780 MPa hot-rolled high-strength steel with high hole expansion ratio and manufacturing method thereof

A technology of high-reaming steel and manufacturing method, applied in the field of hot-rolled high-strength steel, which can solve problems such as low strength, large performance difference, and difficulty reaching 780MPa and above

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in conjunction with the embodiments and the accompanying drawings.

[0064] Table 1 shows the composition of the steel of the example of the present invention, Table 2 shows the manufacturing process of the example of the present invention, and Table 3 shows the mechanical properties of the steel plate of the example of the present invention.

[0065] The process flow of this embodiment: converter or electric furnace smelting→vacuum furnace secondary refining→cast billet (ingot)→steel billet (ingot) reheating→hot rolling+stage cooling process→steel coil.

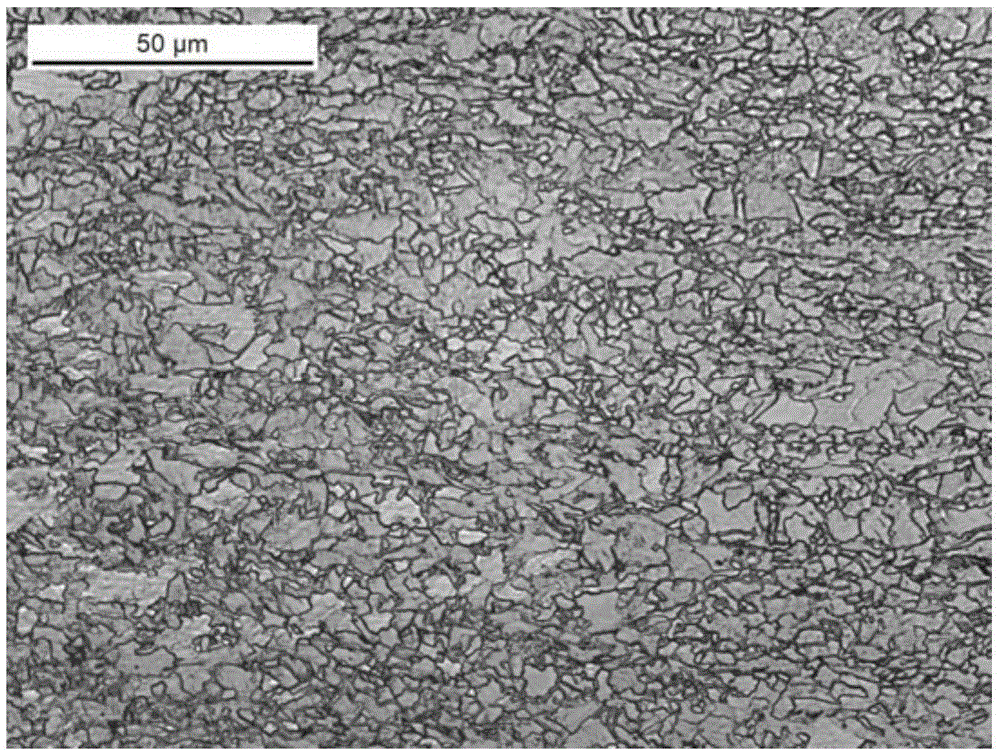

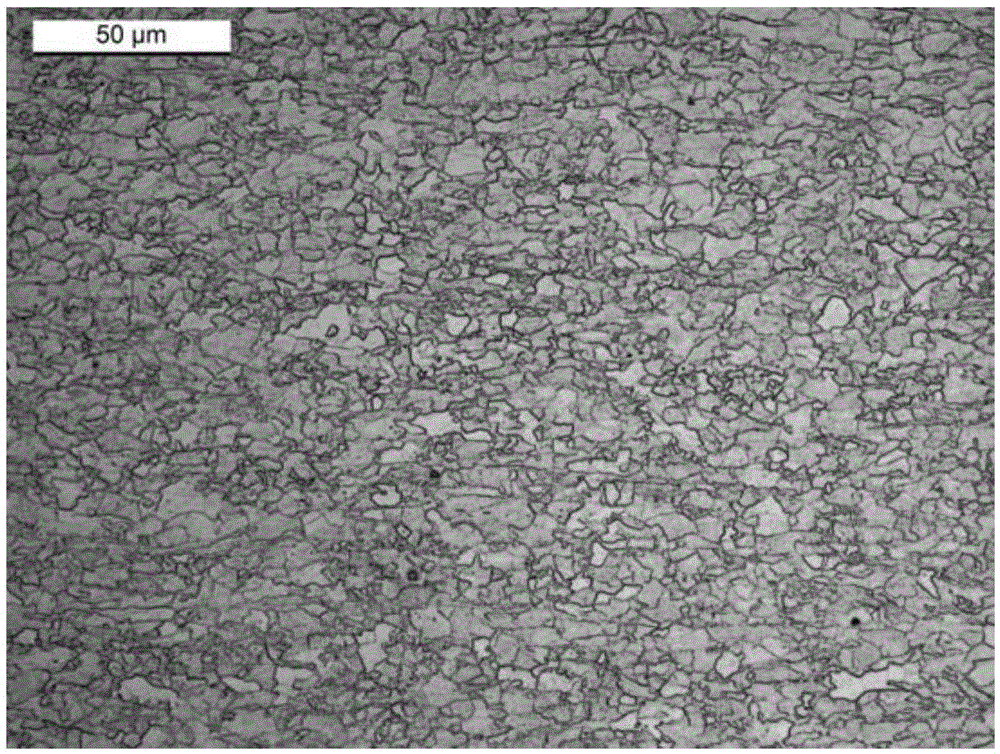

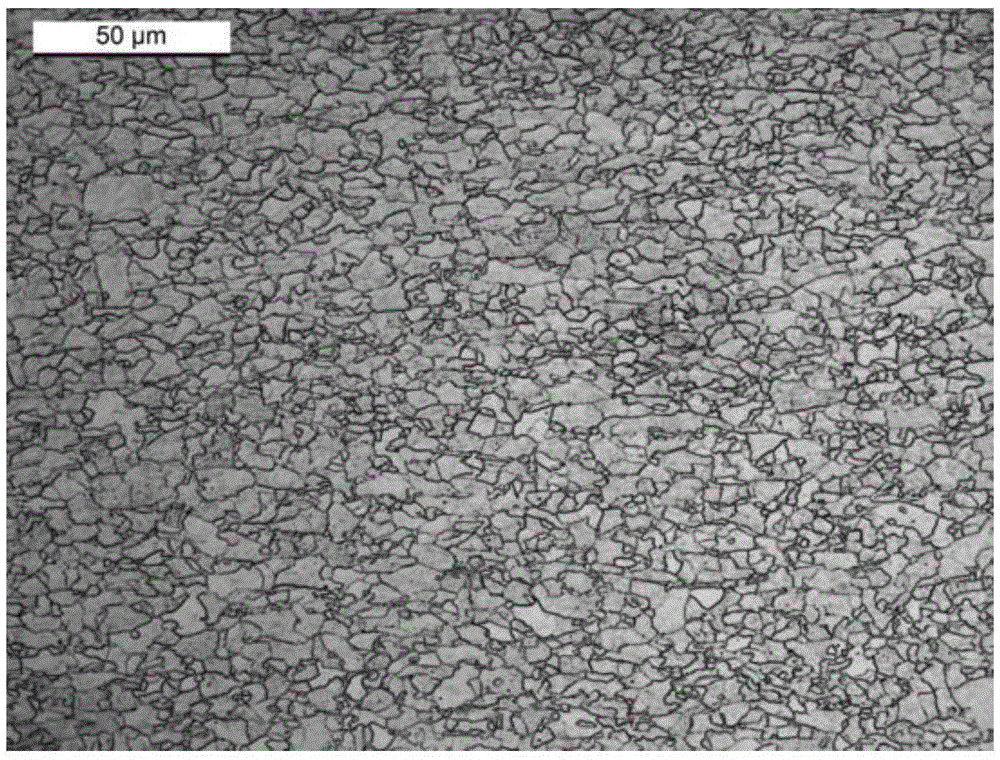

[0066] see Figure 1-Figure 5 , as can be seen from the metallographic photographs, the microstructure of the steel plate of the present invention is fine ferrite+nanoscale carbides (nanoscale carbides cannot be distinguished from the metallographic photographs), and the average ferrite grain size is about 4-5 μm, there is no pearlite type tissue that is unfavorable to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com