Non-aqueous solvent cyanogens-free gold plating solution

A non-aqueous solvent, cyanide-free gold plating technology, applied in the field of gold plating solution, can solve the problems of environmental pollution, hydrogen evolution, cracking or dissolution, etc., and achieve the effect of good conductivity, low toxicity and high polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

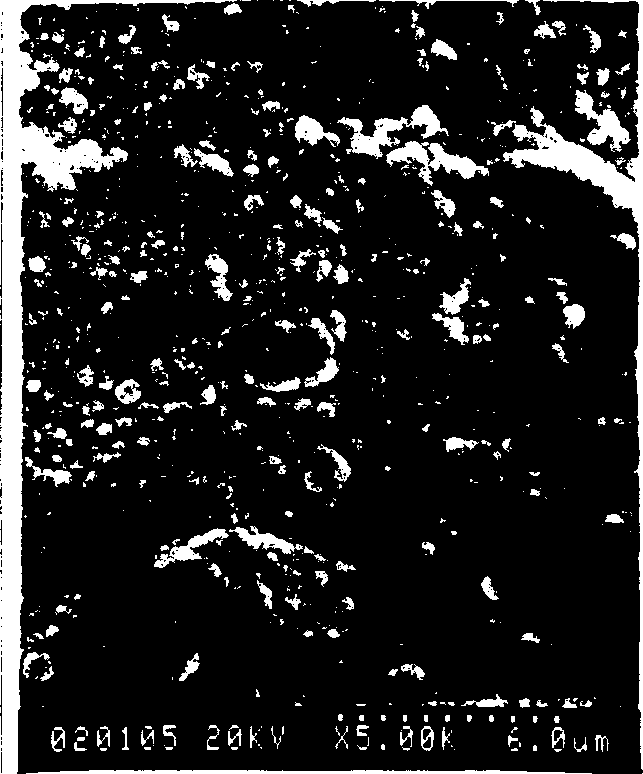

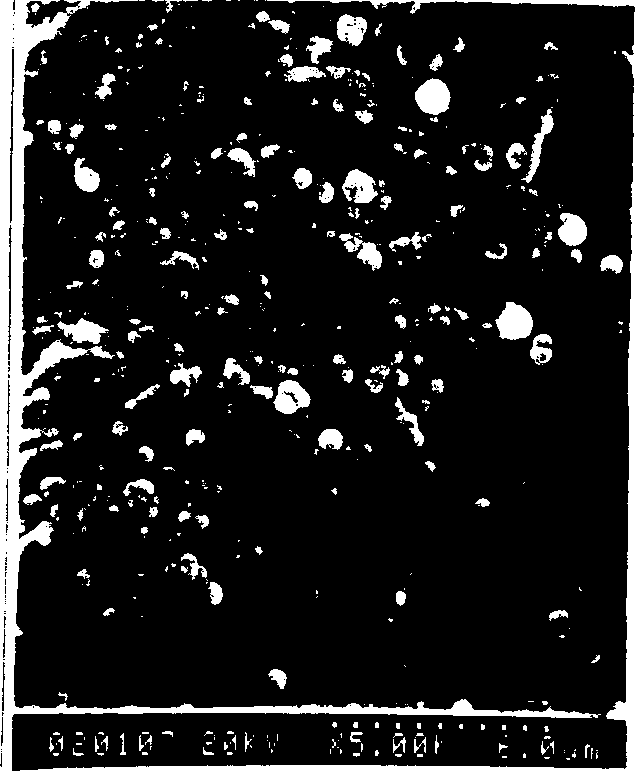

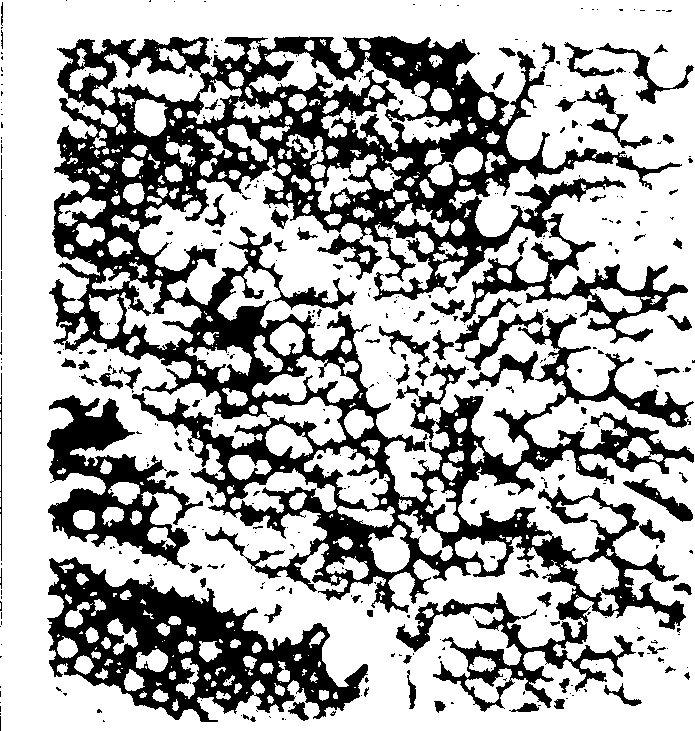

Image

Examples

Embodiment 1

[0049] (1), Research electrode: 12mm×14mm, copper sheet with a purity of 99.5%, use 500 # , 800 * , 1200 # Imported metallographic sandpaper successively grinds off the oxide film on the copper surface, polishes on a grinder equipped with fine felt cloth, washes with alkali, pickles, washes with distilled water, and blows dry.

[0050] (2) Counter electrode: 10mm×12mm, 99.9% pure gold sheet.

[0051] (3), reference electrode; saturated Ag / AgCl electrode.

[0052] (4), solvent DMSO, gold source AuPPh 3 Cl, supporting electrolyte NH 4Cl. The composition and concentration of the plating solution are:

[0053] Composition Maximum Concentration Range Optimal Concentration Range Optimal Concentration

[0054] (mol / l) (mol / l) (mol / l)

[0055] DMSO

[0056] AuPPh 3 Cl 0.005~0.04 0.008~0.03 0.015

[0057] NH 4 Cl 0.05~0.3 0.1~0.3 0.2

[0058] Add AuPPh to 20ml DMSO 3 Cl, NH 4 Cl to the above concentration range, stirring, the current density is 0.01A / dm ...

Embodiment 2

[0060] Take sample electrode according to embodiment 1, solvent DMSO, gold source AuPPh 3 Br, supporting electrolyte NH 4 Br, glossy coating, golden yellow.

[0061] The composition and concentration of the plating solution are:

[0062] Composition Maximum Concentration Range Optimal Concentration Range Optimal Concentration

[0063] (mol / l) (mol / l) (mol / l)

[0064] DMSO

[0065] AuPPh 3 Br 0.005~0.04 0.008~0.03 0.015

[0066] NH 4 Br 0.05~2.0 0.1~0.5 0.2

Embodiment 3

[0068] According to the plating condition of embodiment one, solvent DMSO, gold source AuPPh 3 I, supporting electrolyte NH 4 I, coating luster, golden yellow.

[0069] The composition and concentration of the plating solution are:

[0070] Composition Maximum Concentration Range Optimal Concentration Range Optimal Concentration

[0071] (mol / l) (mol / l) (mol / l)

[0072] DMSO

[0073] AuPPh 3 I 0.005~0.04 0.008~0.03 0.015

[0074] NH 4 I 0.05~1.5 0.1~0.5 0.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com