Long-term anti-pollution-flashover paint and preparation thereof

An anti-pollution flashover coating, a long-term technology, applied in the direction of coating, can solve the problems of difficult to guarantee quality, need power outage time, short service life, etc. Excellent performance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

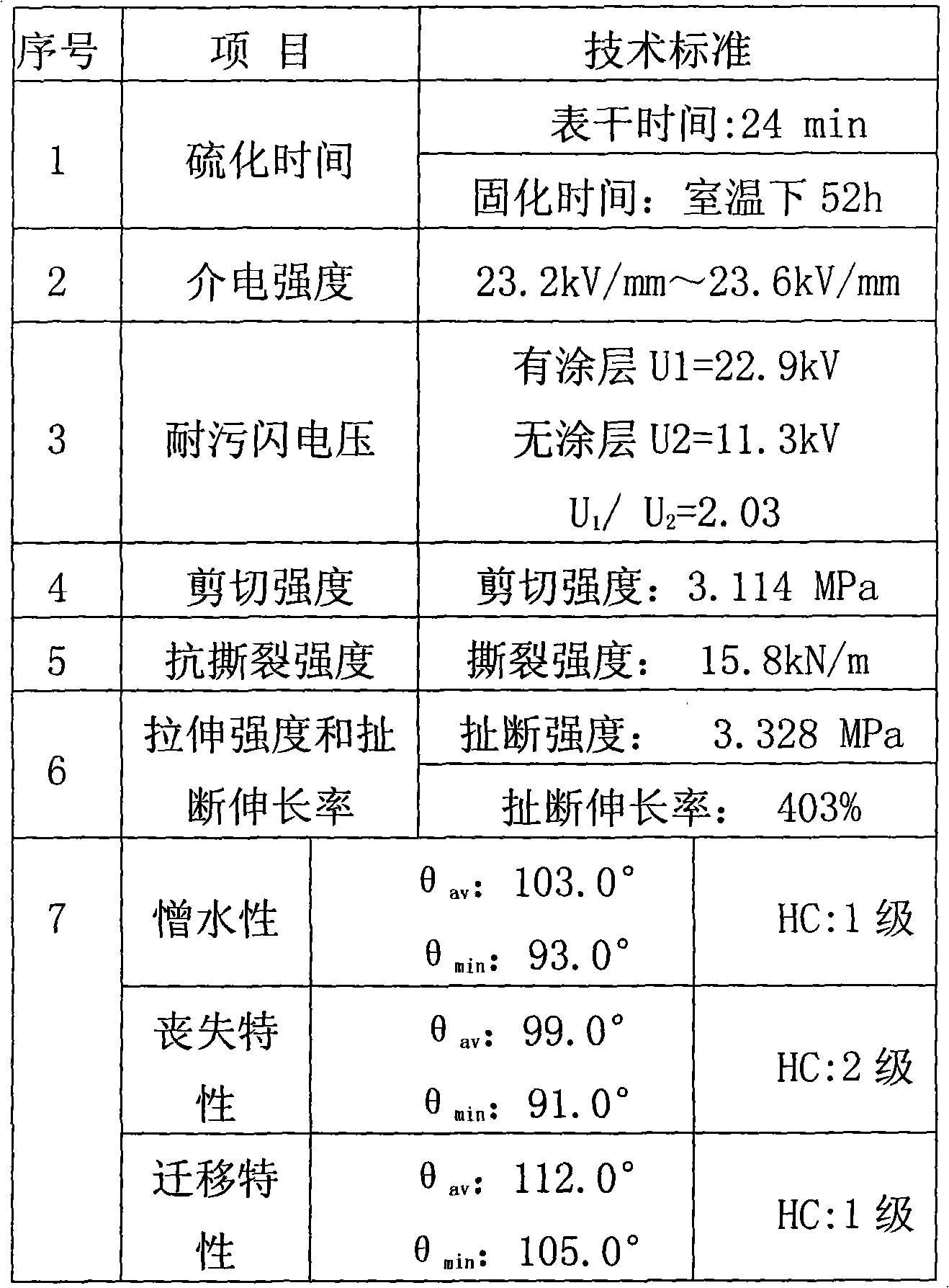

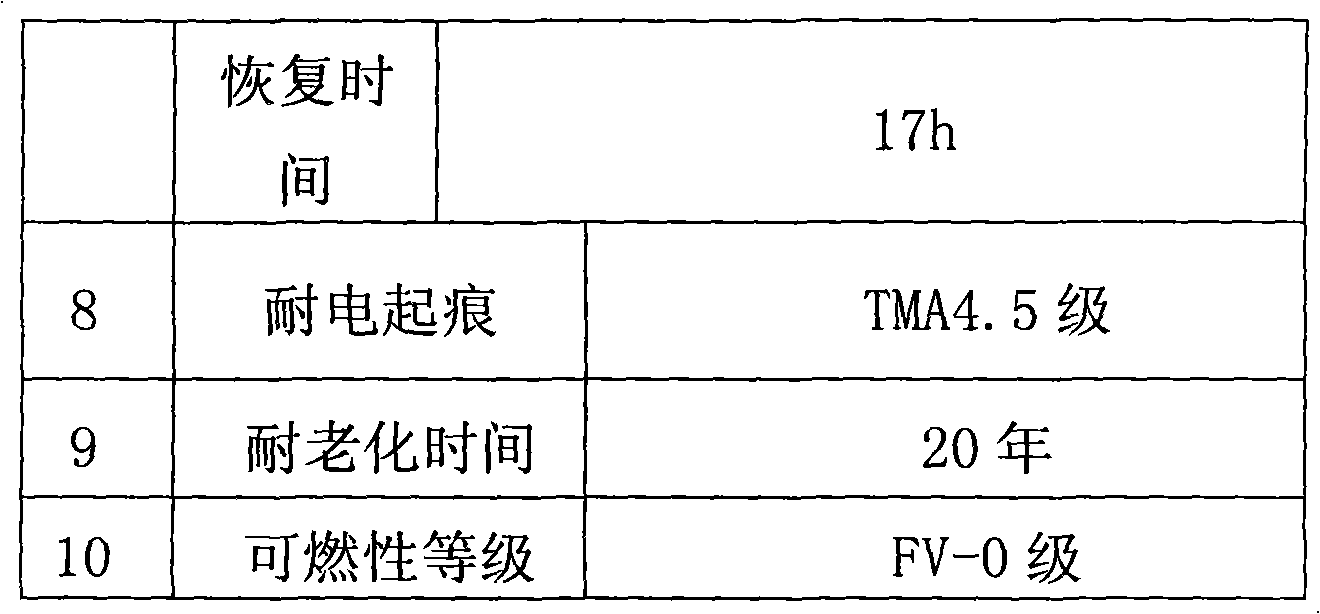

Examples

Embodiment 1

[0019] Aluminum hydroxide Al(OH) 3 Mix 3 parts with 8 parts of methyl silicone oil evenly, and then use a conical mill to grind to a fineness ≤ 5 μm, then add 100 parts of silicone rubber, 6.5 parts of meteorological silica, 5 parts of plasticizer, and 100 parts of trichloroethane, 0.6 parts of crosslinking agent, 3 coloring agents; put the mixed material into a high-speed dispersion tank protected by nitrogen, adjust the rotating speed to 3000r / min, disperse for 15 minutes, and filter the product with 200 mesh gauze to obtain the coating of the present invention.

Embodiment 2

[0021] Aluminum hydroxide Al(OH) 3 Mix 6 parts with 10 parts of methyl silicone oil evenly, then use a conical mill to grind to a fineness ≤ 5 μm, then add 100 parts of silicone rubber, 9 parts of meteorological silica, 8 parts of plasticizer, 120 parts of xylene, and crosslink 0.9 parts of coloring agent, coloring agent 3; Put the mixed material into the high-speed dispersion tank protected by nitrogen, adjust the rotating speed to 3000r / min, disperse for 15 minutes, and filter the product with 200 mesh gauze to obtain the coating of the present invention.

Embodiment 3

[0023] Aluminum hydroxide Al(OH) 3 Mix 5 parts with 9 parts of methyl silicone oil evenly, then grind to fineness ≤ 5 μm with a conical mill, then add 100 parts of silicone rubber, 8 parts of meteorological silica, 6 parts of plasticizer, 120 parts of ethanol, crosslinking agent 0.8 parts, coloring agent 3; put the mixed material into the high-speed dispersion tank protected by nitrogen, adjust the rotating speed to 3000r / min, disperse for 20 minutes, and filter the product with 200 mesh gauze to obtain the coating of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com