Pressure-sensitive graphene film preparation method

A graphene film and graphene film technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of heavy pollution, weak compression fatigue resistance, single airbag wall, etc., and achieve high sensitivity and film thickness Appropriate, Controlling Appropriate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) With 6mg / mL graphene oxide aqueous solution, dry naturally after film formation, obtain the graphene oxide film that thickness is 3um;

[0020] (2) The graphene oxide film is reduced in hydroiodic acid vapor, the hydroiodic acid content is 0.1wt%, the reduction temperature is 80 degrees Celsius, and the reduction time is about 8h; the reduced graphene film is washed with ethanol to remove the surface Reducer, then dry naturally.

[0021] (3) Place the reduced graphene film in a graphite furnace for sintering, perform two-step high-temperature treatment with the parameters described in Tables 1 to 3 below, and test the stability and compressibility of the treated graphene film.

[0022] Table 1

[0023]

[0024] Under the conditions of 1-5 and 1-6, the heating rate in the first stage is too fast, and the gas is released violently, which leads to the damage of the graphene film. On the one hand, the surface of the film is no longer uniform. As for hindering the f...

Embodiment 2

[0034] (1) 10mg / mL graphene oxide aqueous solution is dried naturally after film formation to obtain a graphene oxide film with a thickness of 10um;

[0035] (2) reducing the graphene oxide film in hydrazine hydrate vapor, the hydrazine hydrate content is 15wt%, the reduction temperature is 120 degrees Celsius, and the reduction time is about 12h; the reduced graphene film is washed with ethanol to remove the surface reducing agent, Then let it dry naturally.

[0036] (3) The reduced graphene film is placed in a graphite furnace for sintering, the temperature is raised to 300 degrees Celsius at 4 degrees Celsius per minute, and the temperature is raised to 1600 degrees Celsius at 5 degrees Celsius per minute to obtain a graphene film with high fatigue resistance.

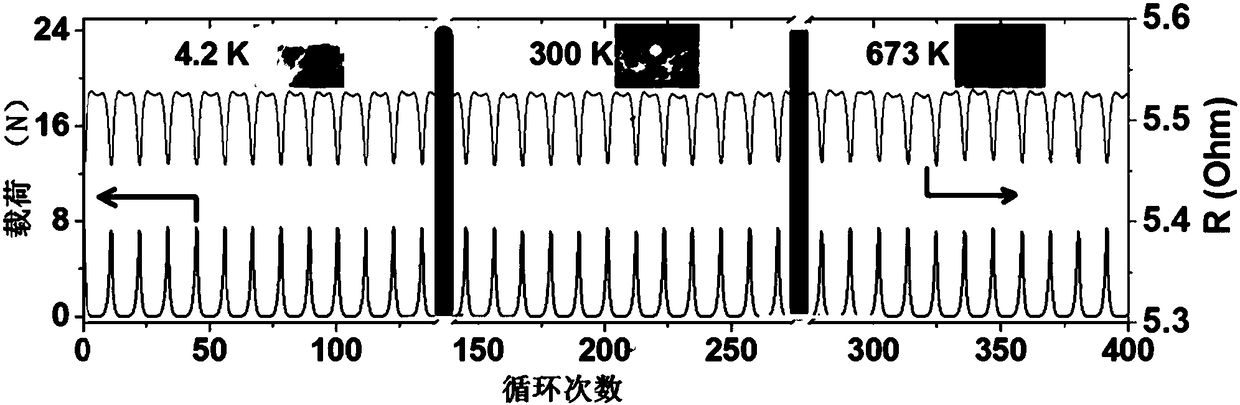

[0037] After testing, the graphene film has a multi-level delamination structure with holes inside, can withstand bending at various extreme temperatures, can still maintain good elasticity after deformation at extr...

Embodiment 3

[0039] (1) With 7mg / mL graphene oxide aqueous solution, dry naturally after film formation, obtain the graphene oxide film that thickness is 5um;

[0040] (2) reducing the graphene oxide film in hydrazine hydrate vapor, the hydrazine hydrate content is 5wt%, the reduction temperature is 100 degrees Celsius, and the reduction time is about 12h; the reduced graphene film is washed with ethanol to remove the surface reducing agent, Then let it dry naturally.

[0041] (3) The reduced graphene film is placed in a graphite furnace for sintering, and the temperature is raised to 300 degrees Celsius at 1 degree Celsius per minute, and to 1800 degrees Celsius at 10 degrees Celsius per minute to obtain a graphene film with high fatigue resistance.

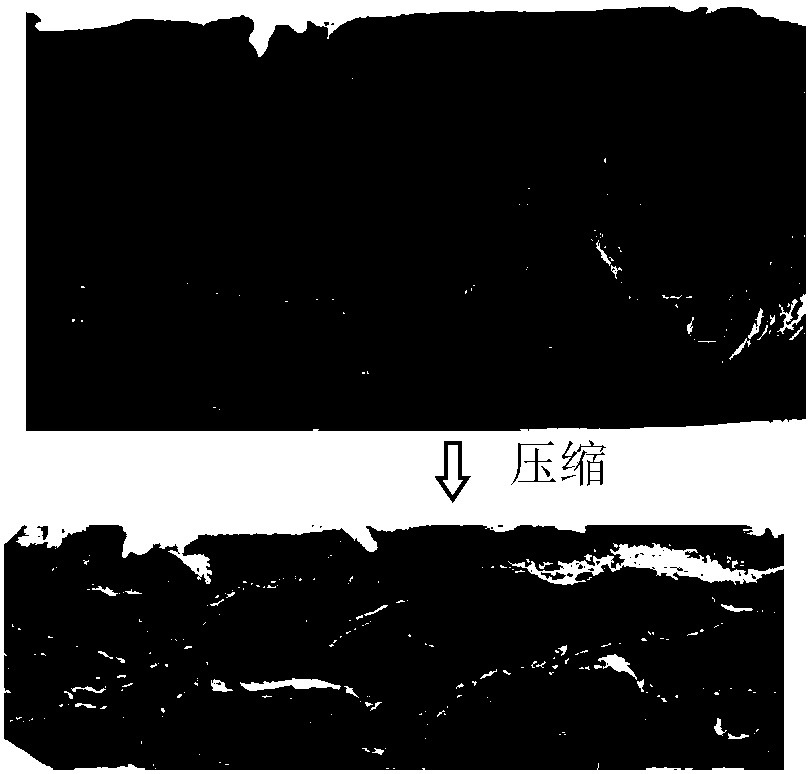

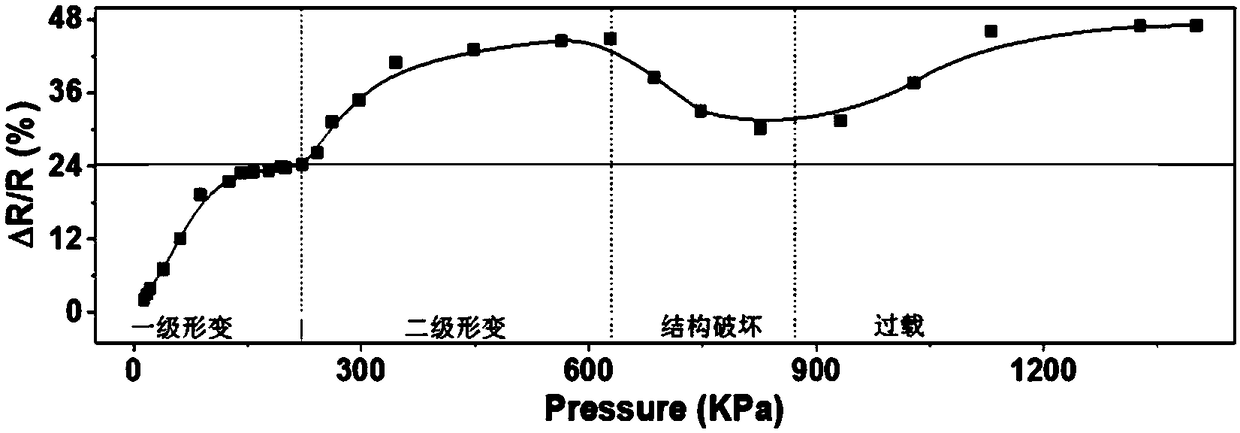

[0042] Such as figure 1 , the porous graphene is compressed and deformed, and the inside of the graphene film is in contact with each other, thereby reducing the resistance. The multi-level delamination structure of the graphene film enabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com