Self-adjustment magnetorheological flexible polishing abrasive wheel and polishing method thereof

A flexible polishing and magnetorheological technology, applied in the direction of wheels, abrasives, metal processing equipment, etc. of flexible working parts, can solve the problems of fast wear and high cost of Poligrind, and achieve the effect of avoiding damage and restoring shape in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

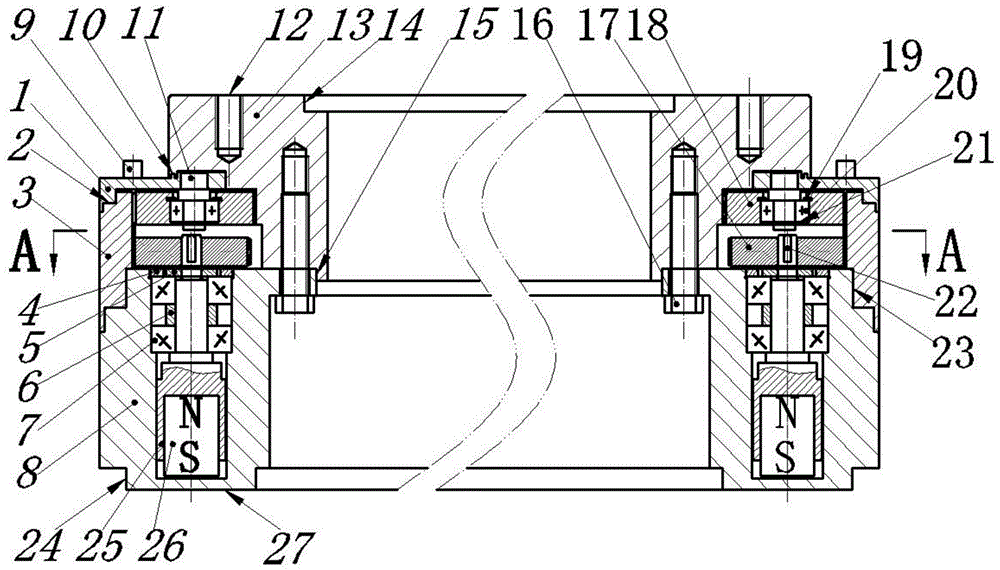

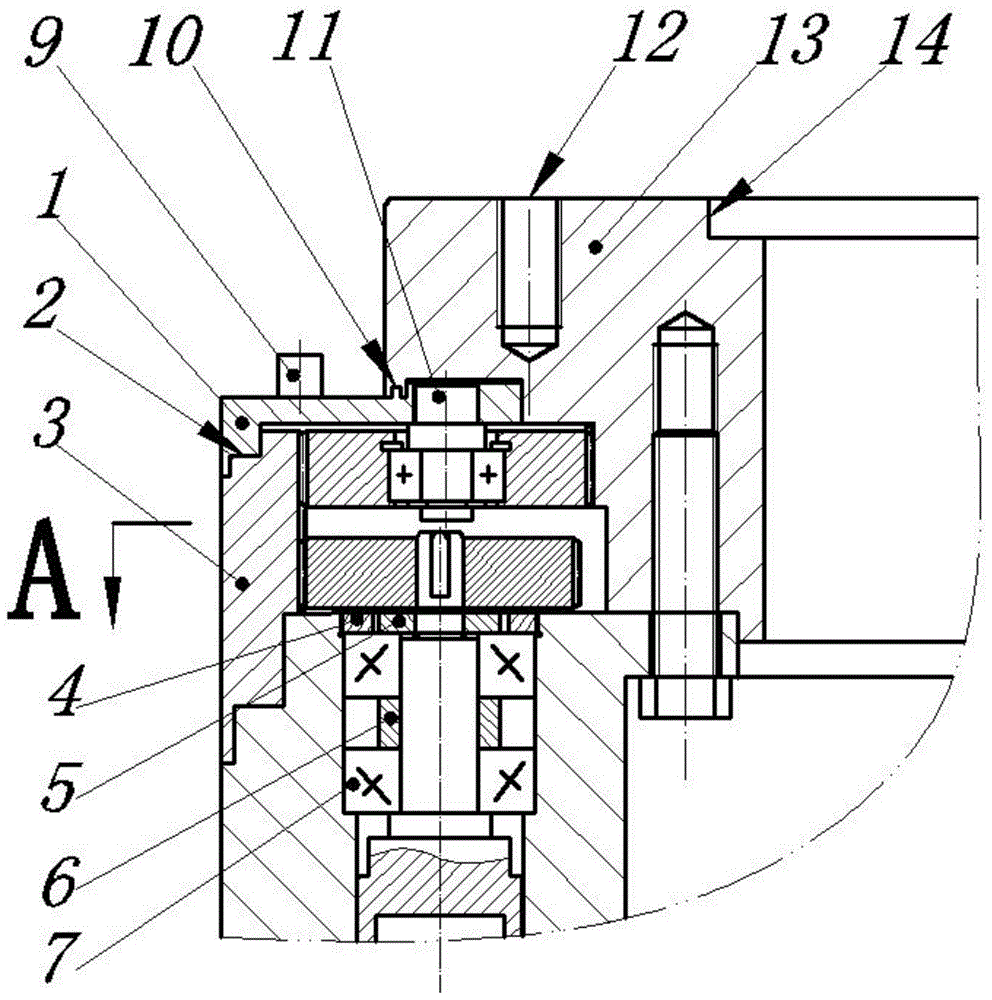

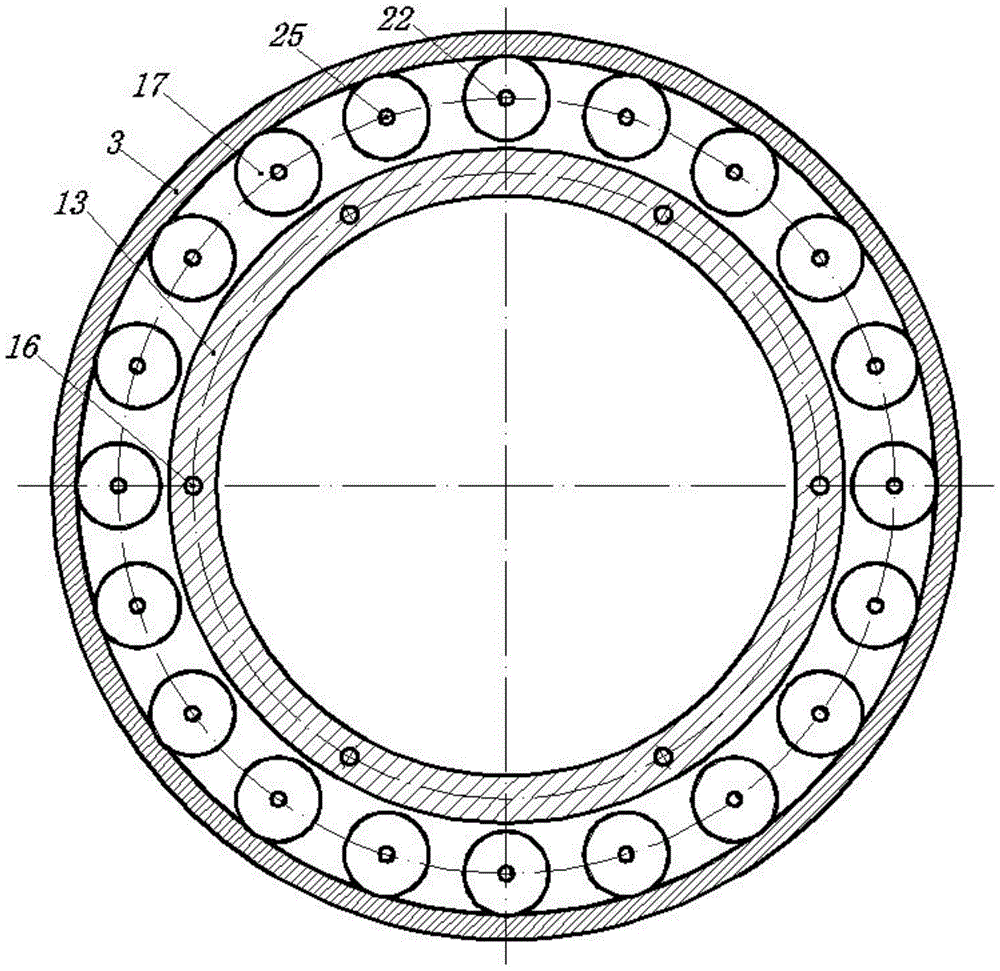

[0030] Such as Figure 1 to Figure 5As shown, a self-dressing magneto-rheological flexible polishing wheel of the present invention includes a fixed ring 1, an internal gear 3, a grinding wheel ring 8, a gear shaft 11, a synchronous rotating gear 17, a planetary gear 18, a rotating shaft 25 and a cylinder Permanent magnet 26, wherein the rotating shaft 25 is installed in the grinding wheel ring 8, the cylindrical permanent magnet 26 is installed in the through hole provided at the lower end of the rotating shaft 25, the internal gear 3 is installed on the top of the grinding wheel ring 8, and the fixed ring 1 Installed on the top of the internal gear 3, and the fixed ring 1 is fixed on the machine tool, the grinding wheel interface 13 is installed on the top of the grinding wheel ring 8 and the fixed ring 1, the grinding wheel interface 13 is connected with the grinding wheel ring 8, and the grinding wheel interface 13 is provided with an external Gear, the gear shaft 11 is in...

Embodiment 2

[0049] Such as Figure 1 to Figure 5 As shown, a self-dressing magneto-rheological flexible polishing wheel of the present invention is the same as that of Embodiment 1.

[0050] Such as Figure 6 Shown, the grinding and polishing method of self-repairing magneto-rheological flexible polishing emery wheel of the present invention, comprises the steps:

[0051] 1) According to the structure of the VG401MKII grinding machine produced by Okamoto Company, the design is as follows Figure 1 to Figure 5 Adapted self-dressing magneto-rheological flexible polishing wheel structure;

[0052] 2) According to the characteristics of the 6-inch single crystal Si substrate, the selected cylindrical permanent magnet 26 with a magnetic field strength of 3800Gs is installed adjacent to the same magnetic pole in the self-tuning magnetorheological flexible polishing wheel, and the rotation axis 25 is adjusted so that the cylindrical permanent magnet The distance from the lower end surface of ...

Embodiment 3

[0060] Such as Figure 1 to Figure 5 As shown, a self-dressing magneto-rheological flexible polishing wheel of the present invention is the same as that of Embodiment 1.

[0061] Such as Figure 6 Shown, the grinding and polishing method of self-repairing magneto-rheological flexible polishing emery wheel of the present invention, comprises the steps:

[0062] 1) According to the structure of LapmasterSFT Corp.'s DMG-6011V vertical single-axis ultra-precision precision end grinder machine tool, the design is as follows Figure 1 to Figure 5 Adapted self-dressing magneto-rheological flexible polishing wheel structure;

[0063] 2) According to the characteristics of the 4-inch single crystal sapphire substrate, the selected cylindrical permanent magnet 26 with a magnetic field strength of 4500Gs is installed adjacent to the same magnetic pole in the self-tuning magnetorheological flexible polishing wheel, and the rotation axis 25 is adjusted to make the cylindrical permanent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com