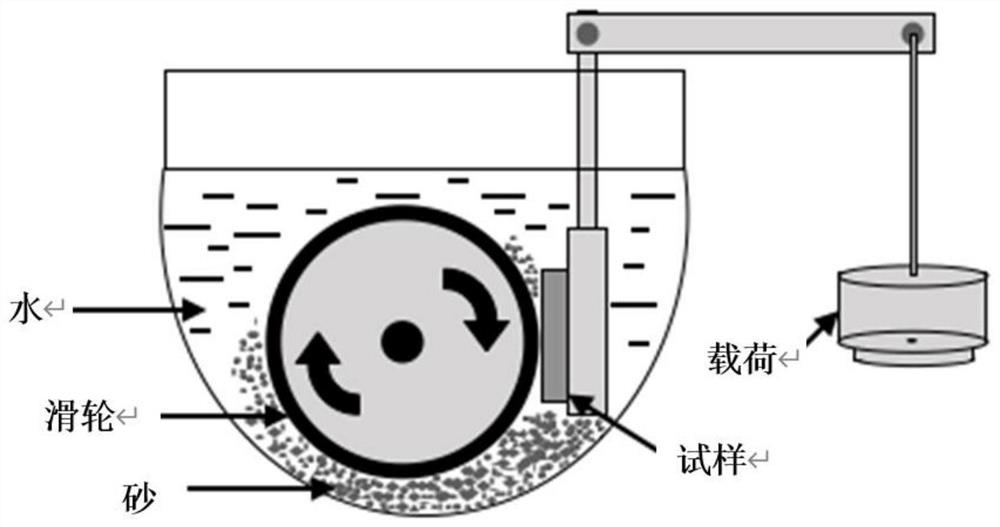

Bainite-based wear-resistant steel and production method thereof

A production method, bainite technology, applied in the field of hot strip rolling, can solve the problems of difficulty in popularization and poor plasticity, and achieve the effects of low cost, improved wear life and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

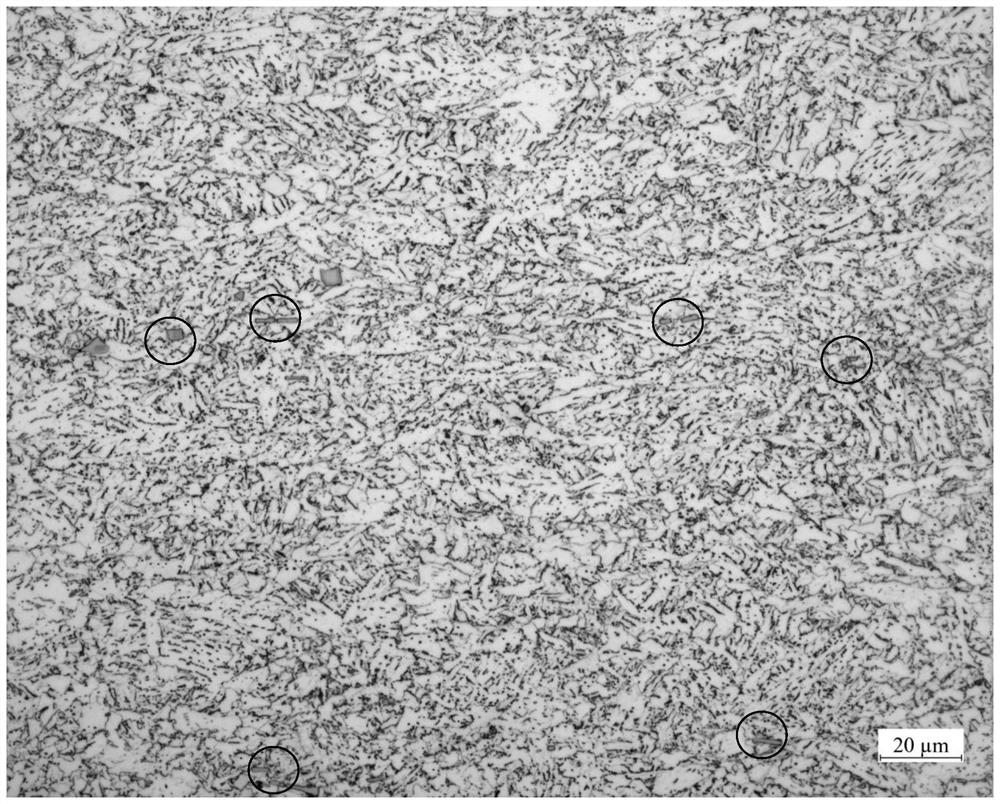

Image

Examples

Embodiment 1

[0039] The composition of molten steel after the steelmaking step is: 0.18% by weight of C, 0.38% by weight of Ti, 0.22% by weight of Cr, 0.19% by weight of Mo, the balance is Fe and unavoidable impurities, and the thickness of the continuous casting slab is 230mm , and then soaked in a heating furnace at 1250°C, the thickness of the intermediate billet after rough rolling is 43mm, the start rolling temperature of finish rolling is 1060°C, and the finish rolling temperature is 840°C. The thickness of the steel plate after finishing rolling is 4.0mm, and then cooled to 460°C at a cooling rate of 62°C / s for coiling after the first stage of interlayer cooling. The coil yield strength (ReL), tensile strength (Rm), elongation (A), impact value at -20°C, and wear resistance index are shown in Table 1.

Embodiment 2

[0041] The composition of molten steel after the steelmaking step is: 0.21% by weight of C, 0.48% by weight of Ti, 0.021% by weight of Nb, 0.25% by weight of Mo, the balance is Fe and unavoidable impurities, and the thickness of the continuous casting slab is 200mm , and then soaked in a heating furnace at 1230°C, the thickness of the intermediate billet after rough rolling is 45mm, the starting temperature of finish rolling is 950°C, and the finishing temperature of finish rolling is 810°C. The thickness of the steel plate after finish rolling is 5.0mm, and then cooled to 530°C at a cooling rate of 54°C / s for coiling after the first stage of interlayer cooling. The coil yield strength (ReL), tensile strength (Rm), elongation (A), impact value at -20°C, and wear resistance index are shown in Table 1.

Embodiment 3

[0043] The composition of molten steel after the steelmaking step is: 0.24% by weight of C, 0.43% by weight of Ti, 0.012% by weight of Nb, 0.36% by weight of Cr, 0.28% by weight of Mo, and the balance is Fe and unavoidable impurities. The thickness of the cast slab is 220mm, and then it is soaked in a heating furnace at 1240°C. The thickness of the intermediate slab after rough rolling is 36mm. The thickness of the steel plate after finish rolling is 5.0mm, and then cooled to 420°C at a cooling rate of 57°C / s for coiling after the first stage of interlayer cooling. The coil yield strength (ReL), tensile strength (Rm), elongation (A), impact value at -20°C, and wear resistance index are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com