Parts mounting apparatus and parts mounting method and waste materials recovering apparatus

A recovery device and parts installation technology, which is applied in the field of parts installation, can solve problems such as increased configuration of the rotating drive device, longer stop time, and obstacles to high-speed speed, and achieve the effects of preventing bad situations, eliminating contact states, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] A waste material recycling apparatus according to a first embodiment of the present invention will be described below with reference to the drawings. In addition, in each of the following embodiments, the same reference numerals are used for the same constituent elements as those of the prior art, and in each of the following descriptions, differences from the prior art will be mainly described.

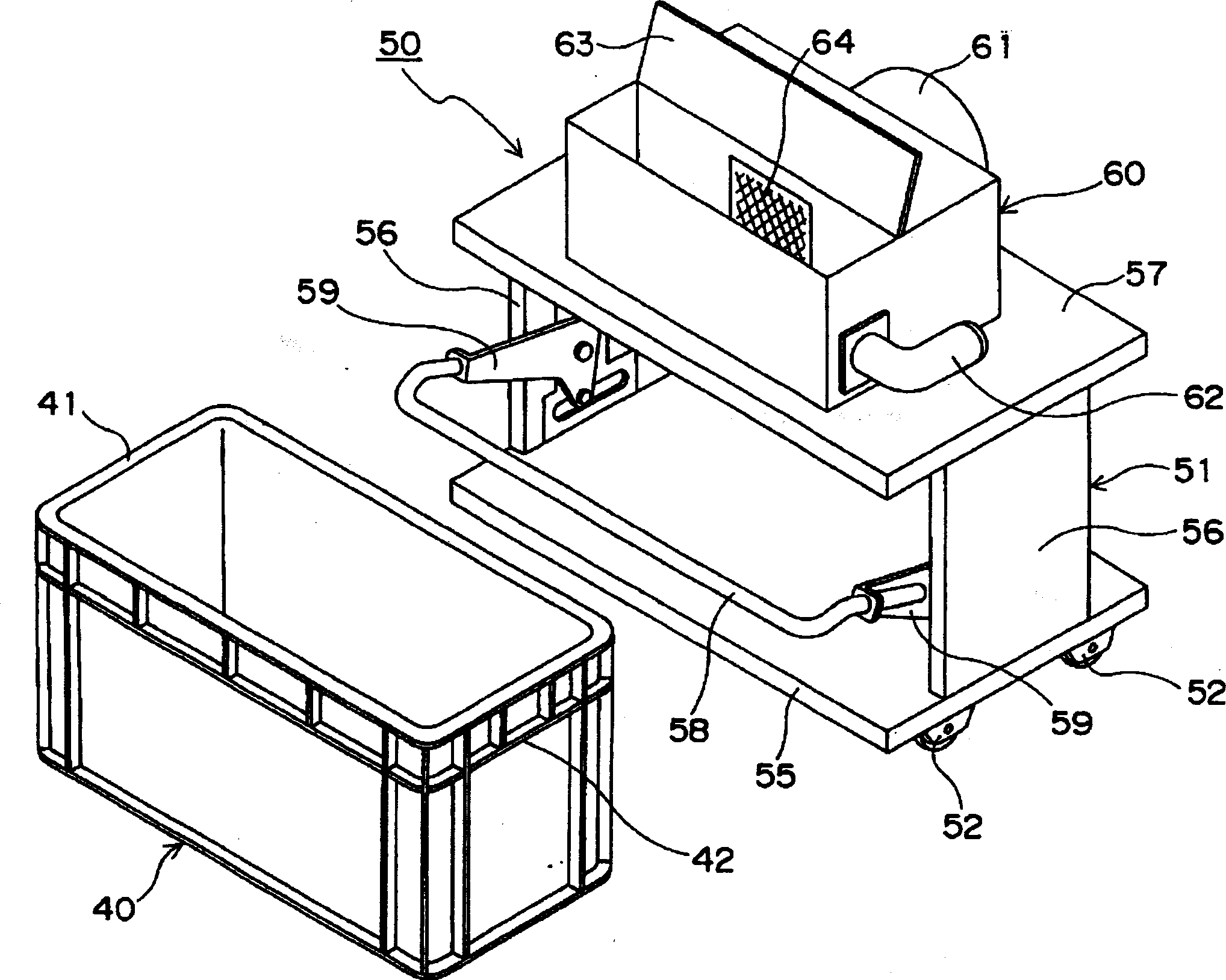

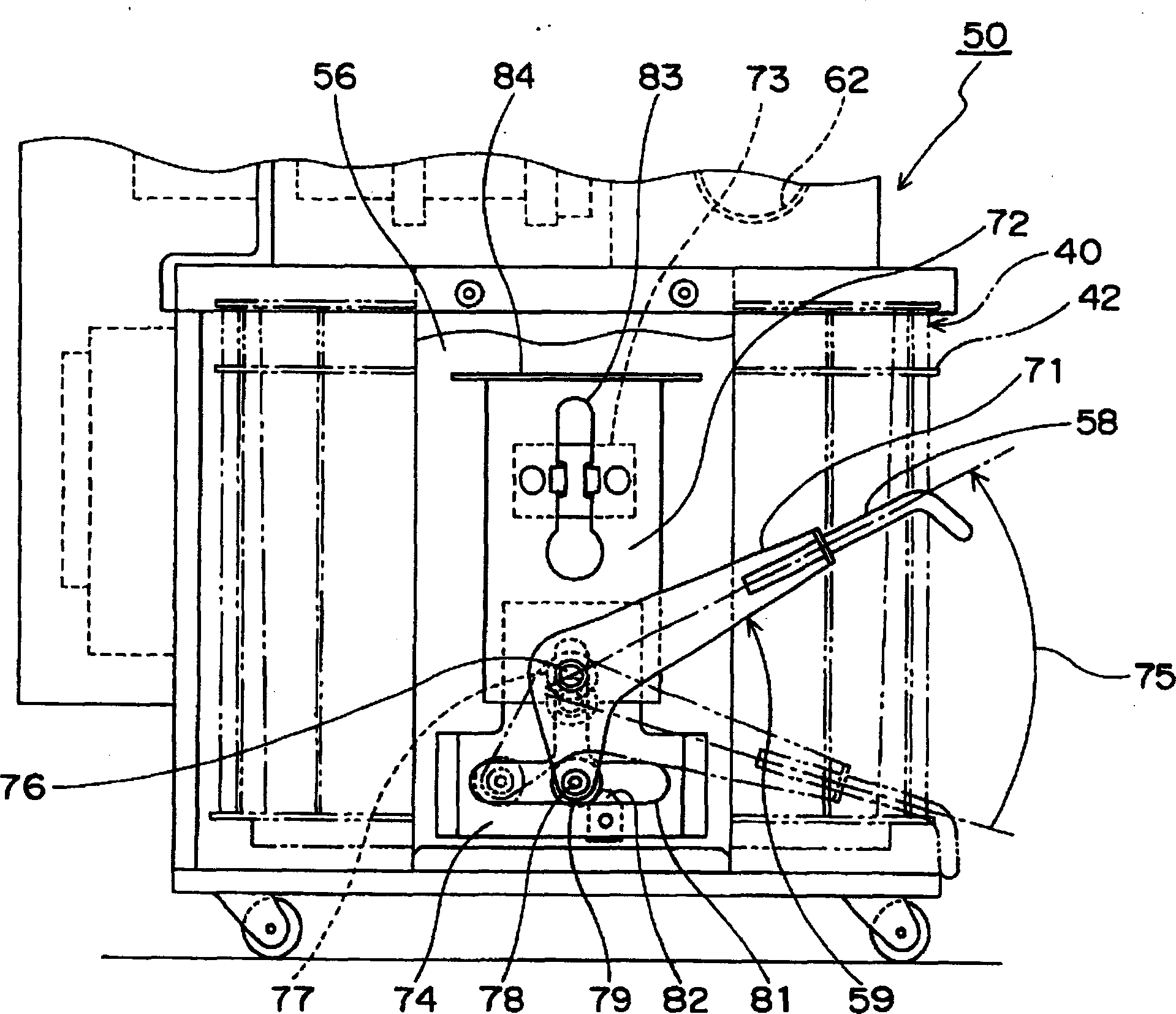

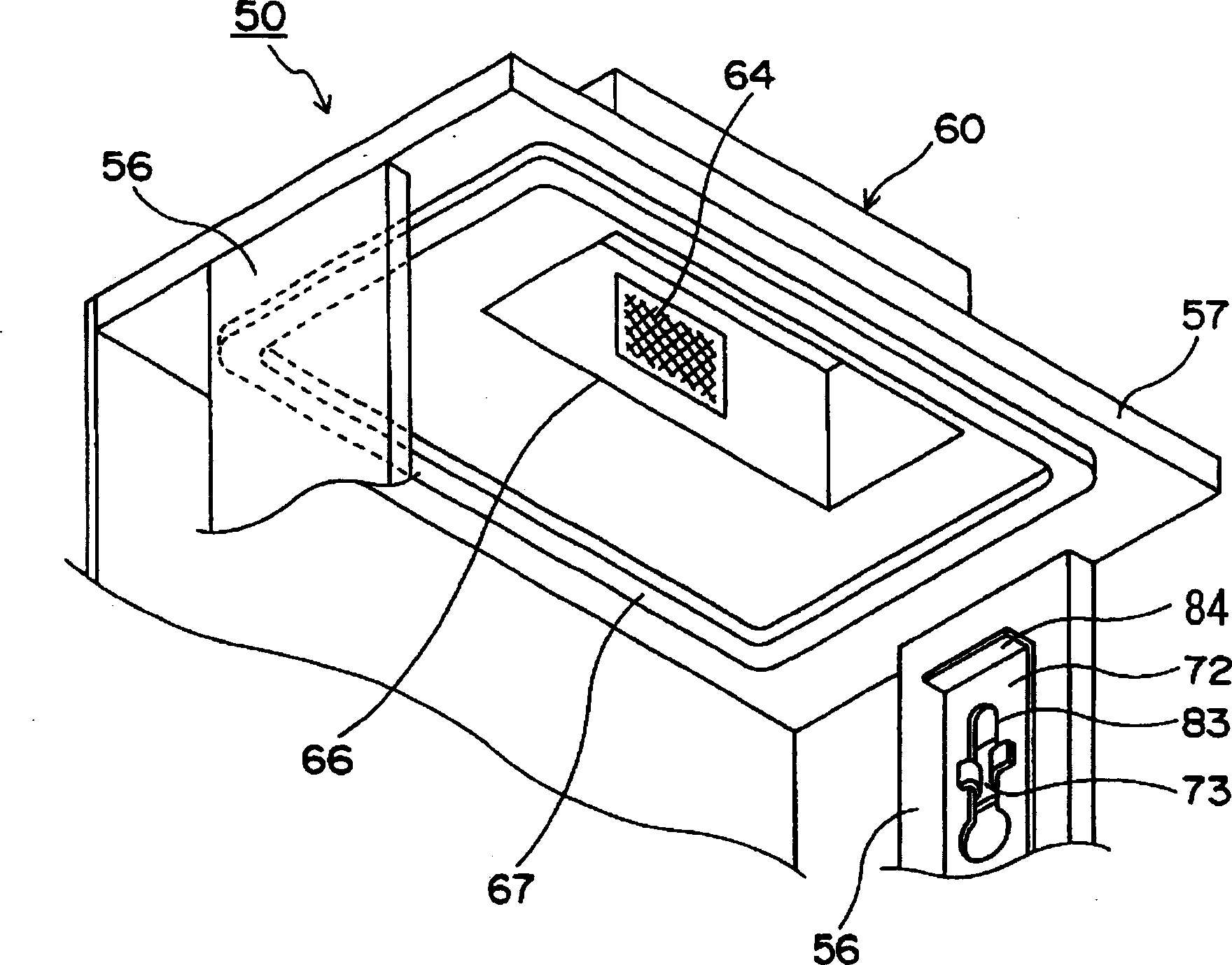

[0084] figure 1Indicates the waste material recycling apparatus related to this embodiment. This waste material recovery device can be used, for example, to recover tape scraps generated after cutting the parts supply tape after the parts supply is completed. In the figure, the waste material recycling device 50 of this embodiment mainly includes: a frame portion 51 of a peripheral frame composed of a lower frame body 55, a pair of side frame bodies 56, and an upper frame body 57; The negative pressure suction unit 60 for sucking waste materials from the component mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com