Special-shaped tube broacher

A technology for reaming machines and special-shaped tubes, which is applied in the direction of reaming devices, reaming devices, metal processing machinery parts, etc., and can solve the problems of lack of processing equipment, high strength of carbon fiber tubes, and difficulty in processing carbon fiber tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

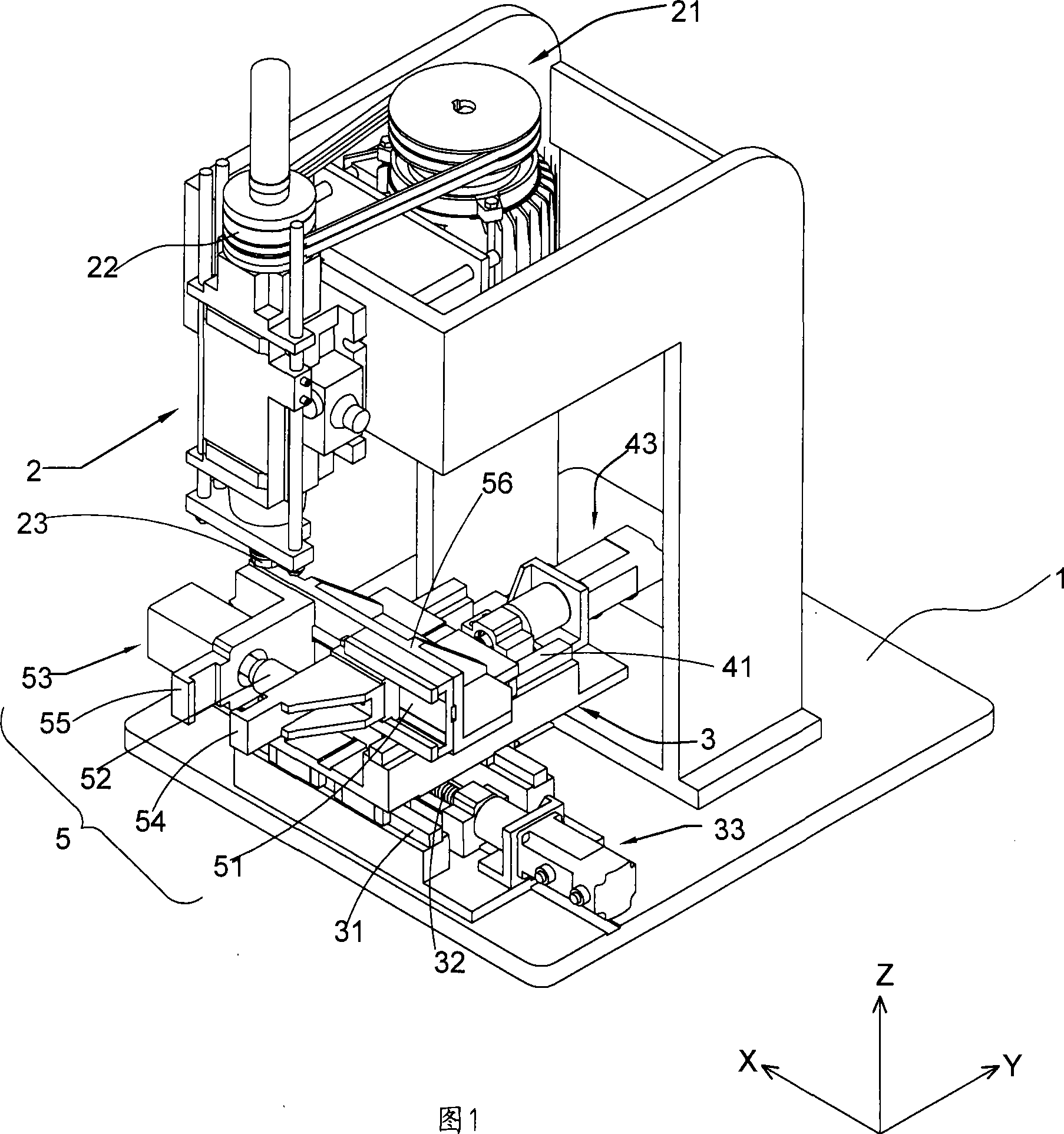

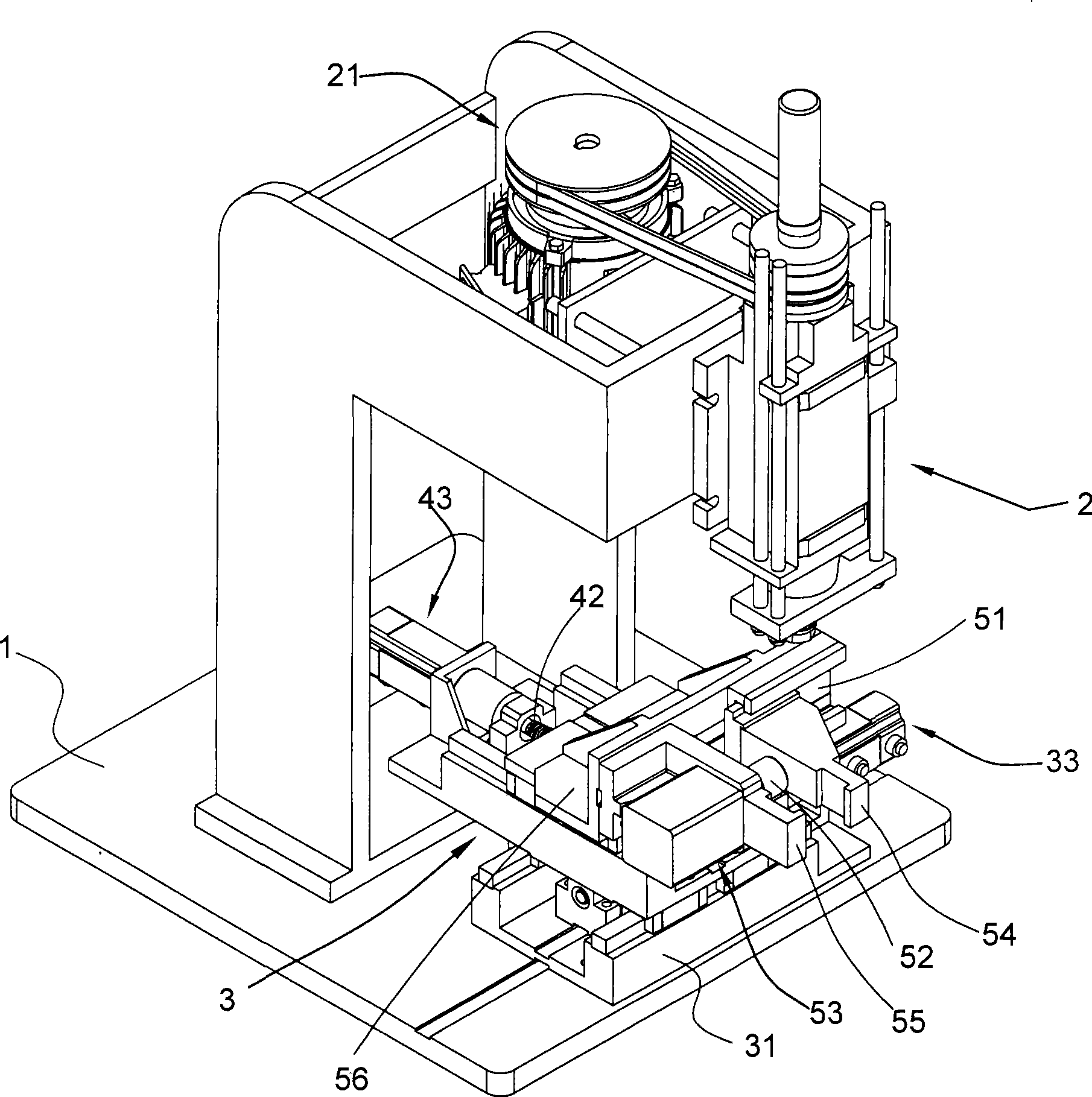

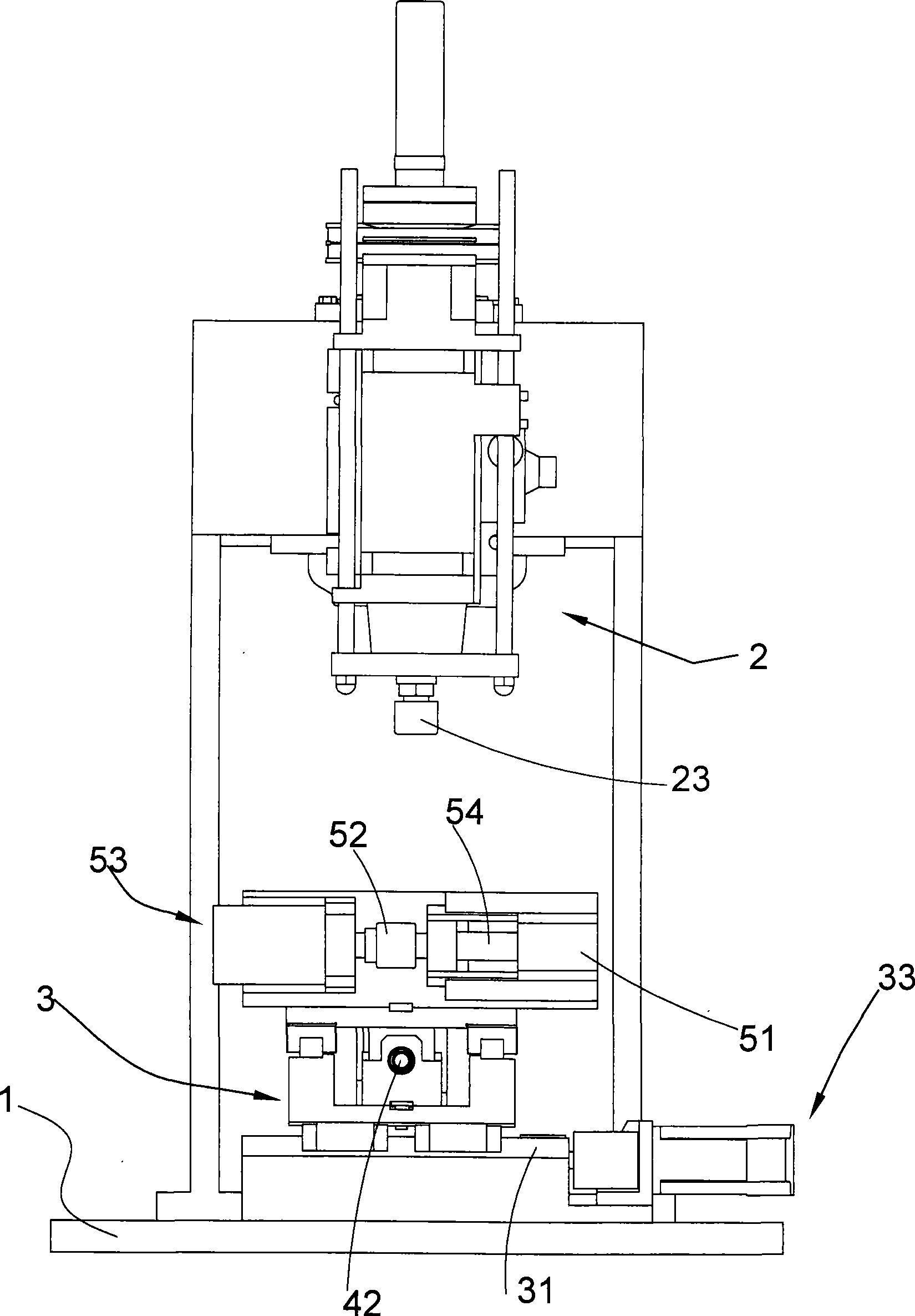

[0016] See Figure 1 to Attached Figure 4 , a special-shaped pipe reaming machine, which includes a frame 1, a tool seat 2 fixedly arranged on the frame 1, a clamping mechanism 5 for clamping a pipe to be processed, and a tool seat 2 is rotatably provided with a The cutter 23 that rotates along its own axis has emery on the outer peripheral surface of the cutter 23; the X-direction rail 31 extending along the X direction is arranged on the seat body 1, and the X-direction slide seat 3 is slid and fitted on the X-direction rail 31 There is a Y-guiding rail 41 perpendicular to the X-direction on the X-direction slide 3, the clamping mechanism 5 is slidably arranged on the Y-guiding rail 41, and the axis direction of the tool 23 is perpendicular to the X-direction and the Y-direction. The base body 1 is fixedly provided with a motor 21, and the motor 21 drives the tool 23 to rotate around its own axis through the main shaft 22, thereby completing the processing; since the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com