Methanol low temperature cracking device

A technology of low-temperature cracking and methanol, applied in the direction of sustainable manufacturing/processing, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor uniformity of reaction temperature, high equipment investment cost, low use efficiency, etc., and achieve a large use temperature span , Simple structure, easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

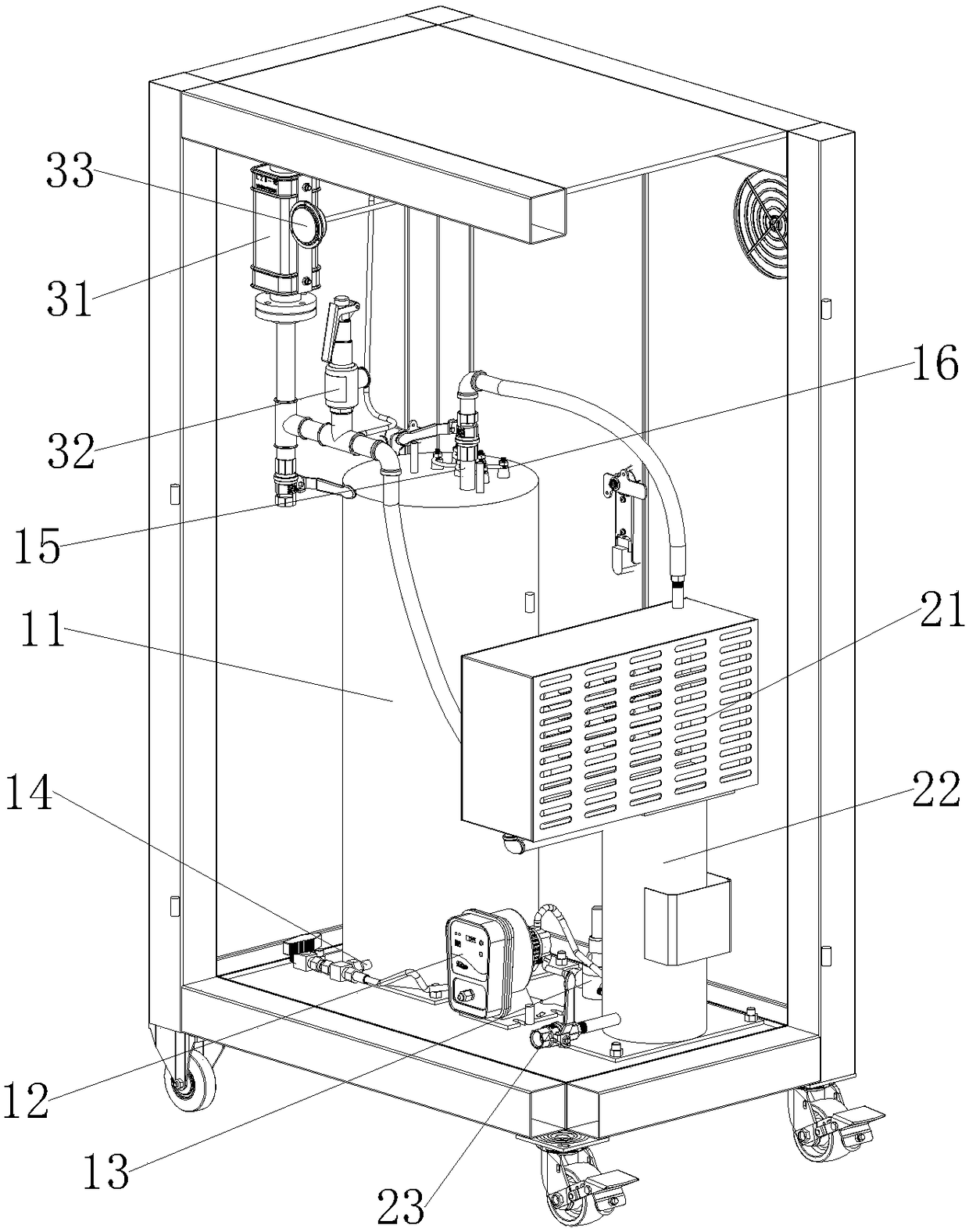

[0033] The present invention will now be further described with reference to the accompanying drawings.

[0034] like figure 1 As shown, the methanol low-temperature cracking device includes a cracking reactor 11 and a condenser 21; the liquid inlet 14 of the cracking reactor 11 is respectively connected with the nitrogen and methanol liquid storage tanks, and the methanol liquid storage tank and the liquid inlet 14 are also installed There is a liquid inlet metering pump 12 and a back pressure valve 13; an inlet flow meter is installed between the nitrogen gas and the liquid inlet 14; the gas outlet 15 of the cracking reactor 11 is connected to the condenser 21, and the condenser 21 is equipped with a condensing fan, which condenses The outlet of the condenser 21 is connected with the gas outlet flowmeter 31, and the gas outlet flowmeter 31 is connected with the gas outlet of the mixer; a safety relief valve 32 and a pressure gauge 33 are also installed between the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com