Shot-peening apparatus, and shot-peening execution method

A shot peening, construction method technology, applied in shot peening. It can solve the problems of difficult recycling of pellets, and achieve the effect of reliable recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

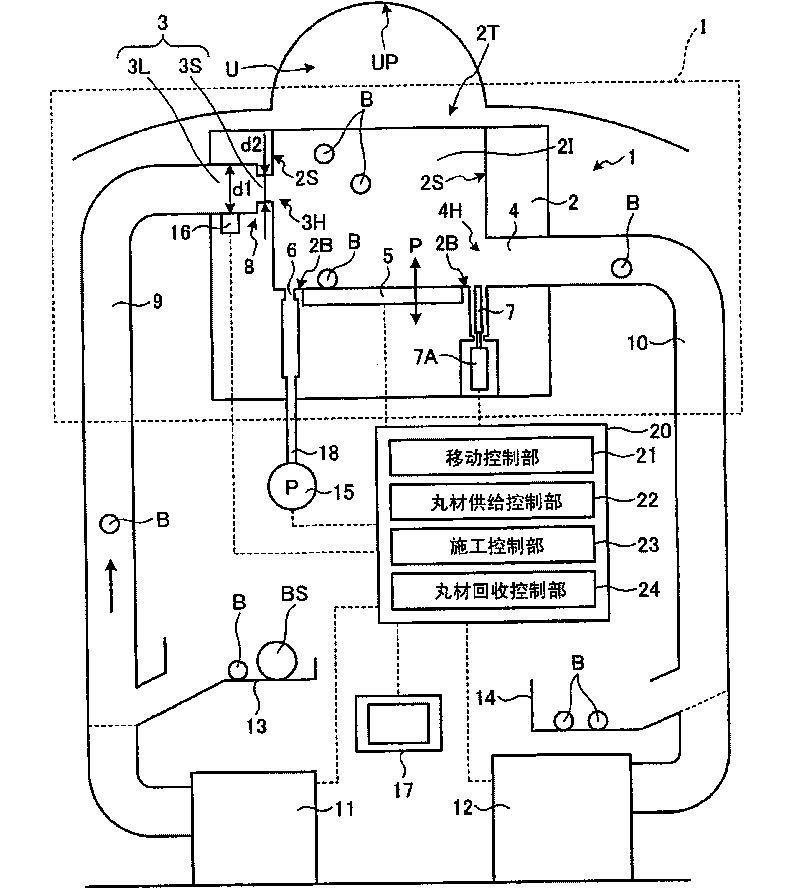

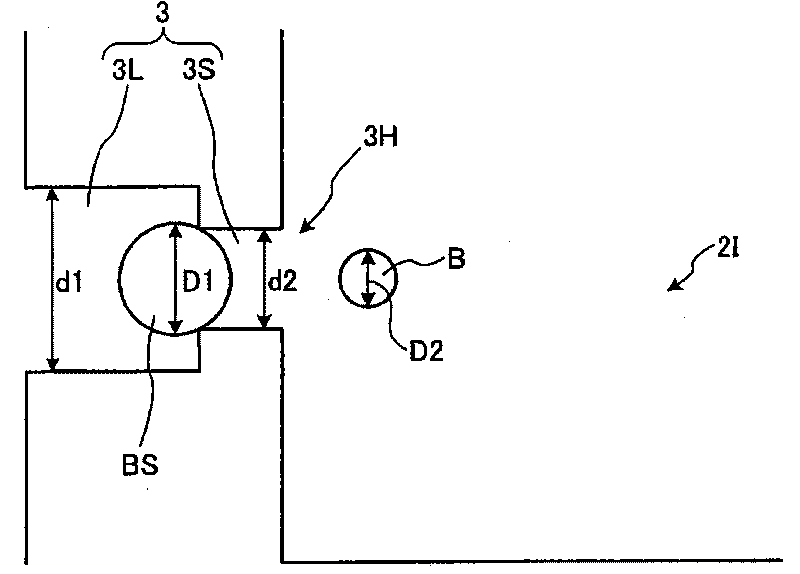

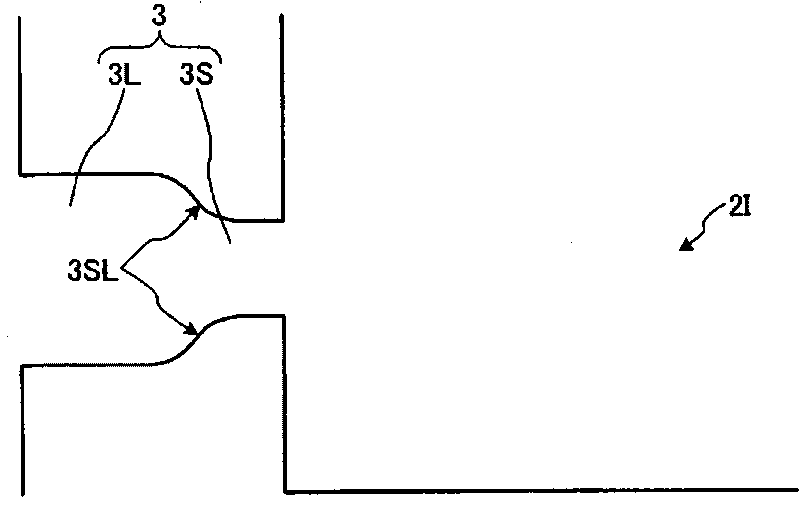

Embodiment 1

[0065] This invention is suitable for the shot peening of a concave shape part or a convex part shape part. In addition, in this invention, the construction part of shot peening is not limited to a welded part. In addition, the present invention can be fully applied to, for example, the inner and outer surfaces of steam generator inlet and outlet sockets used in power generation equipment, fluid piping, pressure vessels, etc., where shot peening is required, and the application objects of the present invention are not particularly limited. . In addition, the present invention is particularly effective when performing shot peening in a closed space.

[0066] This embodiment is characterized in that the shot material used for the construction of shot peening is collected from the shot peening apparatus by suction at the construction site, and then the shot peening apparatus is moved from the construction site. First, the structure of the shot peening apparatus of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com