Ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and manufacturing method thereof

A technology of bending properties and manufacturing methods, applied in the fields of products, ultra-high strength hot-rolled multi-phase steel sheets and steel strips and their manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment.

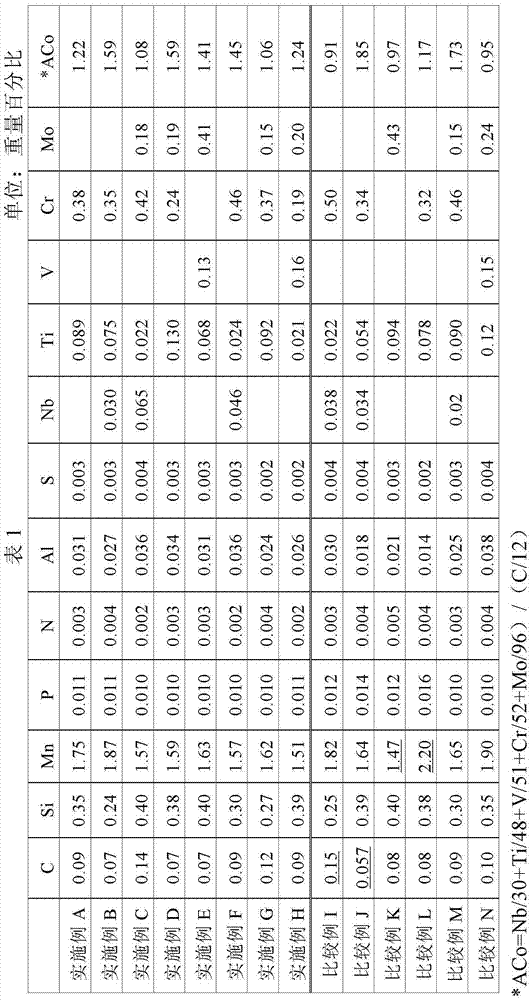

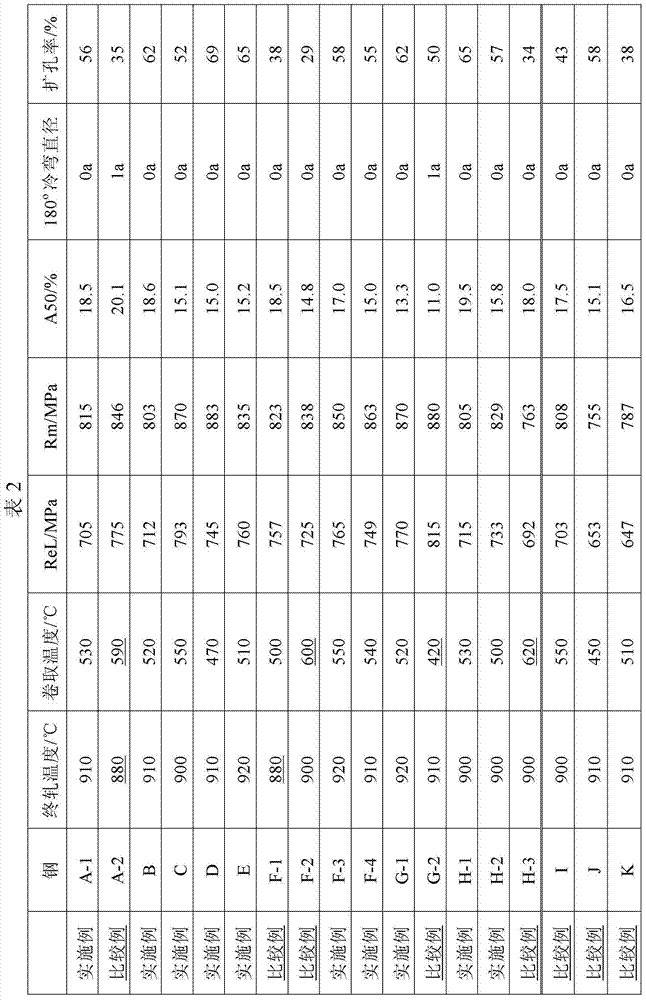

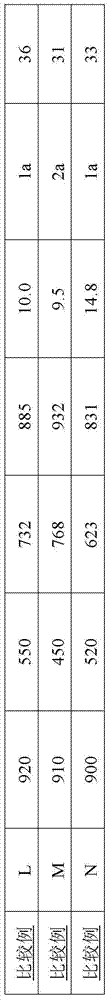

[0040] The steels with different compositions shown in Table 1 were smelted and then reheated at 1250°C, followed by hot rolling and coiling at the finishing rolling and coiling temperatures shown in Table 2 to obtain steel plates with a thickness of less than 6mm. Take the JIS 5# tensile specimen along the transverse direction, and the test data are shown in Table 2. Cold bending performance refers to the performance of metal materials that can withstand bending without cracking at room temperature. The degree of bending is generally expressed by the ratio of bending angle α (external angle) and bending center diameter d to material thickness a. The larger a or the smaller d / a, the better the cold bending property of the material. The cold bending performance in Table 2 is the cold bending diameter of 180° bending. The hole expansion test is a sheet formability test. Use the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com