System and method for surface cleaning

A technology for cleaning and cleaning heads, applied in the direction of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve problems such as difficult to reach or access, inconsistent cleaning quality, etc., to achieve the goal of reducing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The following specific embodiments are made with reference to the accompanying drawings, which illustrate specific aspects of the present disclosure. Other aspects with different structures and operations do not depart from the scope of the present disclosure. In different drawings, similar reference signs may refer to the same elements or parts.

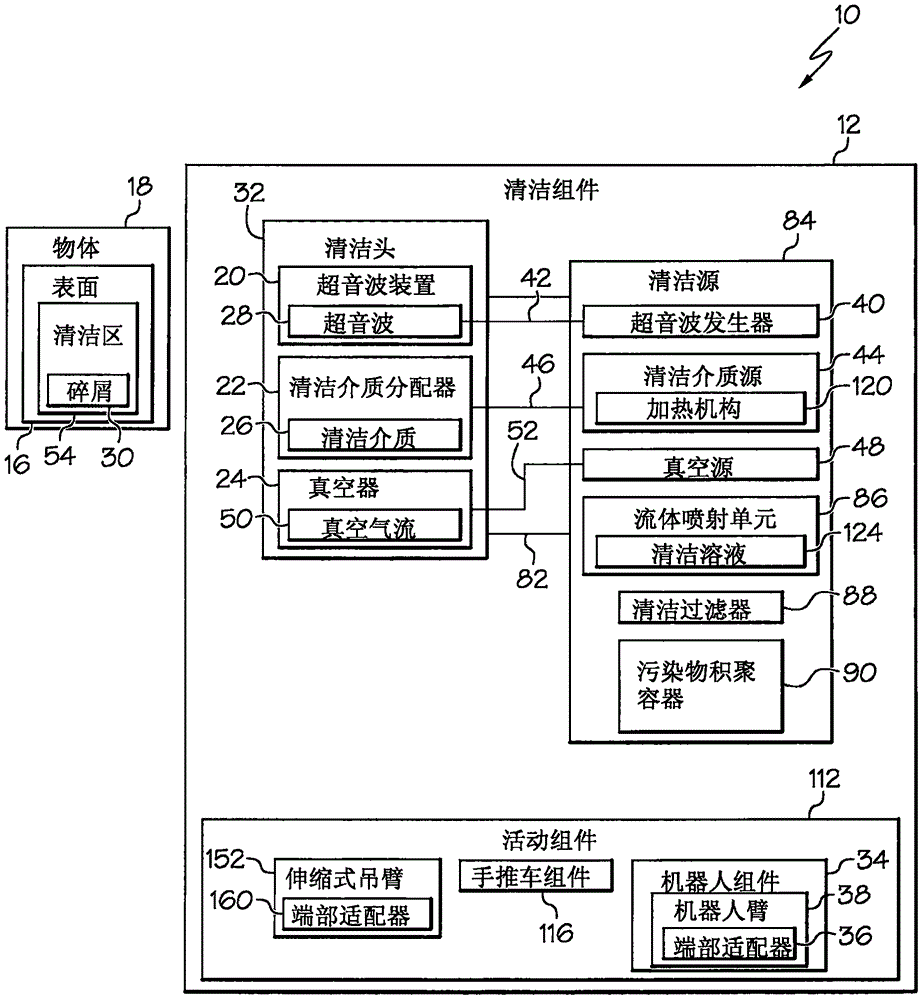

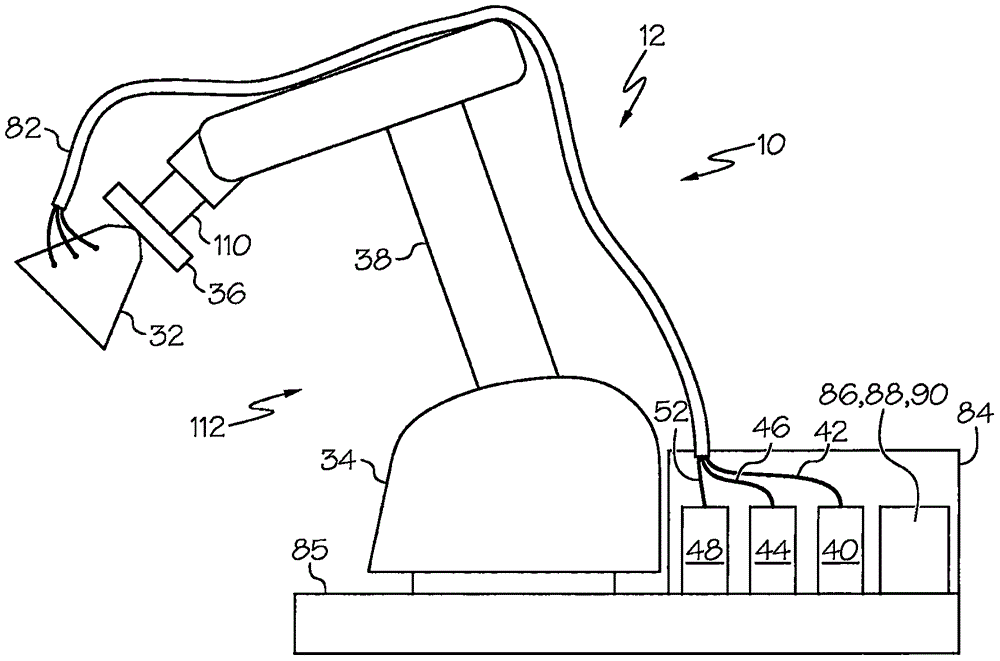

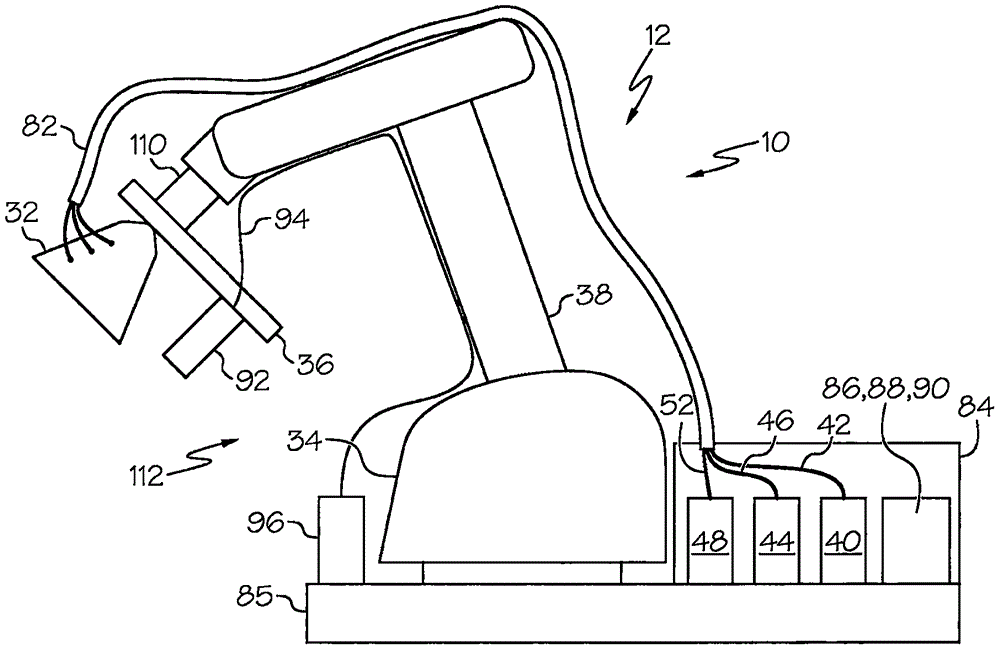

[0071] reference figure 1 One aspect of the disclosed system (generally denoted as 10) for cleaning the surface of an object may include a cleaning assembly 12 for cleaning one or more objects such as during the production, assembly, and / or maintenance of the object 18. One or more surfaces 16 of each object 18 are cleaned. For example, the object 18 may include any manufactured part, component, assembly, or subassembly having a large and / or complex surface 16, including, but not limited to, a complex three-dimensional object 18 and / or a large, two-dimensional object 18, such as Aircraft components (for example, aircraft wings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com