Shape correction and strengthening method for postwelding prestressing force of moderately thick light alloy plate

A lightweight alloy, prestressed technology, used in metal processing equipment, explosion generating devices, abrasives, etc., can solve the problems of low efficiency of laser shot peening portable shot peening, weld cracking, etc., to reduce energy, avoid Damage, easy to operate and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

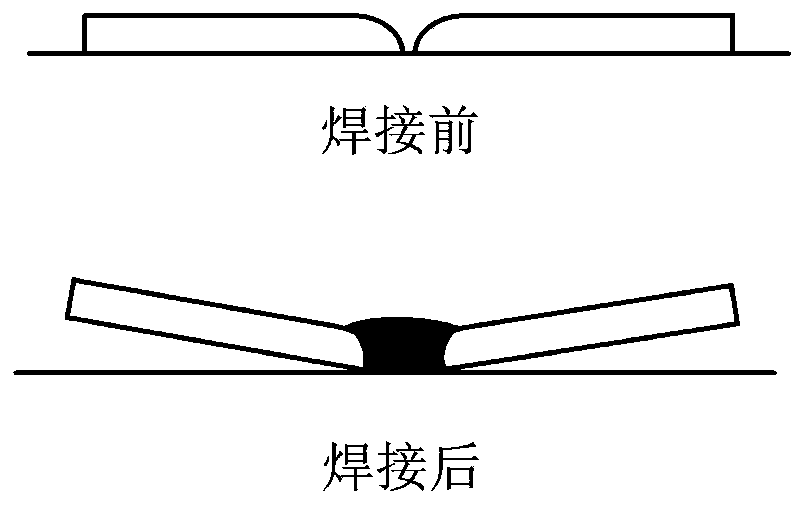

[0031] figure 1 It is a schematic diagram of the deformation before and after welding in the constraint release state. It can be seen that the weldment has obvious angular deformation, and the two sides are upturned.

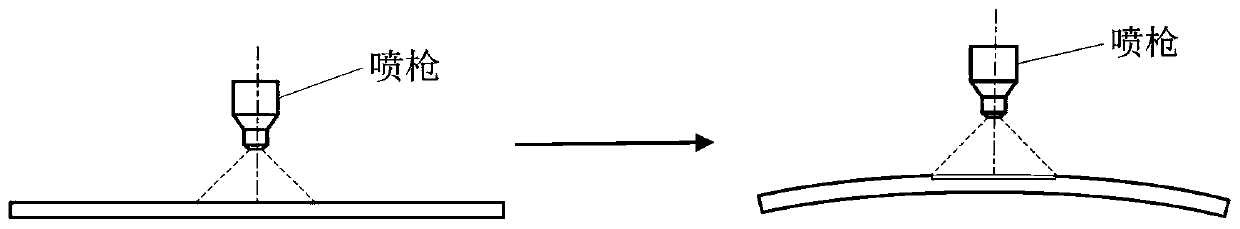

[0032] figure 2 It is a schematic diagram of deformation correction by ultrasonic shot peening. The deformation trend is just opposite to the deformation after welding. Therefore, the deformation after welding can be corrected by ultrasonic shot peening method under the condition that the restraint is not released, so as to realize high-efficiency and low-cost deformation correction.

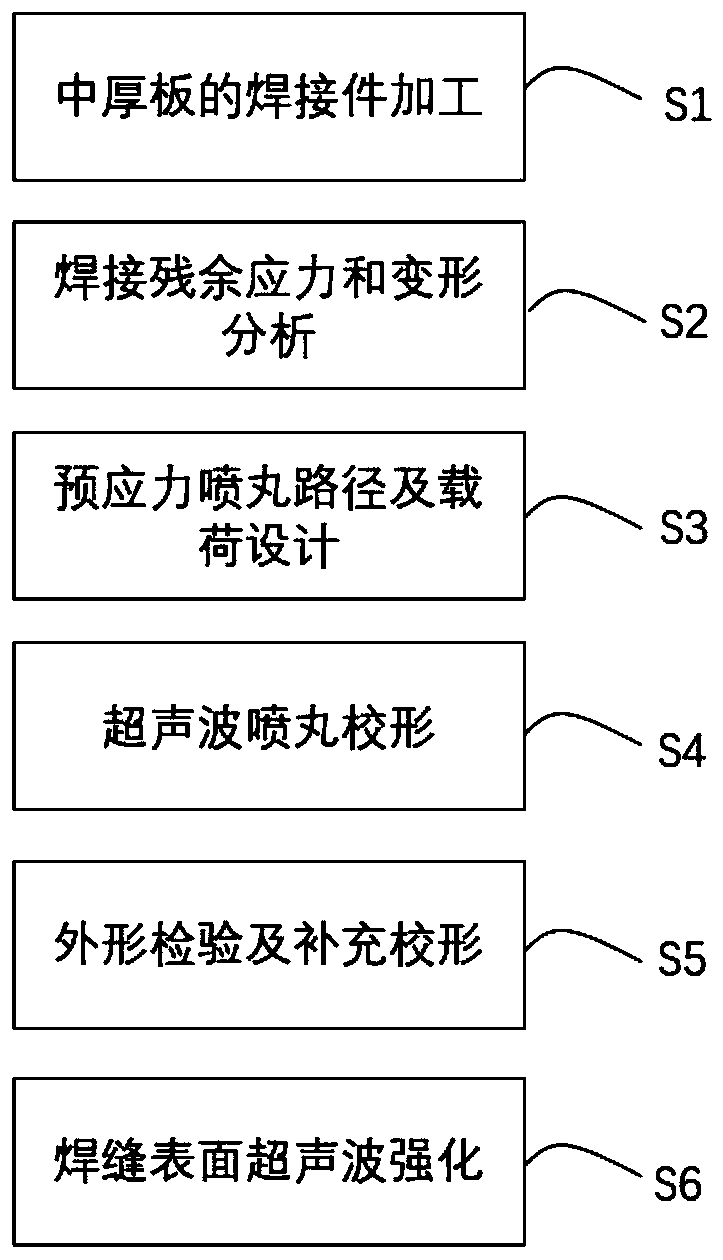

[0033] refer to image 3 , image 3 Disclosed is a flow chart of post-weld prestress shape correction and strengthening in an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com