Preparation method of reversible covalent cross-linked reprocessable epoxy resin containing thioester bonds

An epoxy resin and covalent cross-linking technology, which is applied in organic chemistry, plastic recycling, recycling technology, etc., can solve the problems of unreported thioester bonds, etc., and achieve excellent reprocessing performance, wide source of raw materials, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

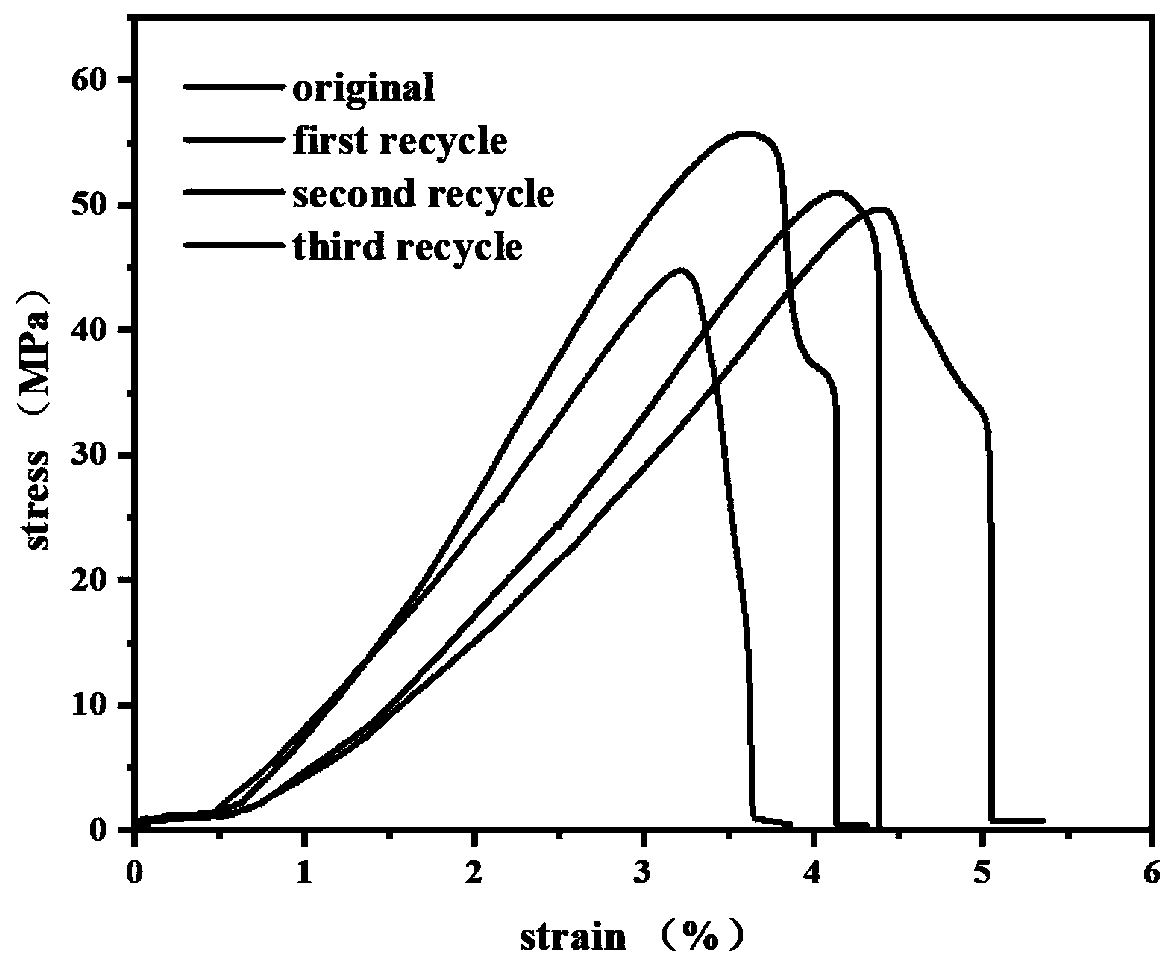

Examples

Embodiment 1

[0024] Into a round bottom flask equipped with magnetic stirring was put 5 g of succinic anhydride, followed by 45 ml of anhydrous acetonitrile and 5 ml of anhydrous pyridine. Stir at room temperature to form a homogeneous solution. Then 5.3 g of 3-mercaptopropionic acid and 0.35 g of 4-dimethylaminopyridine were added. The reaction was stirred overnight. The reaction solution was concentrated, adjusted to pH=1, extracted with ethyl acetate, and the organic layer was collected and concentrated to obtain a white dicarboxylic acid epoxy curing agent.

[0025] Take 5g of epoxy curing agent and 8.25g of bisphenol A diglycidyl ether, heat the epoxy curing agent with a heat gun to melt and mix evenly, heat in a vacuum oven at 100°C for 8 hours, and cool naturally to room temperature to obtain the available Reprocessed epoxy resin.

Embodiment 2

[0027] Into a round bottom flask equipped with magnetic stirring was put 5 g of succinic anhydride, followed by 45 ml of anhydrous acetonitrile and 5 ml of anhydrous pyridine. Stir at room temperature to form a homogeneous solution. Then 4.6 g of thioglycolic acid and 0.35 g of 4-dimethylaminopyridine were added. The reaction was stirred overnight. Concentrate the reaction solution, adjust the pH to 1, extract with ethyl acetate, collect the organic layer, and concentrate to obtain a dibasic carboxylic acid epoxy curing agent.

[0028] Take 5g of epoxy curing agent and 8.86g of bisphenol A diglycidyl ether, heat the epoxy curing agent with a heat gun to melt and mix evenly, heat in a vacuum oven at 120°C for 6 hours, and cool naturally to room temperature to obtain the available Reprocessed epoxy resin.

Embodiment 3

[0030] Into a round bottom flask equipped with a magnetic stirrer was charged 5 g of phthalic anhydride, followed by 45 ml of anhydrous acetonitrile and 5 ml of anhydrous pyridine. Stir at room temperature to form a homogeneous solution. Then 3.58 g of 3-mercaptopropionic acid and 0.35 g of 4-dimethylaminopyridine were added. The reaction was stirred overnight. Concentrate the reaction solution, adjust the pH to 1, extract with ethyl acetate, collect the organic layer, and concentrate to obtain a dibasic carboxylic acid epoxy curing agent.

[0031] Take 5g of epoxy curing agent and 3.96g of trimethylolpropane triglycidyl ether, heat with a heat gun to melt the epoxy curing agent and mix evenly, heat in a vacuum oven at 100°C for 10 hours, and cool naturally to room temperature. A reworkable epoxy resin is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com