Full-angle flexible needle type ultrasonic shot blasting device

An ultrasonic shot peening, all-angle technology, applied in the directions of vibration devices, explosion generating devices, abrasives, etc., can solve the problems of workpiece deformation and difficult to function effectively, and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

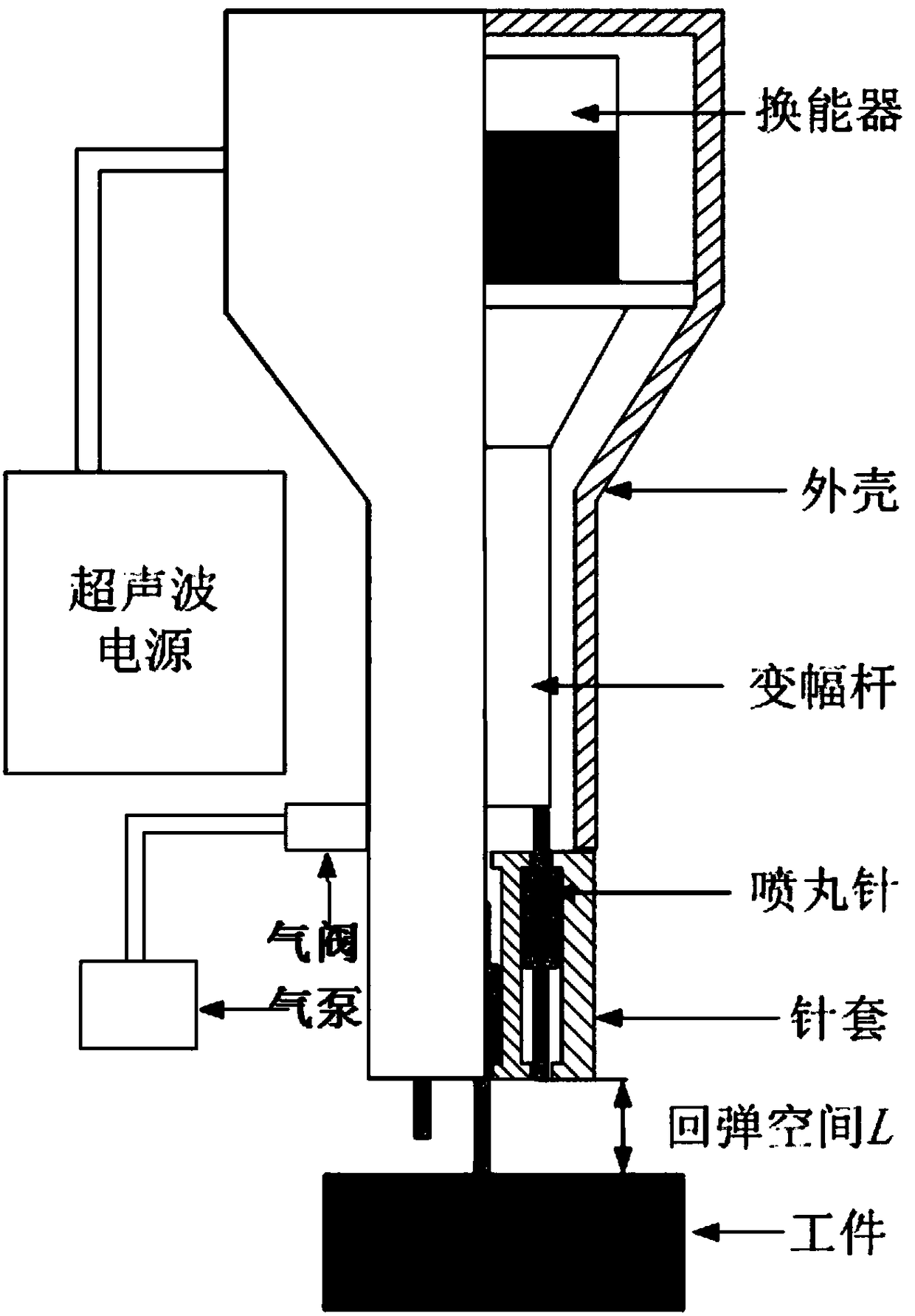

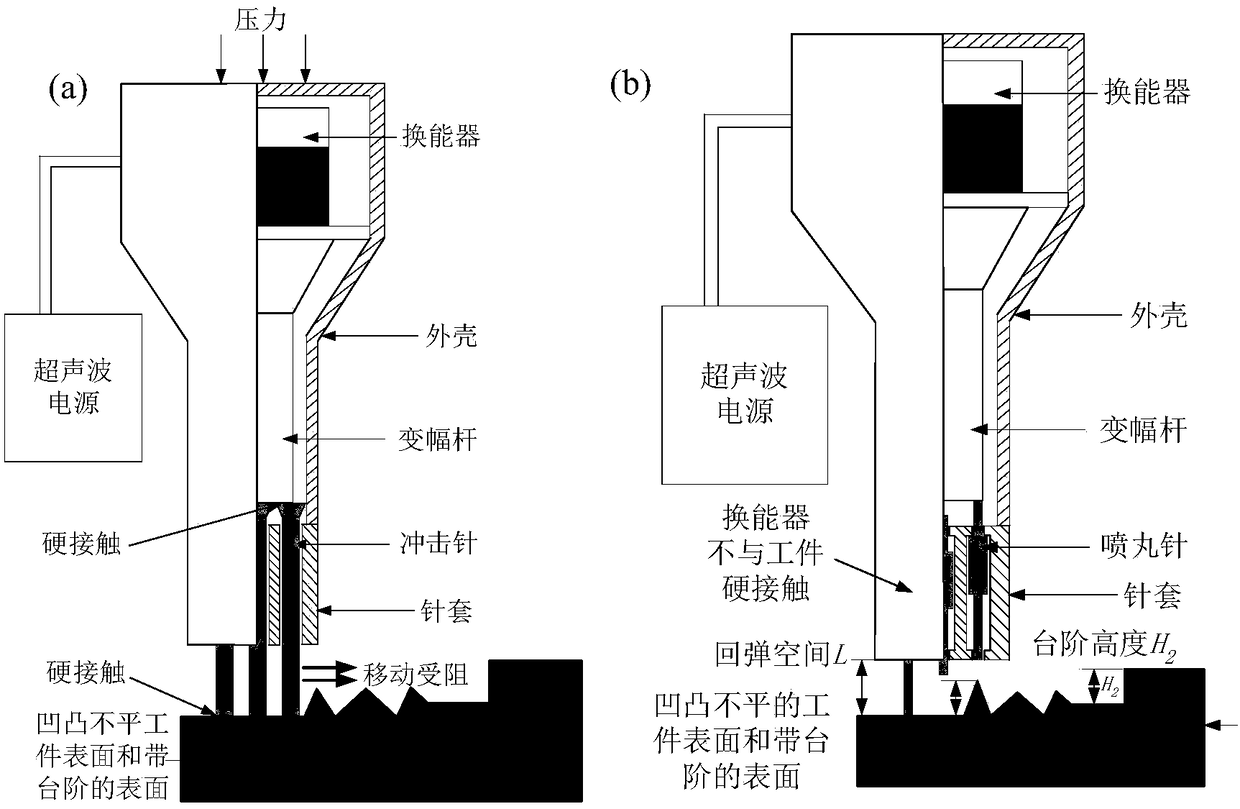

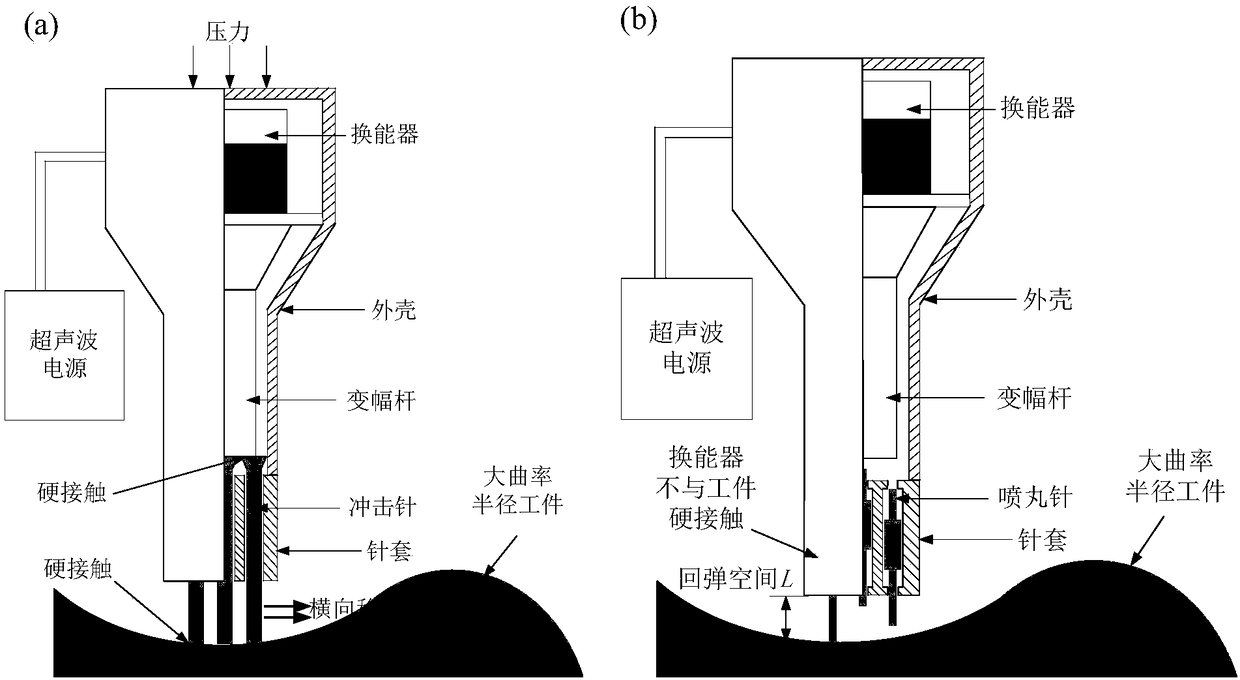

[0019] As shown in the attached figure, the full-angle flexible needle type ultrasonic shot peening device includes an ultrasonic generator (that is, an ultrasonic power supply), a transducer, a horn and a shot peening needle, and the transducer and the horn are arranged in the casing. The ultrasonic generator passes through the shell and is connected with the transducer; the shell is provided with a suction port and connected with the suction device and sealed; the front end of the shell is provided with a needle sleeve connected to it and sealed, and the size of the needle sleeve is set in the needle sleeve. Matching pinholes are used for the reciprocating movement of the shot peening needle; in this design, the air suction device is used to form a negative pressure in the space around the horn, so that the shot peening needle is adsorbed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com