Pretreatment technology of surface metal plating of titanium alloy and metal plating method

A surface metal and titanium alloy technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of notch effect, fatigue strength reduction of titanium alloy, etc., and achieve low pollution, low temperature, and few pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

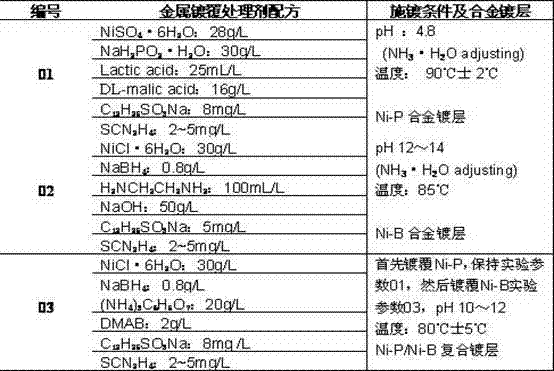

[0026] Prepare the Ni-P metal plating solution according to the formulation requirements of No. 01 plating process in Table 1, and adjust the pH value of the plating solution to 4.8 for later use. The titanium alloy material processed into 15mm × 10mm × 5mm is subjected to pickling, alkali washing, etching, activation and reduction treatment in sequence, and the titanium alloy rinsed with distilled water is immersed in the plating solution with a temperature controlled at 90 ± 2°C. Electroless plating was applied for 2 hours with stirring to make the thickness of the coating reach 15 μm. After taking it out, rinse it with tap water and distilled water in turn, and dry it. Then the obtained Ni-P alloy was sintered in a muffle furnace at 250° C. for 2 hours, and dried naturally to obtain a titanium alloy-plated Ni-P alloy coating.

[0027] The structural composition, surface morphology and cross-sectional structure of the coating were observed by XRD and SEM. The results showed...

Embodiment 2

[0029] Except preparing the Ni-B metal plating solution according to the formula requirement of No. 02 plating process in Table 1, and adjusting the pH value of the plating solution to 12.5, all the other are the same as in Example 1.

[0030] The structural composition, surface morphology and cross-sectional structure of the coating were observed by XRD and SEM. The results showed that the obtained Ni-B alloy coating was amorphous after heat treatment at 250℃×2h, and the crystal plane structure was uniform and complete. The test method of the bonding strength of the coating adopts tensile test, thermal shock test and scratch method, and the results show that under certain conditions, the coating does not peel, evenly crack and fall off. The electrochemical corrosion behavior of Ni-P alloy coating was evaluated by Tafel curve and salt water immersion test. The results show that the coating greatly improves the corrosion resistance of the metal substrate.

Embodiment 3

[0032] The pretreated titanium alloy was first immersed in the prepared Ni-P metal plating solution at 90°C for 30 minutes, and then metal-plated with Ni-B alloy coating at 85°C for 60 minutes to obtain Ni -P / Ni-B composite coating. After taking it out, rinse it with tap water and distilled water in turn, and dry it. Then the obtained Ni-P / Ni-B composite coating was sintered in a muffle furnace at 250°C for 2h, and then dried naturally.

[0033] The surface morphology and cross-sectional morphology of the sample after two platings were observed by SEM, and the results showed that the two coatings were closely bonded, had good compatibility, and had no obvious pores. Tensile test, thermal shock test and scratch method are used to test the combination of coatings. The results show that the coatings are not peeled, evenly cracked and peeled off under certain conditions. The electrochemical corrosion behavior of Ni-P alloy coating was evaluated by Tafel curve and salt water imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com