Sand prevention hydraulic anchor

A hydraulic anchor and anchor claw technology, which is applied to wellbore/well components, earthwork drilling, etc., can solve the problems such as the failure of normal tripping of the operation pipe string, the overhaul of oil and water wells, and the tedious installation and use, so as to achieve low cost of use, Reliable recovery and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

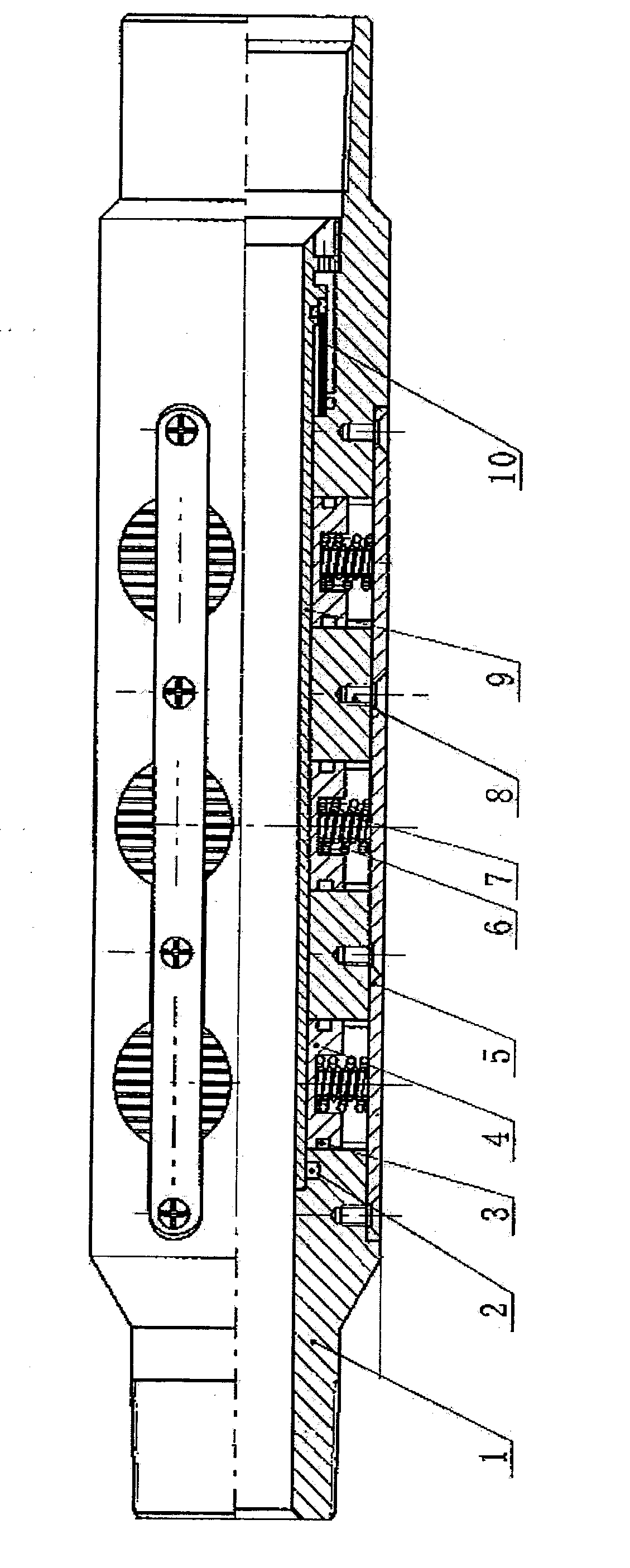

[0011] A sand-proof hydraulic anchor, including an anchor body 1, a sealing ring 2, a sealing ring A3, an anchor claw 4, a pressure plate 5, an outer spring 6, an inner spring 7, a pressure plate screw 8, a sand control intubation tube 9, and a sand filter screen 10, its features The anchor body 1 is provided with an inner seal groove and a pressure plate groove, there are three seal rings A3, three anchor flukes 4, four pressure plate screws 8, and the inner spring 7. There are three sets of outer springs 6 respectively. Insert the sealing ring 2 into the inner sealing groove of the anchor body 1, set the sand filter screen 10 on the outer cylindrical surface of the sand control intubation tube 9, and then connect it through the inner thread of the anchor body 1. Tighten. The fluke 4 is provided with an outer sealing groove, and the sealing ring A3 is respectively embedded in the outer sealing groove of the fluke 4, and the inner spring 7 and the outer spring 6 are placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com