High-activity ultrafine aluminum powder preparing process and device

A preparation process and technology of active aluminum, which is applied in the field of preparation process and device of ultra-fine high-activity aluminum powder, can solve problems such as irregular shape and influence on surface activity, achieve low environmental impact, high surface activity, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

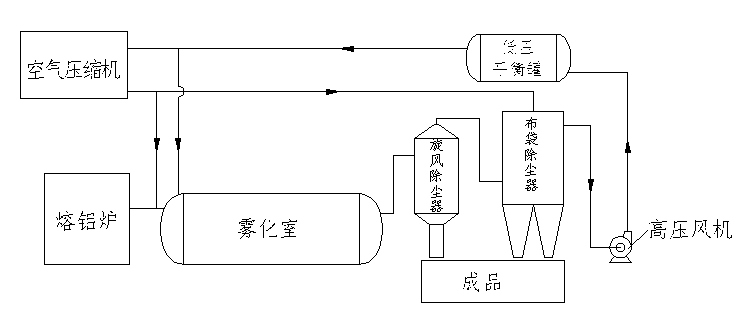

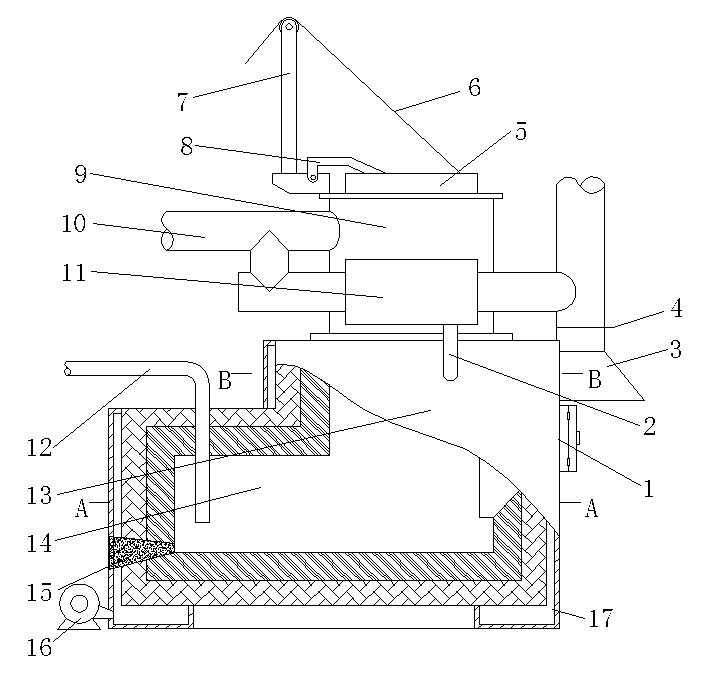

[0036] Such as figure 1 , 2 Shown, the preparation technology of superfine high-activity aluminum powder is as follows:

[0037] 1) Melting: The aluminum ingot is melted in the aluminum melting furnace, and the melted aluminum liquid is stored in the heat preservation area of the aluminum melting furnace, and the temperature of the aluminum liquid in the heat preservation area is kept at about 760°C;

[0038] 2) Atomization: The aluminum liquid in the heat preservation area of the aluminum melting furnace is transported to the atomization chamber through the aluminum liquid delivery pipe, and sprayed out through the gas atomization nozzle installed in the atomization chamber for atomization and granulation. The injection direction of aluminum liquid is horizontal injection.

[0039] The aluminum liquid in the heat preservation area is under the influence of the liquid surface pressure of the aluminum liquid and the mixed gas on the gas atomization nozzle. The pressure is...

Embodiment 2—5

[0048] On the basis of Example 1, change the aluminum liquid temperature in the heat preservation zone, the pressure of the mixed gas, the flow rate and the ratio of nitrogen and oxygen in the mixed gas, and the finished aluminum powder is shown in the following table:

[0049] Example Aluminum liquid temperature pressure flow rate nitrogen to oxygen ratio Aluminum powder particle size 2 780 8 4 99.9%:0.1% 6 3 800 9 5 99.9%:0.1% 4 4 820 10 5 99.99%:0.01% 3 5 840 12 6 99.999%:0.001% 1

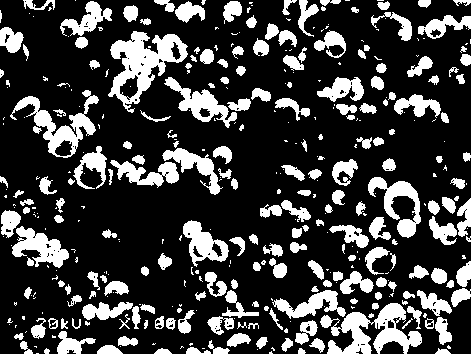

[0050] In the above examples, the water surface coverage dispersion of the finished aluminum powder is >10000cm 2 / g, active aluminum is greater than 99%, and the particle size of aluminum powder is the average particle size.

[0051] In step 3 of Example 2, the classifier uses a pulse back-blowing bag filter.

[0052] In Step 3 of Example 3-5, the classifier adopts a two-stage classification in which a multi-tube ceramic dust collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com