Shot, devices, and installations for ultrasonic peening, and parts treated thereby

a technology of ultrasonic peening and ultrasonic peening chamber, which is applied in the field of ultrasonic peening shot, devices and installations, and parts treated thereby, can solve the problems that the use of such shot does not enable sufficient treatment intensity, and achieves the effects of reducing treatment time, reducing the angle of incidence of shot, and facilitating and accelerating the treatment of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Shot

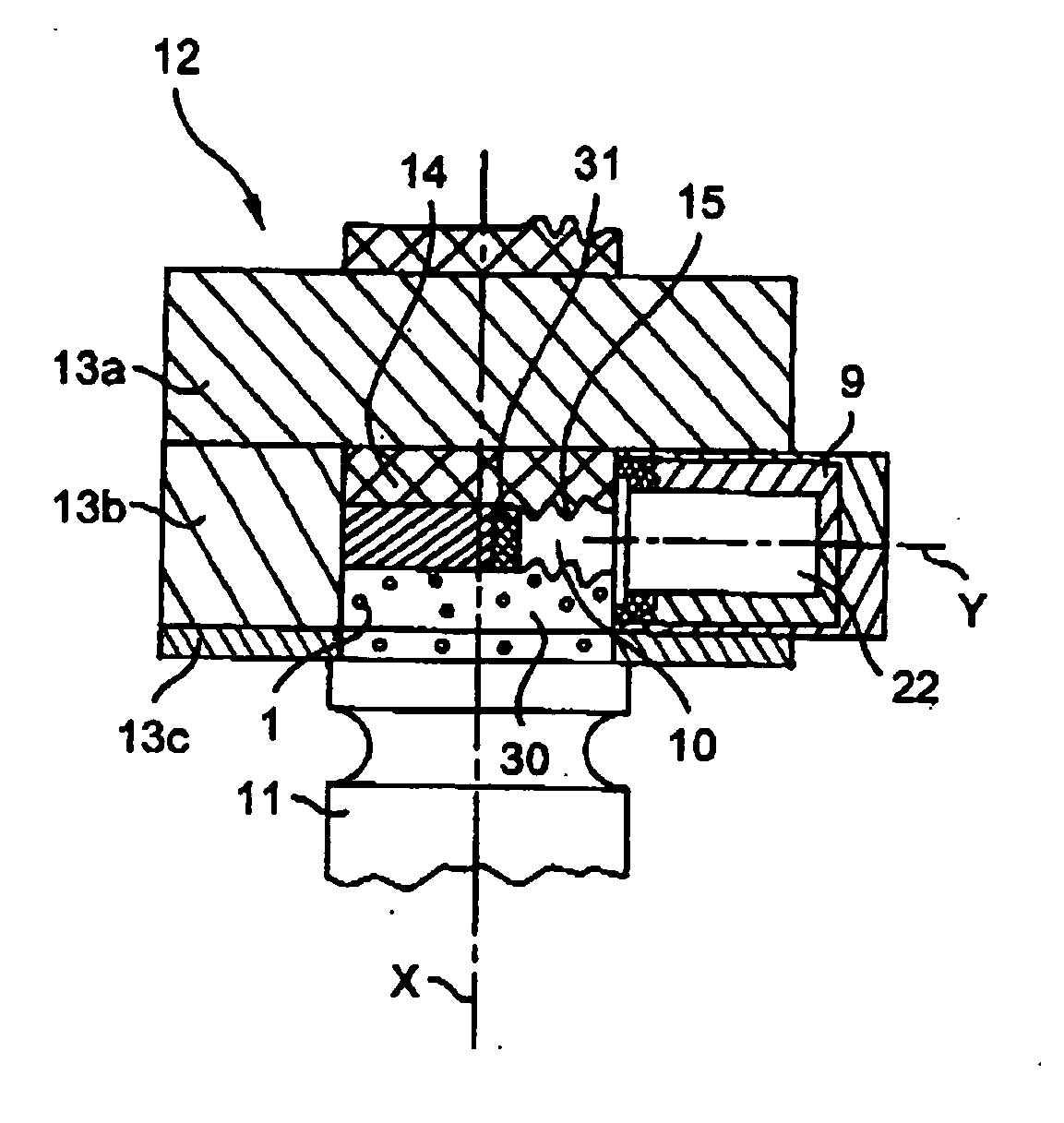

[0068] In one of its aspects, the invention relates to shot for use in a peening installation comprising a sonotrode that is set into vibration at ultrasound frequencies by a suitable generator. The shot may be characterized by hardness greater than or equal to 800 HV, density greater than or equal to 8 g / cm3, and pieces having a maximum dimension that is less than or equal to 1.5 mm.

[0069]FIG. 1 shows a piece of shot 1 satisfying this definition, and that is substantially spherical shape, with the above-mentioned maximum dimension corresponding to the diameter d of the sphere. Preferably, the tolerance on its sphericity is better than ±60 μm.

[0070] Its hardness is preferably greater than or equal to 1300 HV, and its density is preferably greater than or equal to 12 g / cm3.

[0071] By way of example, the shot 1 is made entirely out of tungsten carbide or any other material presenting the required hardness and density. The tungsten carbide includes a binder of cobalt or nickel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com