Biological latex used for papermaking and preparation method thereof

A bio-latex and bio-glue technology, applied in the field of coatings, can solve the problems of poor ink absorption performance and paper brittleness, and achieve the effects of improving coating performance, improving toughness and mechanical properties, and reducing the number of hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

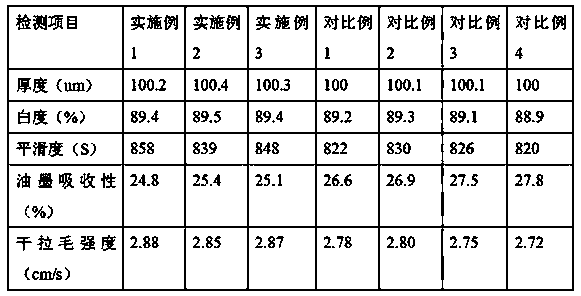

Examples

preparation example Construction

[0023] The preparation method of biological glue base material is:

[0024] (1) Take waxy corn starch and add sodium acetate buffer solution with pH 5.0 according to the mass ratio of 1~4:10~15, stir and mix for 20~30min, heat up to 50~55℃ and keep it for 20~30min to obtain the mixture, take glucose starch The enzyme is mixed with α-amylase at a mass ratio of 3~5:1~3 to obtain a mixed enzyme, and the mixture is added with a mixed enzyme at a mass ratio of 80~100:1~4, enzymatically hydrolyzed at 45~55°C for 10~15 hours, and extinguished For enzymes, first adjust the pH to 8.5-9, stir and mix for 30-50 minutes, then adjust the pH to 7-7.2, filter, take the filter cake to dry, crush through a 100-mesh sieve, and collect the sieved particles;

[0025] (2) Take the sieved particles and add deionized water according to the mass ratio of 2~5:8~10, raise the temperature to 45~50℃, add anhydrous sodium sulfate with 4~7% of the sieved particles, keep it warm for 5~10min, adjust pH to 8...

Embodiment 1

[0034] The preparation method of biological glue base material is:

[0035] (1) Take waxy corn starch and add pH5.0 sodium acetate buffer at a mass ratio of 1:10, stir and mix for 20 minutes, heat up to 50°C and keep it for 20 minutes to obtain a mixture, take glucoamylase and add α- Mix amylase to obtain a mixed enzyme, take the mixture and add the mixed enzyme at a mass ratio of 80:1, enzymolyze at 45°C for 10 hours, inactivate the enzyme, first adjust the pH to 8.5, stir and mix for 30 minutes, then adjust the pH to 7, filter, and filter The cake is dried, crushed and passed through a 100-mesh sieve, and the sieved particles are collected;

[0036] (2) Take the sieved particles and add deionized water at a mass ratio of 2:8, heat up to 45°C, add anhydrous sodium sulfate with 4% of the sieved particles, keep warm for 5 minutes, adjust the pH to 8, and then add deionized water 10% hexamethyldisilazane, keep it at pH 5.0 and 45°C for 2 hours, filter, take the filter cake a, w...

Embodiment 2

[0045] The preparation method of biological glue base material is:

[0046] (1) Take waxy corn starch and add pH5.0 sodium acetate buffer solution at a mass ratio of 4:15, stir and mix for 30 minutes, heat up to 55°C and keep warm for 30 minutes to obtain a mixture, take glucoamylase at a mass ratio of 5:3 and add α- Mix amylase to obtain a mixed enzyme, take the mixture and add the mixed enzyme at a mass ratio of 100:4, enzymolyze at 55°C for 15 hours, inactivate the enzyme, first adjust the pH to 9, stir and mix for 50 minutes, then adjust the pH to 7.2, filter, and filter The cake is dried, crushed and passed through a 100-mesh sieve, and the sieved particles are collected;

[0047] (2) Take the sieved particles and add deionized water at a mass ratio of 5:10, raise the temperature to 50°C, add anhydrous sodium sulfate with 7% of the sieved particles, keep it warm for 10 minutes, adjust the pH to 9, and then add deionized water 15% hexamethyldisilazane, heat at pH 5.0, 50°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com