Series connection type hydraulic automobile regenerative braking energy recycling system

An energy recovery and serial technology, applied in brakes, brake components, vehicle parts, etc., can solve the problems of less recovered energy, more recovered energy, and low mutual conversion efficiency, and achieve improved working stability, reliability and effectiveness The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

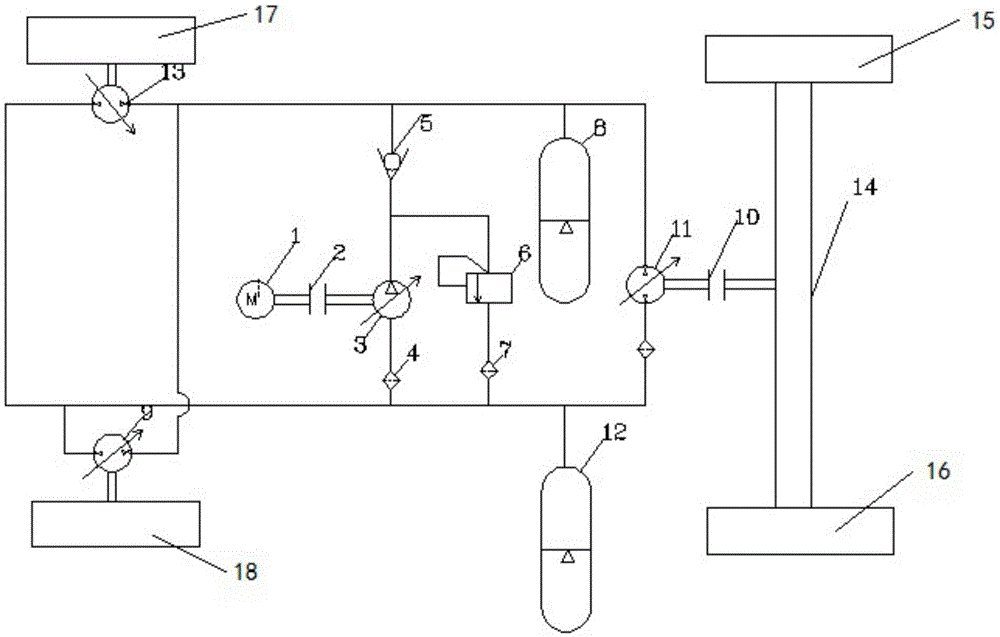

[0031] figure 1 It is a schematic structural diagram of a series hydraulic vehicle regenerative braking energy recovery system according to an embodiment of the present invention.

[0032] Such as figure 1 As shown, the series hydraulic vehicle regenerative braking energy recovery system described in this embodiment may include:

[0033] The hydraulic power source includes an engine 1, a first clutch 2, and a first variable pump 3. The engine 1 is connected to the first variable pump 3 after being connected to the first clutch 2;

[0034] The rear-wheel hydraulic drive assembly is arranged on the side of the rear wheel of the automobile and connected to the first variable pump 3; and

[0035] The front axle hydraulic drive assembly is connected to the front axle 14 of the automobile. The front axle 14 connects the left front wheel 15 and the right front wheel 16. The front axle hydraulic drive assembly is connected to the output end of the first variable pump 3.

[0036] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com