Chambering drilling machine

A technology of reaming drills and drilling rigs, which is applied to drill bits, drilling equipment, earthwork drilling and mining, etc., and can solve problems such as high processing accuracy and sealing requirements, blade wear and stirring, and uneven hardness and softness of the formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

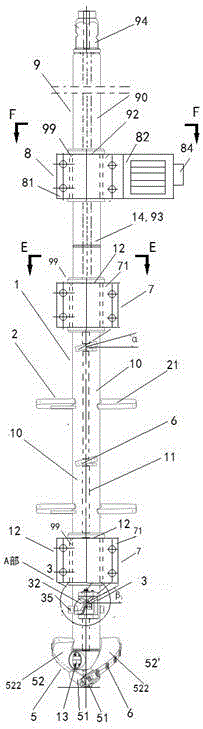

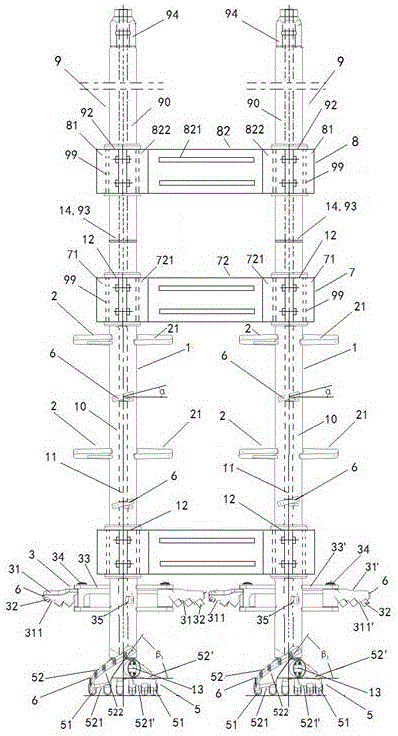

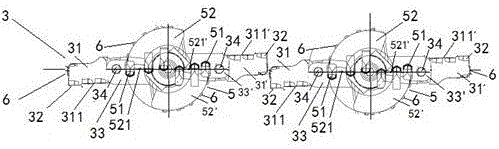

[0034] Such as Figure 1-7 As shown, a reaming drilling machine includes: two hollow light drill rods on the left and right, each hollow light drill rod 9 includes: a polished rod body 90, a guide groove 92, and a female joint 93 and a male joint 94 respectively located at the lower end and the upper end of the polished rod body Two reaming drills on the left and right, each reaming drill 1 includes: comprising a hollow pipe body 10, a grouting pipe 11 arranged in the inner cavity of the hollow pipe body, a grouting valve 13 positioned at the lower end of the hollow pipe body and The outer joint 14 that is located at the upper end of the hollow pipe body and cooperates with the female joint 93 of the hollow light drill pipe, the outer wall of the hollow pipe has a support groove 12; the enlarged cutting wing 3 includes an enlarged arm 31, a multi-piece mounted on the enlarged arm A reamer body 32, a frame 33 welded to the outer wall of the hollow tubular body 10, a pin shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com