Patents

Literature

109results about How to "Skinny" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

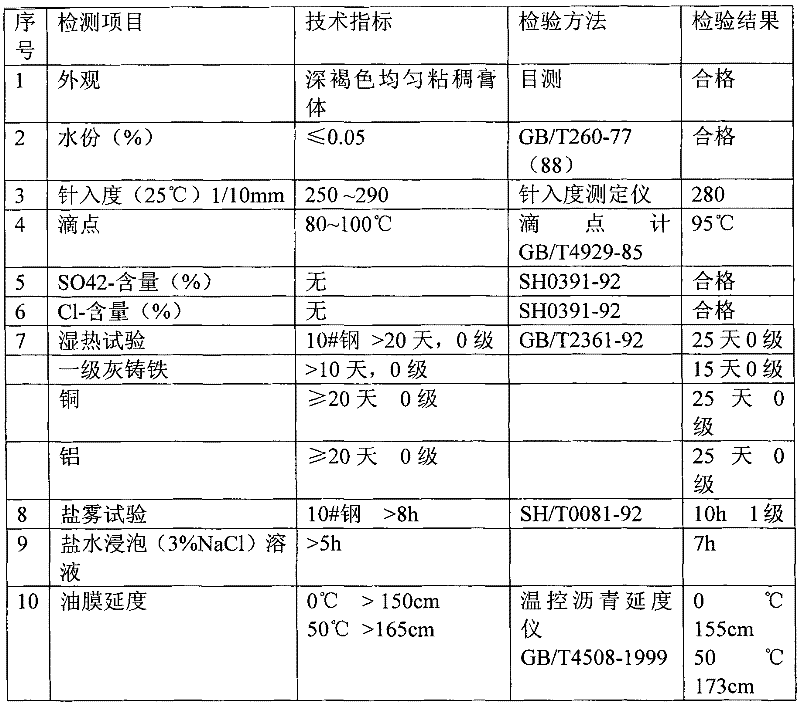

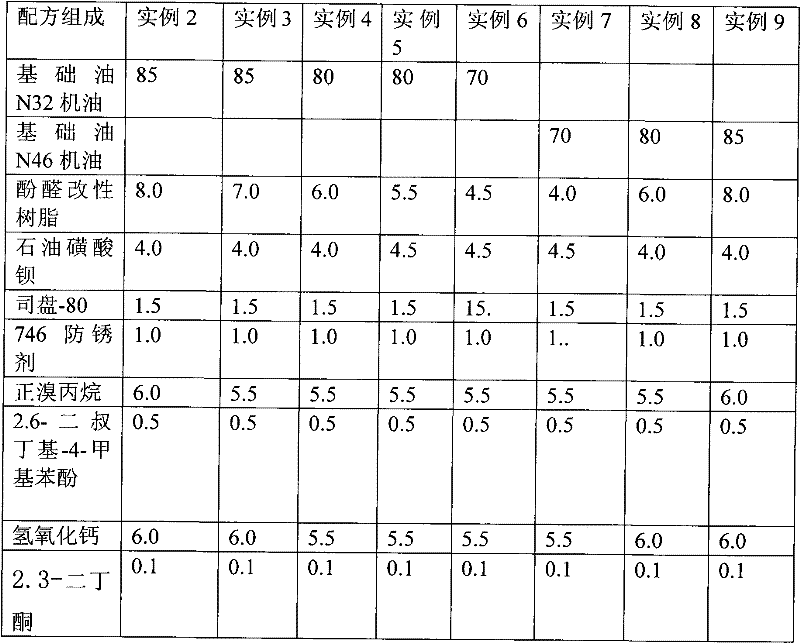

Long-acting antirust grease and preparation method thereof

ActiveCN102229845AImprove physical stabilityGood chemical stabilityLubricant compositionEngineeringFilm-forming agent

The invention belongs to the field of chemistry and relates to long-acting antirust grease and a preparation method thereof. The long-acting antirust grease mainly comprises the following components ( by weight): 70 to 90 parts of base oil, 3 to 6 parts of thickening agent, 4.5 to 8 parts of antirust additive, 4 to 8 parts of film-forming agent, 0.5 to 1 part of antioxidant, and 3 to 6 parts of assistant. The antirust grease has the characteristics that: the application of the grease is easy; the durability is high; the detachment of fasteners at next time is easy; the application range is wide; and the like. The long-acting antirust grease is suitable for outdoor steel fasteners which require anti-corrosion treatment and cannot be coated with paint.

Owner:麻城天安化工股份有限公司

Inorganic dry powder texture coating

ActiveCN102092989AAvoid pollutionEliminate hazardsSolid waste managementFilling pastesFiberPolyvinyl alcohol

The invention provides an inorganic dry powder texture coating, which comprises the following components in percentage by weight: 12 to 15 percent of gray calcium powder, 20 to 30 percent of quartz powder, 10 to 15 percent of quartz sand, 30 to 40 percent of coarse calcium powder, 0.5 to 0.6 percent of hydroxypropyl methyl cellulose (HPMC), 1 to 2 percent of redispersible emulsion powder, 1 to 2 percent of polyvinyl alcohol powder and 0.3 to 0.4 percent of wood fiber. The coating is environmentally-friendly, and most used raw materials are readily available inorganic materials, so that pollution caused by the volatilization of an organic solvent into the atmospheric air is avoided, and harm to body health and possible risks such as fire and the like during production, transportation, storage and construction of the coating are eliminated; the coating is easy and convenient to construct, can be directly constructed on a qualified substrate without any primer, is suitable for various construction tools and has good texture and a high decorating property, and pigments can be doped as required; and the coating has high weather resistance, is free from peeling, is cracking-resistant, is convenient to transport, and is suitable for building coating in various environments and under various climate conditions.

Owner:现代精密化工(郑州)有限公司

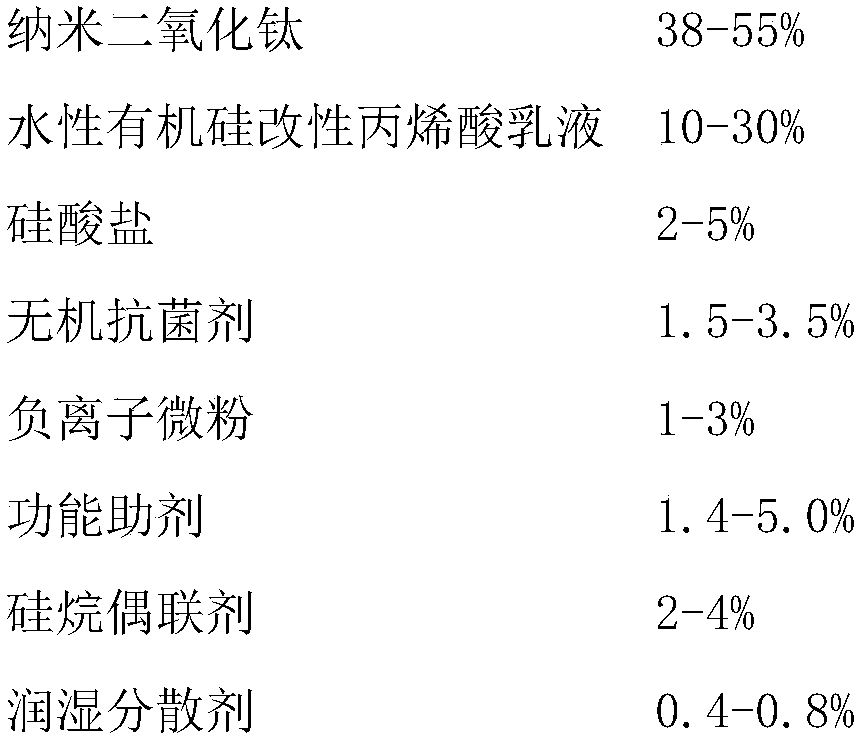

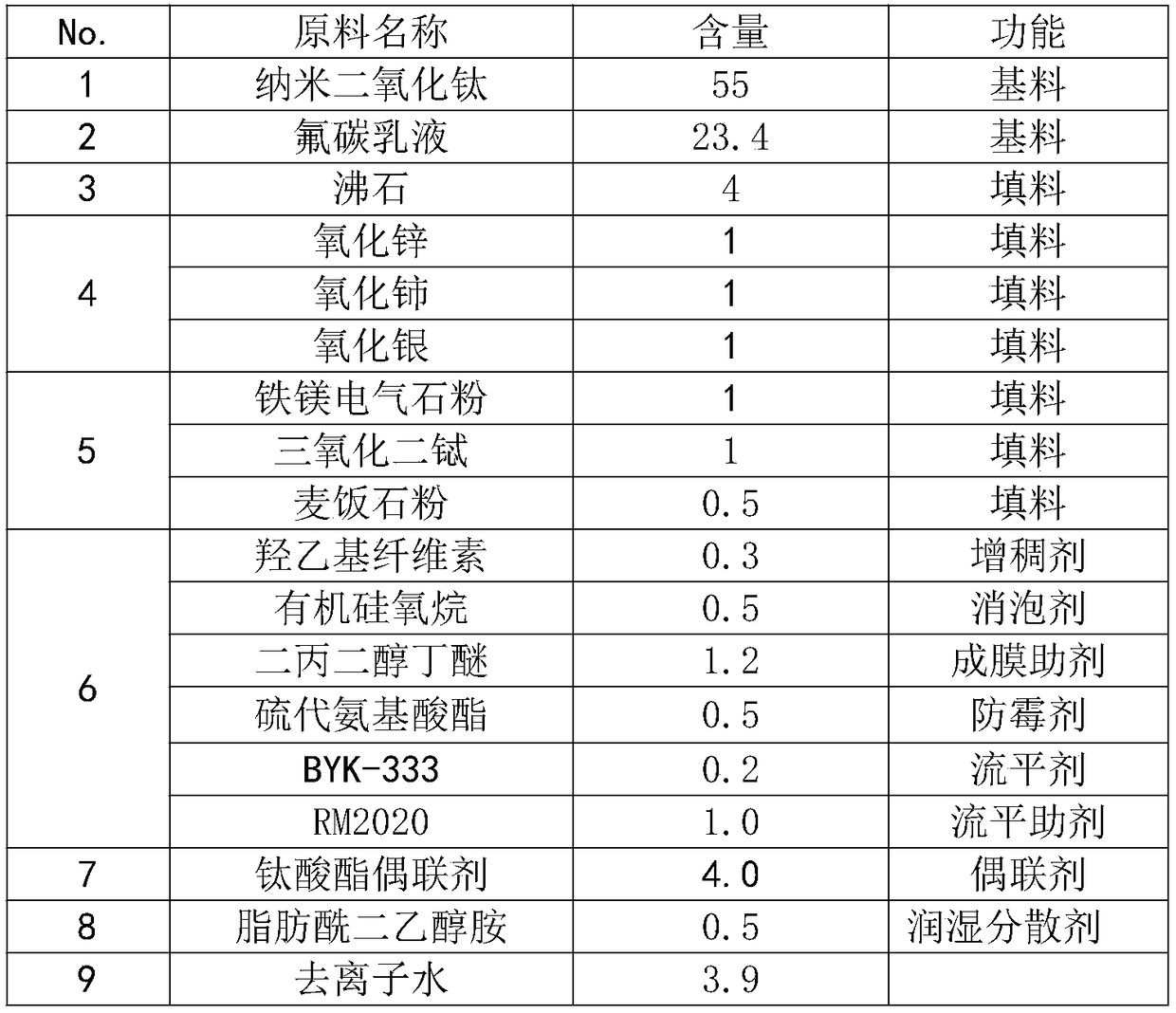

Water-based nanometer titanium dioxide photocatalytic sterilization purification coating and preparation method thereof

InactiveCN108485441APurifying airPrevent mildewAntifouling/underwater paintsPaints with biocidesWater basedCement mortar

The invention discloses a water-based nanometer titanium dioxide photocatalytic sterilization purification coating and a preparation method thereof. The coating is prepared from 38-55 wt% of nanometertitanium dioxide, 10-30 wt% of a waterborne organosilicone modified acrylic emulsion, 2-5 wt% of silicate, 1.5-3.5 wt% of an inorganic antibacterial agent, 1-3 wt% of negative ion micro-powder, 1.4-5.0 wt% of a functional assistant, 2-4 wt% of a silane coupling agent, 0.4-0.8 wt% of a wetting dispersant, and the balance of water. The coating has air purifying and bacterium killing effects, is green and environmentally friendly, has excellent anti-aging property, scrub resistance, cohesiveness, corrosion resistance and the like, can directly replace putty powder and a latex paint, and can be directly firmly bonded with a cement mortar wall without peeling, shedding or cracking.

Owner:合肥易美特建材有限公司

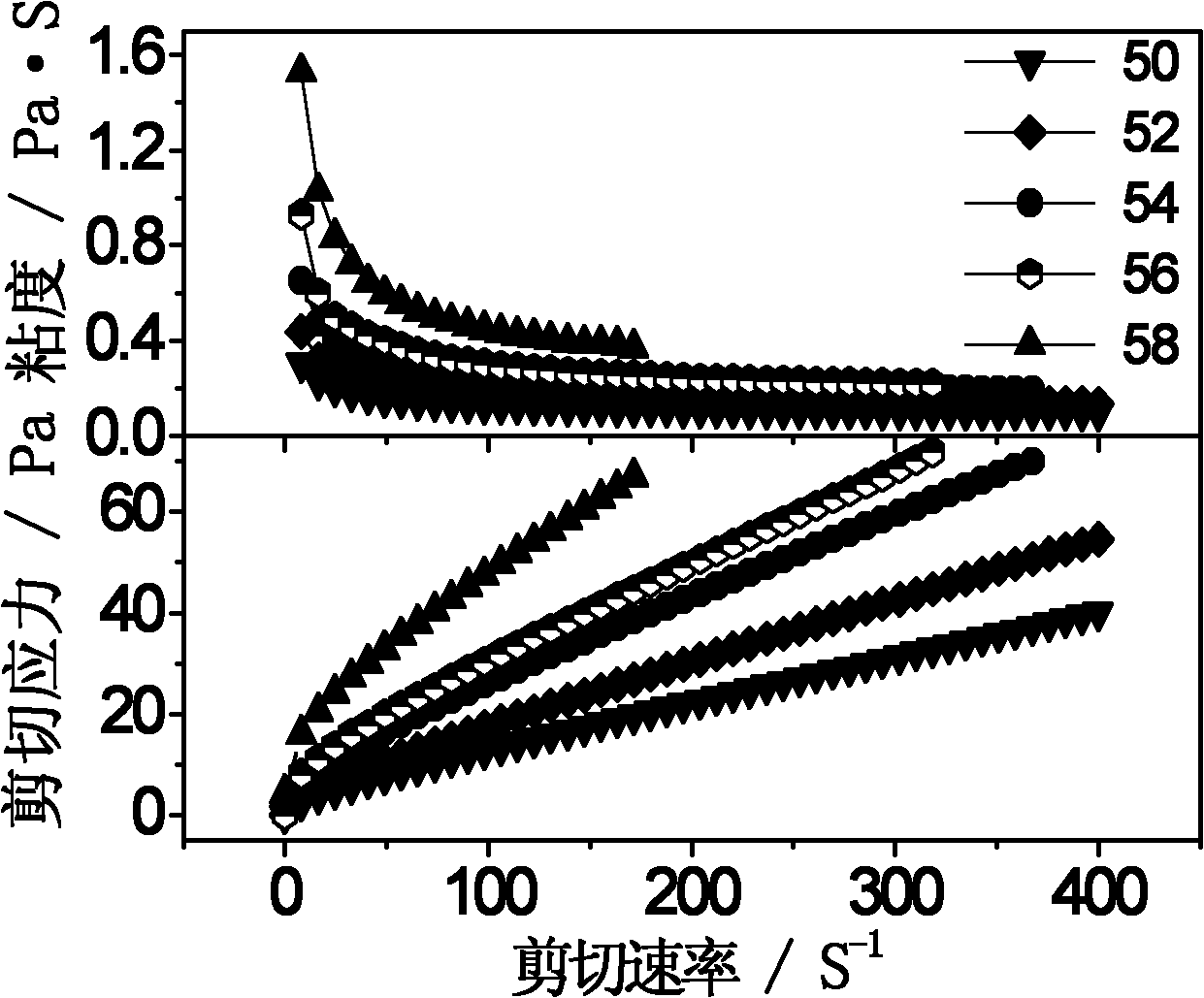

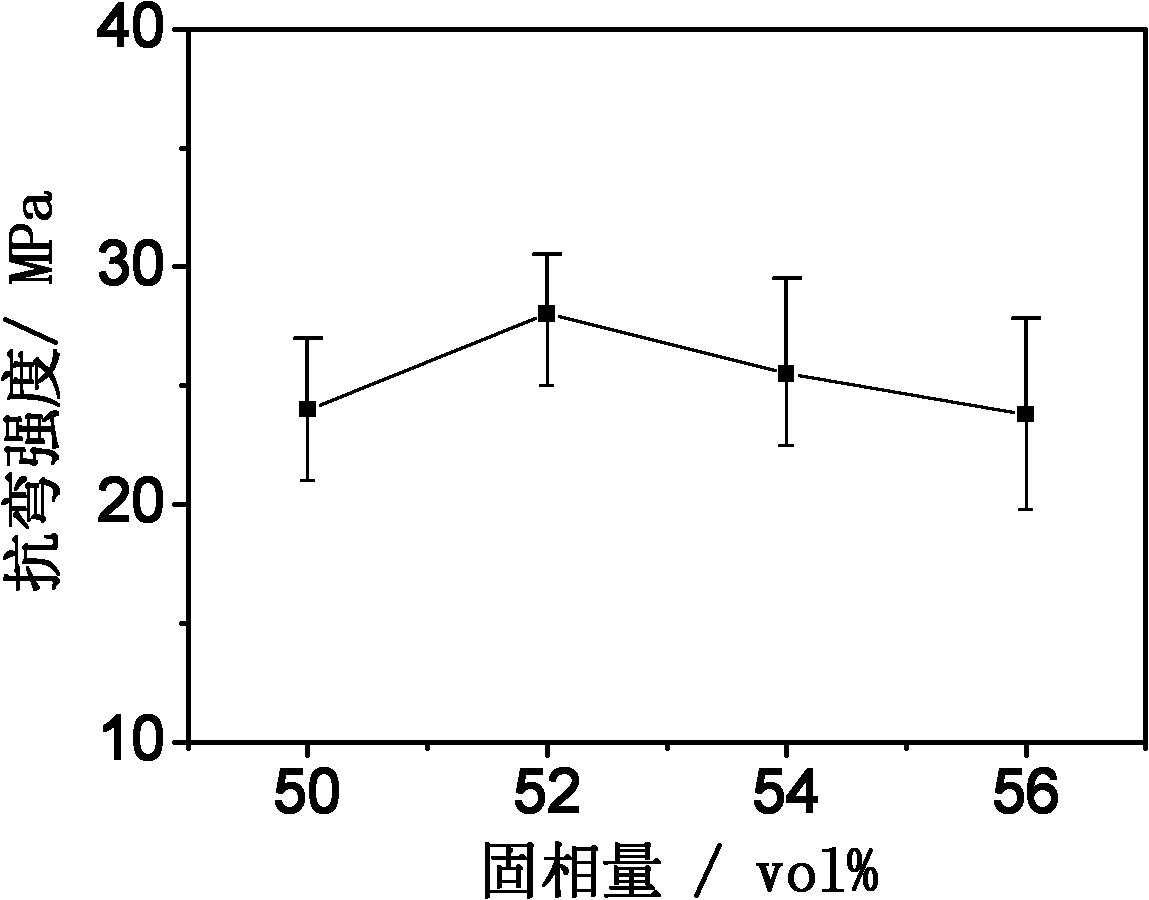

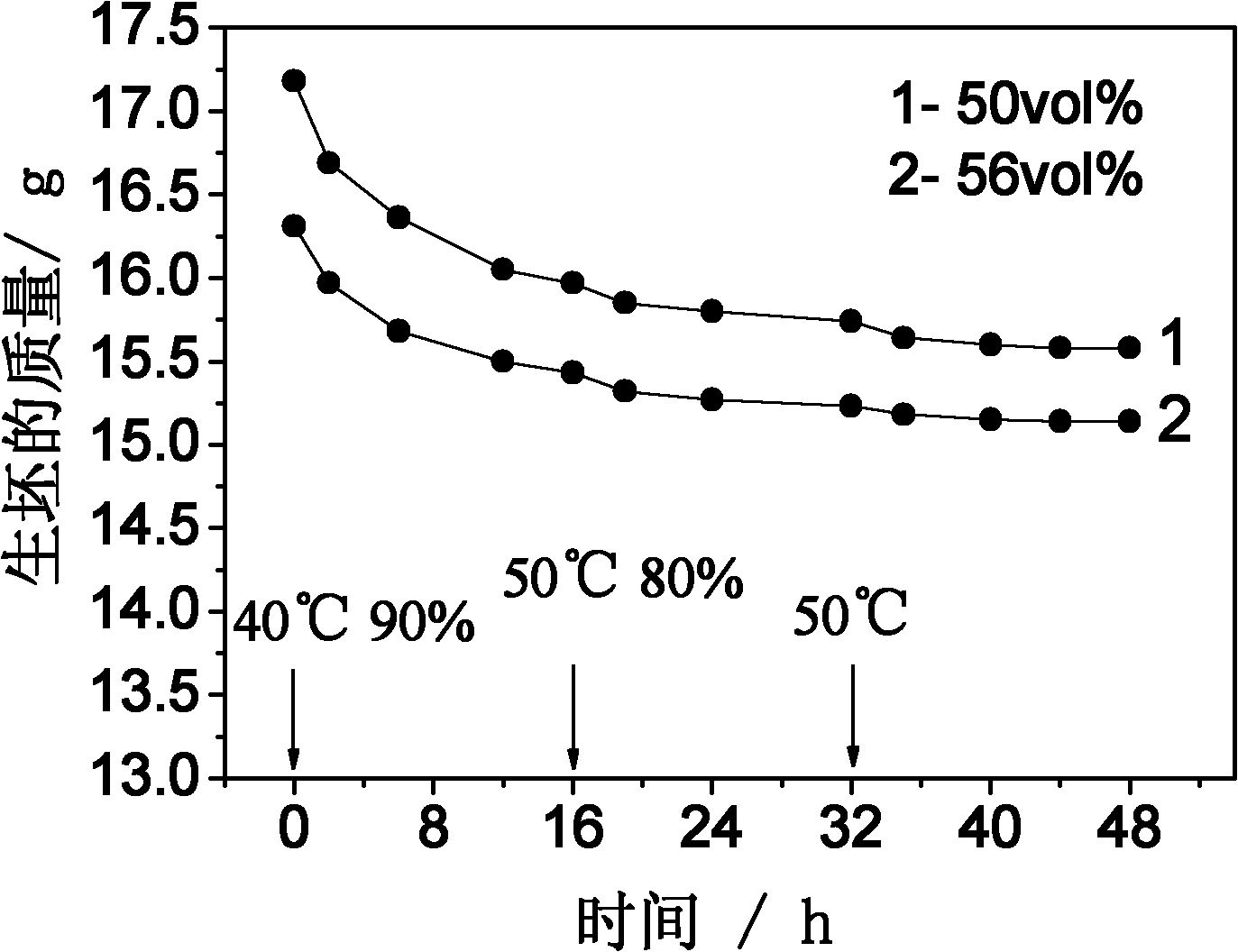

Method for preparing zirconium oxide ceramic

The invention relates to a method for preparing zirconium oxide ceramic, which comprises the following steps of: preparing high solid phase slurry by adopting low-toxicity gel and dispersant, then adding an initiator, performing vacuum deaeration, injecting the slurry into a mold, curing and stripping to obtain a green body, and drying and sintering the green body to obtain the ceramic. The method is used for preparing the green body which has good surface finishment, peeling resistance, cracking resistance, good uniformity and high strength, the strength of the green body is 20 to 40MPa, andthe green body can be directly machined so as to effectively reduce the subsequent processing cost; and the green body can be sintered into the ceramic at one time, the yield reaches 100 percent, theceramic has excellent performance and good stability, the strength is 800 to 1,200MPa, the fracture toughness is 10 to 20MPa.m1 / 2, the average strength is 550MPa compared with the strength of the drypressing molded ceramic, the average fracture toughness is 8MPa.m1 / 2, and the performance of the ceramic is greatly improved.

Owner:NANJING UNIV OF TECH

Multifunctional environmental protection putty

InactiveCN101265375AHard wallNo rapid drying of the surfaceFilling pastesCarboxymethyl celluloseEmulsion

The invention discloses multifunctional environment-friendly lacquer putty, which primarily comprises ground chalk powder accounting for 50 to 60 percent by weight; light calcium carbonate powder accounting for 10 to 20 percent by weight; ash-calcium-powder accounting for 30 to 40 percent by weight, carboxymethyl cellulose accounting for 3 to 5 percent by weight; water-soluble dispersible emulsion powder accounting for 5 to 8 percent by weight; and an anion additive accounting for 1 to 3 percent by weight. The multifunctional environment-friendly lacquer putty powder has the advantages of high water-resistance, no peeling, no crackle and so on, and can facilitate construction and release anions.

Owner:何林道

Acrylic resin/SiO2 nano composite tanning agent and preparation method thereof

InactiveCN101240354ASoft and plumpImprove heat and humidity stabilityTanning treatmentAcrylic resinSolvent

The invention relates to an acrylics / SiO2 nano-composite tanning agent. The nano-composite tanning agent appears to be light yellow or yellow semitransparent ropy liquid, the mass concentration is 20 to 35%, the viscosity is 500 to 1000MPa.s, the pH value is 5 to 8, and the storage stable period is over 12 months. With only 2% (relative to the leather weight) chromium powder, the nano-composite tanning agent can thicken the leather by 124.5%, the shrinkage temperature reaches to 95 DEG C.; compared with a chrome tanned leather, a leather tanned by the nano-composite tanning agent has a tensile strength, peeling strength and elongation at break improved by 51.8%, 8.2% and 13.3% respectively, has no obvious stratification or sedimentation during over 12 months of storage period. Water is used as solvent when prepared, which is low-cost and pollution-free; the preparing technology is simple, the reaction is mild, the polymerization process is easy to control, so that the nano-composite tanning agent is easy to realize industrial production, the synthesized material is inexpensive and easy to obtain as well.

Owner:HENAN UNIVERSITY

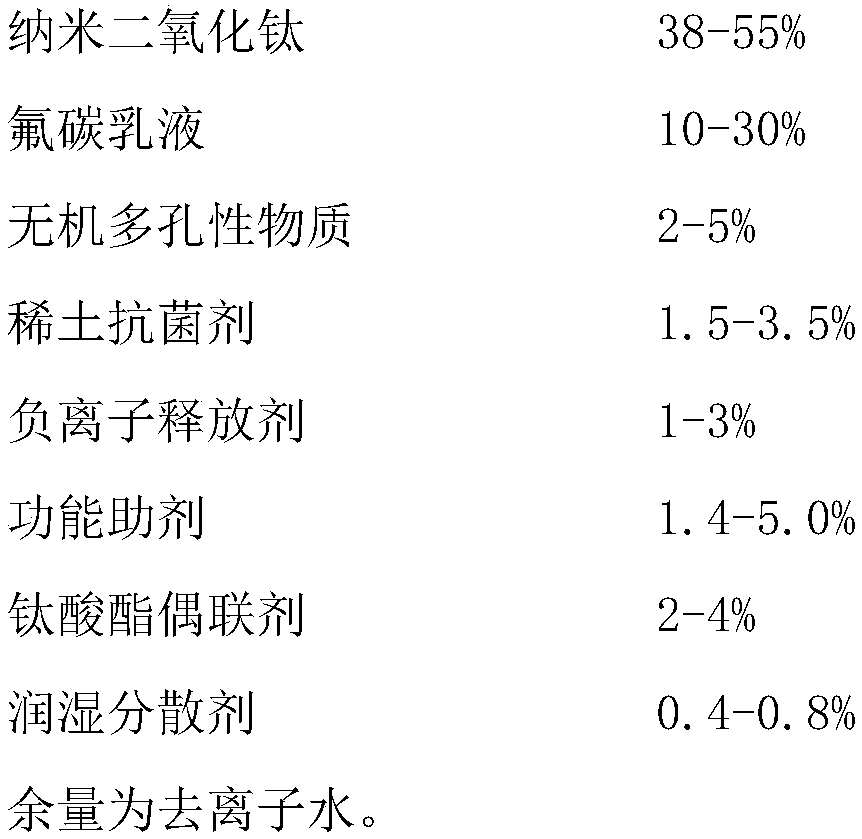

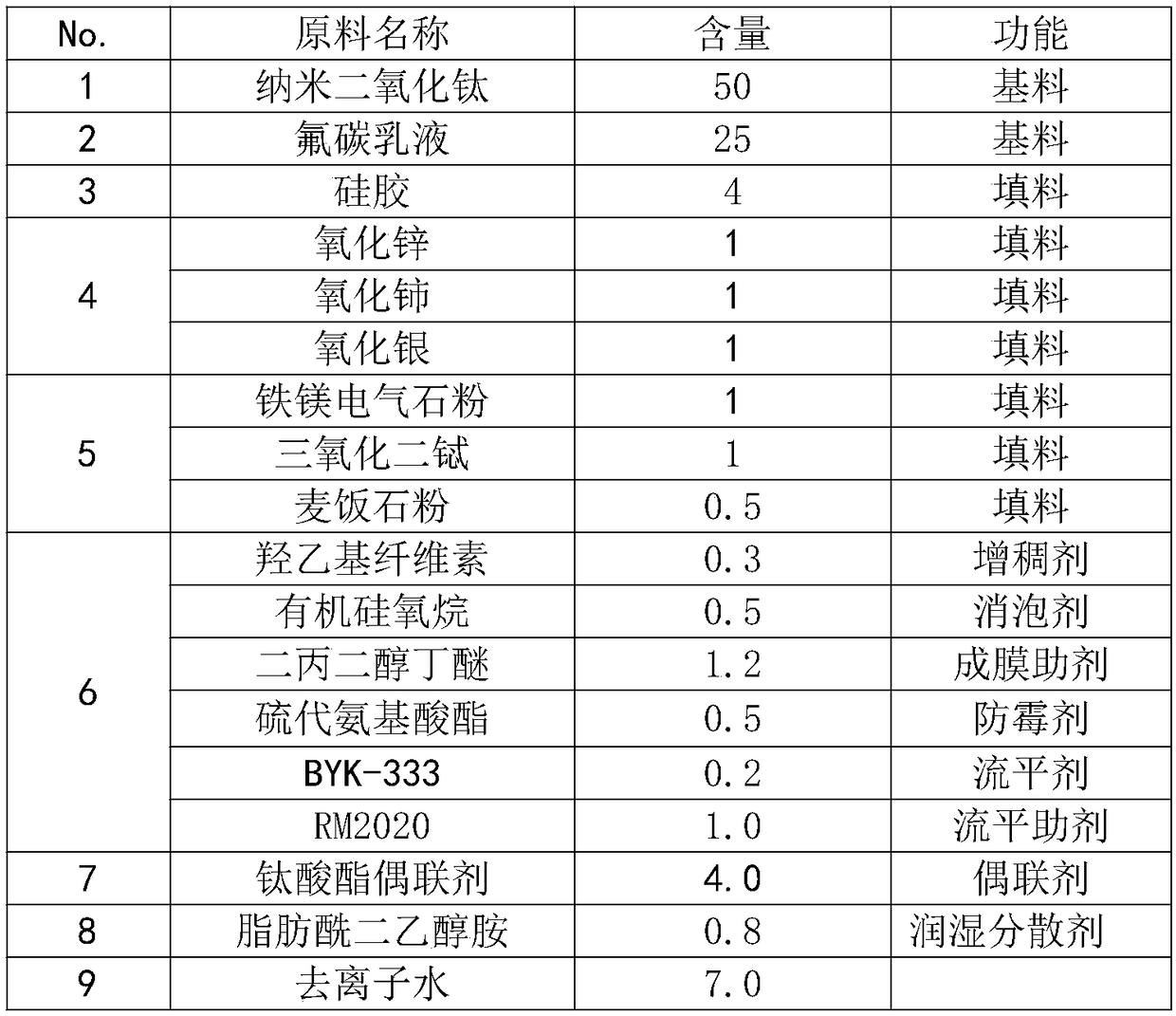

Nano titanium dioxide photocatalytic disinfecting and purifying coating

InactiveCN108587342APurifying airPrevent mildewAntifouling/underwater paintsPaints with biocidesRare earthCement mortar

The invention discloses nano titanium dioxide photocatalytic disinfecting and purifying coating, made from, by weight, 38-55% of nano titanium dioxide, 10-30% of fluorocarbon emulsion, 2-5% of an inorganic porous material, 1.5-3.5% of a rare-earth antibacterial agent, 1-3% of an anion release agent, 1.4-5.0% of functional aids, 2-4% of titanate coupling agent, 0.4-0.8% of a wetting dispersant, andthe balance of deionized water. The nano titanium dioxide photocatalytic disinfecting and purifying coating has the functions such as air purifying and bacteria killing, is green, has excellent properties such as aging resistance, scrubbing resistance, adhesion, corrosion resistance, may directly replace putty powder and latex paint, may be directly bound to a cement mortar wall, and is firm andfree of skinning, separating and cracking.

Owner:张子晗

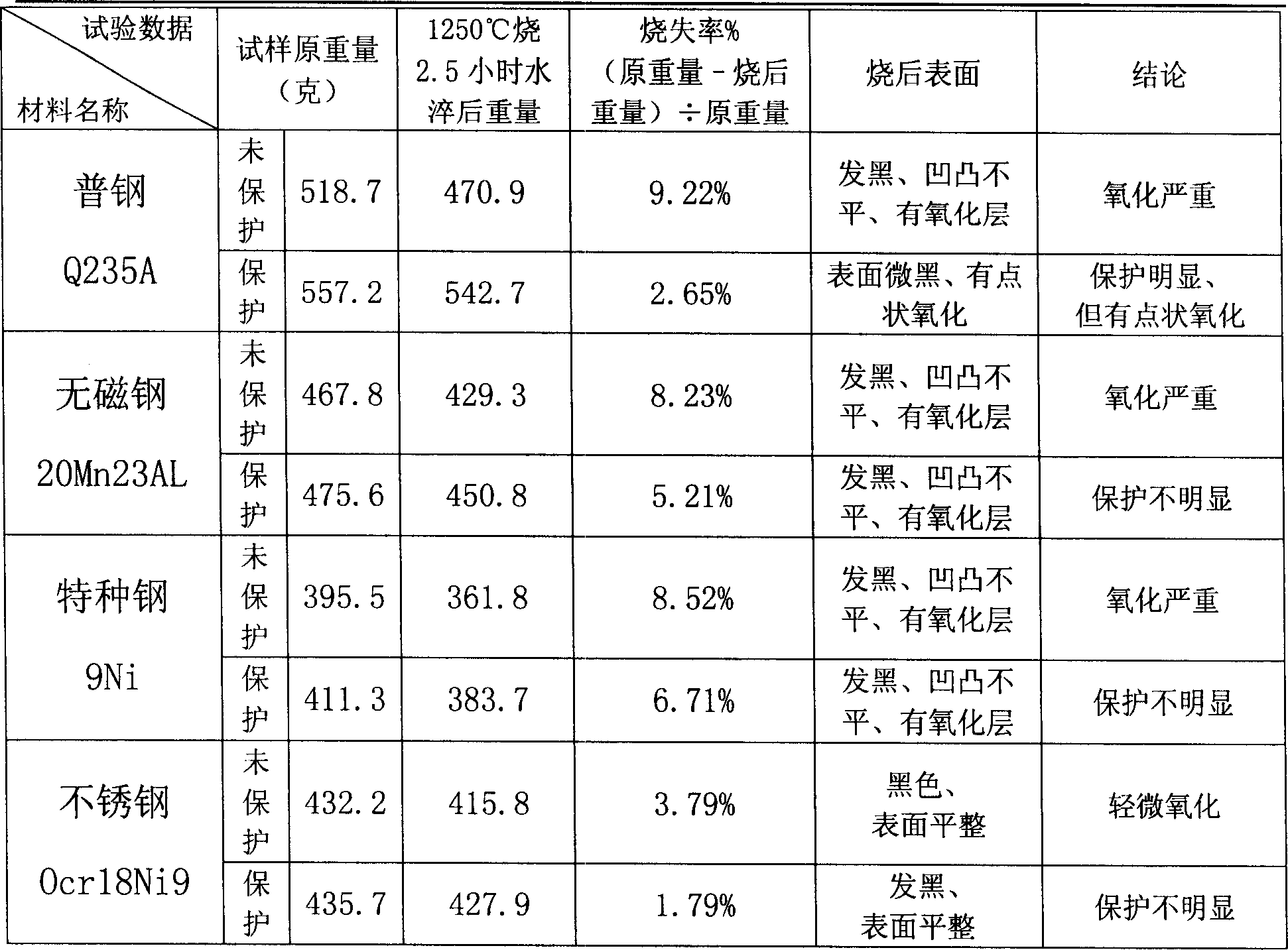

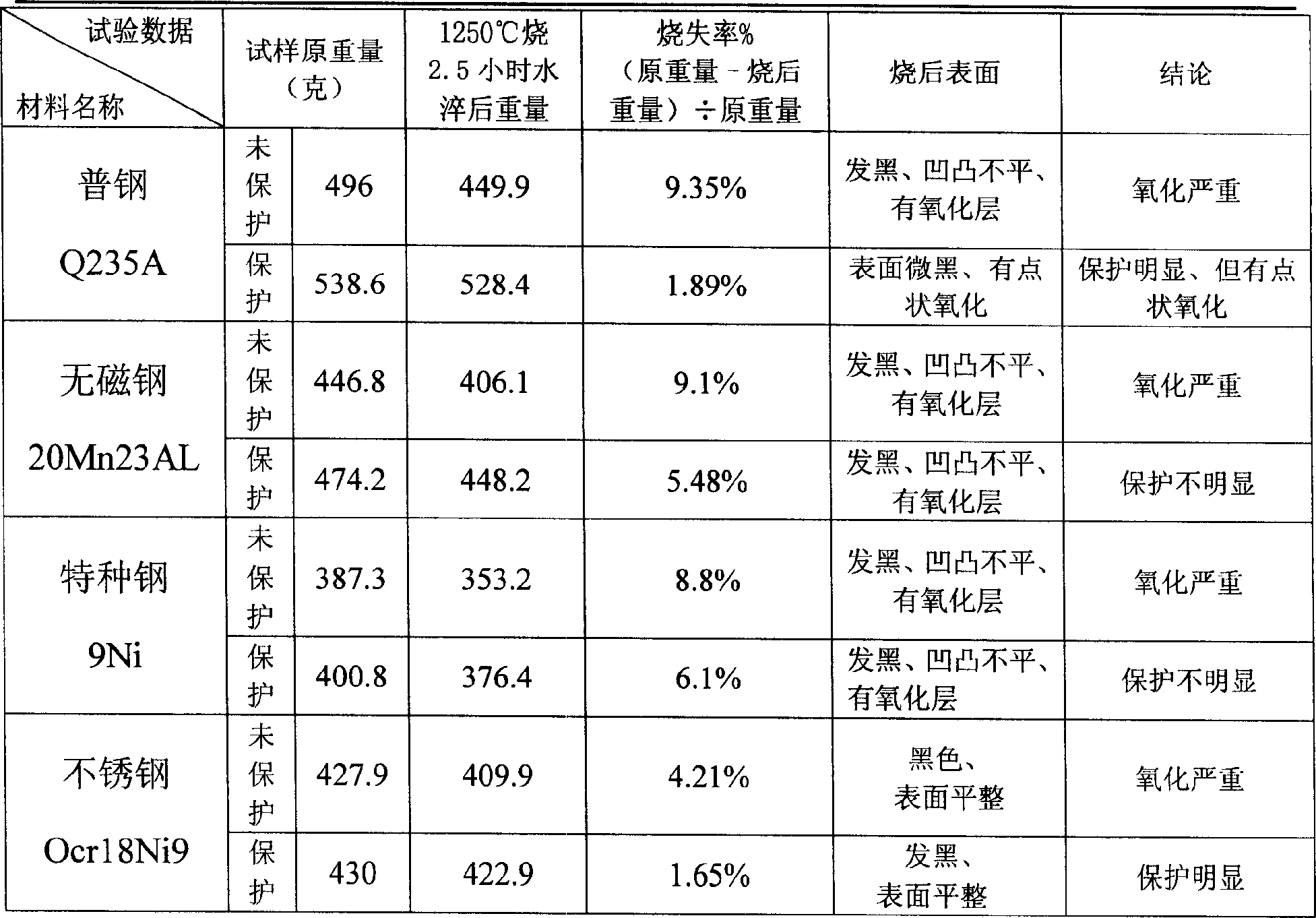

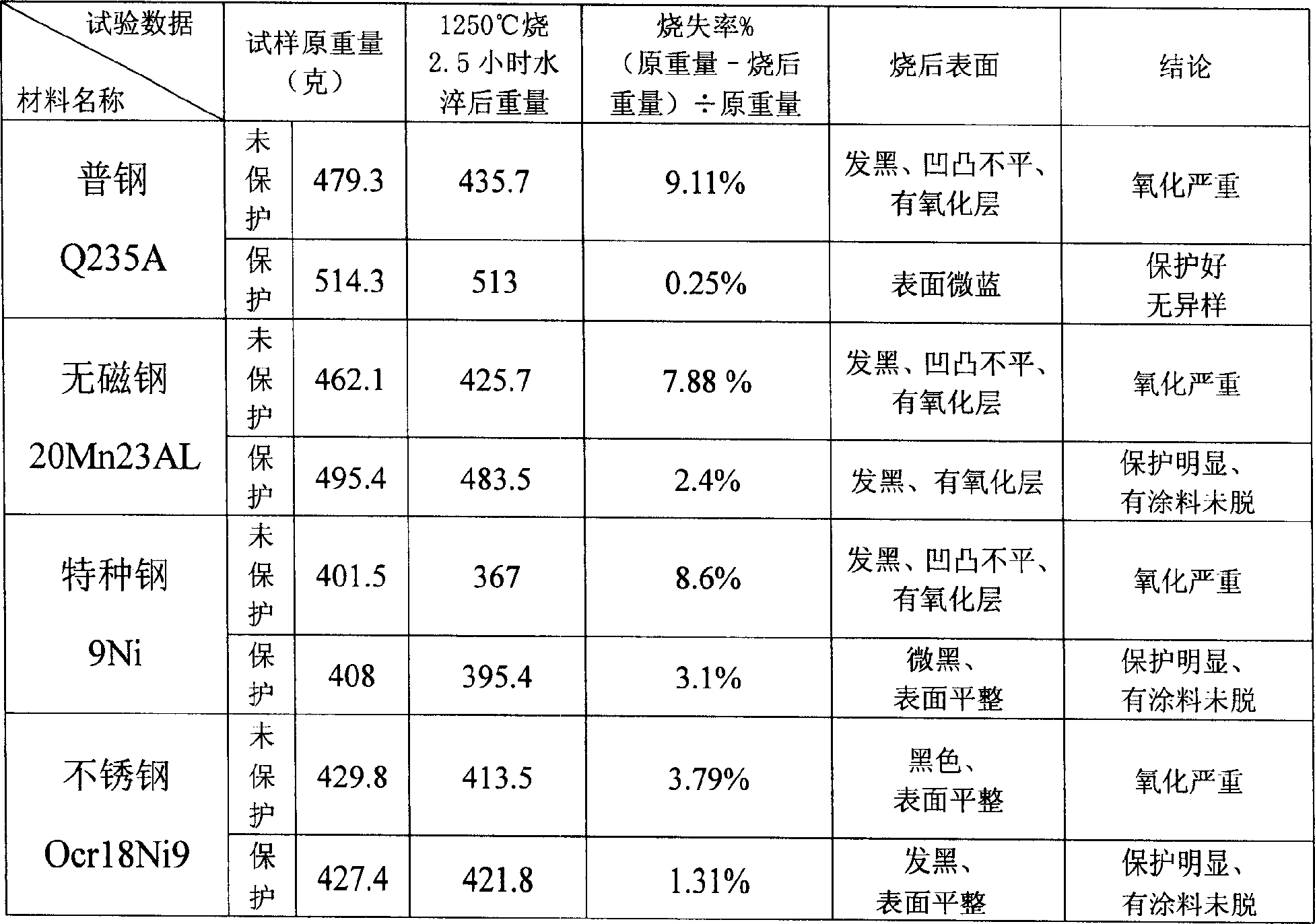

Antioxidation coating material of Nano silicate in use for annealing billet in series

This invention relates to nanoscale silicate anti-oxidation coating for steel billet annealing. The coating is composed of: composite binder 20-30 wt.%, composite phosphate curing agent 8-12 wt.%, and composite aluminosilicate filler 58-72 wt.%. The coating can resist 1500 deg.C high temperature. The coating does not need any surface treatment, and can be directly sprayed onto the surface of steel billet, and cured at normal temperature for 10 min. Before annealed and hot-rolled, the coated steel billet is water-quenched for several seconds so that the coating layer is removed without any trace, and the surface quality is improved. The coating can reduce the loss-on-ignition of various steels, thus can be used for surface protection of refractory materials used as furnace kiln lining. Besides, the coating can also be used as inner and outer wall coating, and metal surface (bridge, bridge pier and dam) coating with water, corrosion and oxidation resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

Wear-resistant high-temperature resistant coating having high adhesive force

InactiveCN107201168AImprove high temperature resistanceNon-foamingFireproof paintsAnti-corrosive paintsWear resistantInorganic pigments

The invention belongs to the technical field of equipment coating, and particularly relates to wear-resistant high-temperature resistant coating having high adhesive force. The coating includes silicone resin, a high-temperature resistant filler, aluminum paste, inorganic pigment, a film forming agent, nanometer zirconia ceramic micropowder, a curing agent and a solvent. The high-temperature resistant filler of the coating is quartz powder, mica powder or talcum powder, and the fineness of the filler is 700-800 meshes. The solvent is one of butyl acetate, xylene and n-butanol. The coating has uniform properties. An obtained coating layer of the coating is smooth, fine and good in adhesive force. The coating has excellent high-temperature resistance, good impact resistance, god wear resistance and good corrosion resistance. The coating is particularly suitable for surface protection of high-temperature motors, high-temperature electric resistance furnaces, and other devices.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

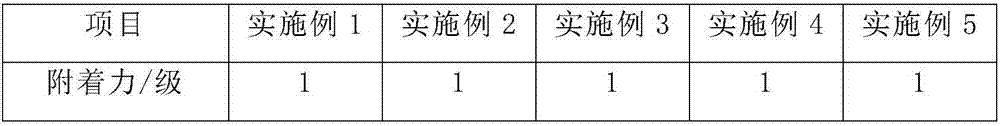

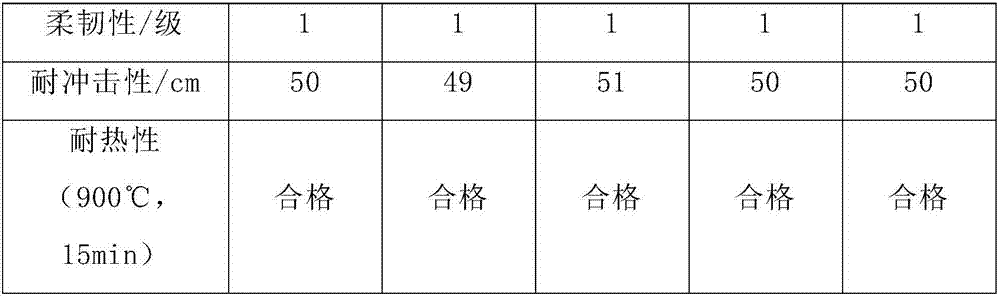

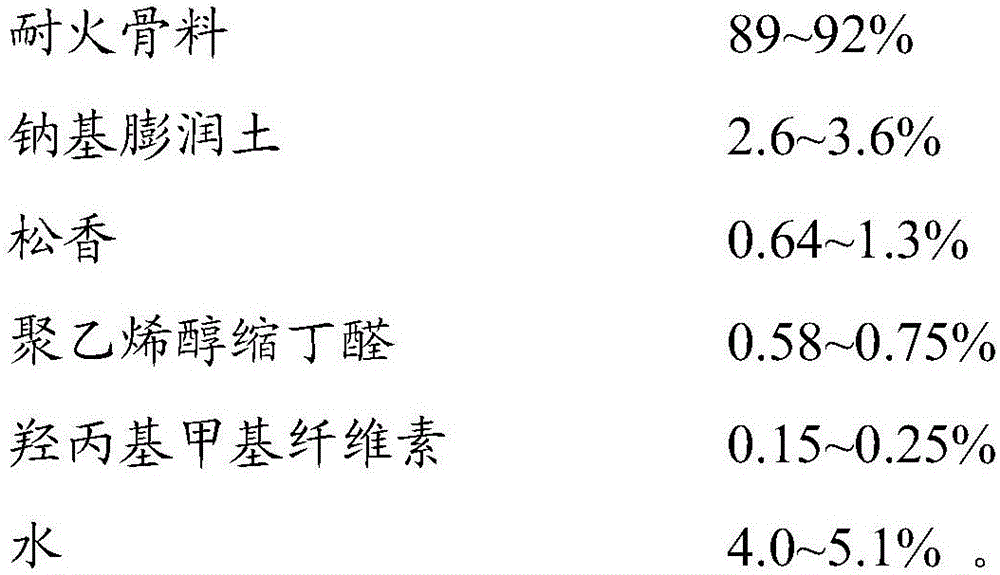

Powdery casting coating as well as preparation method and use method thereof

InactiveCN105935742AImprove performanceImprove suspension stabilityFoundry mouldsFoundry coresAlcohol freeSodium Bentonite

The invention provides a powdery casting coating as well as a preparation method and a use method thereof. The powdery casting coating provided by the invention is composed of the following components in percentage by weight: 89-92% of refractory aggregates, 2.6-3.6% of sodium bentonite, 0.64-1.3% of rosin, 0.58-0.75% of polyvinyl butyral, 0.15-0.25% of hydroxypropyl methyl cellulose, and 4.0-5.1% of water. The powdery casting coating provided by the invention is alcohol-free, and capable of being mutually infiltrated and fused with alcohol in use to obtain a qualified coating.

Owner:HUBEI UNIV OF TECH

Nano water-based functional ceramic composite coating and preparation method thereof

ActiveCN103588443AGood physical and chemical stabilityExcellent abnormal temperature mechanical propertiesEmulsionPliability

The invention discloses a nano water-based functional ceramic composite coating which comprises raw materials in parts by weight as follows: 10-35 parts of silicate inorganic adhesives, 10-35 parts of main filler, 2-10 parts of stabilizing materials, 5-20 parts of toughness-enhancing emulsion type binding agents, 3-10 parts of film forming assistants and 5-25 parts of water. A preparation method comprises the steps as follows: the silicate inorganic adhesives and diluent are poured into a container and stirred at 350-400 r / min for 10-20 min, so that a mixed liquid is obtained; the main filler and the stabilizing materials are added to the mixed liquid, and the mixture is stirred at 350-400 r / min for 50-60 min; and the toughness-enhancing emulsion type binding agents and the film forming assistants are added sequentially, and the mixture is filtered by gauze with 400-600 meshes, so that the composite coating is obtained. A film of the coating is formed at the normal temperature, and the nano water-based functional ceramic composite coating has the characteristics of infiltration, large adhesive force, high density, stone hit resistance, impact resistance, high and low temperature resistance, superior abrasion resistance, washing resistance and good flexibility.

Owner:WUHAN ZHUOYI TECH DEV CO LTD

Cloud wire coating and preparation method thereof

The invention relates to a cloud wire coating and a preparation method of the cloud wire coating. The cloud wire coating comprises the following raw constituents by weight: 4-7 parts of cellulose, 1-4 parts of AMP-95, 1-4 parts of wetting agent, 15-25 parts of coalescing agent, 1-3 parts of preservatives, 8-20 parts of ethylene glycol, 1-4 parts of defoamer, 150-240 parts of pearl powder, 350-500 parts of emulsion, 2-6 parts of thickeners, 3-9 parts of dispersing agent and 200-40 parts of deionized water. The cloud wire coating disclosed by the invention is fine and smooth in quality, and prevents the phenomena of wire fracture and tearing during wire drawing; with the coating, a film can be well adhered, and the seaming, the peeling and the cracking are prevented; and particularly, the coating has strong scrub resistance, water resistance and alkali resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

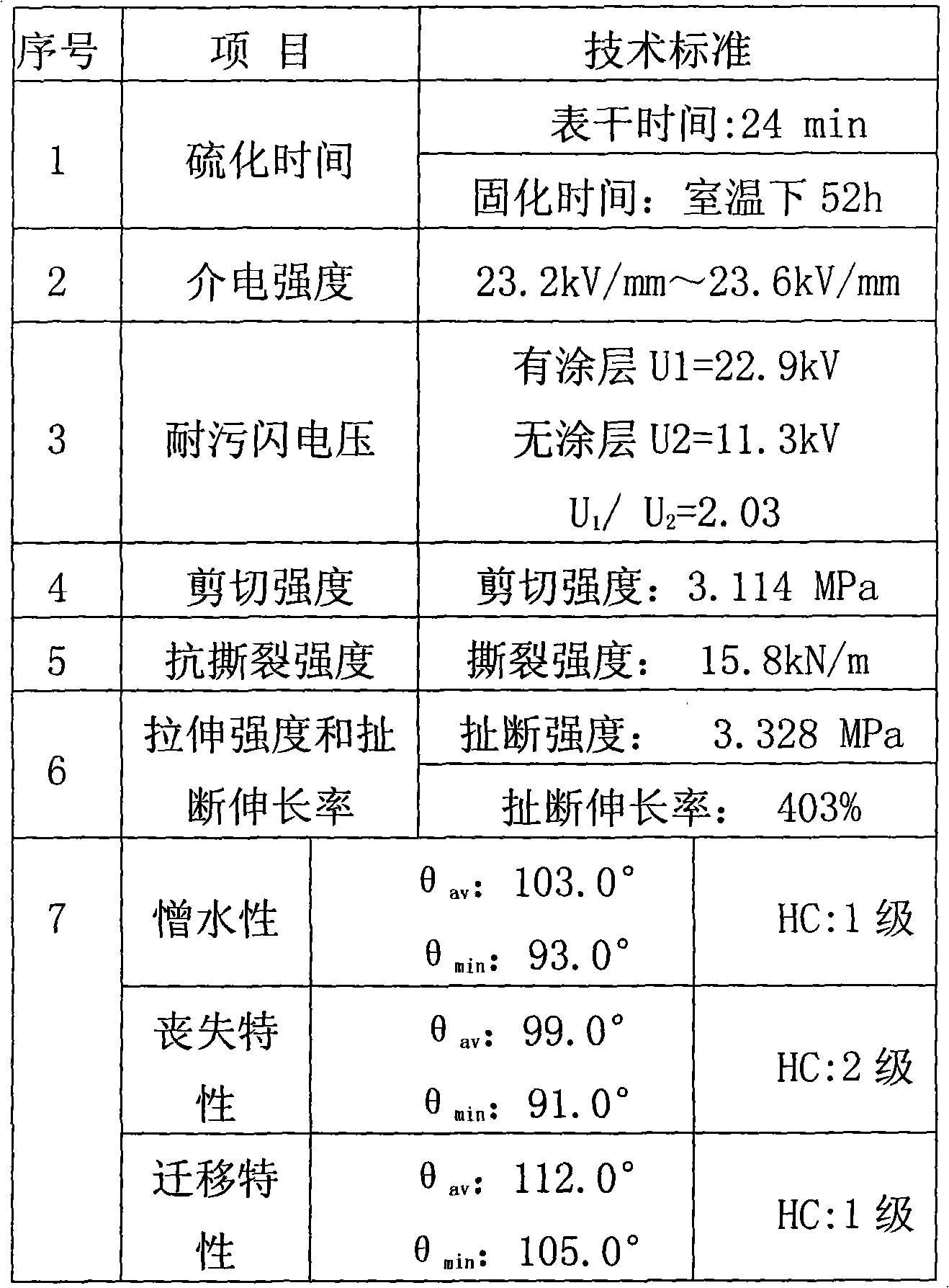

Long-term anti-pollution-flashover paint and preparation thereof

InactiveCN101275055AImprove anti-fouling flashover performanceHydrophobicCoatingsVolumetric Mass DensitySolvent

The present invention provides a coating, specifically a long-life prevent dirt flash coating materials widely used for external insulation surface of the electrical equipment, composed of following components by weight account: silicone rubber 100, weather white carbon black 6.5-9, Al(OH)3 3-6, plasticizer 5-8, solvent 100-120, crosslinking agent 0.6-0.9, methyl silicone oil 8-10. The invention has advantages of excellent hydrophobicity, long-life corrosion resistance and weatherability, and excellent anti-dist flash characteristic, having no peeling, no crack, no falling, bearing the step when the repairing worker repairs, the invention greatly improves equipment anti-dist flash voltage, slat density is 0.1mg / cm<2>; under the condition of gray scale of 1.0mg / cm<2>, the anti-dist flash voltage is increased more than 200%, thus, the coating is widely used for the external insulation surface of the electrical equipment, effectively enhancing the safety credibility operation level of the electrical equipment.

Owner:武汉华瑞防雷科技股份有限公司

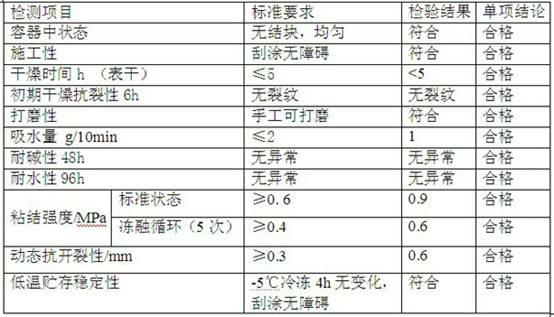

Putty powder for building inner and outer walls and preparation method of putty powder

ActiveCN106590133AEvenly distributedImprove crack resistanceFireproof paintsAntifouling/underwater paintsCellulosePolyethylene glycol

The invention provides putty powder for building inner and outer walls and a preparation method of the putty powder. The putty powder is prepared from ash-calcium, talcum powder, cement, cellulose, rubber powder, a binding agent and reinforcing powder. The reinforcing powder is formed by mixing composite powder, diatomite and calcium oxide, and the composite powder is obtained by sintering clay, silicon carbide, carbon powder and aluminum hydroxide. The binding agent is prepared from alumina micro powder, modified nanosilicon dioxide, polyethylene glycol and water. The putty powder contains the reinforcing powder and binding agent with special ingredients, when the putty powder is manufactured, the ash-calcium, the binding agent and the reinforcing powder are mixed firstly, hot water is added, the materials are stirred, part of ash-calcium is injected into a microcellular structure or adheres to the surface, then the ash-calcium is fully bonded with the cellulose and the rubber powder added later, therefore, the bonding performance between all the ingredients in the putty powder is enhanced, the anti-cracking performance and hardness of the putty powder are enhanced, and the waterproof performance of the putty powder is also improved to a certain degree.

Owner:平顶山锦亦翔墙釉科技有限公司

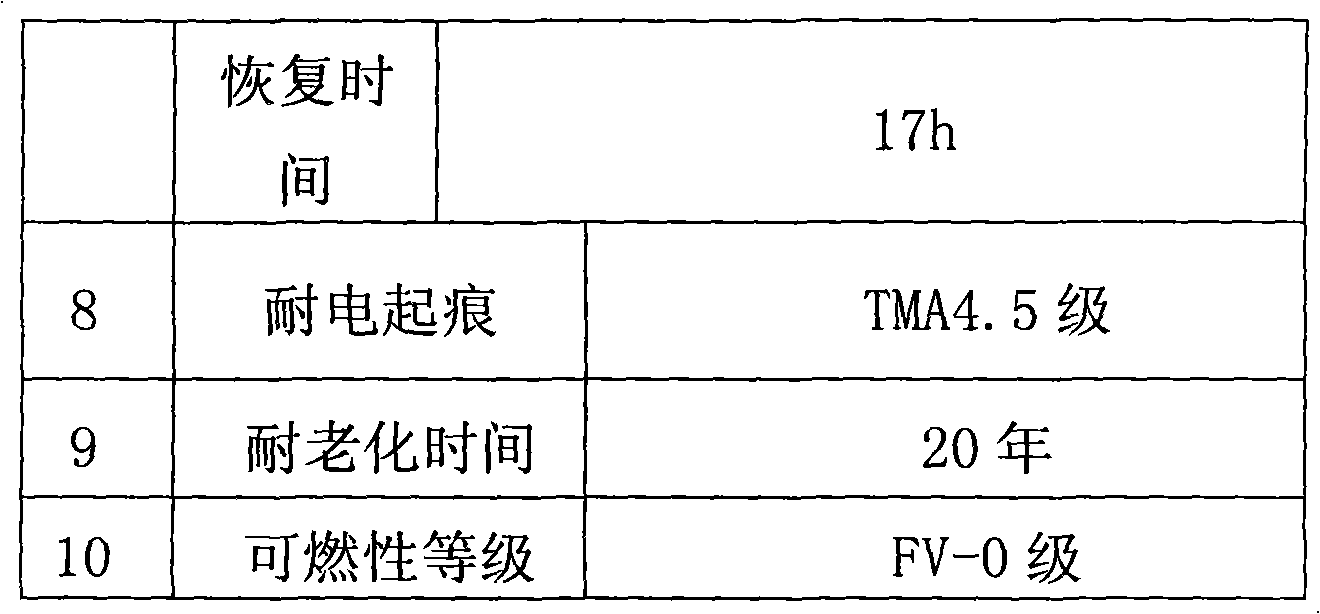

Pretreatment technology of surface metal plating of titanium alloy and metal plating method

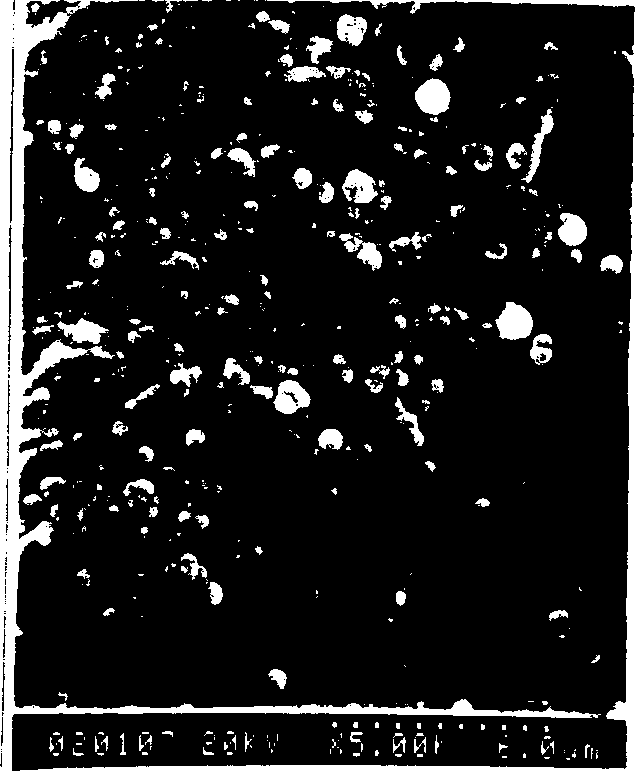

ActiveCN102286734AReduce fatigue strengthImprove wear resistanceLiquid/solution decomposition chemical coatingTitaniumBiological activation

The invention discloses a pretreatment technology of the surface metal plating oftitanium alloy and a metal plating method adopting the pretreatment technology. The pretreatment technology comprises the following steps: performing alkaline degreasing on the titanium alloy, soaking the titanium alloy in H2C2O4 solution at the temperature of 80 DEG C, performing eroding treatment with ultrasonic wave for 3 hours, activating by use of an efficient ionic palladium activation treatment agent for 1-2 minutes, and performing chemical reduction for 30-60 seconds to perform metal plating. The metal plating method comprises the following steps: placing the pretreated titanium alloy in an acidic solution at the temperature of 80-90 DEG C to perform metal plating for 2-3 hours, taking the alloy out, rinsing to obtain Ni-P, Ni-B and Ni-P / Ni-B alloy platings, and drying at 250-350 DEG C for 30-45 minutes to obtain the finished product. The metal plating pretreatment technology of the titanium alloyhas the advantages that the process is simple, the method is environmentally-friendly and fluorine-free, the treatment liquid can be used repeatedly and circularly, and the like.

Owner:京磁材料科技股份有限公司

Putty powder for exterior wall true stone paint

InactiveCN103497562AImprove performanceImprove water resistanceFilling pastesCrack resistanceMaterials science

The invention discloses a putty powder for an exterior wall true stone paint, and the putty powder comprises the following raw materials: by weight, 10-20 parts of heavy calcium powder, 20-30 parts of ash calcium powder, 20-30 parts of black cement, 50-60 parts of modified talcum powder, 1-2 parts of hydroxypropyl methyl cellulose, 0.5-1 part of hydroxypropyl starch ether, 3-5 parts of redispersible latex powder, 0.4-0.8 part of short glass fiber chopped filament, 1-2 parts of wood fiber and 1.5-2 parts of NSJK-6B latex powder. The putty powder has excellent comprehensive properties, has excellent water resistance, weather resistance, impermeability, crack resistance, acid and alkali resistance, scrub resistance, mildew proof and anti-corrosion and other properties, and is high in bonding strength, not easy to crack, non falling, non peeling, non hollowing, and durable in use.

Owner:岑其挺

Thermal insulating sterilization type coating for glass doors and preparation method of thermal insulating sterilization type coating

InactiveCN104449206AImprove self-cleaning abilityEnhanced stain and mildew resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceAluminum silicate

The invention discloses a thermal insulating sterilization type coating for glass doors. The thermal insulating sterilization type coating is characterized by being prepared from the following raw materials in parts by weight: 38-42 parts of aqueous epoxy resin, 12-15 parts of aqueous alkyd resin, 11-14 parts of acrylic resin emulsion, 0.3-0.5 part of a leveling agent BYK-307, 0.2-0.4 part of gas phase nanosilicon dioxide, 1-2 parts of butyl stearate, 0.3-0.5 part of methyl glycidyl acrylate, 0.2-0.3 part of cashew nut oil, 1-3 parts of zinc powder, 0.2-0.3 part of octadecanamide, 1-3 parts of dipropylene glycol butyl ether, 0.5-1.0 part of a silane coupling agent KH, 0.2-0.4 part of a polysiloxane defoaming agent, 0.2-0.4 part of a dispersing agent BYK-415, 0.3-0.5 part of fatty alcohol sodium succinate, 1-2 parts of a polymercaptan curing agent, 1-2 parts of aluminum silicate powder, 0.4-0.8 part of sodium phytate, 3-5 parts of a modified nano titania photocatalyst, 1-2 parts of pigment and 12-15 parts of deionized water. By adopting the thermal insulating sterilization type coating disclosed by the invention, a coated film is smooth and flat, hard in hardness, free of peeling or dropping, resistant to brushing and washing and good in water resistance after being cured, the added aluminum silicate powder has a function of reflection thermal insulation, the added zinc powder has the functions of corrosion resistance, rusting resistance and aging resistance, and due to addition of the modified aluminum silicate powder, the self-cleaning property, the antifouling property, the anti-mildew property, the air purification property and the like of the coating are improved.

Owner:安徽省实防新型玻璃科技有限公司

Purl cowboy fabric

Purl cowboy fabric relates to the field of spinning fabric. The fabric comprises warp and weft, wherein, the warp adopts pure cotton fiber, and the weft adopts composite fiber formed by cladding urethane elastic fiber by elastic composite fiber and pure cotton fiber. The invention has the advantages of clear and refined fabric marks through reasonable disposal to the fabric, longitudinal and transversal bamboo joint effect, strong stereoscopic effect, soft hand feeling, neatness, little possibility of crinkling, and good elastic recovery performance.

Owner:CHANGZHOU OASIS TEXTILE

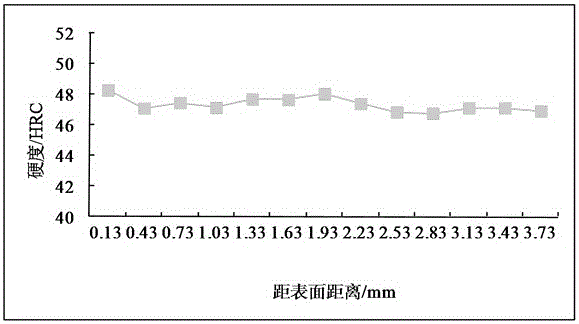

Surface laser strengthening method for plunger of hydraulic support

InactiveCN101967538AImprove corrosion resistanceEnhanced extrusion strength performance indexChromium coatingInduction hardening

The invention relates to a surface laser strengthening method for a plunger of a hydraulic support. The method adopts a CO2 laser-processing system or an optical fiber laser-processing unit, and a special alloy surface strengthening layer is manufactured on the surface of the plungers of an upright column, a middle cylinder and the like, wherein the special alloy surface strengthening layer is 0.5-0.7mm in thickness, has high corrosion resistance and compression strength, can be completely metallurgically fused and firmly combined with a plunger substrate, and has even and compact crystallization. The invention adopts the laser surface-treated plungers of the upright column, the middle cylinder and the like of the hydraulic support, and improves the environmental corrosion resistance of the plungers; the working surface of the laser surface-strengthened plunger has imporosity and high metallurgical bonding strength; and the surface strengthening layer does not peel off, and the service life is improved by more than three times compared with the originally adopted chromium coating. The high-strength alloy working layer manufactured by laser completely achieves the standards of strength property, sealing property and endurance property required after mid-frequency induction hardening and quenched-tempered heat treatment. The invention has the advantages of environmental protection, no pollution, simple processing technique and stable and reliable quality, reduces the production cost, and is suitable for mass production.

Owner:湖北吉隆表面工程有限公司

Environment-friendly multifunctional waterproof paint

InactiveCN102040890ASimple and safe constructionConstruction saves labor and timeChloropene polymer coatingsEmulsionOxide

The present invention discloses a paint, and especially relates to an environment-friendly multifunctional waterproof paint. The paint is prepared from the following raw materials in parts by weight: 5-10 of polyvinyl acetate, 60-70 of chloroprene rubber, 10-20 of aluminum paste, 0.1-1 of zinc oxide, 25-35 of ethene-vinyl acetate emulsion, 0.5-1.5 of dibutyl phthalate, 1-5 of light calcium carbonate. The invention is advantageous in that: the utilization of the invention is simple, working hours and labor are saved, the invention does not induce environment pollution, the invention is not harmful to human body, peeling does not occur after the paint of the invention is used, the film forming effect is good, the solidification is fast, the invention is resistant to ageing, the binding power is strong, the extensibility of the material is good, a waterproof layer is formed on the base surface of materials being painted so that the painted materials are super waterproof. Furthermore, when the paint is applied to outer wall decoration, not only the effects of heat insulation and good decoration but also the impervious, waterproof and nontoxic effects can be achieved. Therefore the paint can be widely applied to the water prevention of roofing and out walls, toilets, gardens on top of buildings, floors, basements, subterranean tunnels, pools and water channels.

Owner:彭晓洁

Magnesium and magnesium alloy surface silver-plating method

The invention discloses a magnesium and magnesium alloy surface silver-plating method, and relates to the technical field of magnesium alloy silver plating. According to the method, eight steps including shot blasting, oil removal, excitation, residual film removal, zinc immersion, copper plating, silver plating in advance and silver plating are adopted, good silver plating layers are obtained after magnesium and magnesium alloy surfaces are specially treated, according to magnesium and magnesium alloy silver pieces processed through operation of the process, the silver plating layer bonding force is checked by thermal shock tests, the plating layers are free of peeling, blistering and falling, parts obtained after thermal shocks are subject to bonding force tests according to a QJ479-90 marking method, and the plating layers are free of peeling, blistering and falling. Through trials and errors, all silver plating layers are good in bonding force and free of peeling, blistering and falling; through an QJ458-88 anti-sulphur test, the silver plating layers are not subject to aftertreatment, the anti-sulphur performance is larger than 1 min, and the anti-sulphur performance of partssubject to aftertreatment after silver plating is larger than 5 min. The electroplating magnesium and magnesium alloy silver-plating parts are good in bonding force, high in anti-sulphur performance and resistant to corrosion, the plating layers are free of peeling, blistering and falling, and the method is worthy of application and popularization on industry.

Owner:贵州航天风华精密设备有限公司

Natural plant gum waterproof putty

InactiveCN104861758AIncrease usage intensityNot volatileFilling pastesCrack resistanceMethyl cellulose

The invention discloses natural plant gum waterproof putty which is prepared from the following raw materials in percentage by mass: 0.05-0.15% of hydroxypropyl methyl cellulose, 0.15-0.25% of latex powder, 0.15-0.25% of special putty gum powder, 0.05-0.1% of multifunctional gum powder, 0.3-0.5% of natural starch, 0.01-0.05% of a mildew preventive, 30-50% of ash-calcium-powder, 3-8% of talcum powder, 30-40% of coarse whiting powder and 15-25% of water. Hydroxypropyl methyl cellulose is taken as a framework, and natural starch is taken as a main adhesive, so that the use strength of putty is improved, and at the same time, no harmful gas can be volatilized; after being coated on a wall, the putty is not peeled off, swelled or dropped off, so that the natural plant gum waterproof putty has the advantages of excellent adhesion strength, scrubbing resistance, alkali resistance, crack resistance and the like; the natural plant gum waterproof putty is low in raw material price and applicable to industrial-scale production.

Owner:赖日清 +4

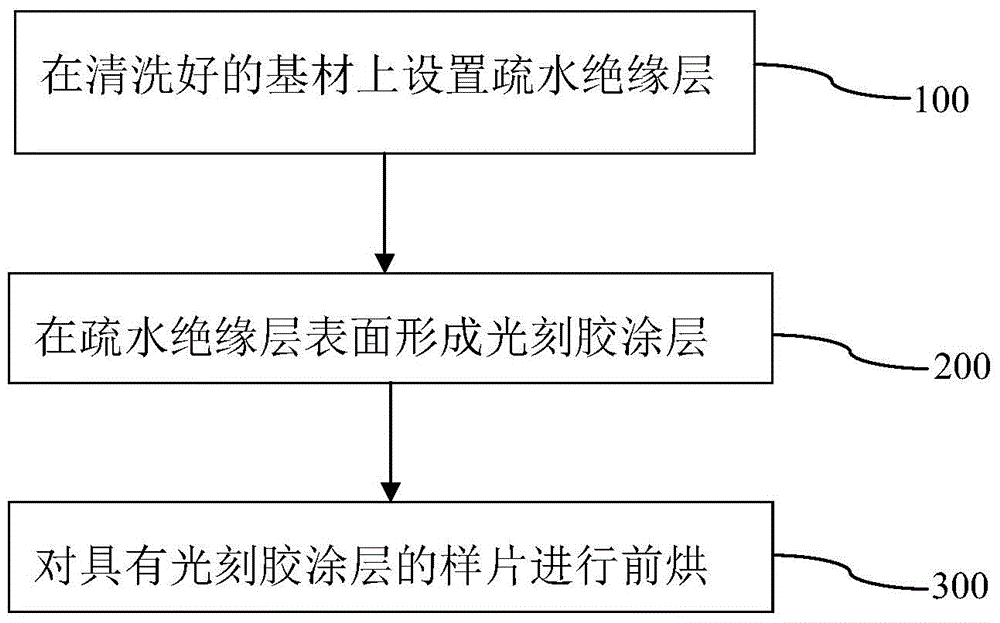

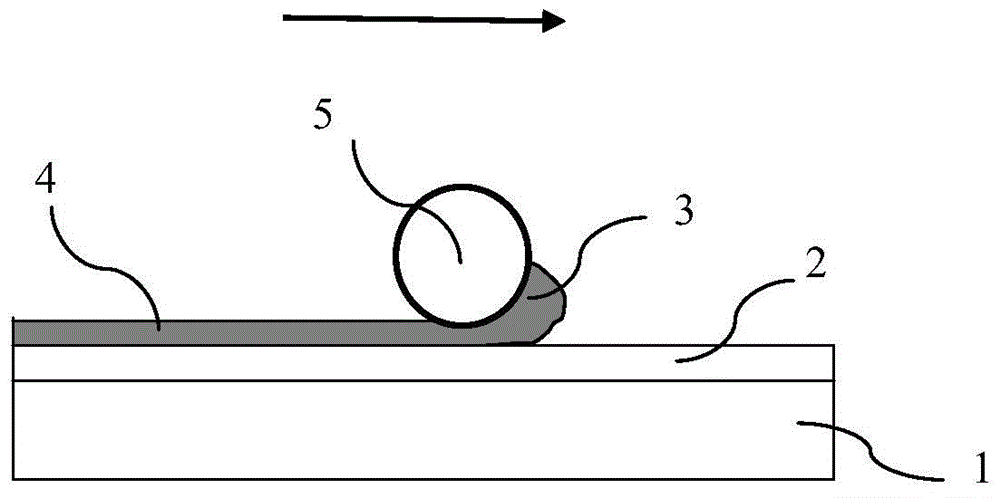

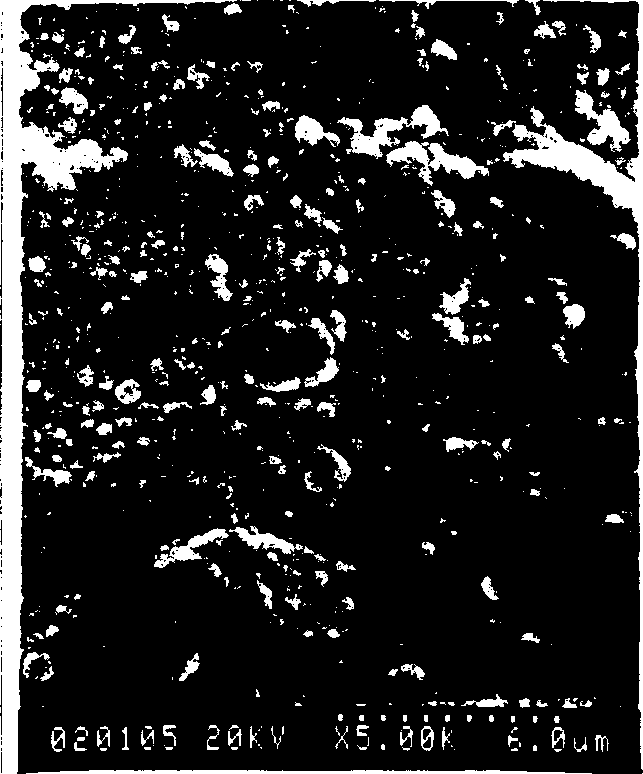

Method for coating photoresist on surface of hydrophobic insulating layer

ActiveCN104409332ASkinnyPeeling will not appearSemiconductor/solid-state device manufacturingPhotoresistViscosity

The invention discloses a method for coating a photoresist on the surface of a hydrophobic insulating layer. The method comprises the steps of directly coating a photoresist solution with high viscosity on the surface of the hydrophobic insulating layer through a coil bar coating method; carrying out vacuum heating which is a special heat treatment method; strictly controlling temperature rise procedures, wherein the photoresist coating is good in viscosity, the bad viscosity phenomena of peeling, separating and the like cannot be caused on the coating in a developing process, and the good quality of a photolithography technique can be realized. The method provided by the invention can be used for electrowetting display, microflow control chip and other fields.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

Aluminum alloy shell of CVT and preparation method thereof

The invention discloses an aluminum alloy shell of a CVT and a preparation method thereof. The aluminum alloy shell is composed of silicon, iron, magnesium, copper, chromium, manganese, titanium, zinc, nickel, lead, tin, zirconium, antimony, molybdenum, strontium and aluminium. The aluminum alloy shell is not prone to deforming and has high temperature resistance, no skin, light weight, no peeling, hardness of 150-200 HV; and a product has high strength, tensile strength of 500-600 MPa, yield strength of 450-550 MPa, bright surface, good fatigue resistance, elongation of 10%-20%, and no bubbles.

Owner:江苏创斯达科技有限公司

Environmental protection type water resisting putty powder in use for inner wall

InactiveCN1260313CNo pollution in the processNot easy to mildewFilling pastesCarboxymethyl celluloseMethyl cellulose

The invention discloses an environment-friendly water-resistant interior wall putty powder, which mainly comprises the following components by weight: heavy calcium carbonate powder 70-75, light calcium calcium powder 20-35, gray matter calcium powder 40-55, Alpha starch 15-20, carboxymethyl cellulose 18-25, water-soluble rubber powder 14-18. This environmentally friendly water-resistant interior wall putty powder has the advantages of strong water resistance, no slag, no peeling, and no cracks. The construction surface is smooth, easy to calender, not easy to mildew, and it is convenient for construction and low in cost.

Owner:赵炜

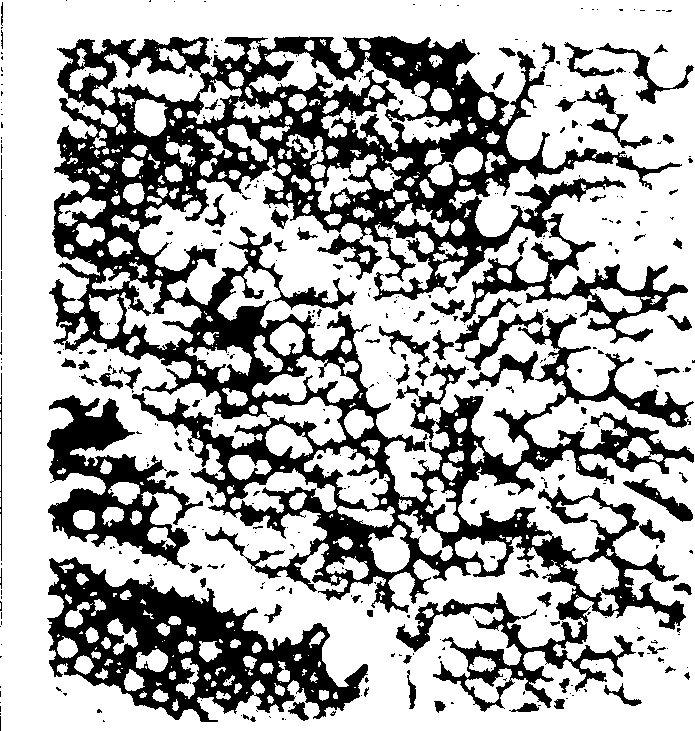

Non-aqueous solvent cyanogens-free gold plating solution

The cyanide-free gold-plating solution includes non-water solvent, gold source and support electrolyte, and features the non-water solvent of DMSO, DMF or PC; gold source of AuPPh3X, where X is Cl, Br, I or acac; and the support electrolyte of inorganic or organic ammonium salt soluble in the non-water solvent, with the inorganic ammonium salt being NH4X, where X is Cl, Br or I, and the organic ammonium salt being R4NX, where R is C2H5 or n-C4H9 and X is Cl, Br or I. The present invention features the green gold-plating solution, expanded gold source owing to the non-water solvent and the spherical crystallized coating structure with excellent performance.

Owner:SUZHOU UNIV

Anti-carburizing painting capable of being removed through washing after quenching and preparation method thereof

The invention discloses an anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting is prepared from, by mass, 25%-35% of boric acid, 15%-25% of filling, 15%-25% of aluminum dihydrogen phosphate, 1%-5% of tinting pigment and 30%-40% of water. The invention further discloses a preparation method of the anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting can be removed through washing after carburizing heat treatment, so that the problem that a traditional anti-carburizing painting is difficult to peel off after the carburizing heat treatment is solved. An inorganic heat-resisting material serves as an anti-carburizing agent in the formula of the anti-carburizing painting, so that an anti-carburizing coating formed after the anti-carburizing agent is brushed on the surface of a workpiece is good in cohesiveness, capable of not peeling and capable of not flowing at a high temperature, and the carburizing atmosphere is not influenced.

Owner:NANJING KERUN LUBRICANTS +1

Manufacturing technique of anti-wrinkle woolen fiber

The invention relates to a manufacturing technique of anti-wrinkle woolen fiber. The manufacturing technique of anti-wrinkle woolen fiber weaves a woolen high count frivolous woolen fleece tweed by using woolen yarn with a metric number of 25 / 1. The woolen high count frivolous woolen fleece tweed has the advantages of good binding cohesion and antistatic property. The woolen high count yarn is characterized by balance evenness, high intensity, frivolous and gentle fabric, full handle, smoothness and bonyskinny. The Newer fiber has the advantages of good handle feeling and strong sense of pendant and laundering durability and good wrinkle resistance, which complements the advantage and disadvantage of each fiber. Thus the anti-wrinkle woolen fiber is characterized by stronger intensity of fabric and better water absorption, heat retaining property and stiff and smooth property, which benefits human health and environmental protection.

Owner:JIANGSU SUNSHINE GRP CO LTD

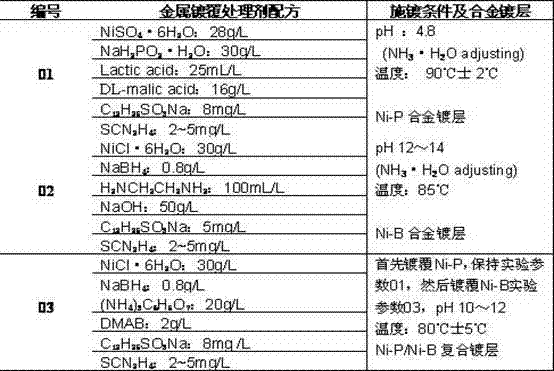

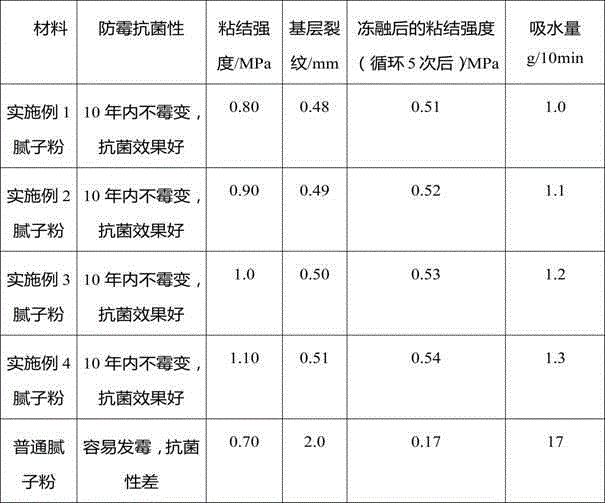

Mildew-proof antibacterial putty powder and using method

InactiveCN105273474AImprove water resistanceHigh bonding strengthFilling pastesFreeze thawingPolymer science

The present invention discloses mildew-proof antibacterial putty powder including a main body material, an adhesive material and a mildew-proof antibacterial material, the main body material, the adhesive material and the mildew-proof antibacterial material are respectively individually packaged in a putty powder large package, before the package, the main body material, the adhesive material and the mildew-proof antibacterial material are respectively individually pulverized, the powder putty basic level crack is 0.48mm-0.51mm, the adhesive strength is 0.80MPa-1.1MPa, the bond strength after 5 times of freeze-thaw cycle is 0.51MPa-0.54MPa, the water absorbing amount is 1.0g / 10min-1.3g / 10min, and the fineness is 50mum-80mum. The putty powder prepared by the invention is not easy to mildew, good in water resistance, and high in bond strength, has the advantages of no dusting, no peeling, no cracking, no mildewing, easy construction, and good antibacterial effect.

Owner:苏锦忠

Low-temperature quick-drying anticorrosive paint

InactiveCN102417788AImprove anti-corrosion effectImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsZinc phosphateN-Butanol

The invention discloses a low-temperature quick-drying anticorrosive paint prepared from stirred raw materials of, by weight: 60-65 parts of polyurethane, 10-12 parts of polytetrafluoroethylene, 10-11 parts of zinc phosphate, 20-24 parts of n-butanol, 5 parts of strontium sulfate, 10 parts of sodium hexametaphosphate, 4 parts of an antifoaming agent, and 3 parts of a dispersant. As a result of industrial experiments, the paint provided by the invention has advantages of good corrosion resistance and high adhesion. With the pant, phenomena of peeling and shelling are prevented. The paint can be dried within tens of minutes under a normal temperature.

Owner:WUJIANG TIANYUAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com