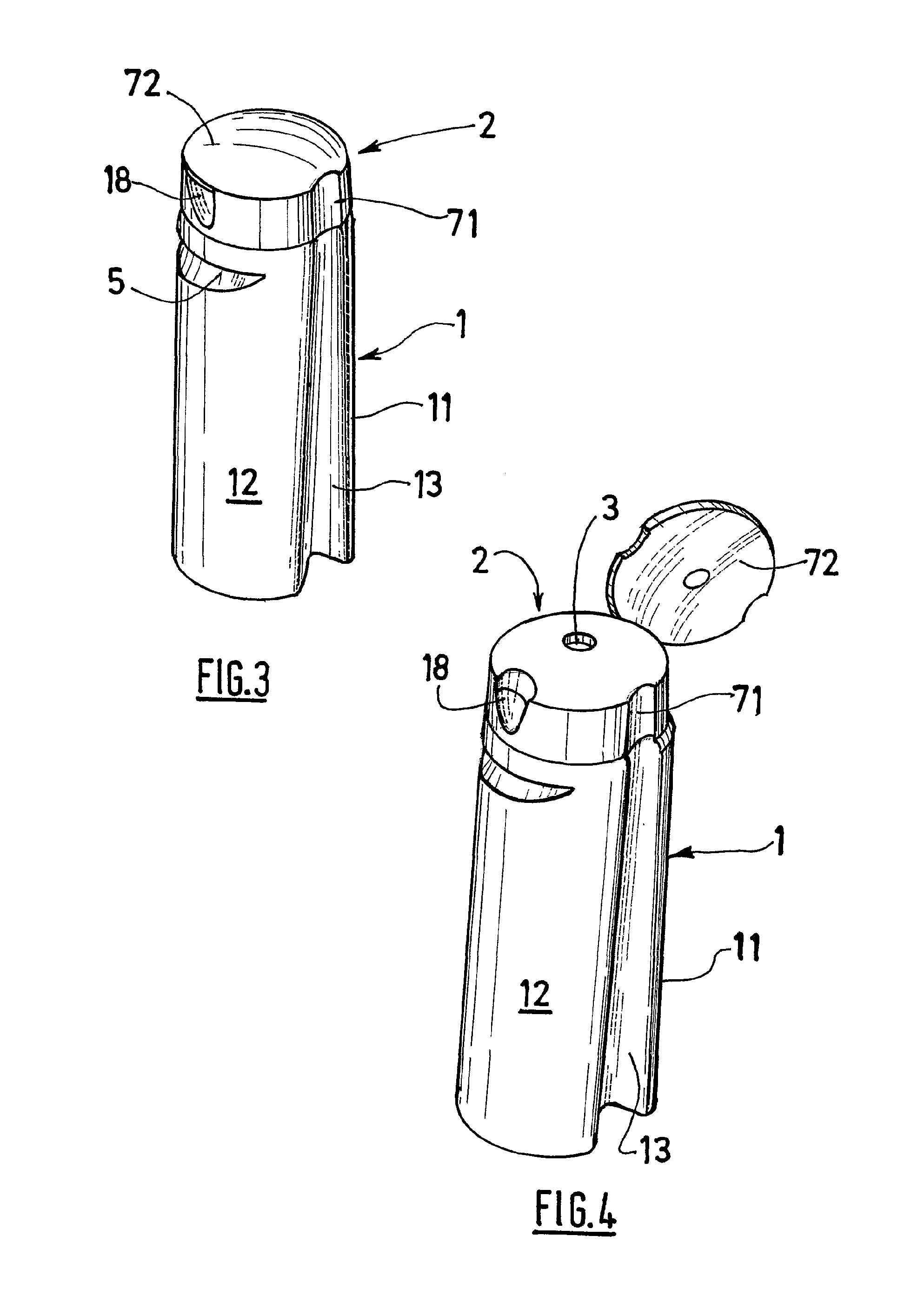

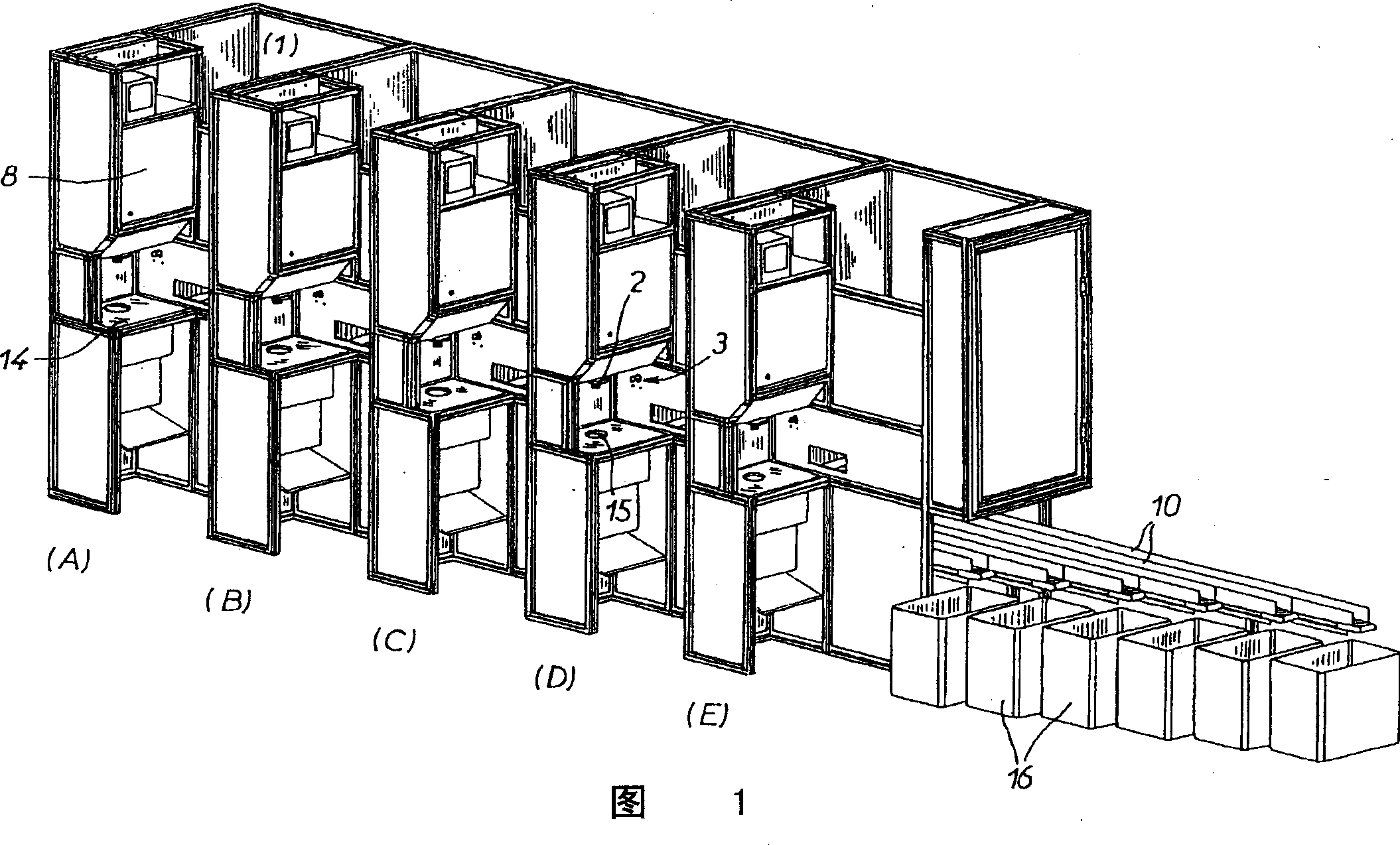

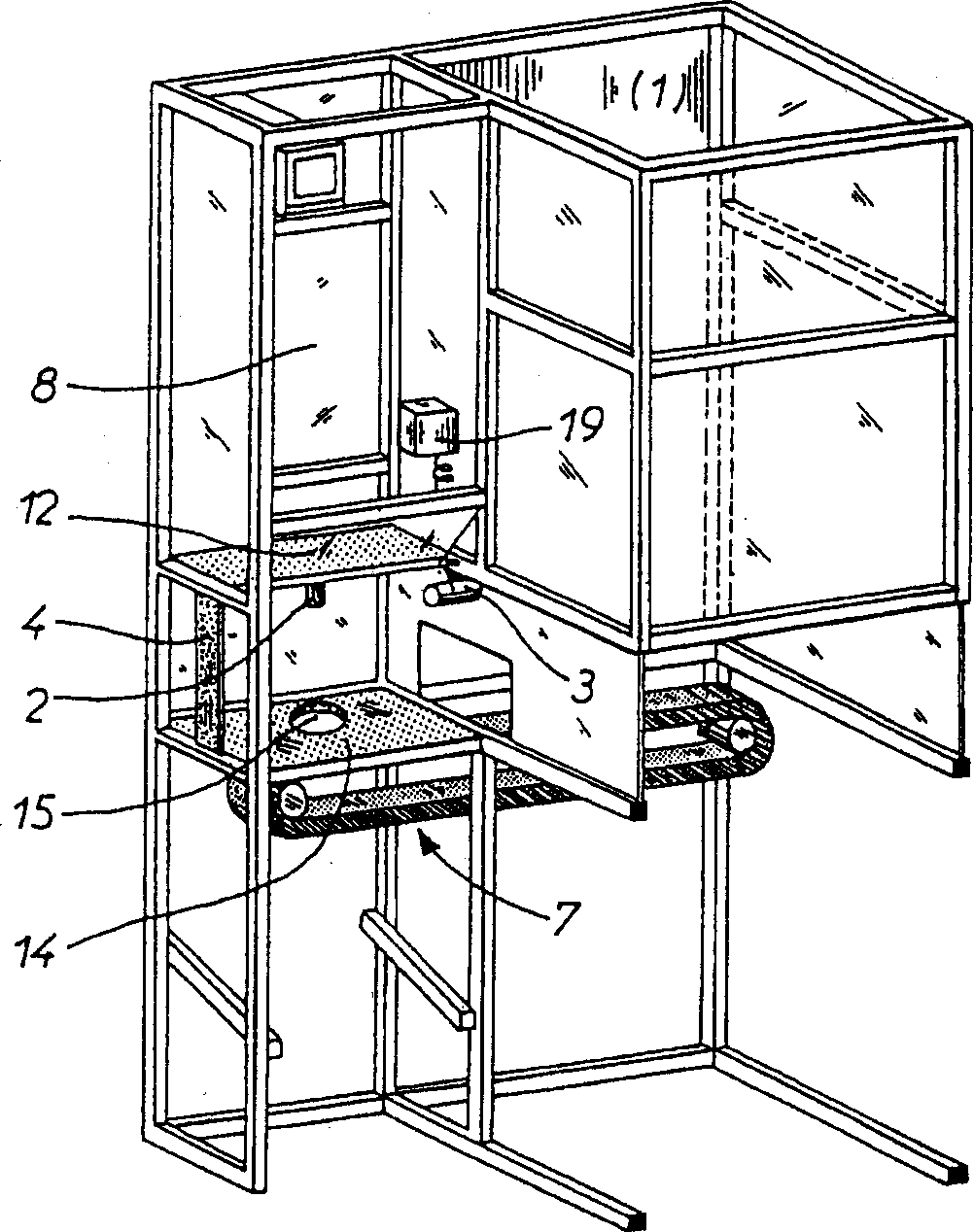

Sorting disposable gloves according to size

InactiveCN1353631AComprehensive collectionEliminate wrinklesDiagnosticsGlovesWorkstationConveyor belt

The invention concerns a machine comprising a plurality of workstations each provided with a receptacle (1) containing gloves to be sorted, a programmed automaton (8), a glove holder (2), a matrix code reader (3), a conveyor belt (7) and a rack dispensing (6) the gloves to individual band conveyors. The invention is useful for treating gloves used in environments with controlled atmosphere.

Owner:R TECH MONACO

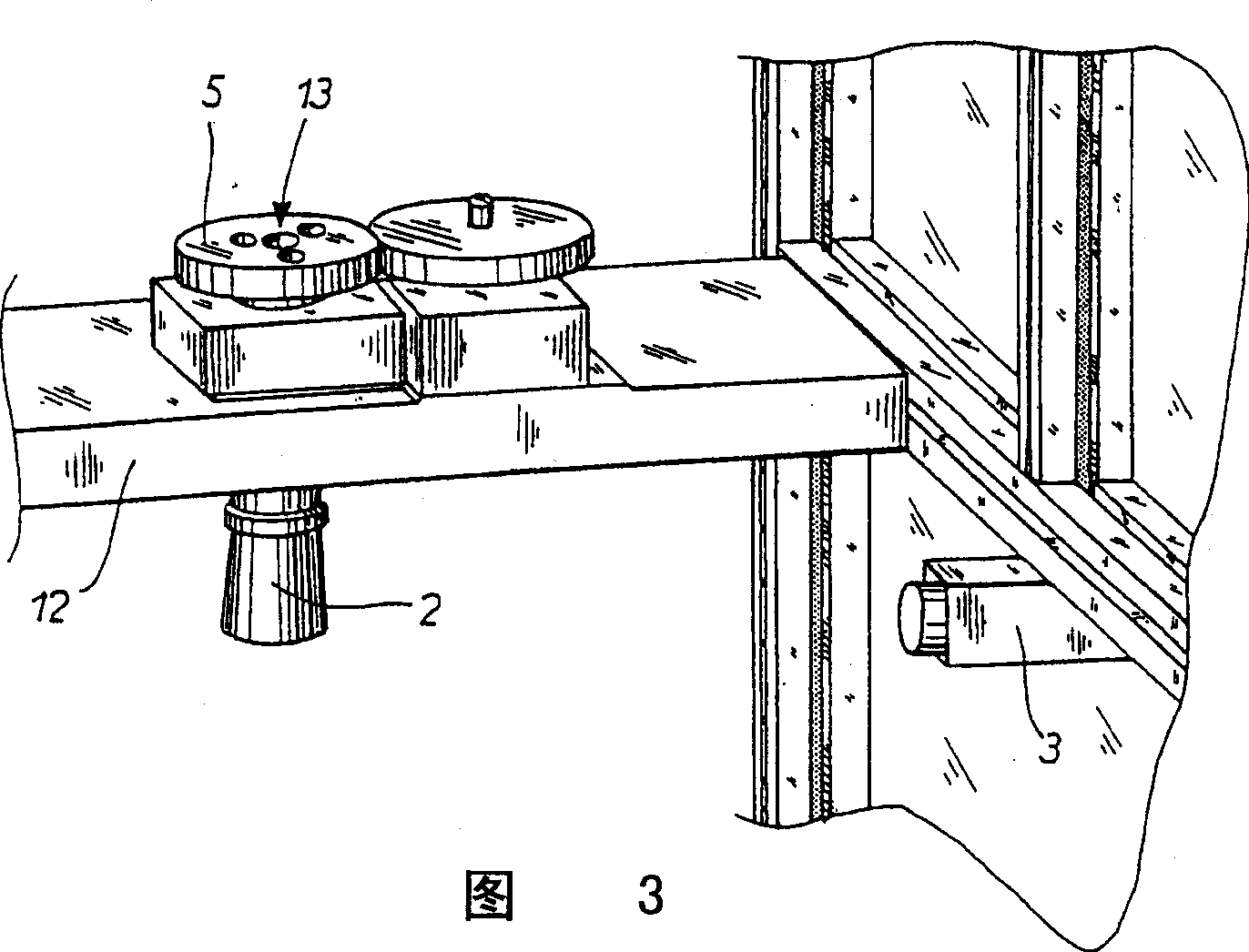

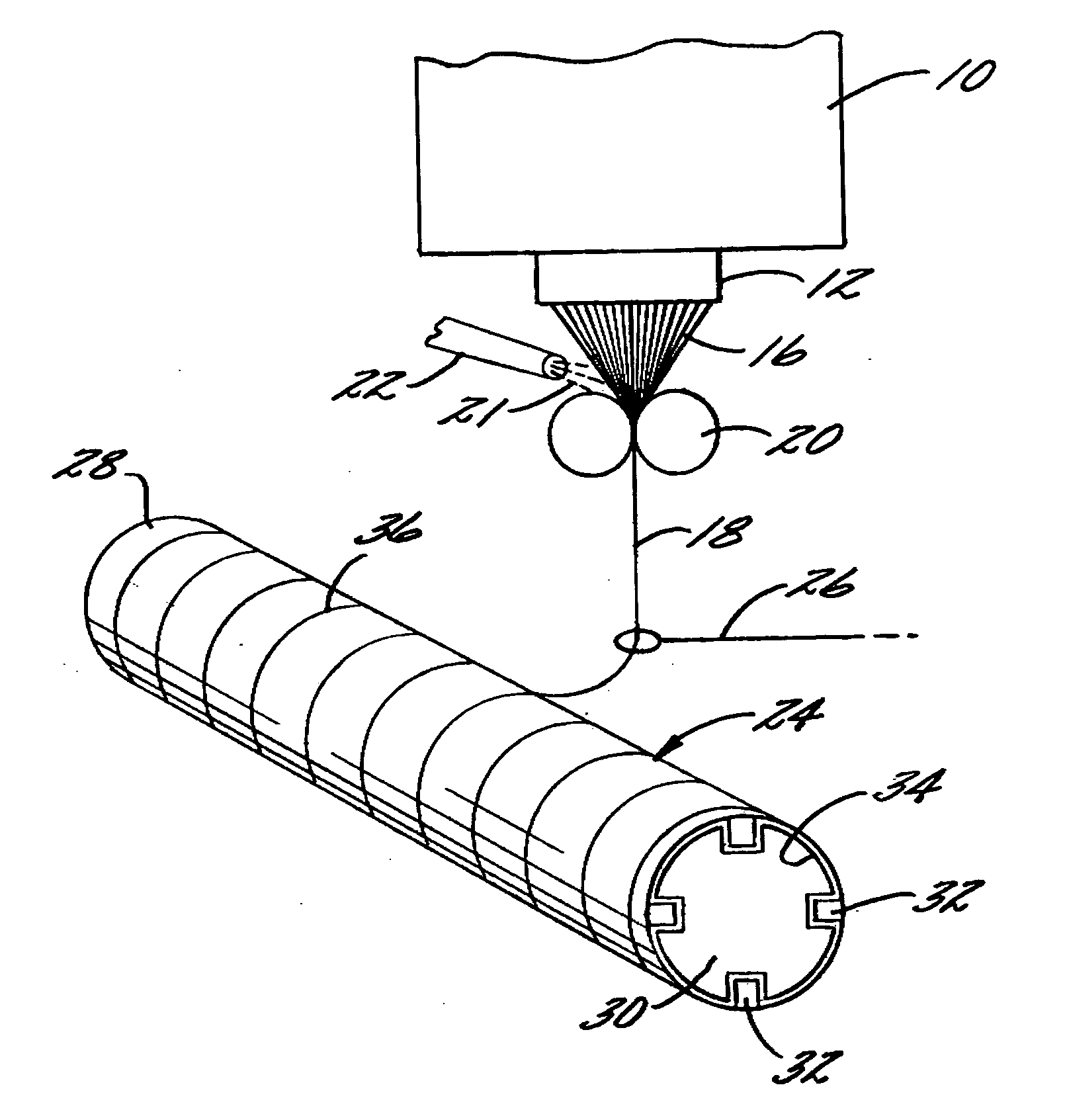

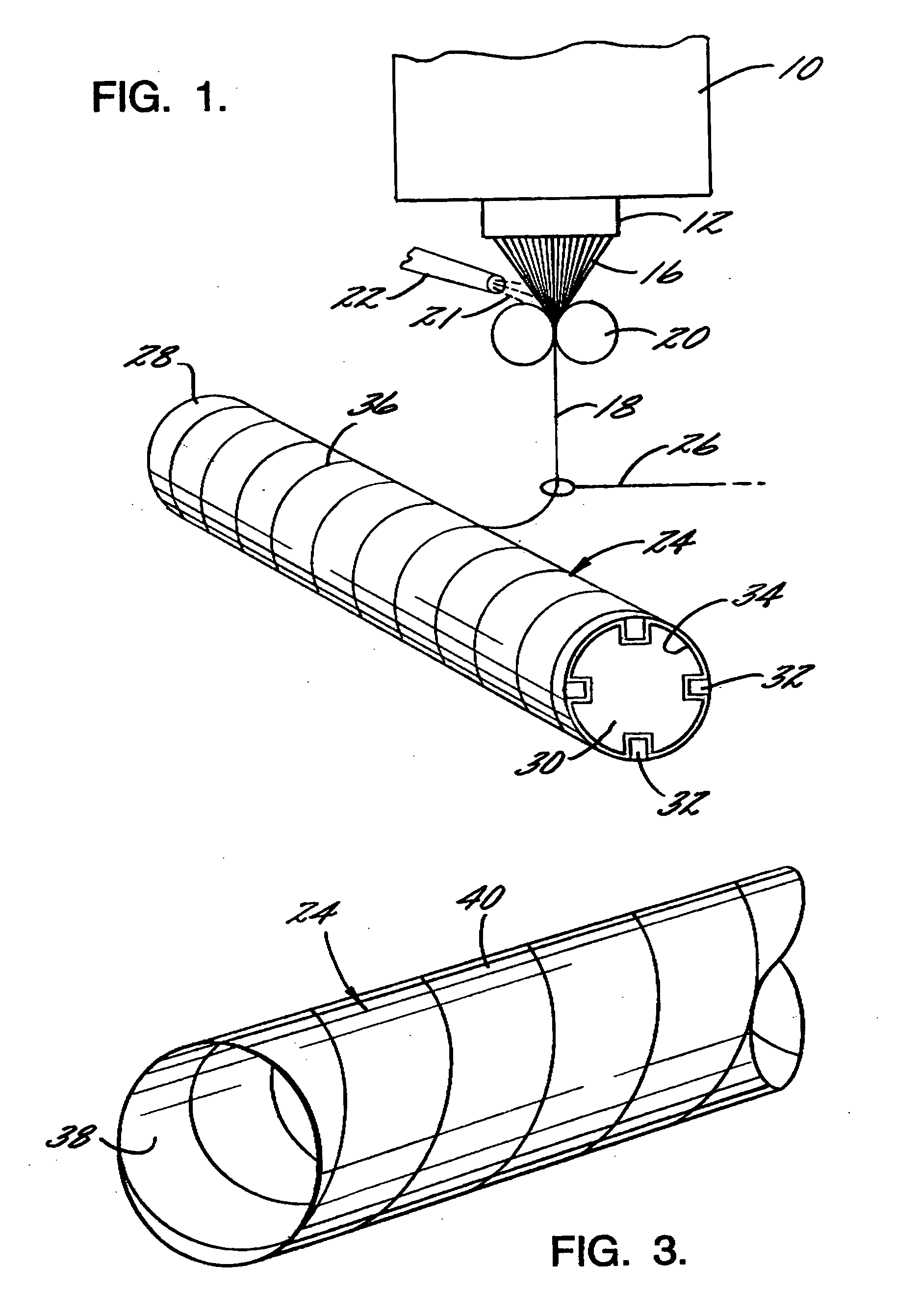

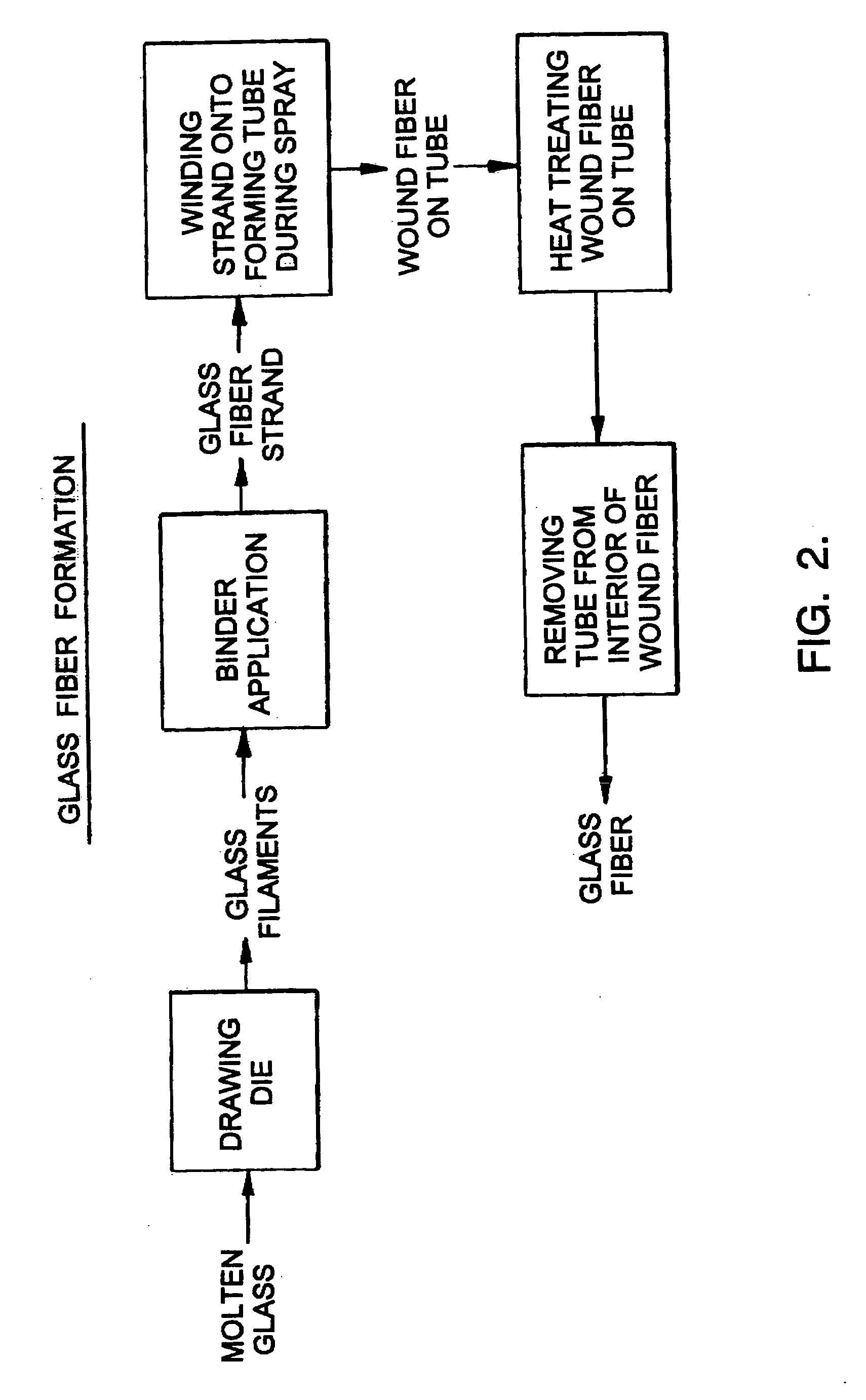

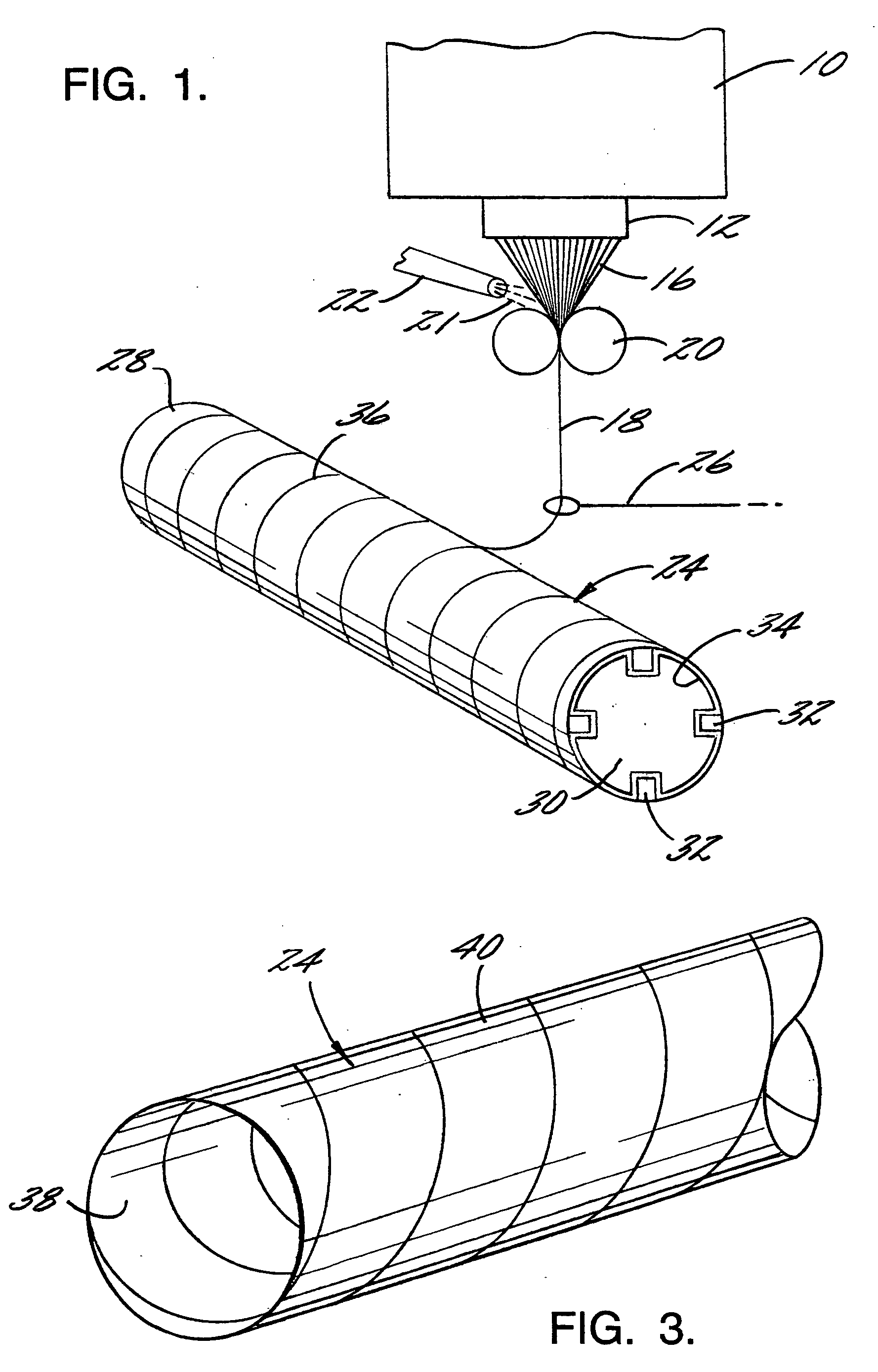

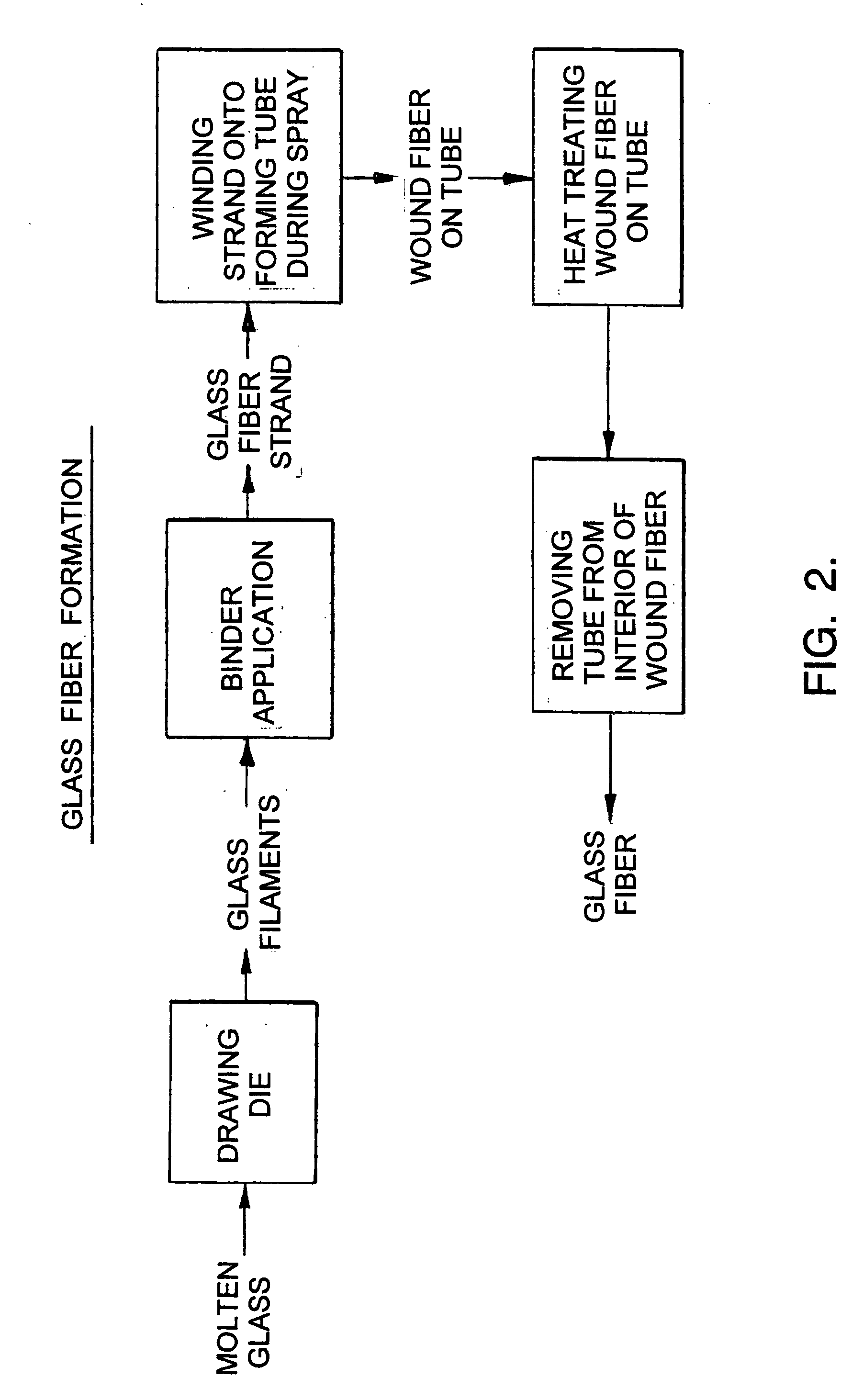

Crimped forming tubes

InactiveUS20060026997A1Cost-effectiveImprove moisture resistanceGlass making apparatusRotary drum furnacesGlass fiberMetallic materials

The invention is a collapsible tube having excellent moisture and temperature-resistance. The collapsible tube, such as a spirally wound or convolute paperboard forming tube, includes moisture-resistant and temperature-resistant layers at its inside and outside surfaces. These moisture-resistant and temperature-resistant layers may be polymeric or metallic materials, particularly metal foil layers. The collapsible tube is especially useful as a reusable forming tube in the manufacture of glass fibers.

Owner:CARAUSTAR INDS

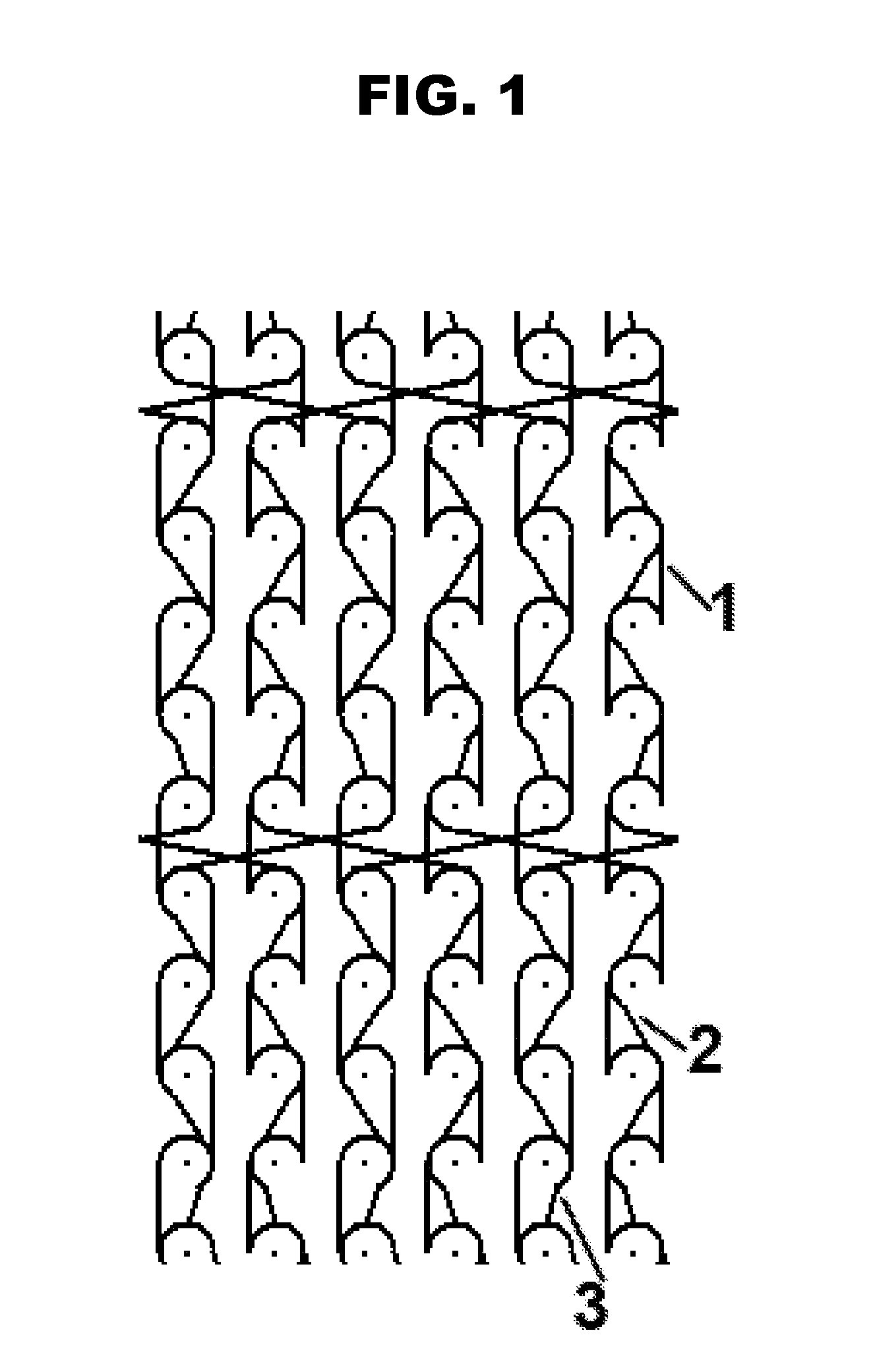

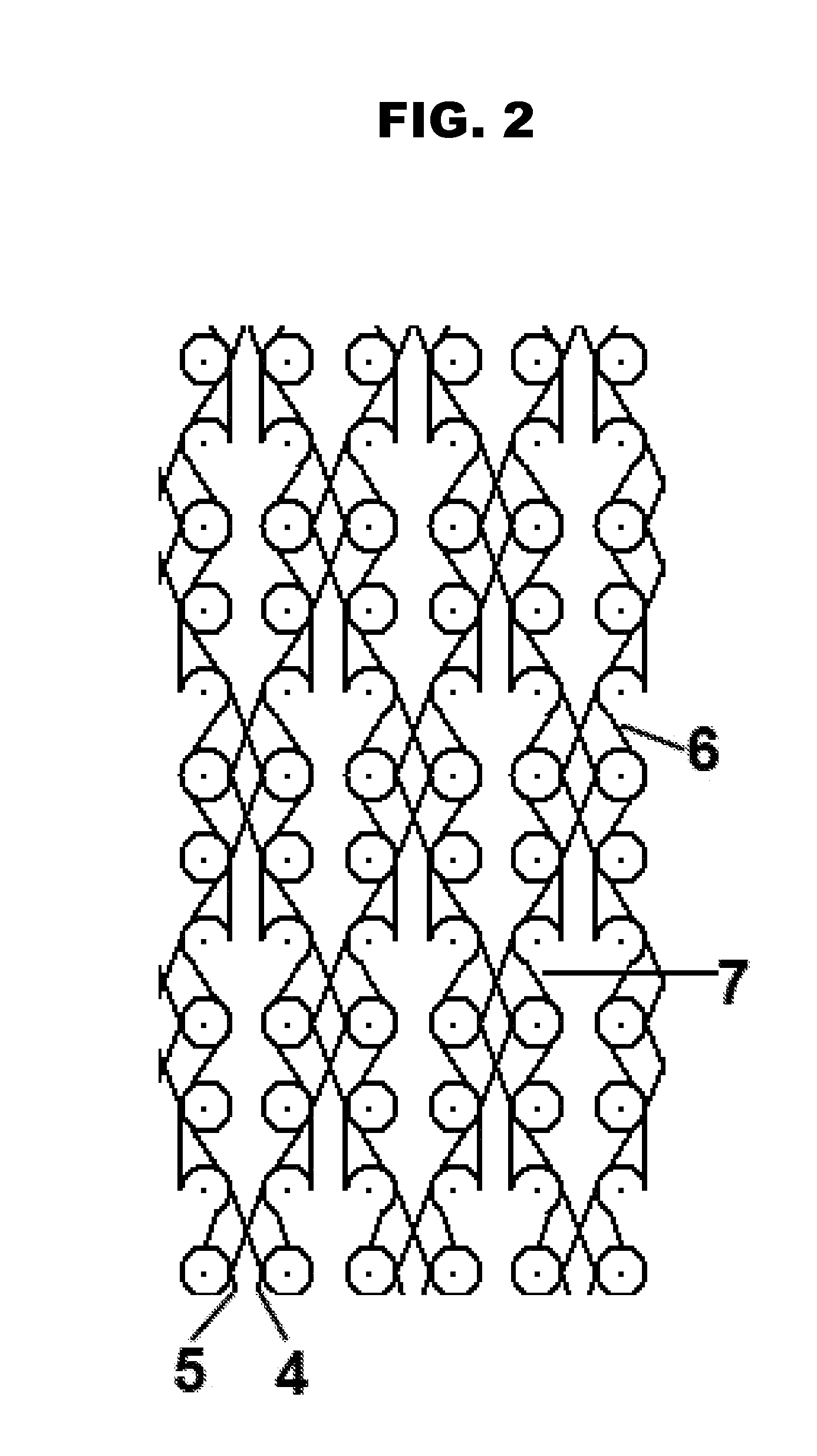

Laminated all elastomeric fabric and bar made thereof

Owner:BEST PACIFIC TEXTILE

Artificial hair fiber having shape memory and shape restoration function, artificial hair fiber having excellent flame resistance, and artificial hair fiber having low gloss appearance

ActiveUS20160255894A1Superior characteristicImprove securityWigsArtifical filament manufactureElastic modulusPolyamide

Artificial hair fiber having shape memory and shape restoration function, artificial hair fiber having excellent flame resistance, and artificial hair fiber having low gloss appearance are provided.Provided is an artificial hair fiber including a resin composition including at least one polyamide, the artificial hair fiber satisfying at least one of constitutions (1) to (3): (1) the fiber has a modulus of elasticity of 2400 to 3000 N / mm2; (2) the polyamide has a weight average molecular weight Mw of 6.5×104 to 15×104 and the fiber has a modulus of elasticity of 500 to 15000 N / mm2; (3) the fiber has a modulus of elasticity of 500 to 15000 N / mm2 and the resin composition contains 5 to 20 parts by mass of fine particles with respect to 100 parts by mass of the polyamide.

Owner:DENKA CO LTD

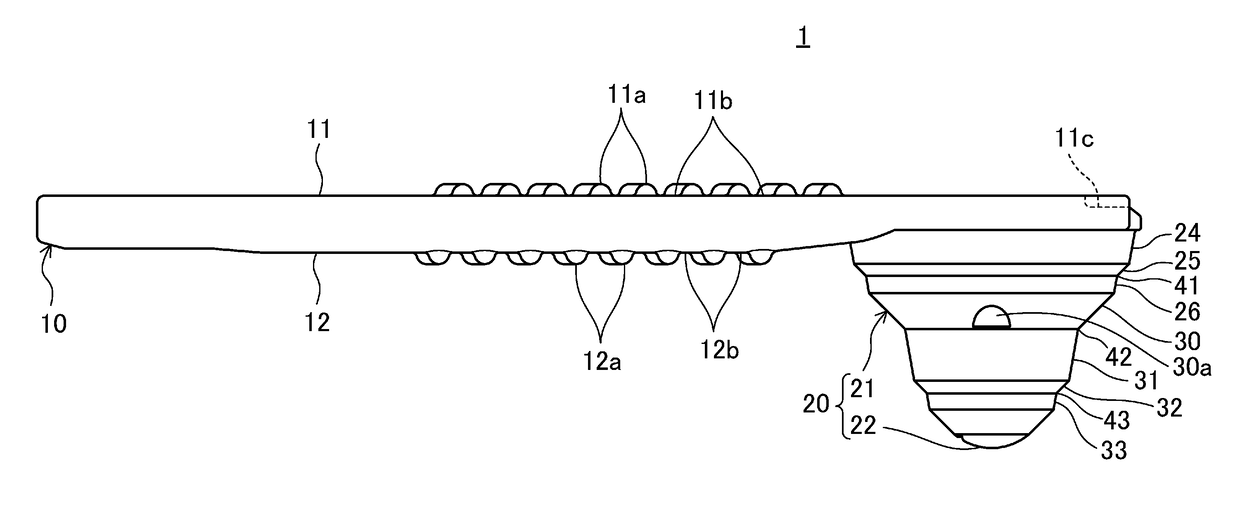

Oral cavity function training tool

ActiveUS10029144B2Increase motivationFunction increaseResilient force resistorsVibration massageOral functionIntermediate region

An exercise tool 1 for improving oral function inserted and used in an oral cavity includes: a base 10 inserted in the oral cavity; and a hollow bulge 20 which is made of an elastic body and protrudes from the base 10. Level difference portions 41-43 and 51-53 are provided in a vertically intermediate region of at least one of an outer surface and an inner surface of the bulge 20.

Owner:JMS CO LTD

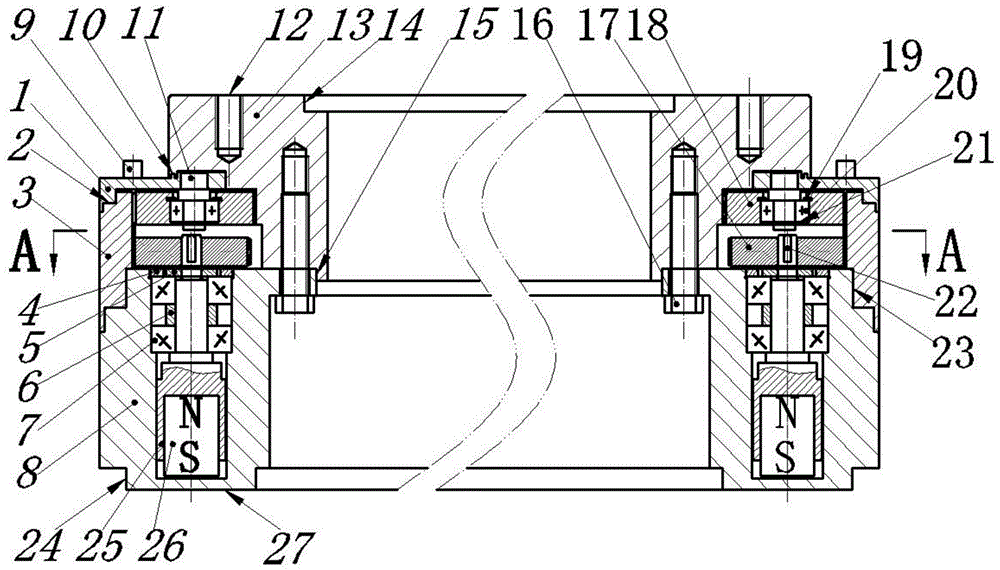

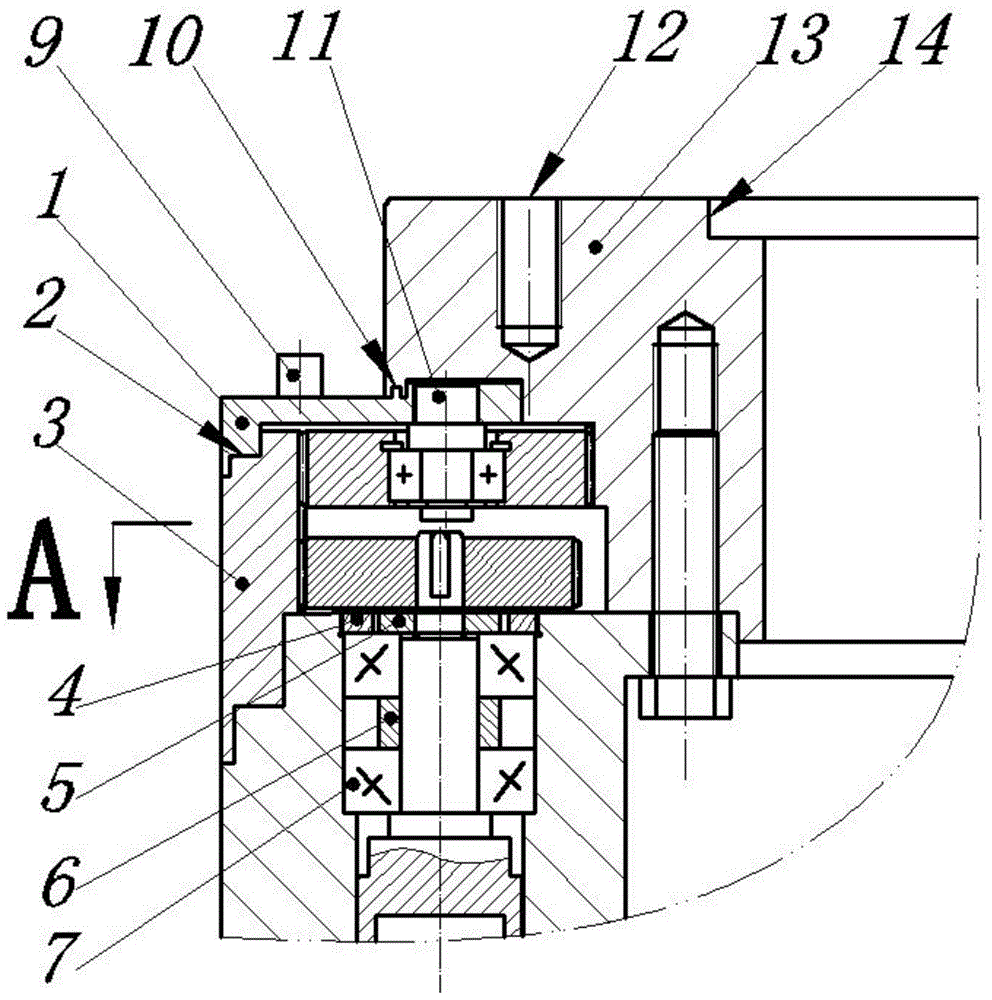

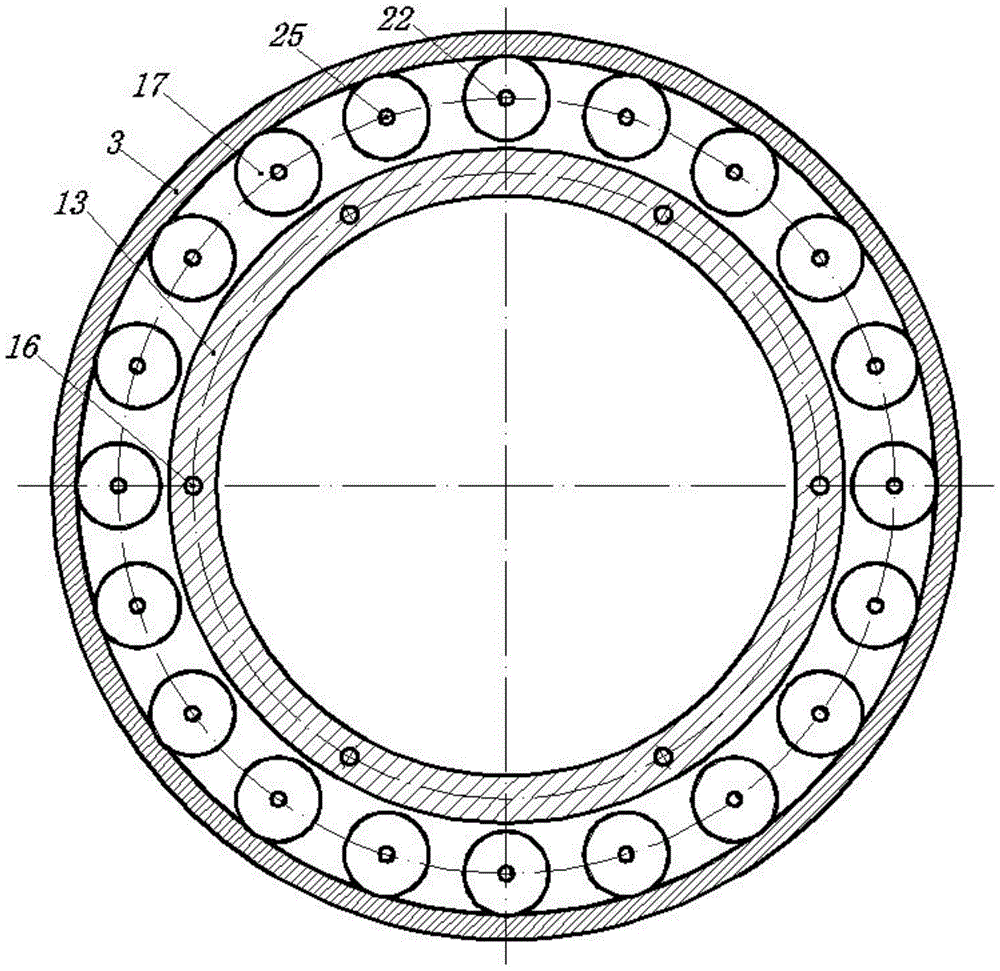

Self-adjustment magnetorheological flexible polishing abrasive wheel and polishing method thereof

The invention relates to a self-adjustment magnetorheological flexible polishing abrasive wheel and a polishing method thereof. The self-adjustment magnetorheological flexible polishing abrasive wheel comprises a fixing ring, an inner gear, an abrasive wheel ring, a gear shaft, a synchronous rotation gear, a planetary gear, a rotary shaft and a cylinder permanent magnet. The rotary shaft is arranged in the abrasive wheel ring. The cylinder permanent magnet is arranged in a through hole formed in the lower end of the rotary shaft. The inner gear is arranged on the upper portion of the abrasive wheel ring. The fixing ring is arranged at the top of the inner gear and fixed to a machine tool. An abrasive wheel connector is arranged at the top of the abrasive wheel ring and the top of the fixing ring. The abrasive wheel connector is connected with the abrasive wheel ring. An outer gear is arranged on the abrasive wheel connector. The gear shaft is arranged on the abrasive wheel connector. The planetary gear is arranged on the gear shaft. The synchronous rotation gear is arranged at the upper end of the rotary shaft. The planetary gear is engaged with the outer gear arranged on the abrasive wheel connector. The synchronous rotation gear and the planetary gear are engaged with the inner gear. According to the self-adjustment magnetorheological flexible polishing abrasive wheel and the polishing method thereof, replacing and self-sharpening of abrasive materials and real-time recovery of the shape of an abrasive wheel block are achieved, and the self-adjustment magnetorheological flexible polishing abrasive wheel and the polishing method thereof are suitable for efficient, super-smooth and uniform grinding and polishing of planes of photoelectronic / microelectronic substrates and optical elements.

Owner:GUANGDONG UNIV OF TECH

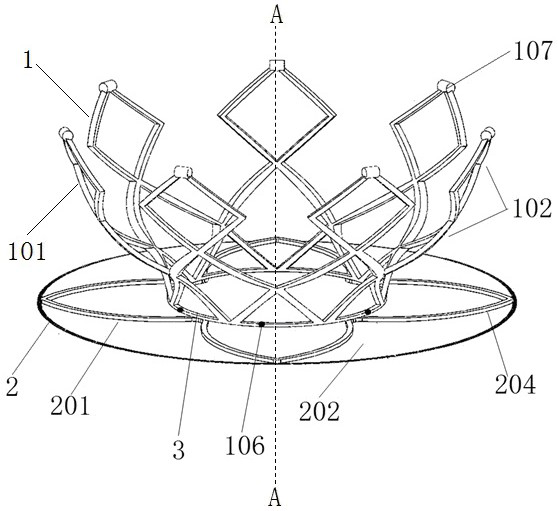

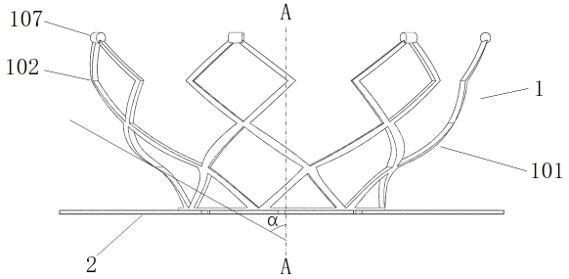

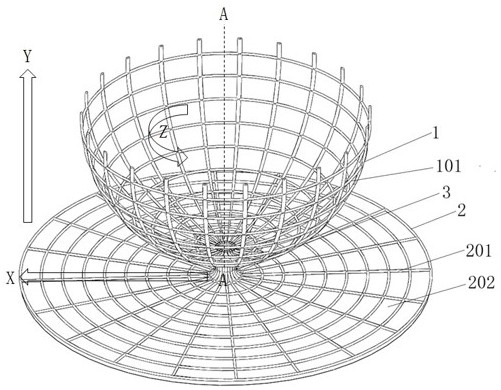

Aneurysm plugging device

The invention relates to an aneurysm plugging device, which comprises a supporting part and a plugging part. The supporting part comprises a supporting frame, and the diameter of the bottom end of the supporting frame is smaller than the maximum diameter of the supporting frame; the plugging part comprises a framework, and the framework is fixed to the bottom end of the supporting frame. Compared with an existing spring ring packing method, the blood can be immediately prevented from entering the aneurysm, the effects of improving hemodynamic force at the aneurysm neck and promoting aneurysm healing are achieved, and treatment of ruptured aneurysm is particularly facilitated. Compared with an existing dense net stent or covered stent intervention method, the method only aims at covering the arterial aneurysm neck opening, the blood flow of collateral vessels is not affected, and the problem of local ischemia caused by the dense net stent or covered stent intervention method is solved.

Owner:MICROPORT NEUROTECH SHANGHAI

Method for remedying water-eroded defects on surface of engine cylinder block

The invention discloses a method for remedying water-eroded defects on the surface of an engine cylinder block and belongs to the technical field of engine cylinder refabrication. The method includes: polishing the defective surface to expose a cylinder block body; polishing sharp corners or edges of the cylinder block body; removing oil at defective positions; re-polishing; cleaning the defective positions; remedying the defective positions by electric spark ionic microwelding to make the welded positions higher than the surface of the cylinder block; and polishing the welded positions to make the welded positions level to the surface of the cylinder block. The method effectively guarantees fine bonding of welding material and the cylinder block body during welding. The cylinder block body is not heated, deformed or undercut, and the welding material is metallurgically combined with the cylinder block body under fine intensity. The shape and precision of the defective positions are restored fully, original properties of a workpiece are restored, and the water-eroded defects on the surface of the engine cylinder block are remedied.

Owner:WEICHAI POWER CO LTD

Blood vessel tail artifact removal method and system for blood flow signal intensity layered filtering

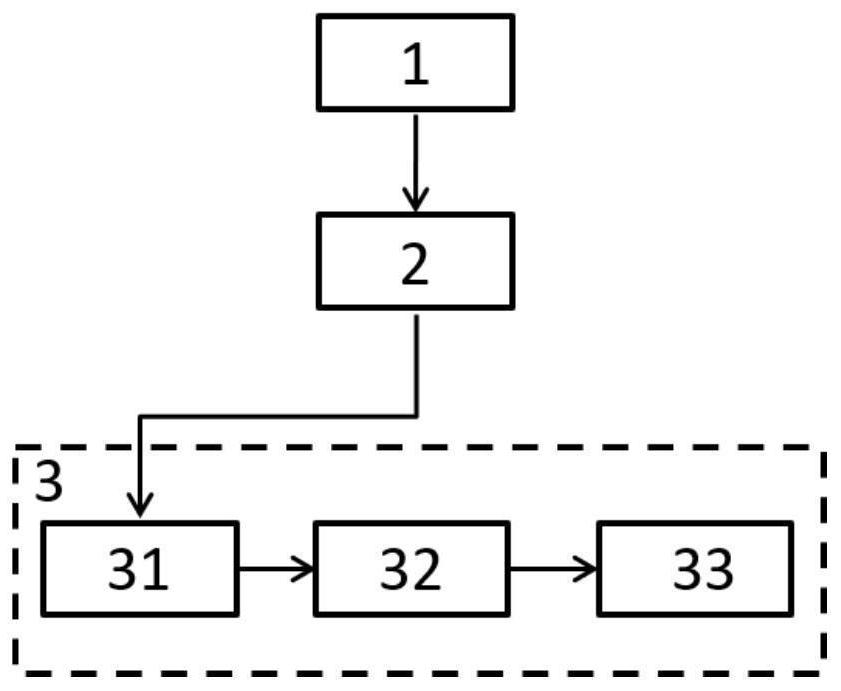

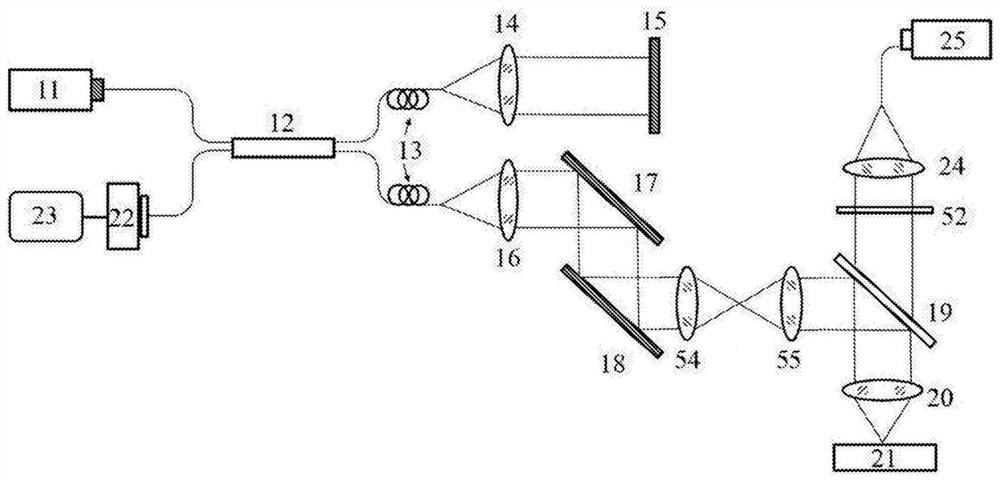

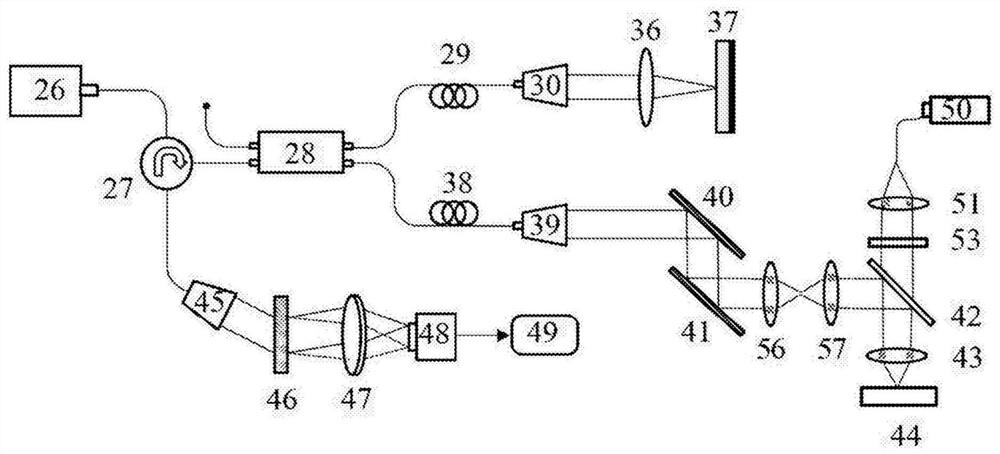

ActiveCN113017593ADoes not affect removalImprove discriminationSensorsBlood flow measurementBlood flowThree-dimensional space

The invention discloses a blood vessel tail artifact removal method and system based on blood flow signal intensity layered filtering. The method comprises the following steps: collecting OCT scattered signals in a three-dimensional space from a biological tissue sample through a signal acquisition method; combining a blood flow signal intensity calculation method with the intensity of an OCT scattered signal and decorrelation to represent the intensity of the blood flow signal; enabling the blood flow signal intensity to be subjected to layered comparison in the depth direction through a layered filtering method for the blood flow signal intensity, and removing artifacts at the tail of the blood vessel. According to the method, the distinction degree between the blood vessel signal and the blood vessel tail artifact signal can be improved, the blood vessel tail artifacts are effectively removed, and meanwhile the capacity of recovering the shape of the blood vessel shielded by the artifacts is achieved.

Owner:ZHEJIANG UNIV

Alternative moisture and temperature resistant forming tubes

InactiveUS20060029755A1Cost-effectiveHigh strengthGlass making apparatusPaper/cardboard wound articlesGlass fiberCardboard

The invention is a collapsible tube having excellent moisture and temperature-resistance. The collapsible tube, such as a spirally wound or convolute paperboard forming tube, includes moisture-resistant and temperature-resistant layers at its inside and outside surfaces. These moisture-resistant and temperature-resistant layers may be polymeric, parchment, or metallic materials, particularly metal foil layers. The collapsible tube is especially useful as a reusable forming tube in the manufacture of glass fibers.

Owner:DAIMLER AG +1

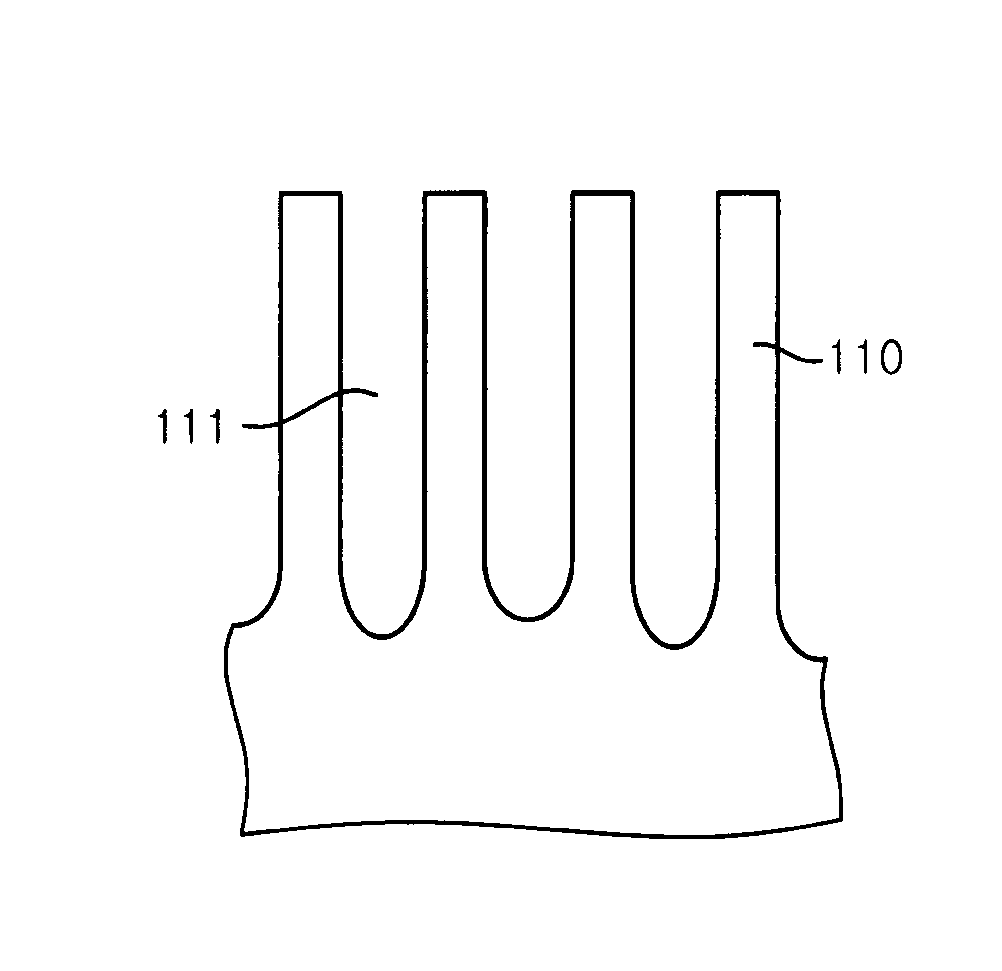

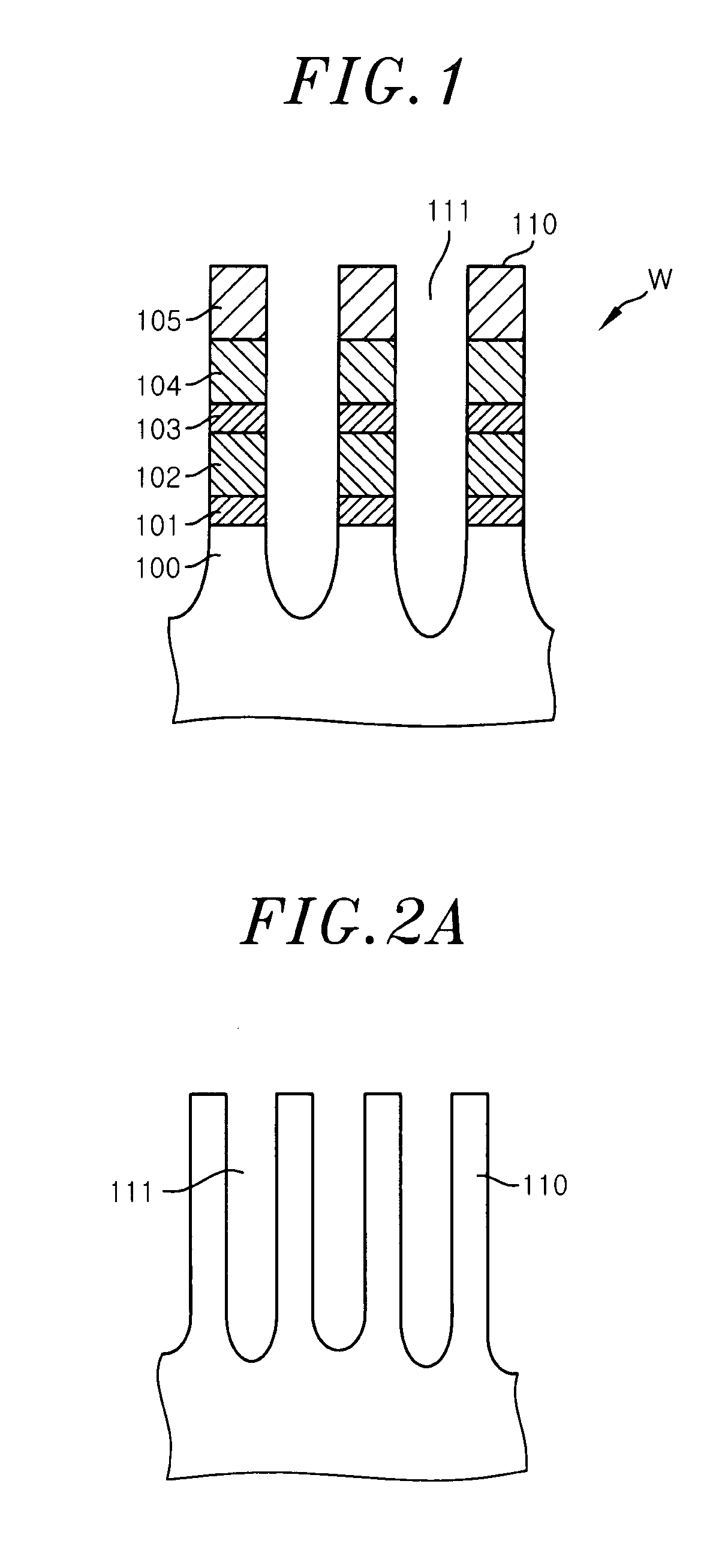

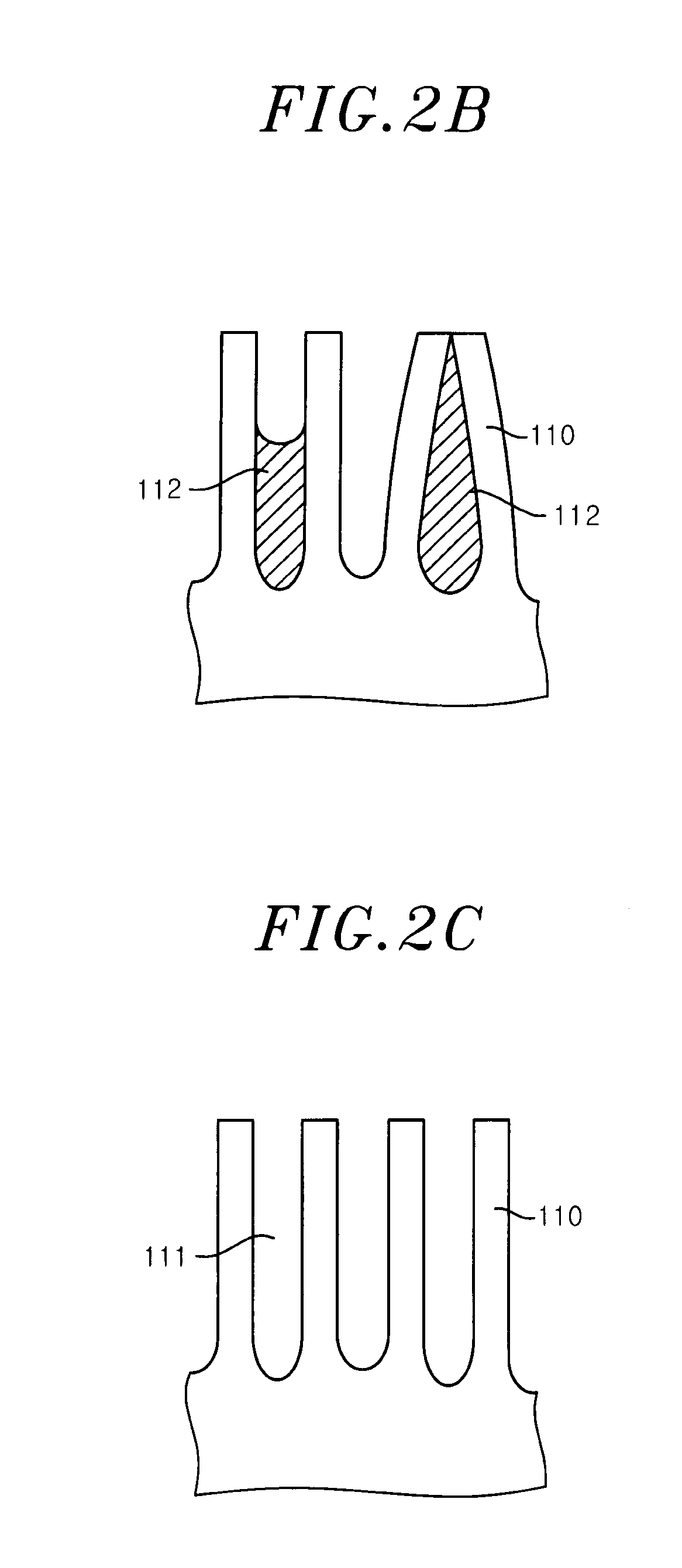

Method and apparatus for recovering pattern on silicon substrate

InactiveUS20110174337A1Regain shapeLighting and heating apparatusSemiconductor/solid-state device manufacturingForeign matterSilicon

Owner:TOKYO ELECTRON LTD

Preparation method of reversible covalent cross-linked reprocessable epoxy resin containing thioester bonds

ActiveCN110804162AImprove mechanical propertiesExcellent reworkabilityOrganic chemistryPlastic recyclingPolymer scienceFirming agent

The invention relates to a preparation method of reversible covalent cross-linked reprocessable epoxy resin containing thioester bonds. The preparation method comprises the following steps: firstly, synthesizing an epoxy curing agent containing a reversible covalent bond-thioester bond by utilizing acid anhydride and mercaptocarboxylic acid, then mixing the epoxy curing agent with an epoxy monomer, and curing epoxy at a specific temperature to obtain the epoxy resin capable of being reprocessed for multiple times. The epoxy curing agent is simple to synthesize, easy to operate and wide in rawmaterial source. And the synthesized epoxy curing agent can be used for various epoxy monomers. Because the dynamic covalent bond thioester bond can be subjected to dynamic exchange reaction, the cured epoxy resin not only has excellent mechanical properties, but also has excellent reprocessing properties.

Owner:西安智聚复合材料科技有限公司

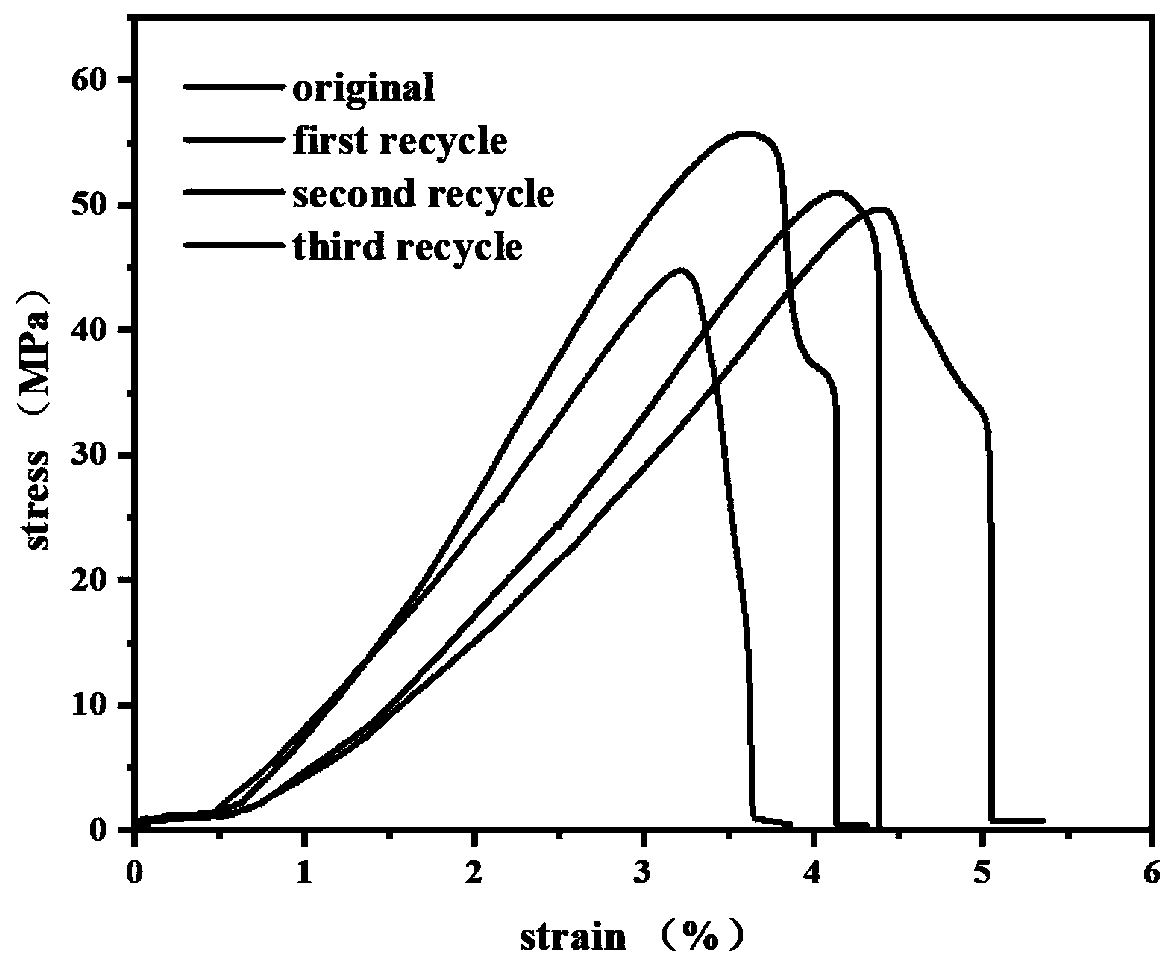

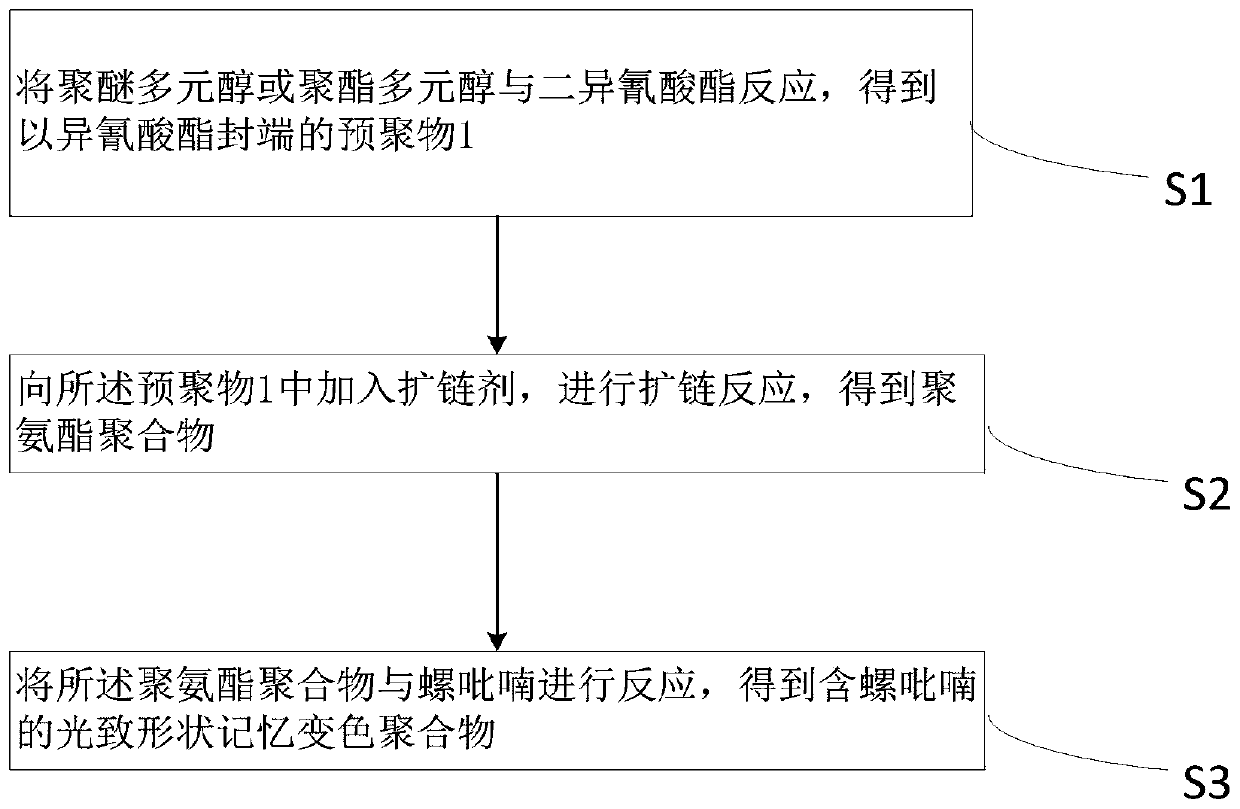

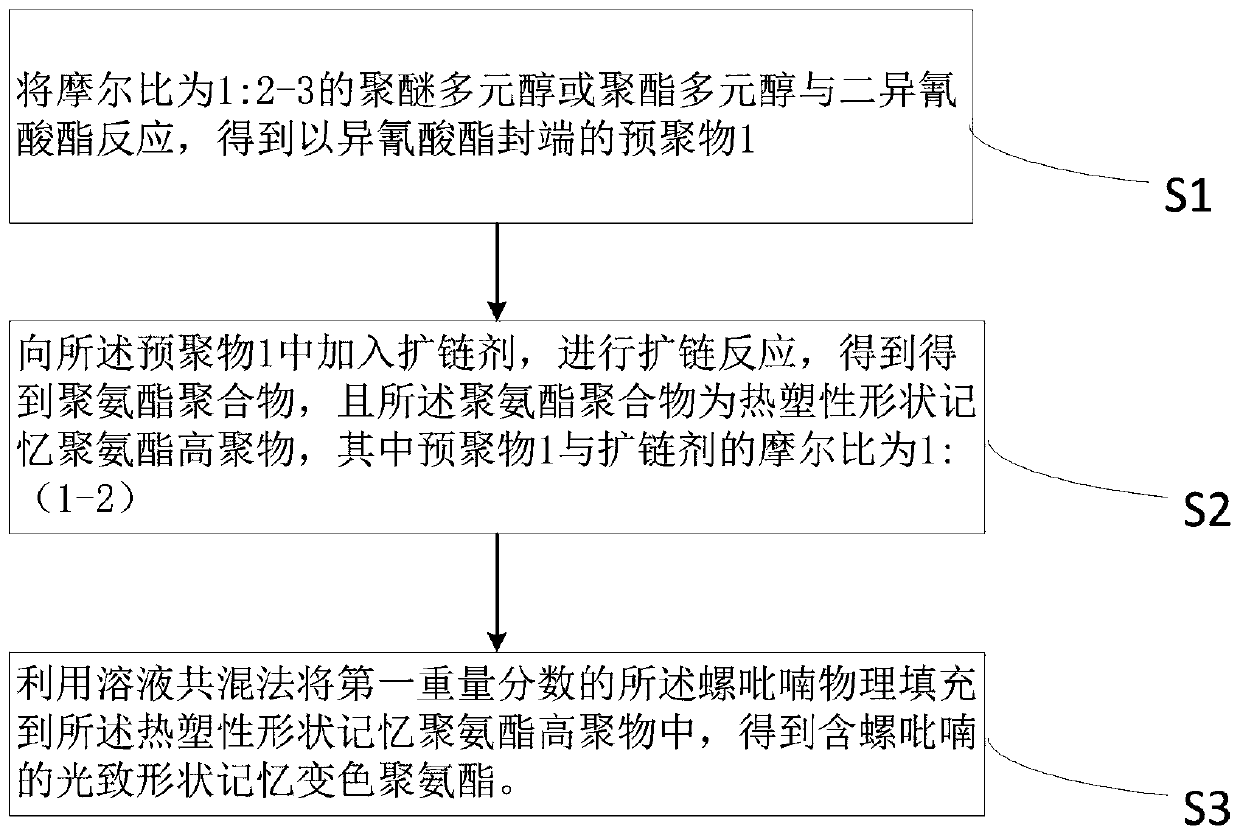

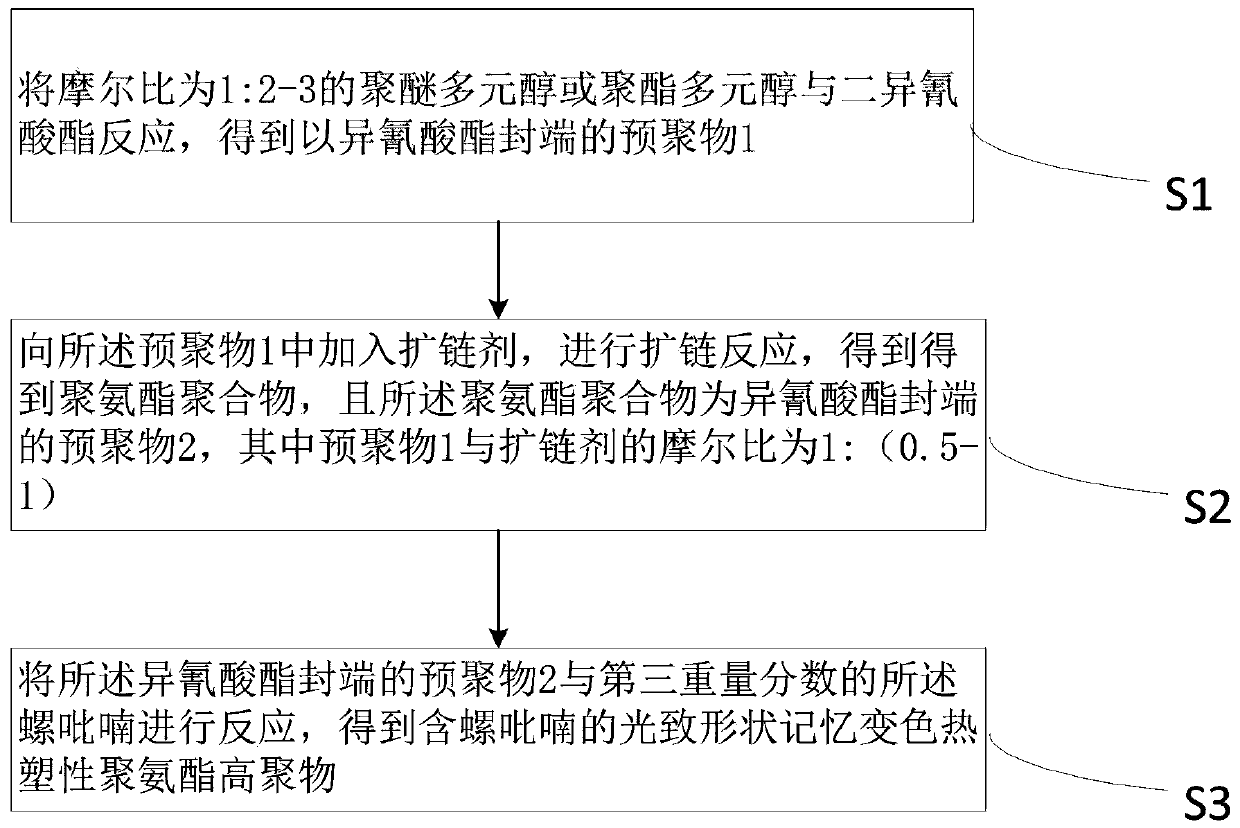

Spiropyrane-containing photoinduced shape memory discoloration polymer and preparation method thereof

ActiveCN111269384AGood shape fixationPhotoplasticizing effectTenebresent compositionsPrepolymerPolyester

The invention provides a spiropyrane-containing photoinduced shape memory discoloration polymer and a preparation method thereof, and belongs to the technical field of functional polymer preparation.The preparation method of the spiropyrane-containing photoinduced shape memory discoloration polymer comprises the following steps: reacting polyether polyol or polyester polyol with diisocyanate to obtain an isocyanate-terminated prepolymer 1; adding a chain extender into the prepolymer 1, and carrying out a chain extension reaction to obtain a polyurethane polymer; and reacting the polyurethanepolymer with spiropyrane to obtain the spiropyrane-containing photoinduced shape memory discoloration polymer. The spiropyrane-containing photoinduced shape memory discoloration polymer gives consideration to a photoinduced shape memory effect and a photoinduced discoloration effect, i.e., the spiropyrane-containing photoinduced shape memory discoloration polymer has very good shape fixing rate, shape recovery rate and discoloration rate, and can be widely applied to the fields of information storage, counterfeiting prevention, flexible camouflage robots and the like.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com