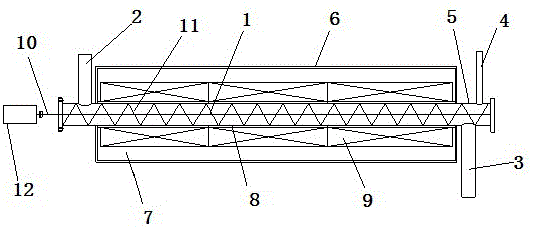

Fancy spiral electronic waste pyrolysis device

A technology of pyrolysis of e-waste, which is applied in special forms of dry distillation, indirect heating of dry distillation, petroleum industry, etc., can solve the problems affecting the straight screw conveying materials, the pyrolysis process of e-waste cannot be continuous, and improve the conveying capacity, so as to achieve partitioning Precise control of temperature, improvement of internal spiral tar bonding, and avoiding the effects of adhesion and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

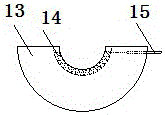

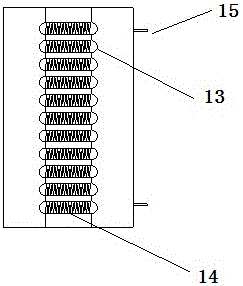

Embodiment 1

[0032] Embodiment 1: The electric heating system is heated by an electric heating wire, the diameter of the electric heating wire is 1.4mm, and the total length is 15m. Electronic waste materials (mainly circuit boards, wires and keyboards) are made into 3-6mm particles, and the amount of imported materials is 1kg / h, the final pyrolysis slag is 0.8kg / h, and the pyrolysis oil gas is 0.286 Nm3 / h, which realizes continuous material in and out. During the pyrolysis process, the temperature is kept at 600°C, and the heat source is very stable. By using the fancy screw to propel the material, the problem of tar sticking is reduced, and the oil sticking on the pipe wall can be scraped off, which solves the problem that the screw is easy to block. The pitch of the fancy screw is 54mm, and the thickness of the screw blade is 8mm, the helix rotates in the counterclockwise direction, and each turn of the helix is counterclockwise to set a 15° opening gap every 60°, the slag and gas are...

Embodiment 2

[0036] Example 2: The diameter of the heating wire is 1.4mm, and the total length is 15m. Electronic waste materials (circuit boards, wires, keyboards, etc.) are made into 3-6mm particles, and the amount of imported materials is 1kg / h. The slag material is 0.7kg / h, and the pyrolysis oil gas produced is 0.225 Nm3 / h, which realizes continuous material in and out. During the pyrolysis process, the temperature is kept at 600°C, and the heat source is very stable. By using the fancy screw to propel the material, the problem of tar sticking is reduced. The pitch of the fancy screw is 54mm, the thickness of the screw blade is 8mm, the screw rotates counterclockwise, and each turn of the screw is set at 15 degrees counterclockwise every 45° ° opening gap, slag discharge and gas discharge are continuous and smooth, and can ensure that the pressure inside the spiral casing is stable, and the pressure fluctuation range is 3~5kpa.

[0037] The oil and gas assay components are as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com