Demountable ring-shaped ammonia-feeding pipe equipped on nitriding furnace for making atmosphere homogeneous

A technology for ammonia inlet pipes and nitriding furnaces, applied in the field of heat treatment, which can solve the problems of inconsistency in the infiltration layer and performance of workpieces, easy cracking and damage of ammonia inlet pipes, and affecting the normal use of nitriding furnaces, so as to achieve stable quality, improvement, and replacement Convenient, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

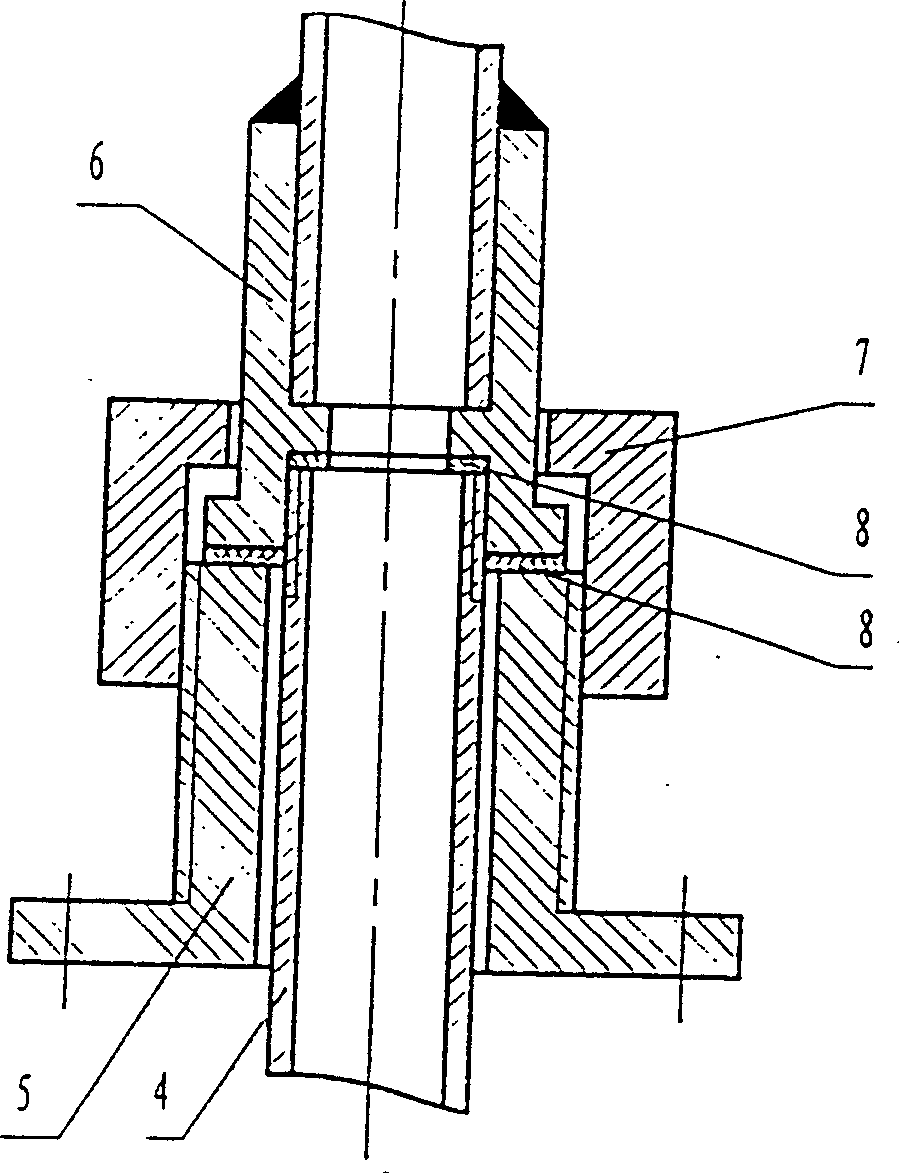

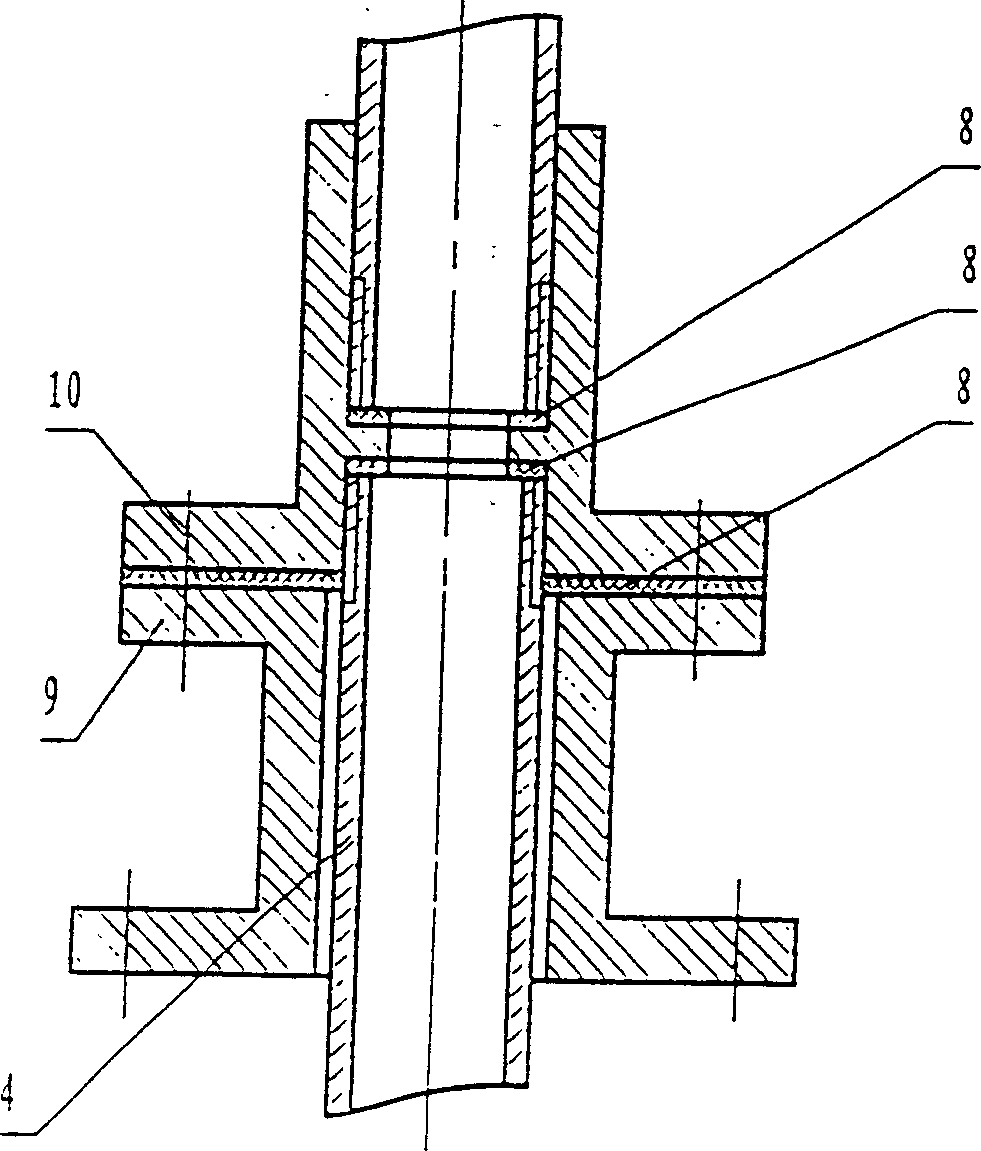

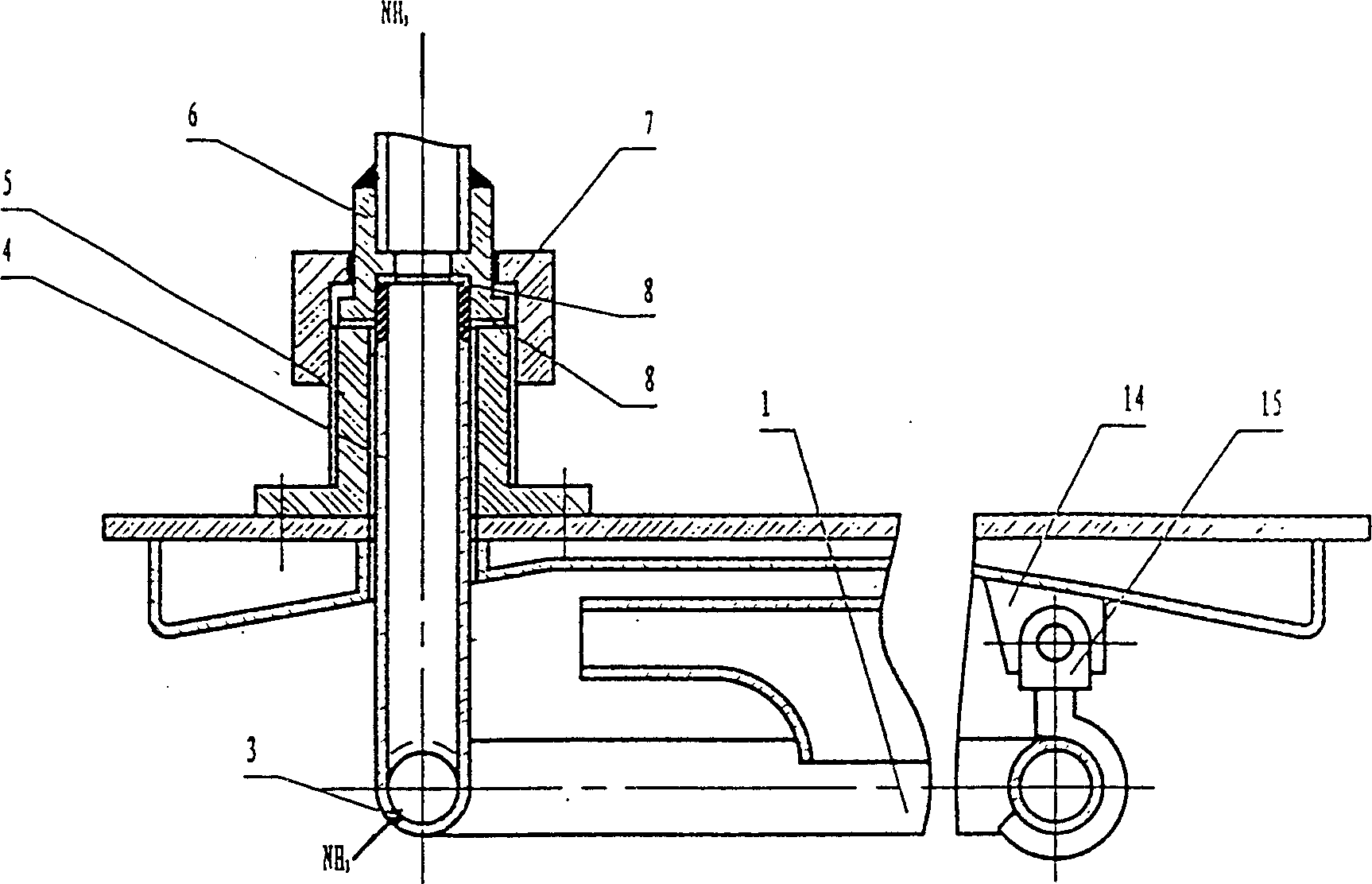

[0019] Such as figure 1 , figure 2 and image 3 , Figure 4 As shown, the present invention includes: an annular ammonia inlet pipe 1 and an ammonia inlet pipe seat assembly 2, the detachable annular ammonia inlet pipe 1 is arranged directly below the furnace cover of the well-type furnace, and is arranged in a horizontal balance, and the ammonia inlet pipe seat assembly 2 Set on the furnace cover plate, the lower part of the annular ammonia inlet pipe 1 is evenly opened with small holes 3 at an angle of 45°, and the straight ammonia inlet pipe 4 welded on the annular ammonia inlet pipe 1 passes through the hole reserved on the furnace cover and the ammonia inlet pipe The seat assembly 2 is connected by a compression nut type or a blue type structure.

[0020] When the annular ammonia inlet pipe 1 and the ammonia inlet pipe seat assembly 2 are connected by a compression nut structure, the ammonia inlet pipe seat assembly is composed of the ammonia inlet pipe seat 5, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com