Shot peening device and oscillator for shot peening

A shot peening and vibrator technology, which is used in vibration devices, explosion generating devices, machine tools suitable for grinding workpiece edges, etc. equipment and other problems to achieve the effect of inhibiting construction inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

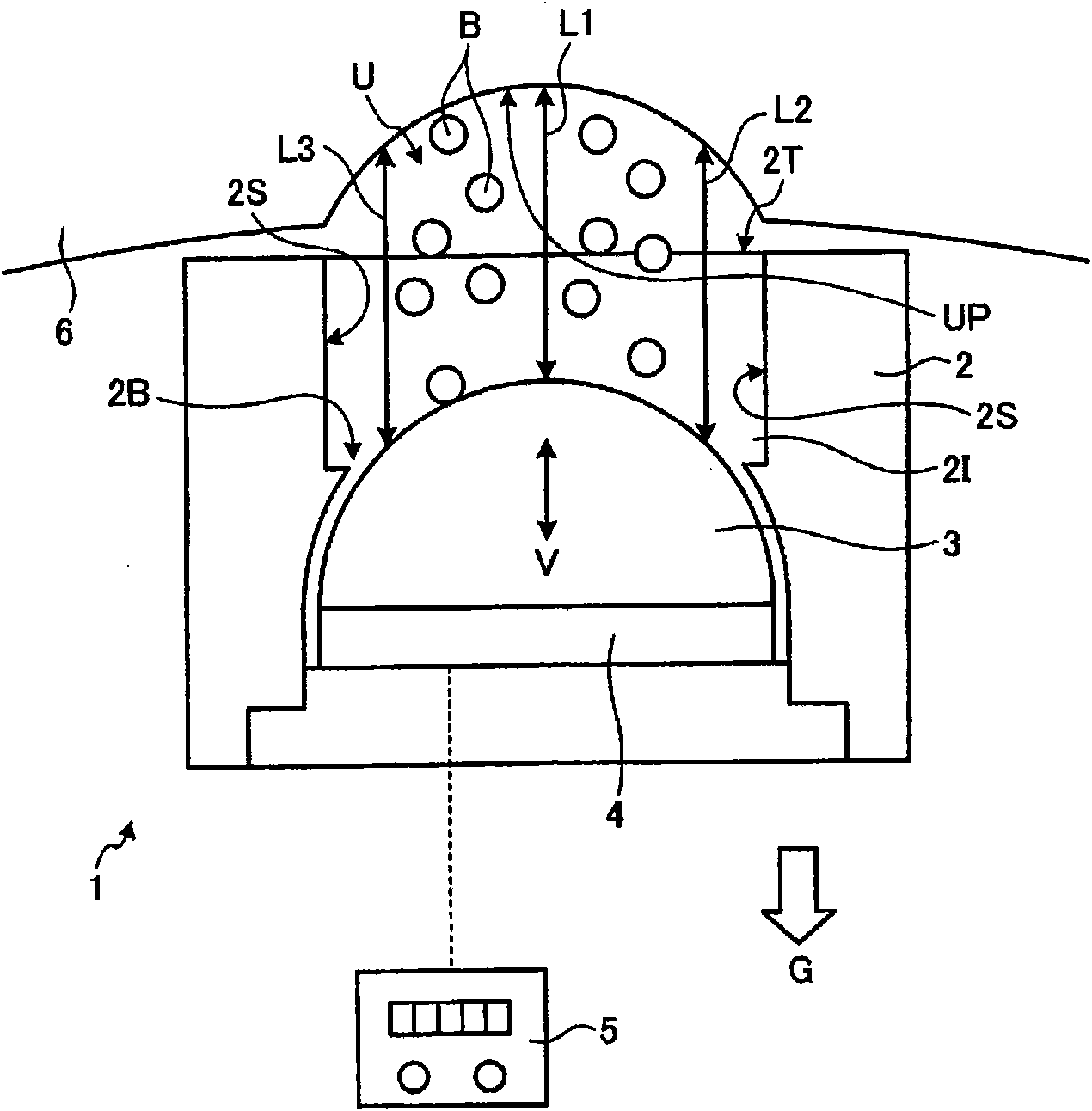

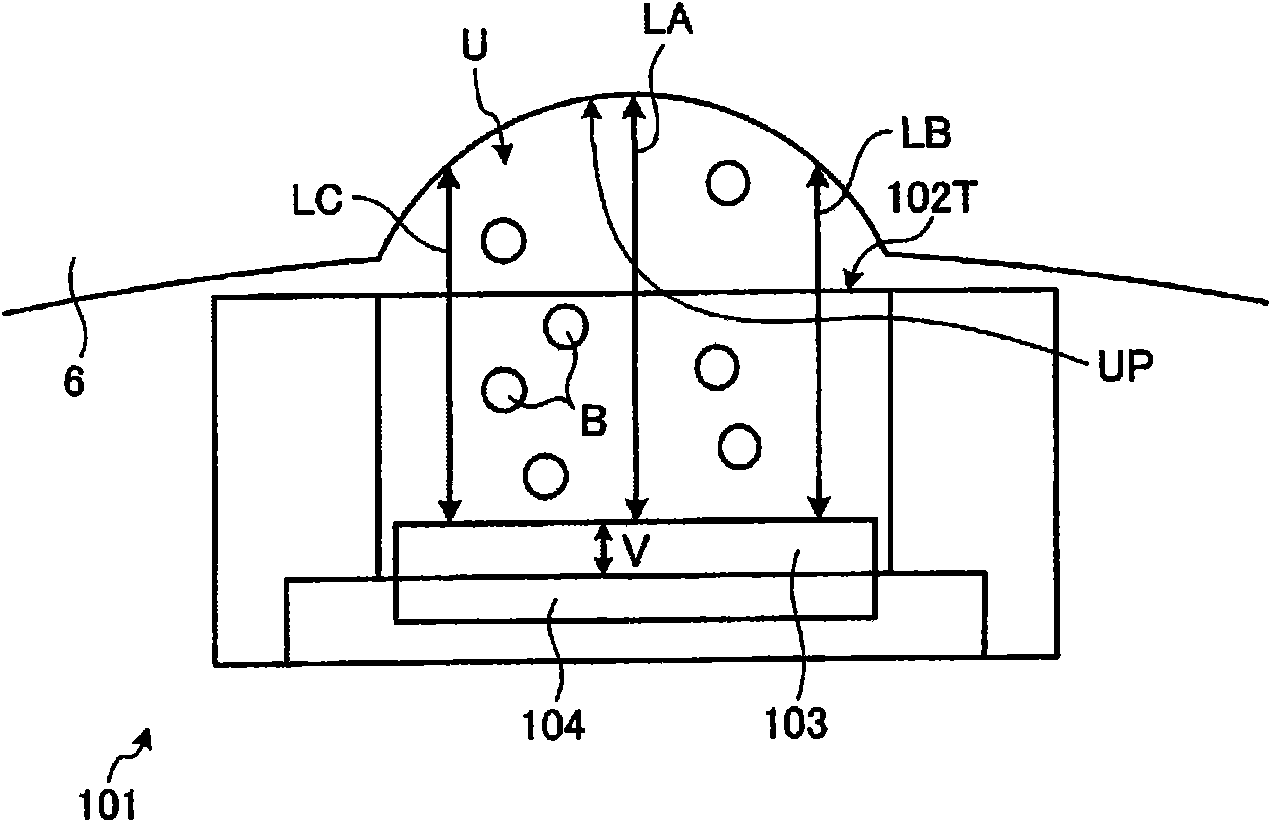

[0028] Hereinafter, the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to the best form (henceforth an Example) for carrying out this invention. In addition, the constituent elements in the following examples include elements that can be easily conceived by those skilled in the art, are substantially the same, and are within the so-called equivalent range.

[0029] The present invention is suitable for shot blasting of concave or convex shapes. In addition, in this invention, the construction part of a shot blast process is not limited to a welded part. In addition, the present invention is generally applicable to, for example, the inside and outside of the inlet and outlet of steam generators used in power generation equipment, fluid piping, pressure vessels, and other parts that require shot blasting, and the applicable objects of the present invention are not particularly limited.

[0030] This embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com