Flavored fermented rice cake and preparation method thereof

A rice cake and flavor technology, which is applied in the directions of bacteria and food ingredients used in food preparation as encapsulating agents, lactobacilli, etc., can solve the problem of not fully reflecting microbial biological flavor enhancement and improving nutrition, flavor components, content and stability. Improvement, the fermentation performance of microbial starter cannot be guaranteed, etc., to achieve the effect of strong technical guidance, practical control of process parameters, and white and moist appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

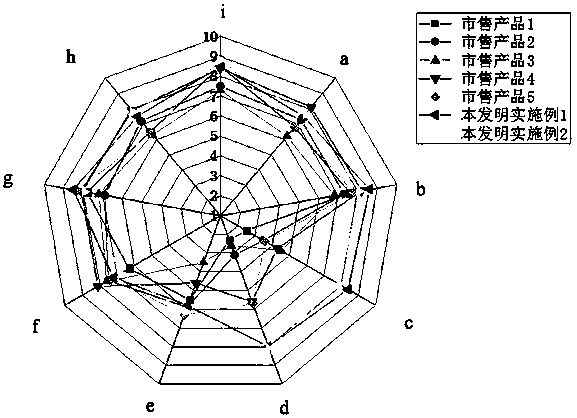

Examples

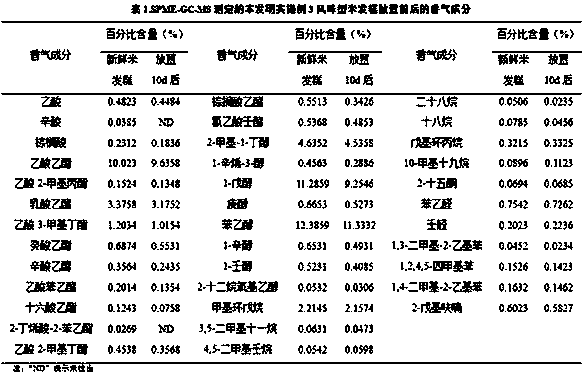

Embodiment 1

[0060] (1) Preparation of compound starter: take 20g of Lactobacillus plantarum seed suspension and 20g of Saccharomyces cerevisiae seed suspension, mix them together and inoculate them into 800g of PDA medium, and co-cultivate them at 32°C / 120rpm for 24 hours to obtain a starter starter; take grape 2.3 g of Hansenula spp. seed suspension and 4.6 g of Saccharomyces fumigatus seed suspension were mixed and co-inoculated into 138 g of PDA medium, and co-cultivated at 32° C. / 120 rpm for 36 hours to obtain an aroma-enhancing starter;

[0061] (2) Flour making: Weigh indica-type broken rice and wash it. The mass ratio of rice to water at room temperature is 1:3. Add water to soak for 1 hour. After draining, take half of the soaked rice and dry it in an oven at 60°C. 150-mesh sieve to obtain rice flour; another half of the soaked rice was steamed under normal pressure for 25 minutes to make the degree of gelatinization reach 55%, then placed in an oven at 60°C for drying, and ultrafi...

Embodiment 2

[0073] (1) Preparation of compound starter: Take 50g of Lactobacillus plantarum seed suspension and 100g of Saccharomyces cerevisiae seed suspension, mix them together and inoculate them into 3000g of PDA medium, and co-cultivate them at 31°C / 130rpm for 28 hours to obtain a starter starter; take grape 5 g of Hansenula spp. seed suspension and 15 g of Saccharomyces fumigatus seed suspension were mixed and inoculated into 400 g of PDA medium, and co-cultivated at 31° C. / 130 rpm for 42 hours to obtain an aroma-enhancing starter;

[0074] (2) Flour making: Weigh indica-type broken rice and wash it. The mass ratio of rice to water at room temperature is 1:3. Add water to soak for 1 hour. After draining, take half of the soaked rice and dry it in an oven at 60°C. 180-mesh sieve to obtain rice flour; another half of the soaked rice was steamed under normal pressure for 30 minutes to make the degree of gelatinization reach 65%, then placed in an oven at 60°C for drying, and ultrafinely...

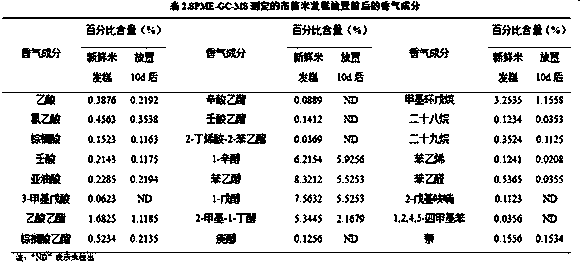

Embodiment 3

[0086] (1) Preparation of compound starter: take 120g of Lactobacillus plantarum seed suspension and 360g of Saccharomyces cerevisiae seed suspension, mix them and inoculate them into 9600g of PDA medium, and co-cultivate them at 30°C / 150rpm for 30 hours to obtain a starter starter; take grape 13g of Hansenula spp. seed suspension and 50g of Saccharomyces fumigatus seed suspension were mixed and co-inoculated into 1260g of PDA medium, and co-cultivated at 30°C / 150rpm for 48h to obtain an aroma-enhancing starter;

[0087] (2) Flour making: Weigh indica-type broken rice and wash it. The mass ratio of rice to water at room temperature is 1:3. Add water to soak for 1 hour. After draining, take half of the soaked rice and dry it in an oven at 60°C. 200-mesh sieve to obtain rice flour; another half of the soaked rice was steamed under normal pressure for 35 minutes to make the degree of gelatinization reach 75%, then placed in an oven at 60°C for drying, and ultrafinely pulverized th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com