Patents

Literature

49results about How to "Simple and safe construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based organic silicon waterproof agent

InactiveCN101580355AGive full play to the effect of waterproofImprove impermeabilityOther chemical processesWater basedBrick

The invention relates to a water-based organic silicon waterproof agent by taking sodium methylsilanolate as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

Wet paved/pre-paved polymer self-adhesive waterproofing rolled material and preparation method thereof

InactiveCN102454226AExtended service lifeWeather resistantUnderground chambersRoof covering using flexible materialsPolymer resinCompound (substance)

The invention provides a wet paved / pre-paved polymer self-adhesive waterproofing rolled material which comprises a modified asphalt self-adhesive layer. The modified bitumen self-adhesive layer contains petroleum asphalt, modifier, softener, tackifier and filler. The wet paved / pre-paved polymer self-adhesive waterproofing rolled material which is prepared from the by taking a polymer resin layer as a base has a long use life, stable chemical properties and excellent waterproof effect, wherein the modified asphalt self-adhesive layer is prepared through single side or double side adhering.

Owner:沈阳蓝光科技发展有限公司

Water-emulsion organic silicon waterproof agent

InactiveCN101580356AGood chemical propertiesImprove bindingOther chemical processesEmulsionCement slurry

The invention relates to a water-emulsion organic silicon waterproof agent by taking alkylalkoxy silane as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

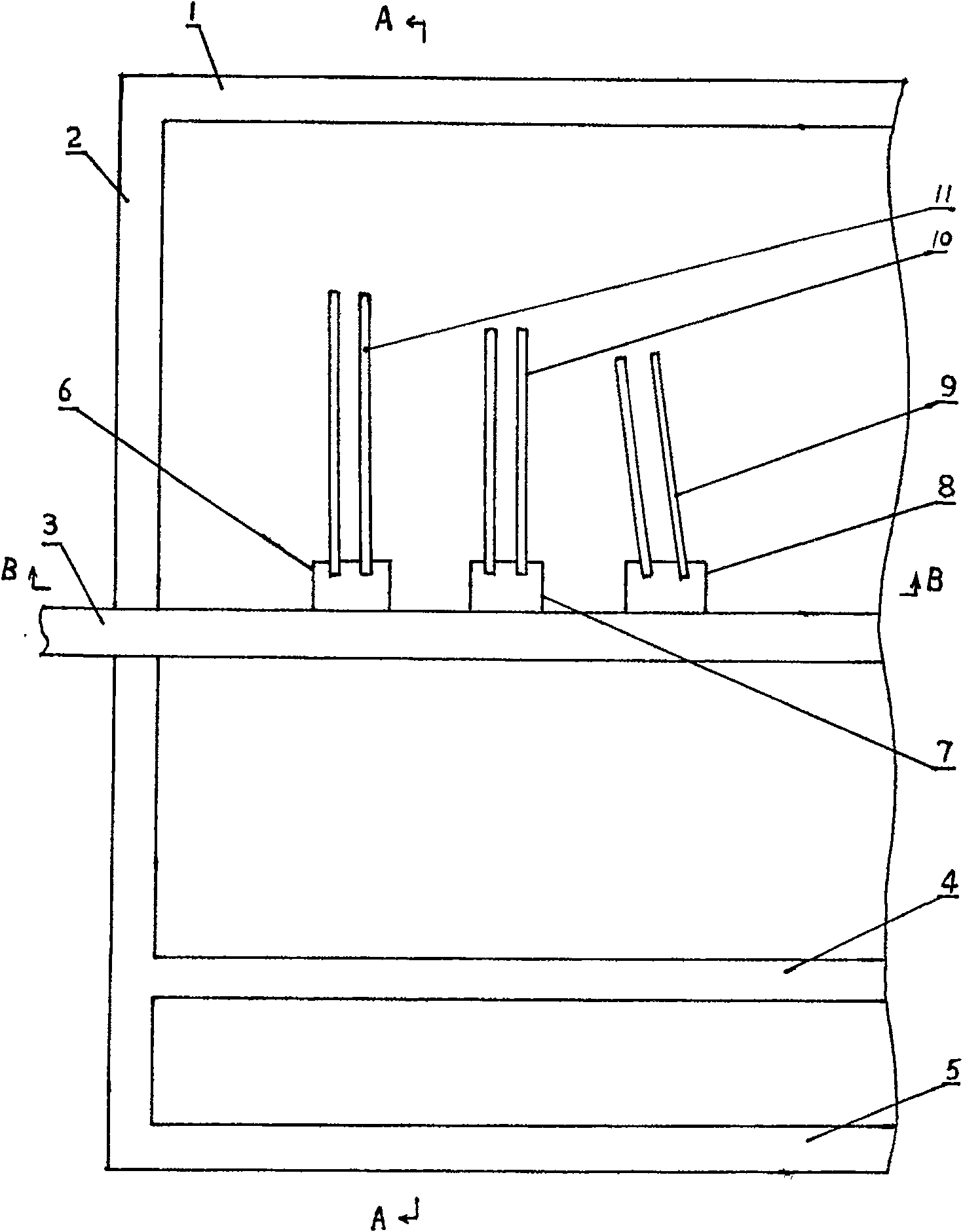

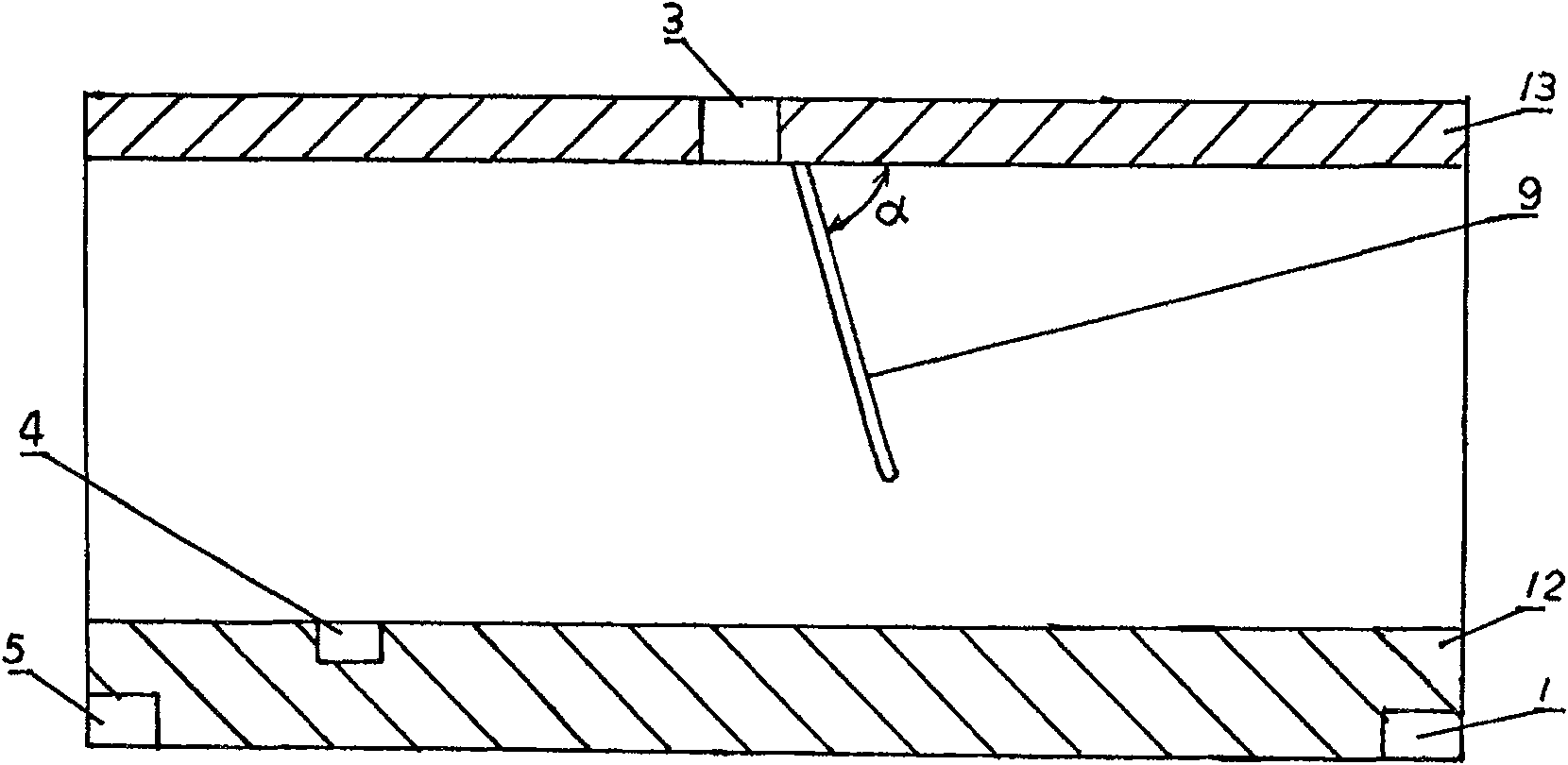

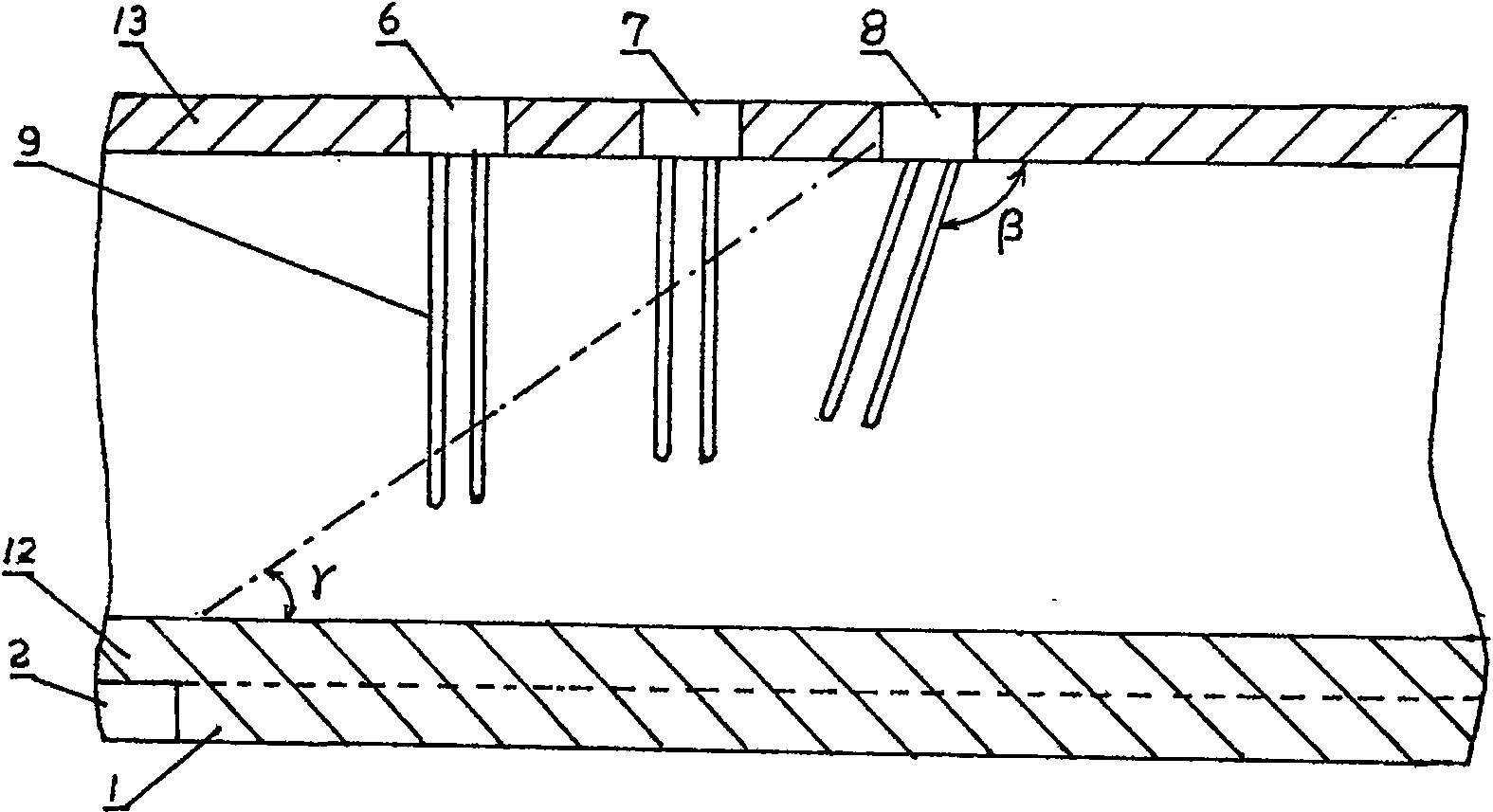

Fully mechanized coal face high suction tunnel lower-returning drilling primary mining gas drainage method

The present invention relates to a gas pumping and exchanging method of downward drilling hole high pumping lane with a comprehensive caving face used in gas initial pumping and exchanging, and aims to create a safe and simple working condition, to improve pumping and exchanging efficiency and to reduce the gas consistency of the working face efficiently; the present invention is to dig two or three drilling fields being suitable for drilling machine working at the place that the inner bottom plate of a trending high pumping lane is horizontally 0 to 50 meters being far away from the cutting lane; and two or three drilling holes are also need to be drilled; besides, towards the working face, the drilling machine can be used to drill downwards drilling holes which can replace the high pumping lane; the drilling holes can be drilled from the high pumping lane to reach the loading belt which is positioned above the working face and is newly developed during the initial mining period. The final drilling hole can be positioned in the angle of 70 degrees formed by the working face roof of the cutting lane and the roof of the coal seam and also can be positioned in the stratum as far as four and five times away from the working face; during the initial mining period, the trending high pumping lane is sealed in wall and pressed with iron tubes to connect with the main pumping and exchanging system; under the condition of high subpressure and through downward drilling holes, the gas lifted to the slit belt is pumped to the trending high pumping lane to enter into the pumping and exchanging system to reach the ground.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

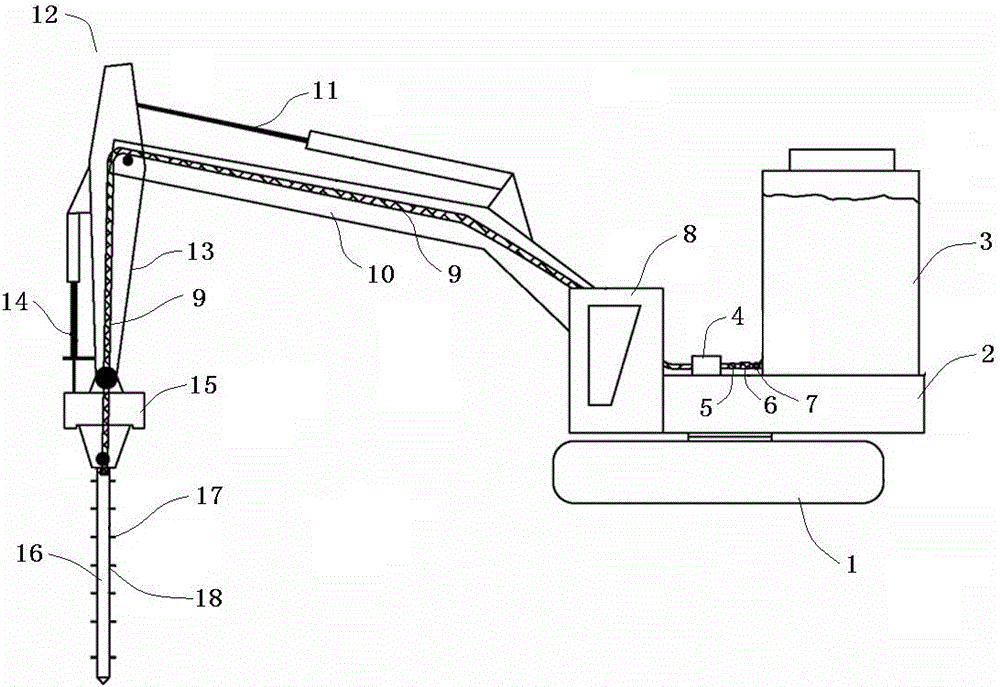

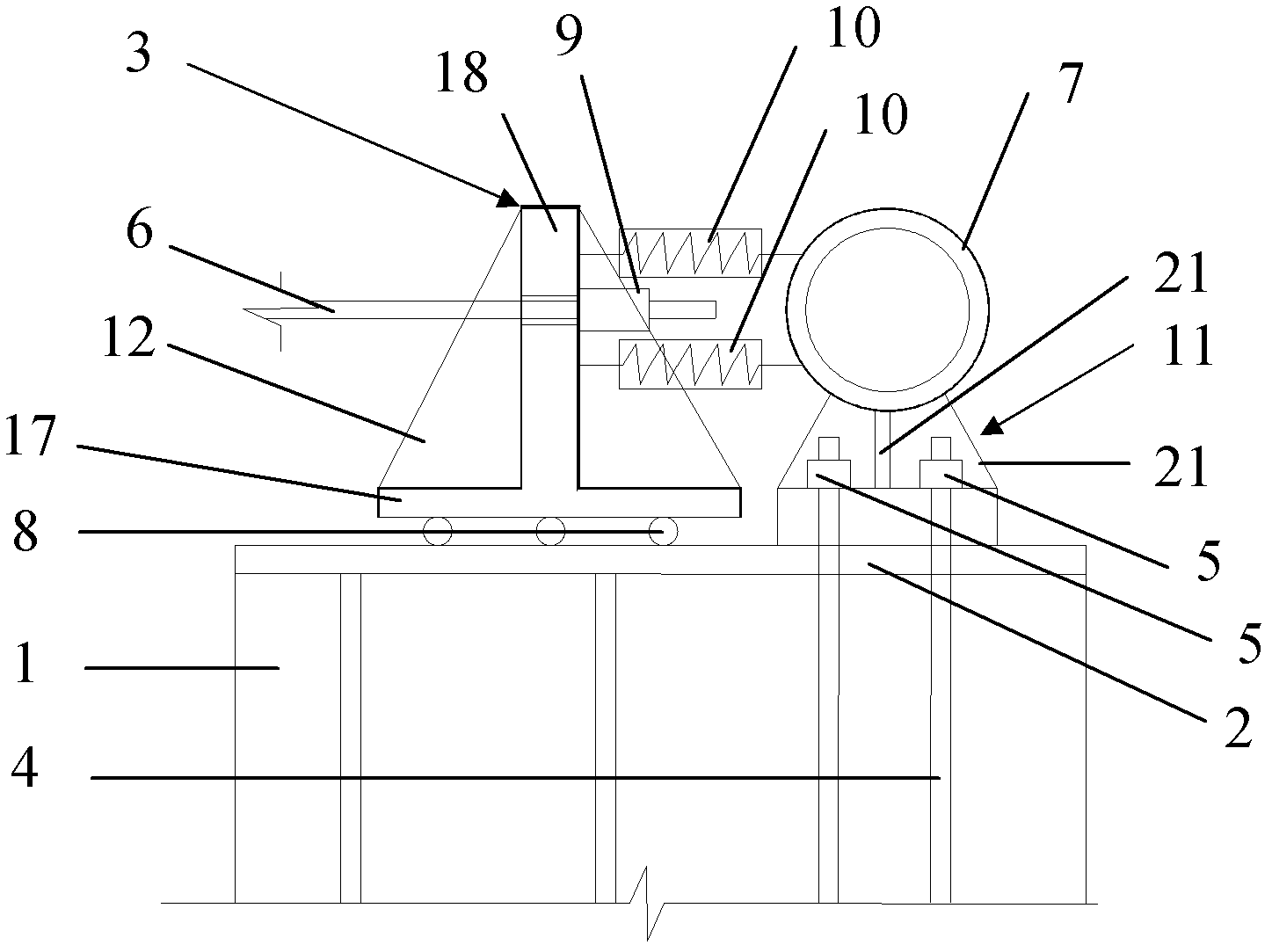

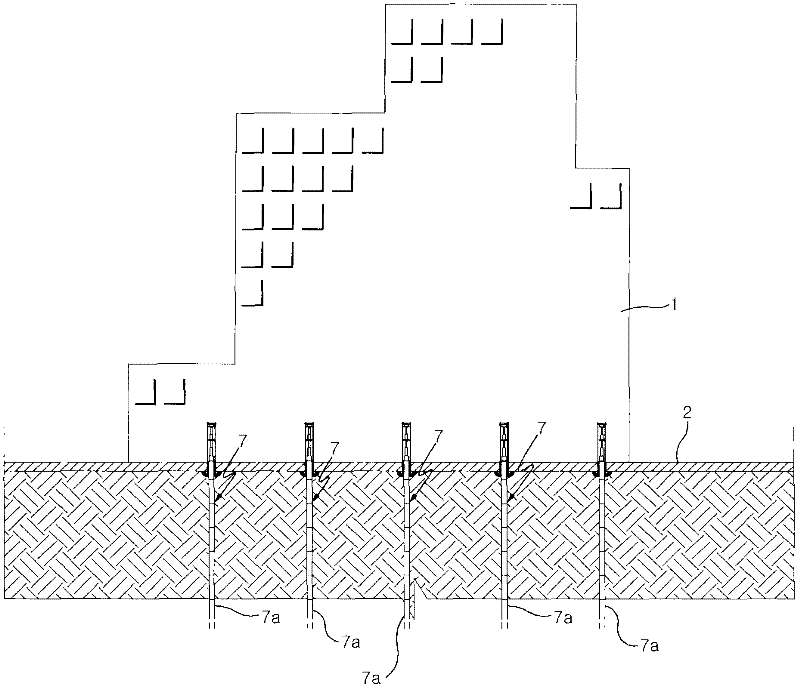

Mobile in-situ quick injection method for contaminated sites

InactiveCN105855288AIncrease construction depthAvoid the disadvantage of being difficult to moveContaminated soil reclamationInjection siteInjection device

The invention discloses a mobile in-situ rapid injection method for contaminated sites, which comprises the following steps: determining a number of injection points in the repair area of the contaminated site; moving a car body with a mechanical arm into the repair area, A front-end injection device is installed at the end of the mechanical arm, and the front-end injection device is an injection tube coaxially arranged with the mechanical arm; the injection tube is vertically pressed into the injection tube by the mechanical arm. The specified depth of the soil at the point, and pump the agent into the injection pipe so that the agent penetrates into the surrounding soil for repair; after the injection is completed, the injection pipe is lifted up and moved to the next injection point, so reciprocating, Complete the injection of all injection points. The advantage of the present invention is that it realizes the integrated in-situ injection without the need to build wells and use multiple equipment, making the construction more efficient, safer and simpler; with the help of the telescopic function of the hydraulic telescopic rod, it is ensured that the front-end injection device can reach a larger construction depth.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

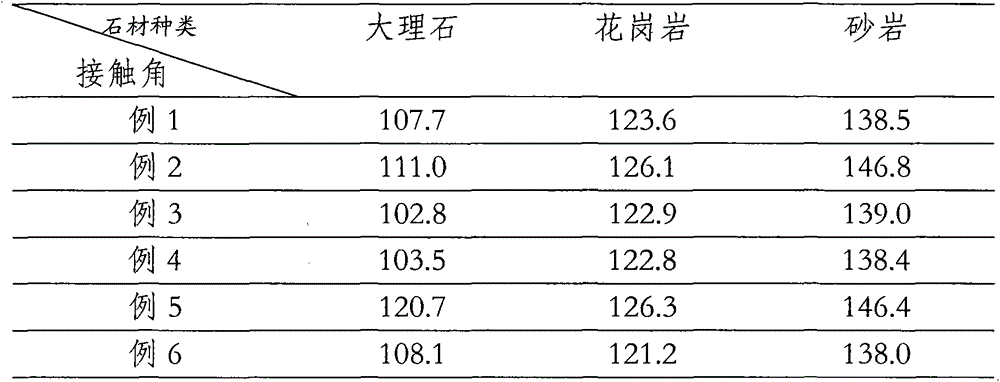

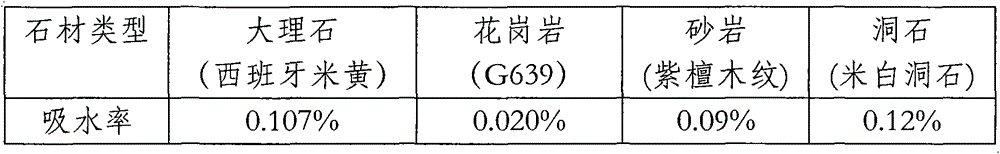

Solvent-type organic silicon stone protectant and preparation method thereof

The invention discloses a solvent-type organic silicon stone protectant and a preparation method thereof. The protectant is characterized by comprising the following polymer monomers by volume percent: at least one alkyl alkoxy silane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one polymethylhydrosiloxane of which the adding volume accounts for 1% to 10% of the total volume of the polymers, at least one titanate catalyst of which the adding volume accounts for 0.05% to 1% of the total volume of the polymers, and at least one solvent oil-type organic solvent of which the adding volume accounts for 79% to 97.95% of the total volume of the polymers. The preparation method comprises the following steps: evenly mixing the alkyl alkoxy silane and the polymethylhydrosiloxane in proportion in partial organic solvents at a room temperature; then carrying out a catalytic reaction by adding the catalyst; and finally, adding the organic solvent and diluting to reach a certain concentration. The protectant which has good permeability can be used for deeply protecting stone and is good in air permeability and recoatability. The protectant is simple in preparation method, simple and convenient to coat as well as relatively low in cost, thereby being suitable for industrial mass production.

Owner:XIAMEN NORNS TECH

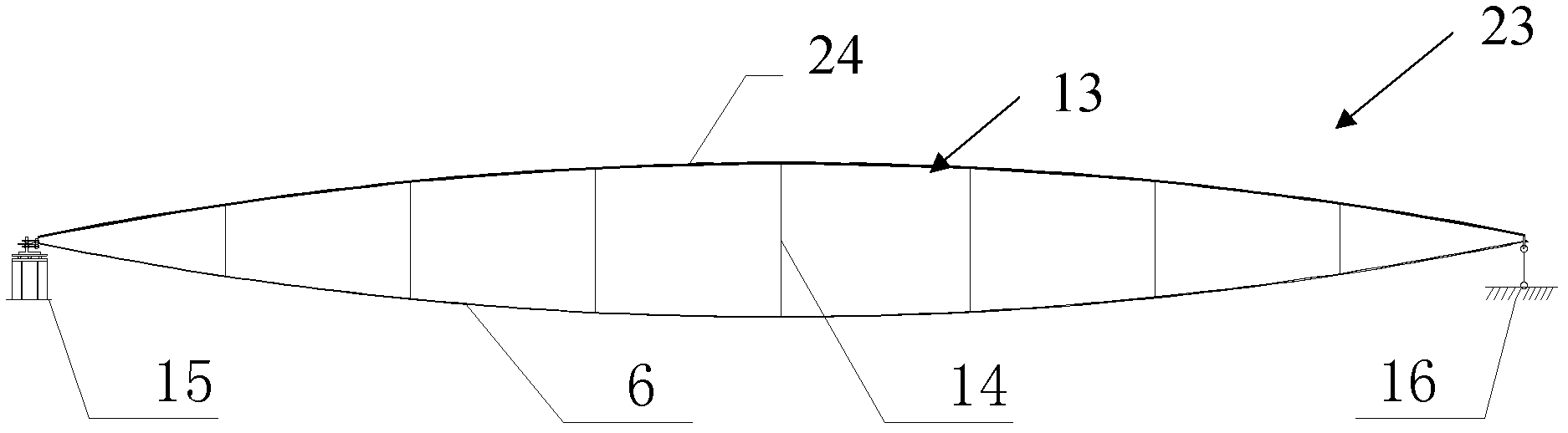

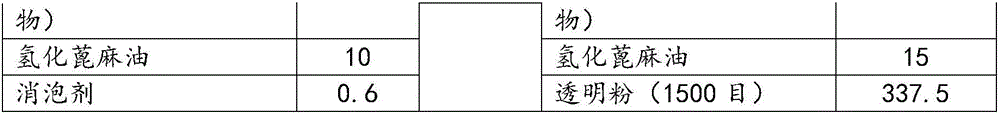

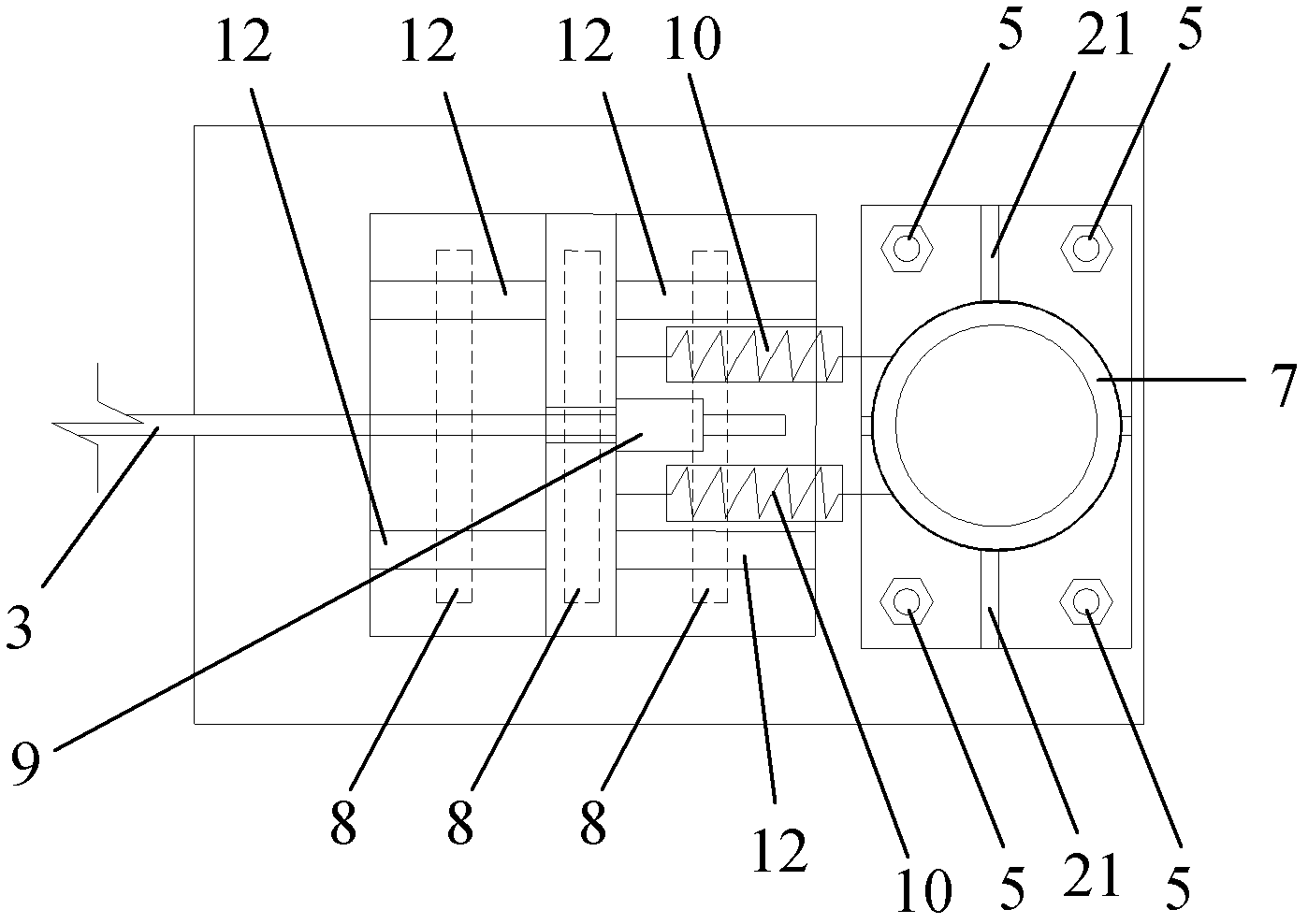

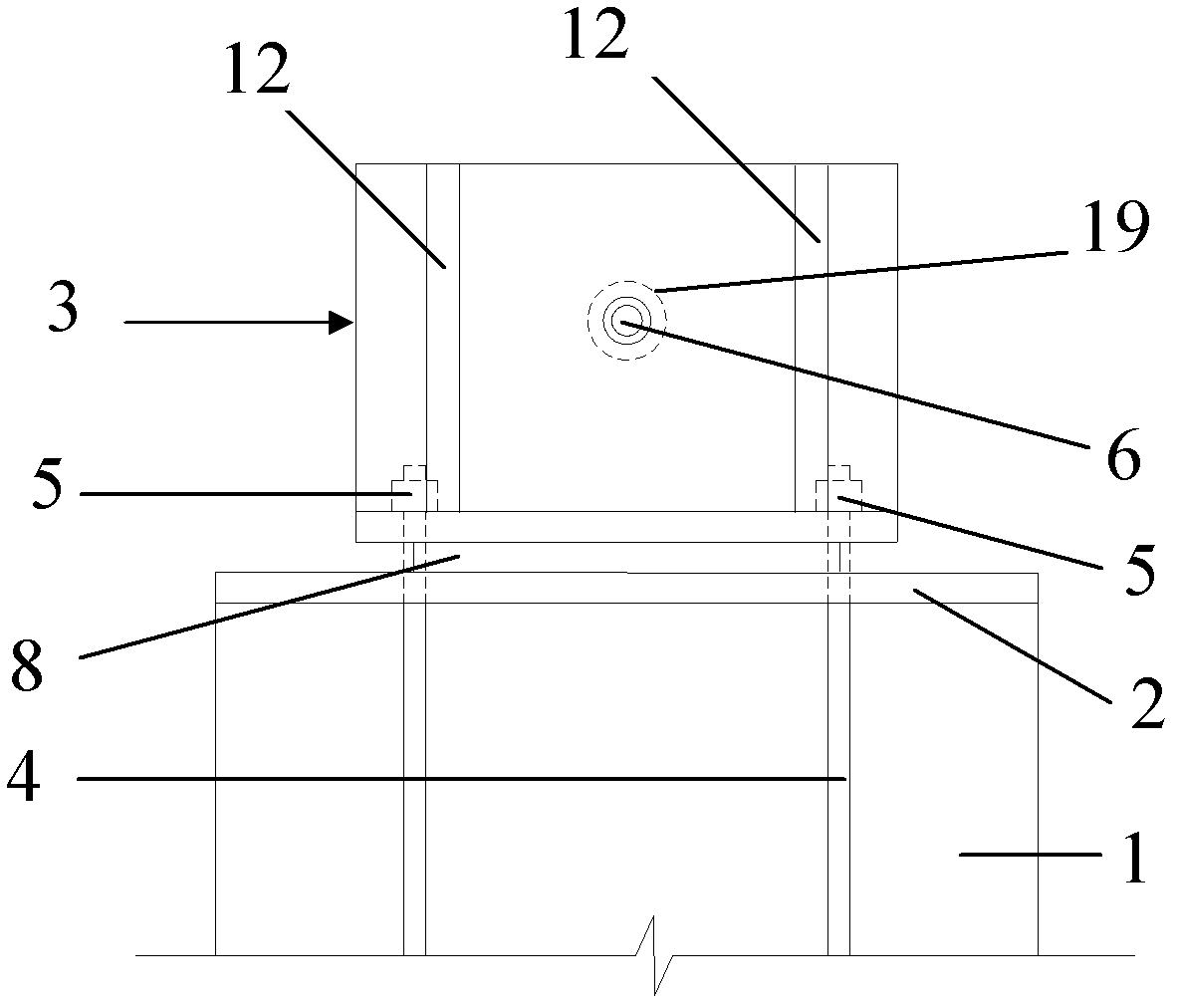

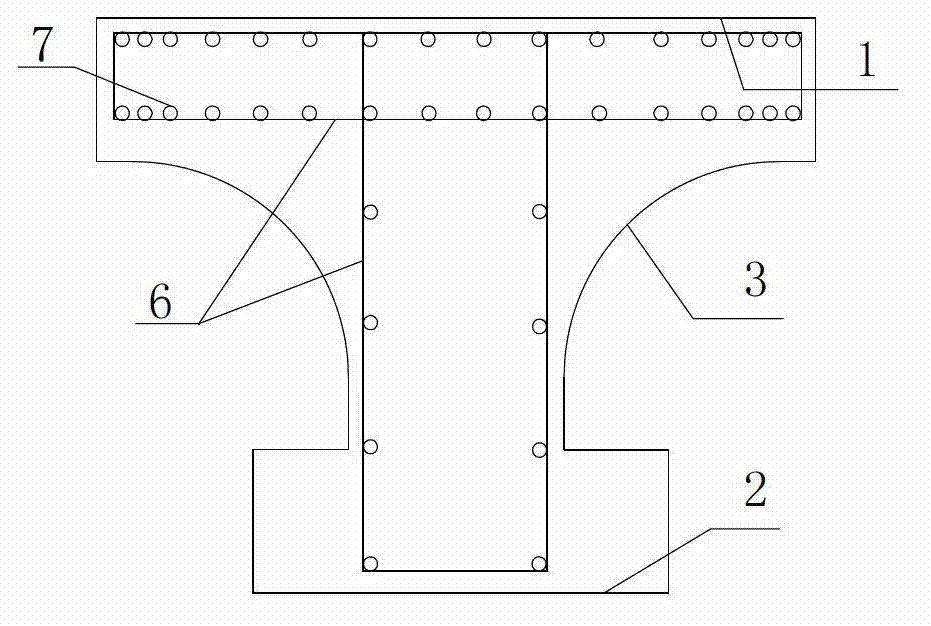

String truss structure with load-relieving effect and implementation method

InactiveCN102587497AImprove tensile capacityIncrease profitBuilding roofsShock proofingEngineeringSlide plate

The invention discloses a string truss structure with a load-relieving effect and an implementation method. The string truss structure comprises an upper string truss, a plurality of stay bars, a guy cable, a spherical joint fixed support and a sliding hinge support, wherein the spherical joint fixed support comprises a lower part supporting structure, a pre-embedded base plate, a reverse T-shaped sliding plate, a plurality of pre-embedded reinforcing steel bars, a fixed spherical joint, a plurality of columnar rolling bearings, an anchoring device, a plurality of damping springs and a support. The string truss structure with the load-relieving effect and the implementation method provided by the invention have the advantages of high material utilization rate, good stress performance, safety and simplicity for constructions, superior safety performance and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

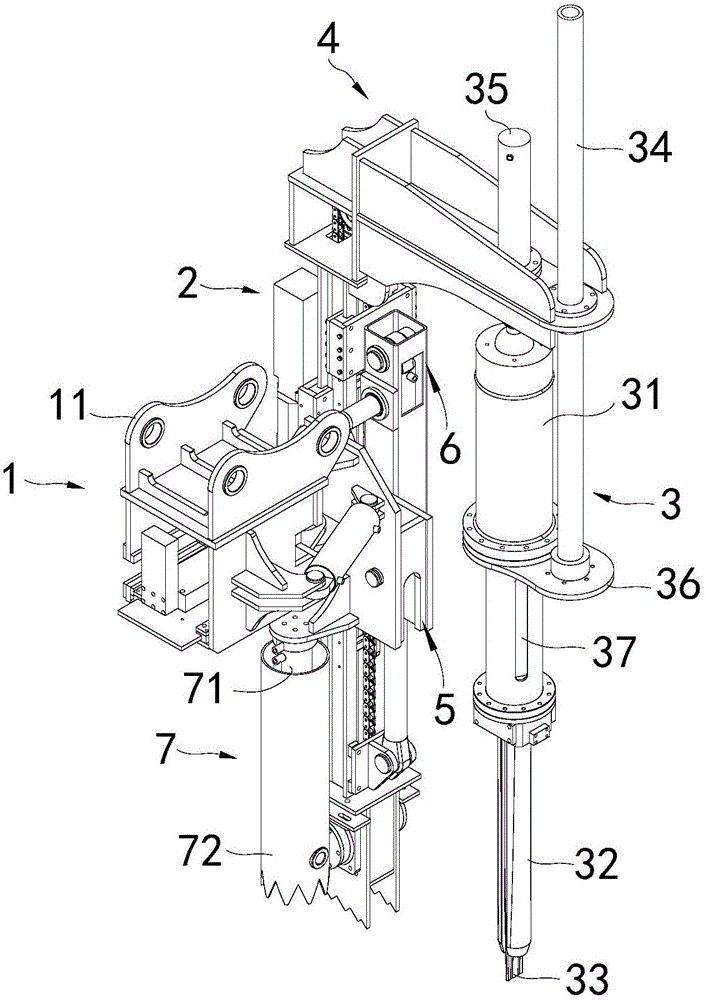

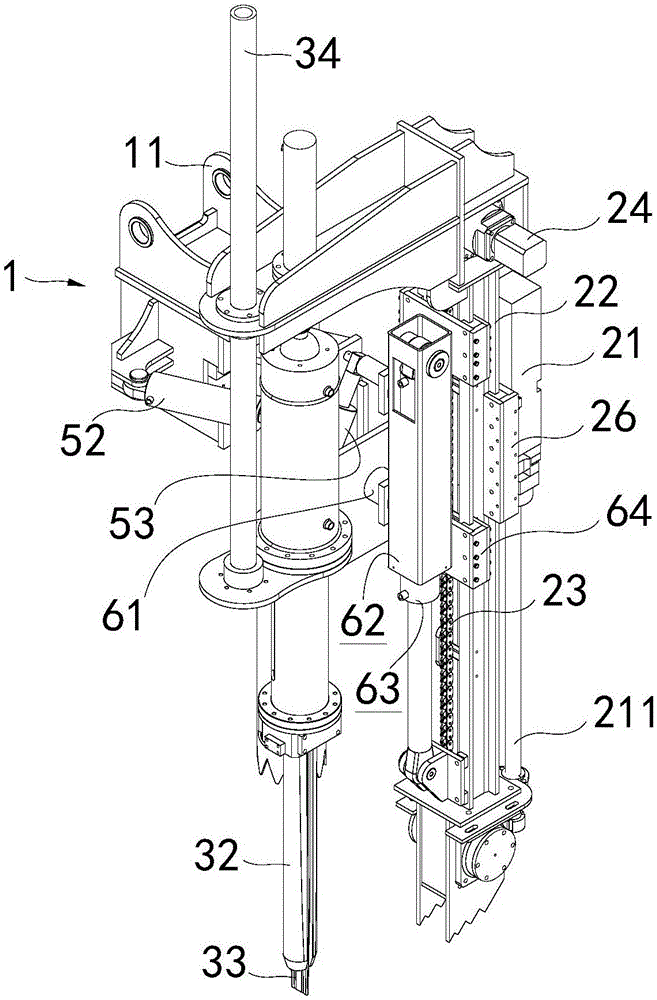

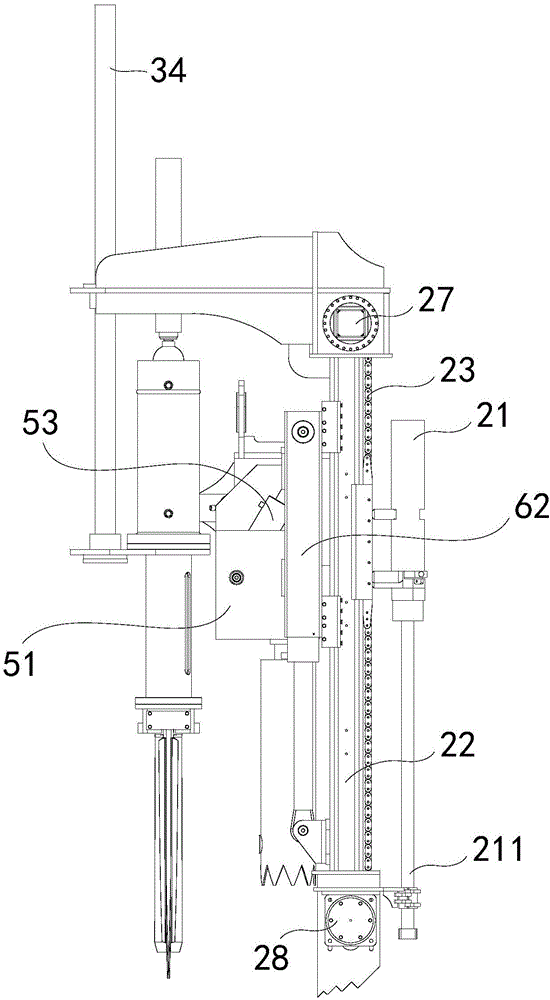

Drilling and blasting machine

ActiveCN106285471AStatic explosion cracking efficiency is highStrong security and reliabilityDisloding machinesDrilling machines and methodsPulp and paper industryDrilling machines

The invention discloses a drilling and blasting machine which comprises a connecting base, a drilling machine, a static blasting machine, a fixing frame, a rotating mechanism, a lifting mechanism and a positioning mechanism, wherein one end of the rotating mechanism is connected with the connecting base and the other end of the rotating mechanism is connected with the lifting mechanism; the lifting mechanism is connected with the drilling machine; the drilling machine and the static blasting machine are arranged at the two ends of the fixing frame oppositely; the positioning mechanism is arranged at the bottom of the rotating mechanism. The drilling and blasting machine provided by the invention integrates the drilling machine with the static blasting machine; the drilling machine can drill quickly, can drill at various angles, especially for hard objects, such as rocks, mountains and the like, can drill at different positions and angles; the drilling and blasting machine is provided with the static blasting machine in the same set of hydraulic system, the static blasting machine is implanted after the surface is drilled, and crushing operation is finished silently and statically.

Owner:苏州鸣尼克重工机械有限公司 +1

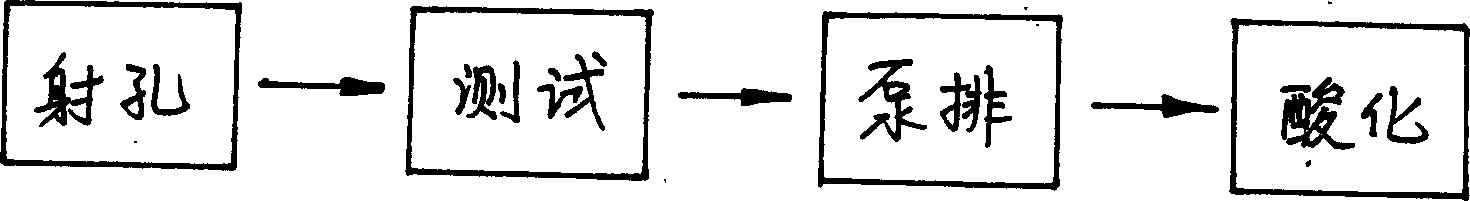

Trial four-linking technology

InactiveCN1818335AImprove qualitySave oil testing costsSurveyFluid removalOil fieldMaterial Perforation

A technique for testing oil in the process of reconnoiters oil field, the working procedures are: perforation, test, pumping and acidification which is the improvement, that can be achieved the four procedures by only one time pipe column which protect oil layer, save fund and quicken the speed of testing oil. In economy benefit, compare with others, it can save 150,000 Yuan and shorten 5 days in one layer each testing oil period, and suit for construct on both land and sea.

Owner:吴永平 +4

Environment-friendly multifunctional waterproof paint

InactiveCN102040890ASimple and safe constructionConstruction saves labor and timeChloropene polymer coatingsEmulsionOxide

The present invention discloses a paint, and especially relates to an environment-friendly multifunctional waterproof paint. The paint is prepared from the following raw materials in parts by weight: 5-10 of polyvinyl acetate, 60-70 of chloroprene rubber, 10-20 of aluminum paste, 0.1-1 of zinc oxide, 25-35 of ethene-vinyl acetate emulsion, 0.5-1.5 of dibutyl phthalate, 1-5 of light calcium carbonate. The invention is advantageous in that: the utilization of the invention is simple, working hours and labor are saved, the invention does not induce environment pollution, the invention is not harmful to human body, peeling does not occur after the paint of the invention is used, the film forming effect is good, the solidification is fast, the invention is resistant to ageing, the binding power is strong, the extensibility of the material is good, a waterproof layer is formed on the base surface of materials being painted so that the painted materials are super waterproof. Furthermore, when the paint is applied to outer wall decoration, not only the effects of heat insulation and good decoration but also the impervious, waterproof and nontoxic effects can be achieved. Therefore the paint can be widely applied to the water prevention of roofing and out walls, toilets, gardens on top of buildings, floors, basements, subterranean tunnels, pools and water channels.

Owner:彭晓洁

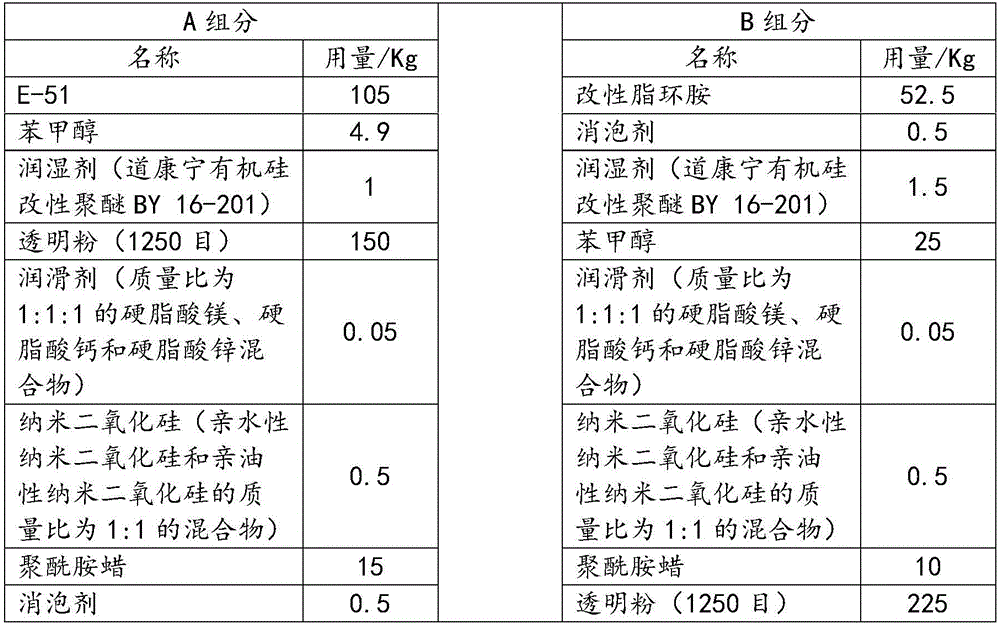

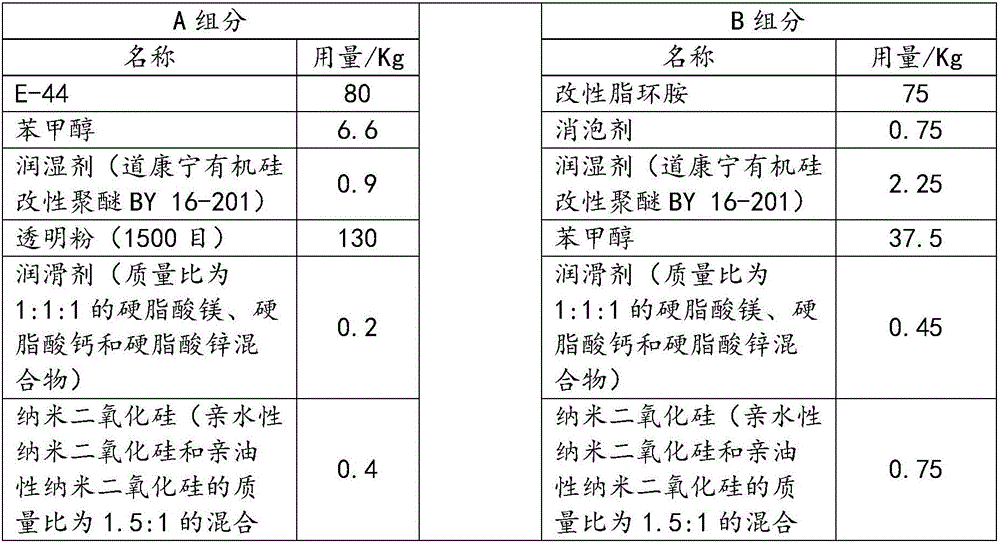

Epoxy seam gum and preparation method thereof

InactiveCN106753122AGood adhesionModerate viscous resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyMetallic materials

The invention provides epoxy seam gum and a preparation method thereof. The epoxy seam gum provided by the invention is prepared from raw materials with specific components and usage, has a strong bonding force for a gypsum board, marble, cement, wood and various metal materials and no yellowing and can be used for a long time. The epoxy seam gum adopts a complex rheological modification system and has the advantages of moderate viscous resistance in allocating, batch scratching and reforming processes, no sagging, excellent construction property and high construction efficiency; the epoxy seam gum can be used after a component A and a component B are uniformly mixed according to the proportions; during construction, the epoxy seam gum is convenient to allocate and simple in metering; the method disclosed by the invention is simple in process and suitable for large-scale production; comprehensive performance of the epoxy seam gum can be effectively guaranteed.

Owner:YANGTZE UNIVERSITY

Technology for reduction of beam section height by use of unbonded steel strand prestress

InactiveCN105569265AEasy constructionNo need to uninstallGirdersJoistsPre stressBuilding construction

Owner:项剑锋

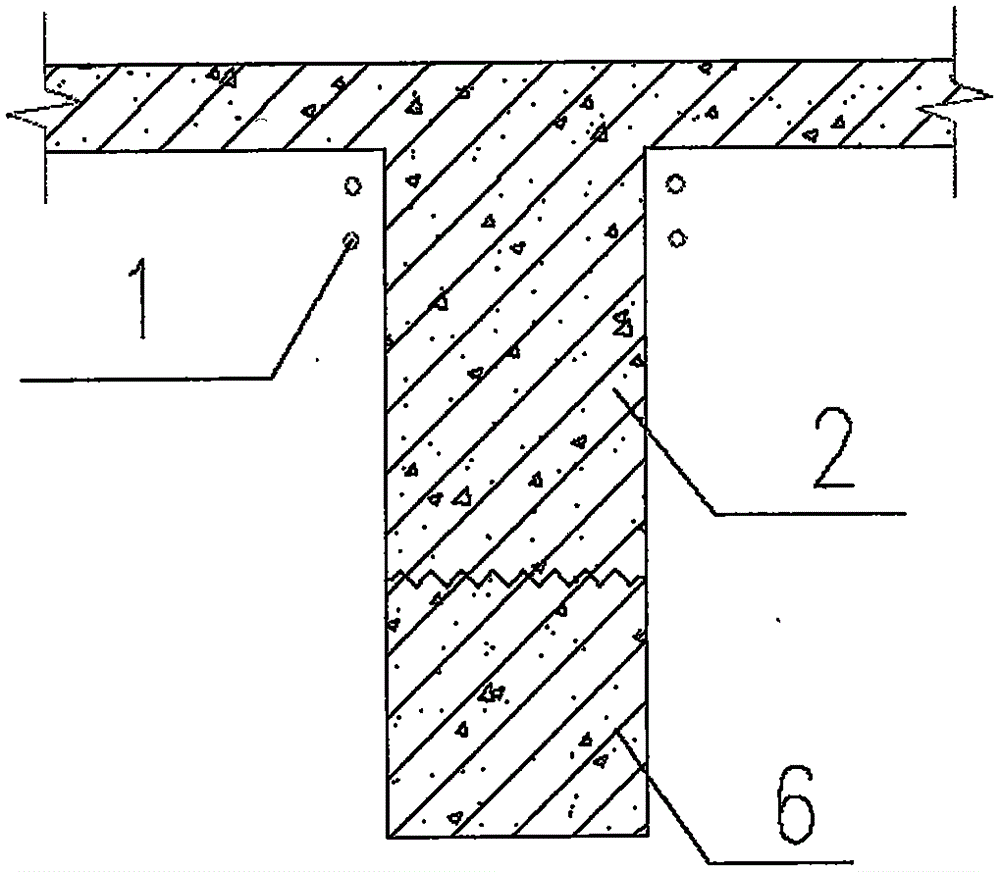

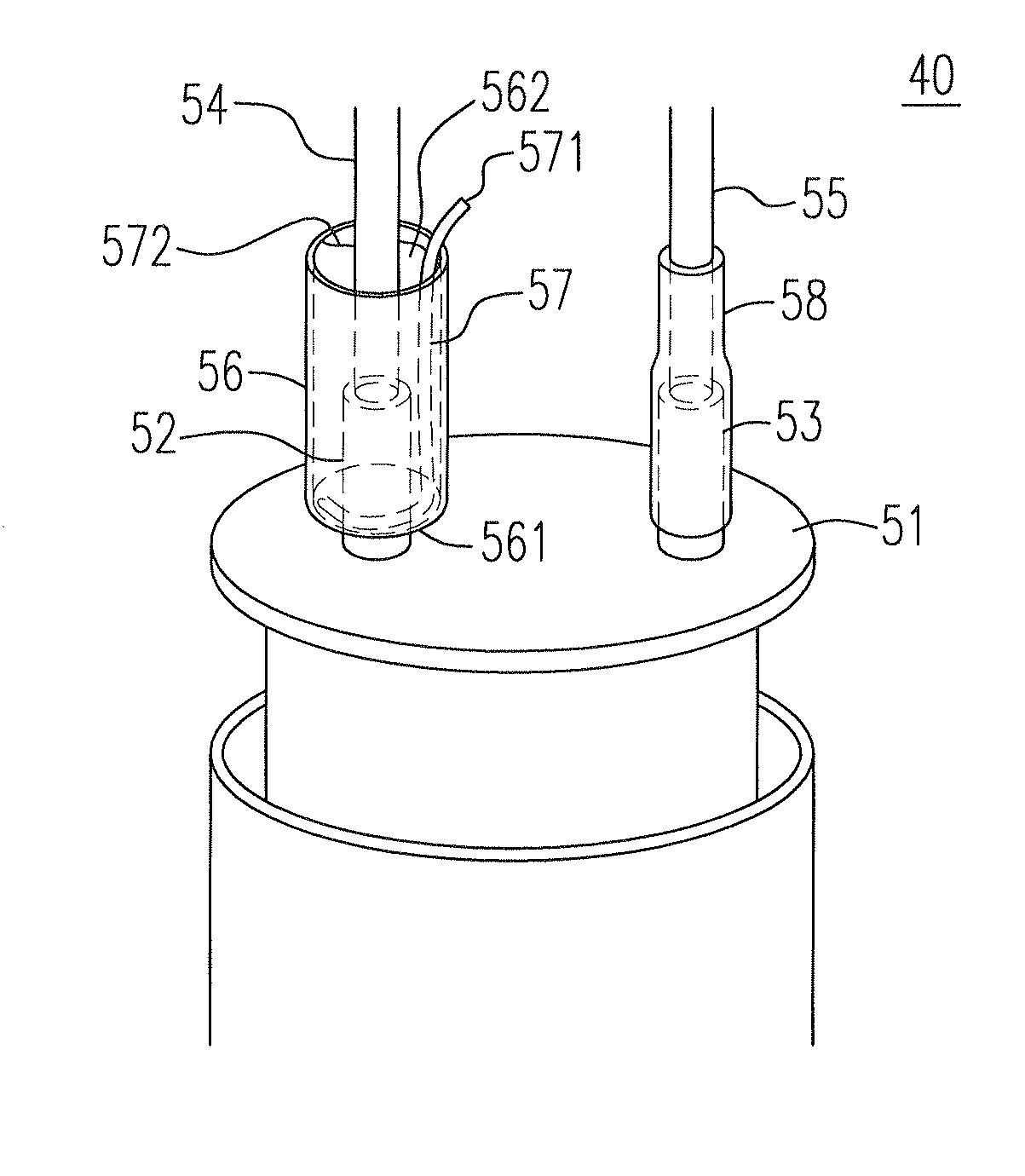

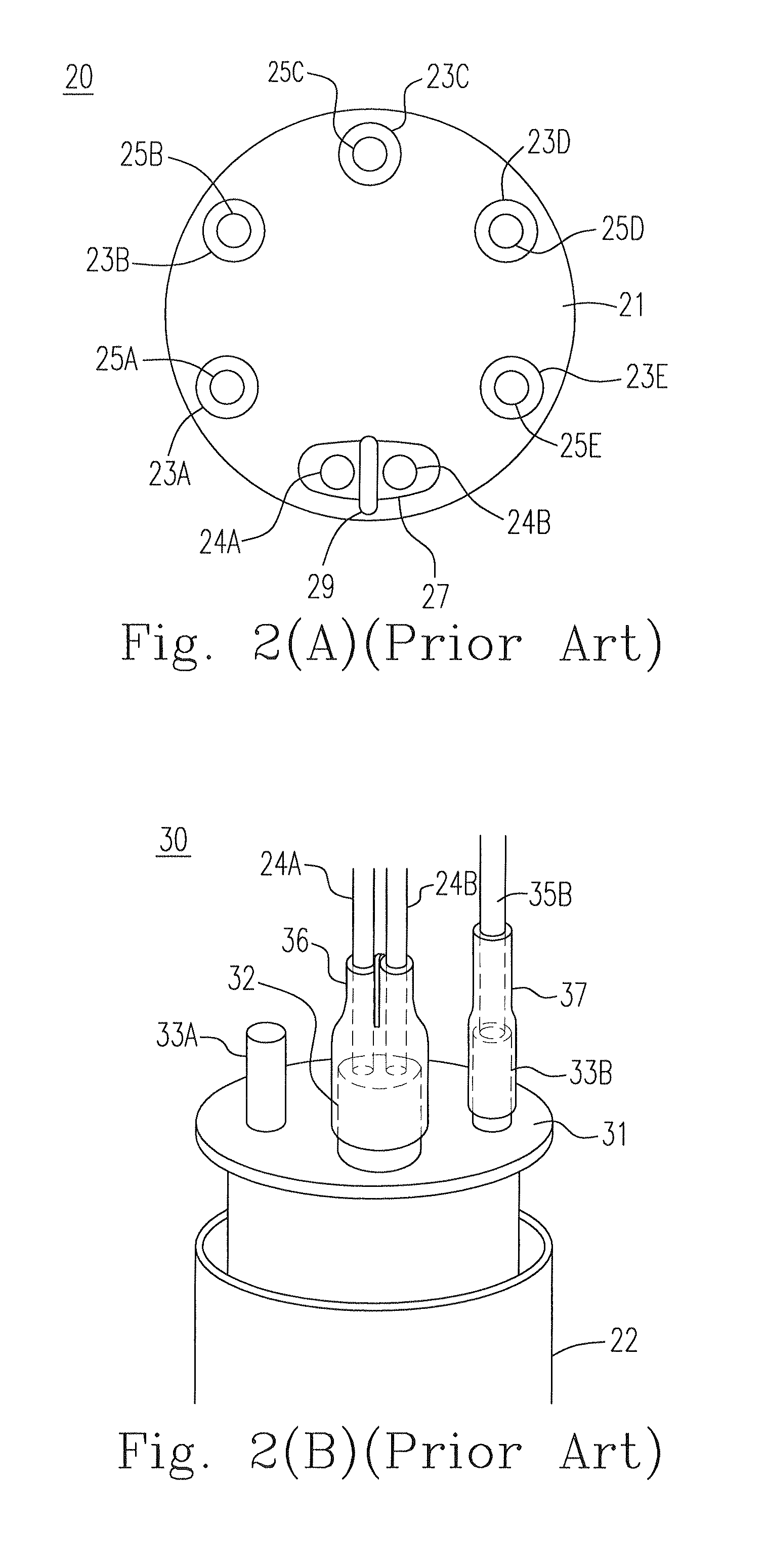

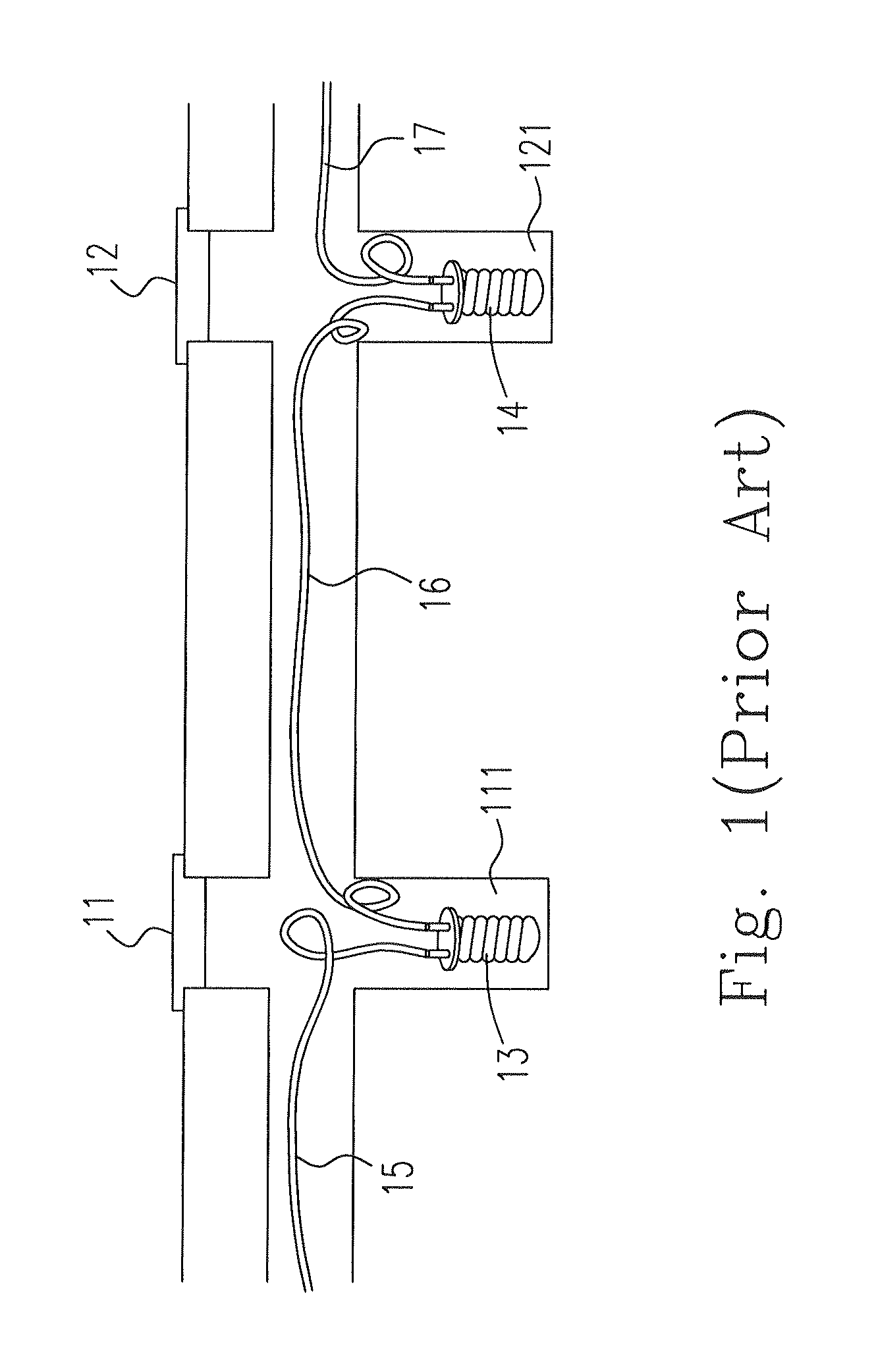

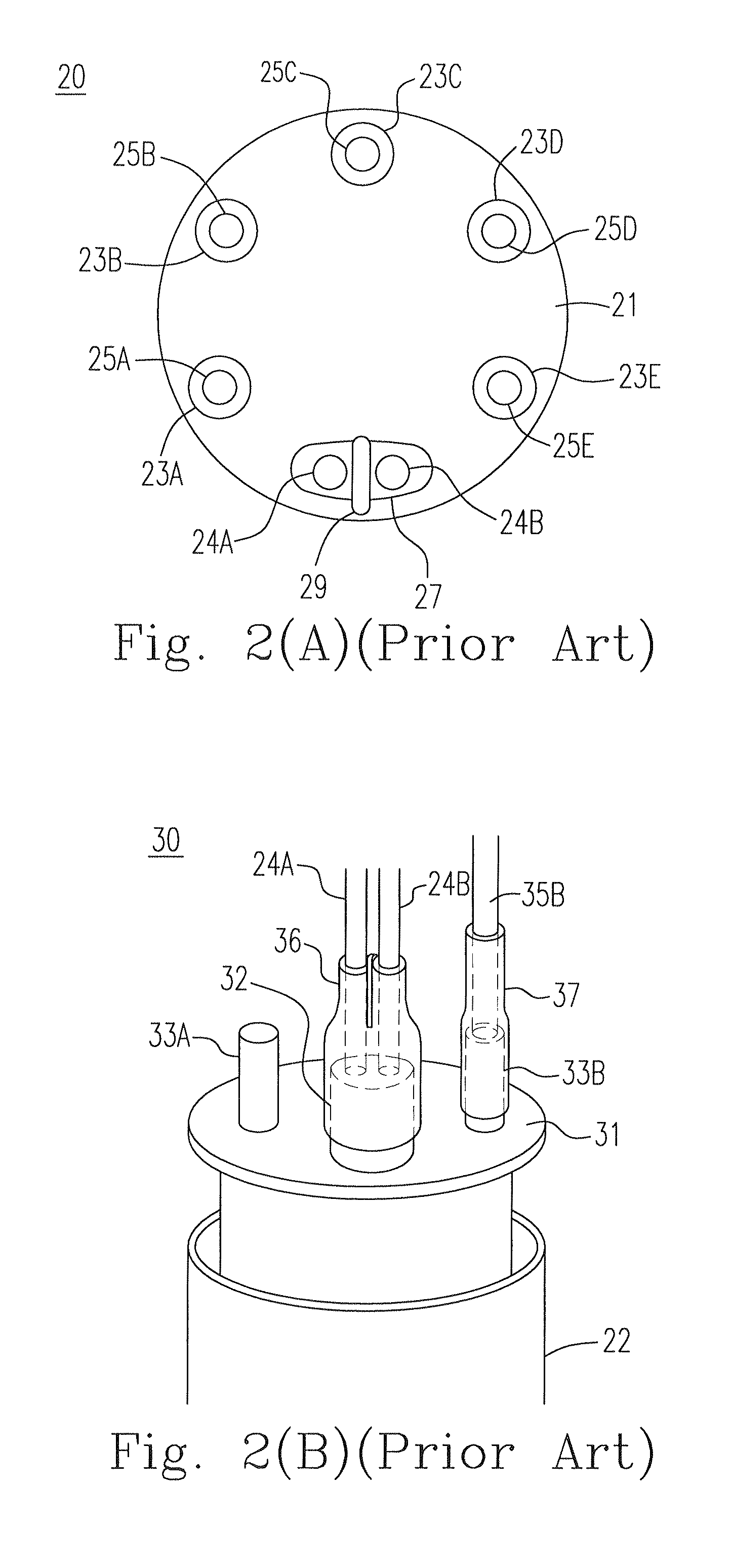

Communication cable connection box with waterproof device of elastic rubber shrinking pipe

ActiveUS20120093472A1Highly ductileHighly flexibleCable installations in cable chambersOptical fibre/cable installationJunction box

A waterproof communication cable connection box includes a protective cover, a cable pass-through end surface, a hollow cylindrical pipe formed on the cable pass-through end surface, an elastic rubber shrinking pipe, and a flexible hard plastic strip provided on the inner wall of the elastic rubber shrinking pipe. The plastic strip will be removed after a cable passes through the cable connection box so that the elastic rubber shrinking pipe closely covers the hollow cylindrical pipe and the cable part exposing outside of the hollow cylindrical pipe.

Owner:KOREA AEROSPACE INDUSTRIES

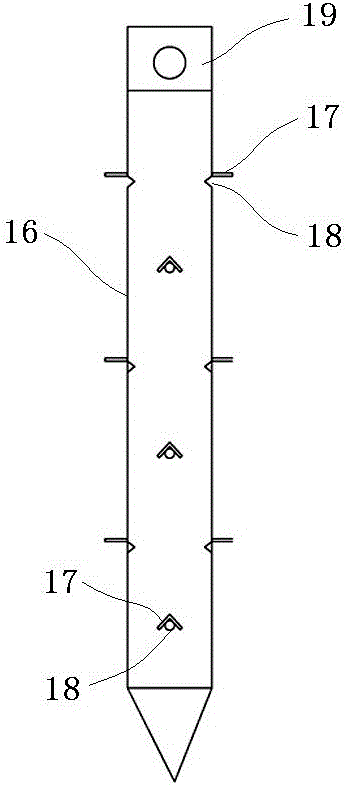

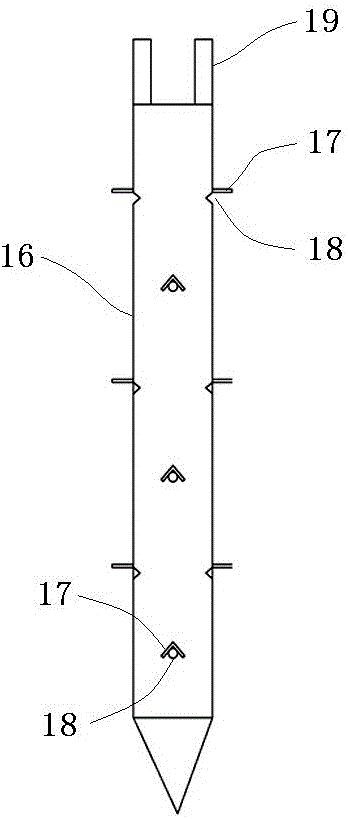

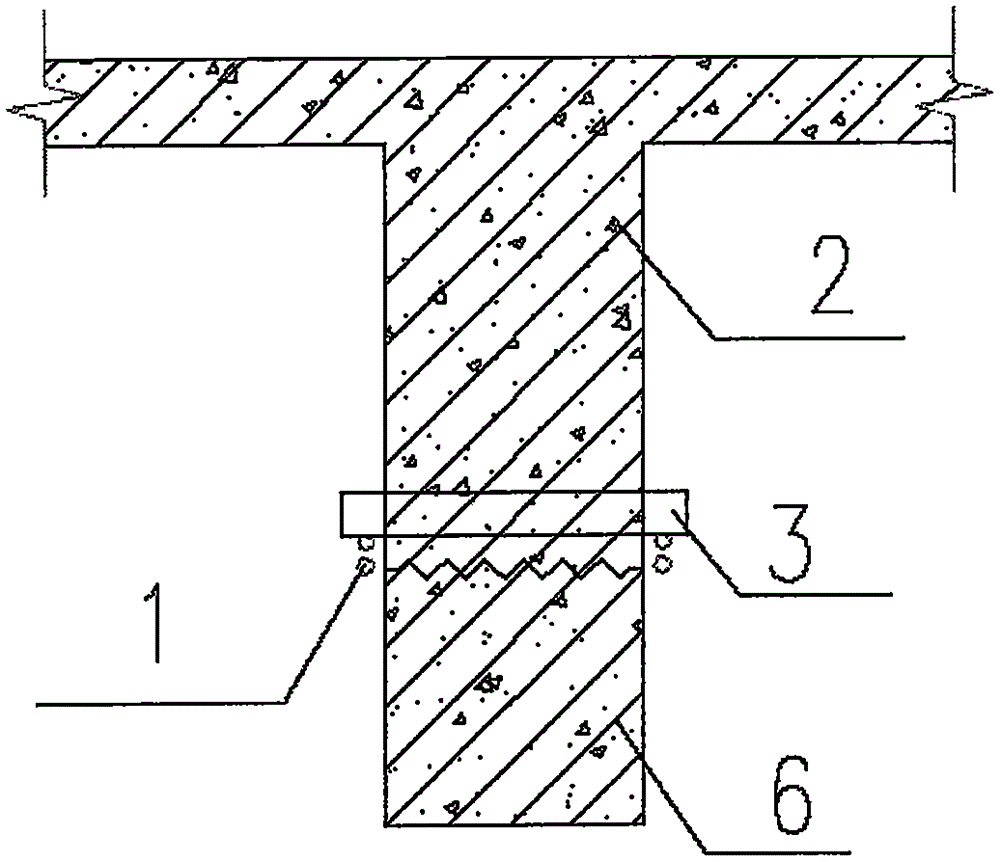

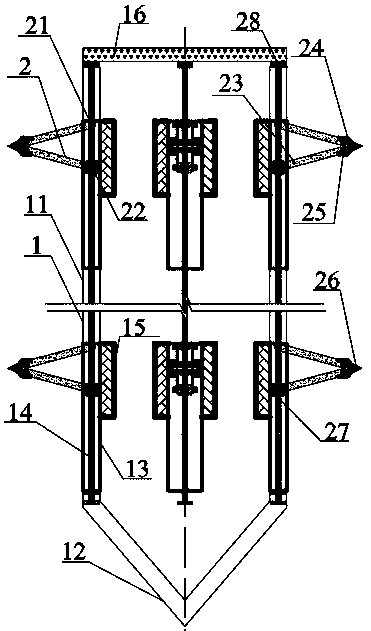

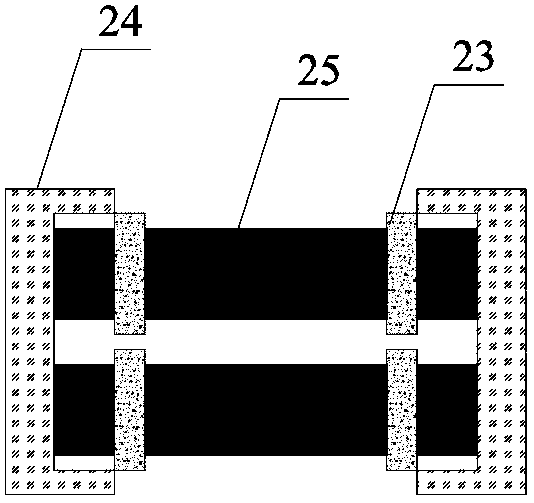

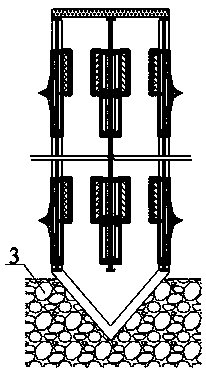

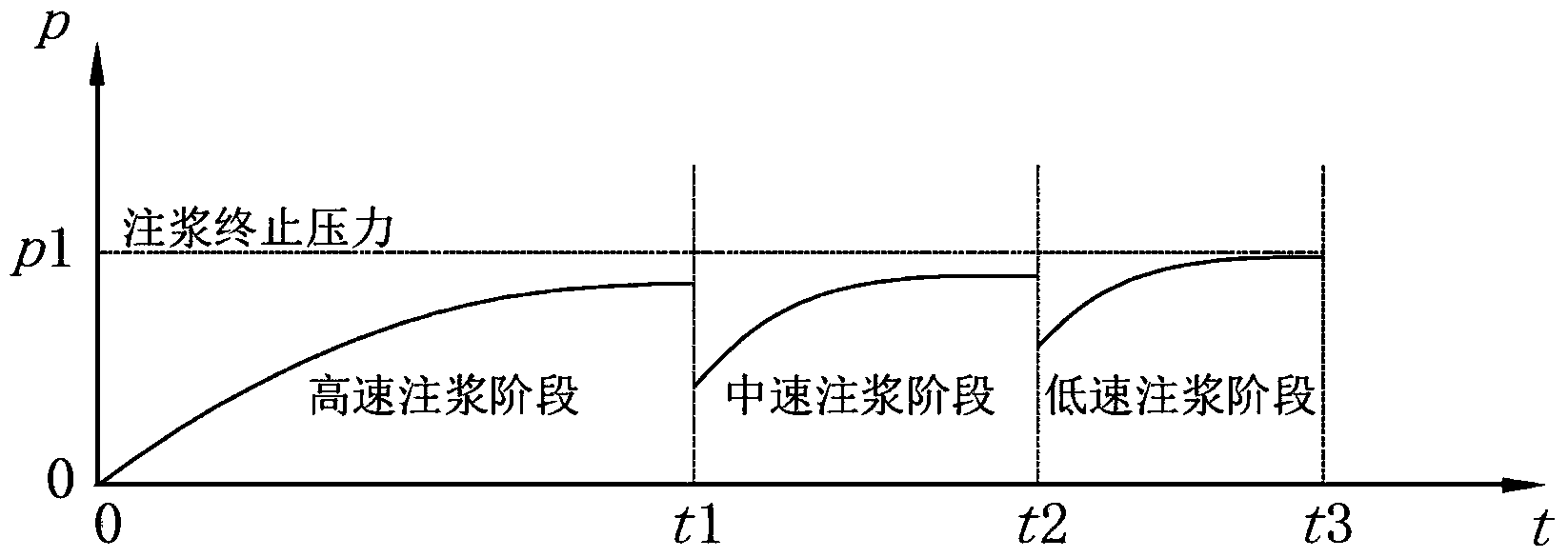

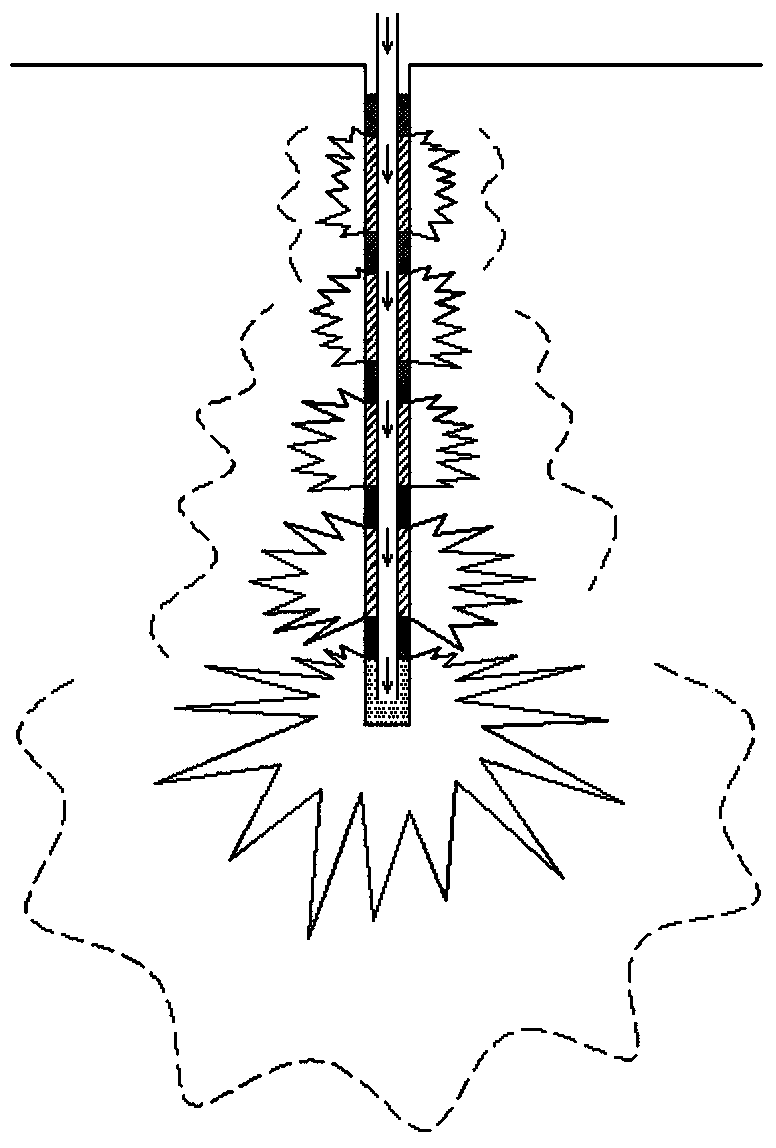

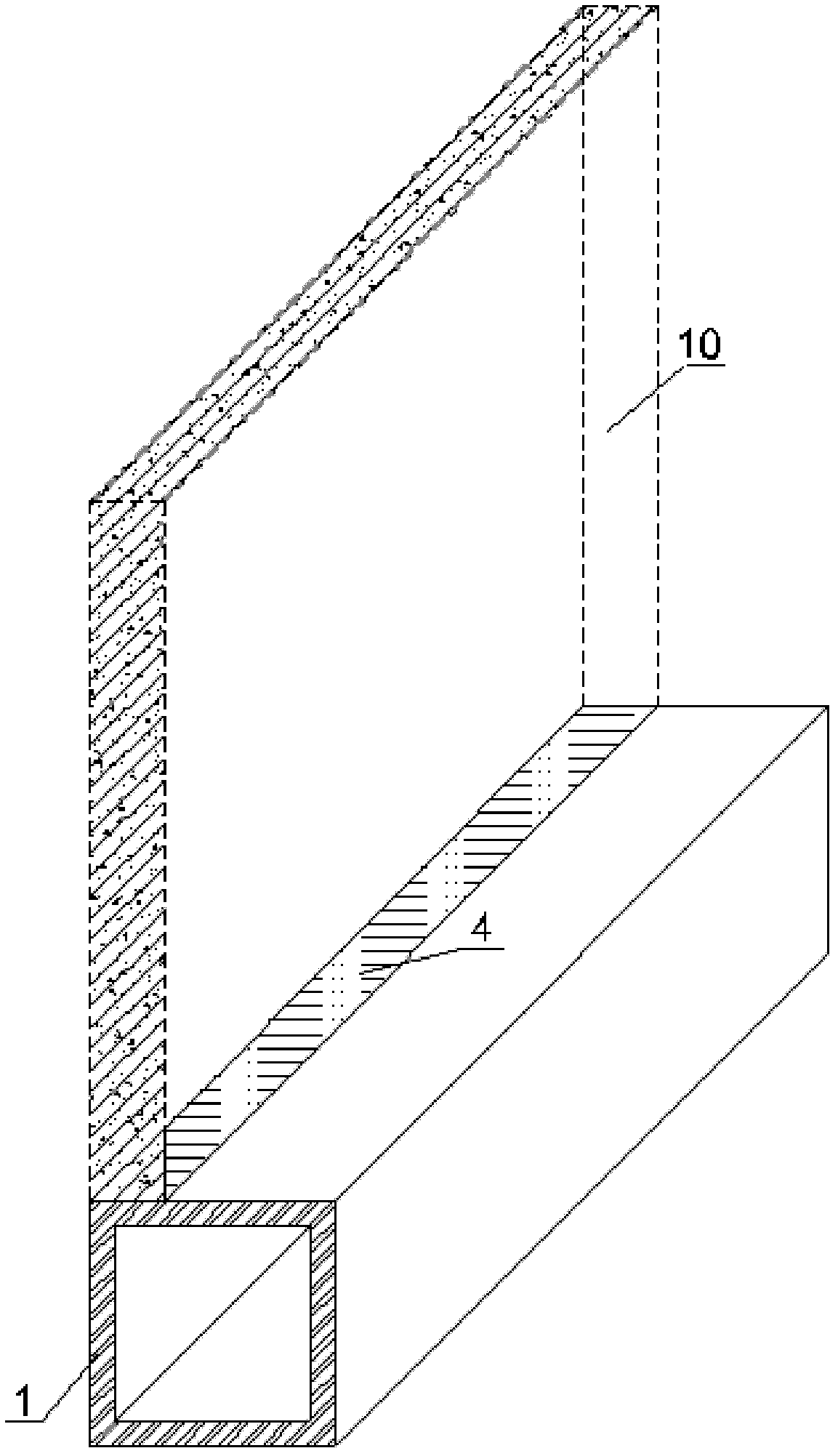

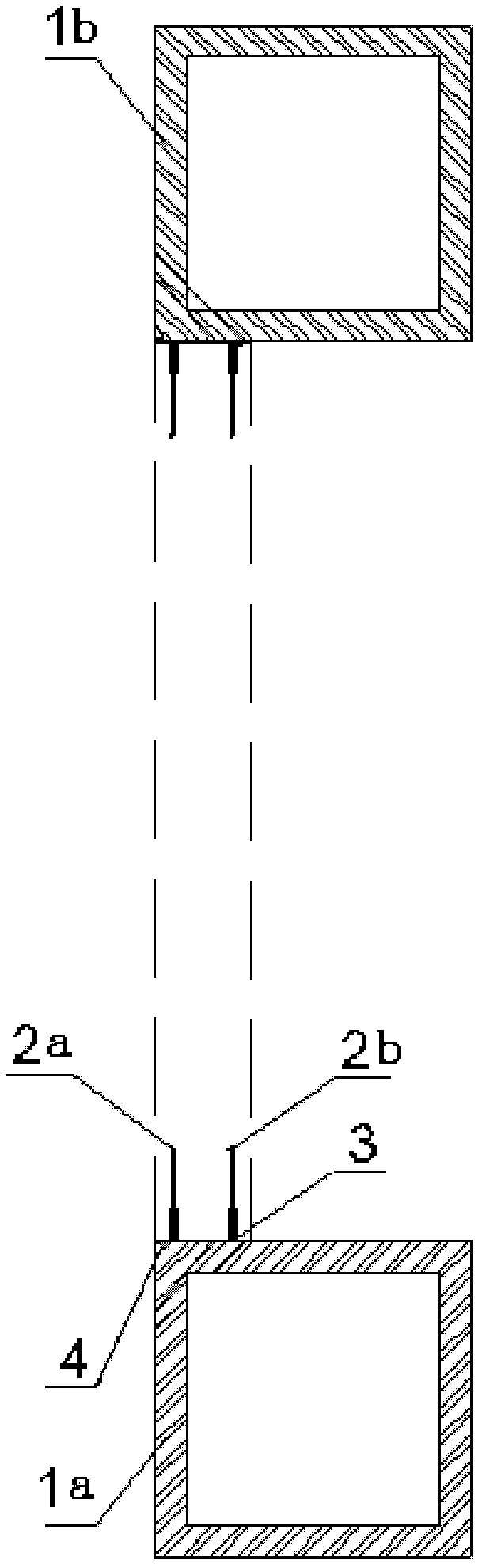

Novel steel structure anchor increasing and grouting uplift pile and construction method thereof

ActiveCN109056713AHigh strengthImproves bond integrityProtective foundationBulkheads/pilesPile capEngineering

The invention discloses a novel steel structure anchor increasing and grouting uplift pile and a construction method thereof. The novel steel structure anchor increasing and grouting uplift pile is composed of a pile body and anchor increasing deformation devices. The pile body is composed of a steel pipe shaft, a tapered pile tip, anchor increasing deformation holes, sliding rails, T-shaped steelstiffening plates and a protective pile cap. The anchor increasing deformation holes are a plurality of rectangular openings formed in the pile body and provide deformation channels for the anchor increasing deformation devices, and the T-shaped steel stiffening plates are welded to the two sides of the anchor increasing deformation holes to improve pile strength. The anchor increasing deformation devices are composed of upper rotating shafts, lower sliding shafts, rotating arms, connecting boxes, connecting bearings, reinforcing caps, sliding threaded sleeves and threaded rods. After the pile body penetrates into the ground, the threaded rods are rotated to drive the sliding threaded sleeved to move upwards, the connecting boxes and the reinforcing caps are squeezed into soil around thepile body through the transmission function of the bearings and the rotating arms to enhance the uplift resistance of the pile body. The novel steel structure anchor increasing and grouting uplift pile and the construction method thereof solve the defects of low strength, insufficient uplift force and complex construction of a pile body of an existing uplift pile, and has a broad application prospect.

Owner:SHANDONG UNIV OF SCI & TECH

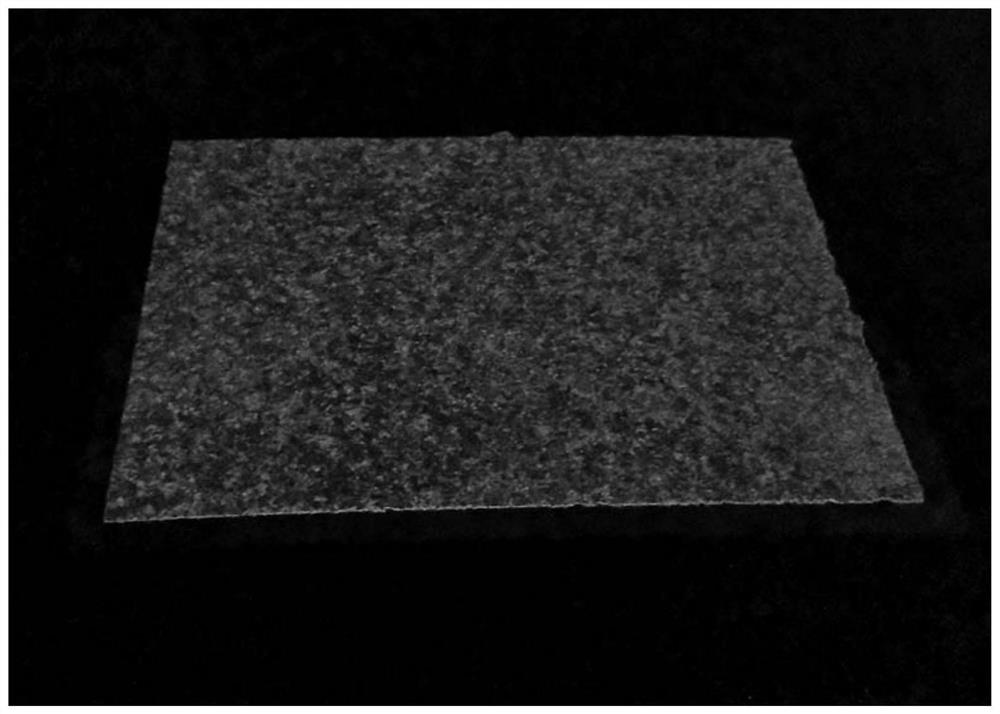

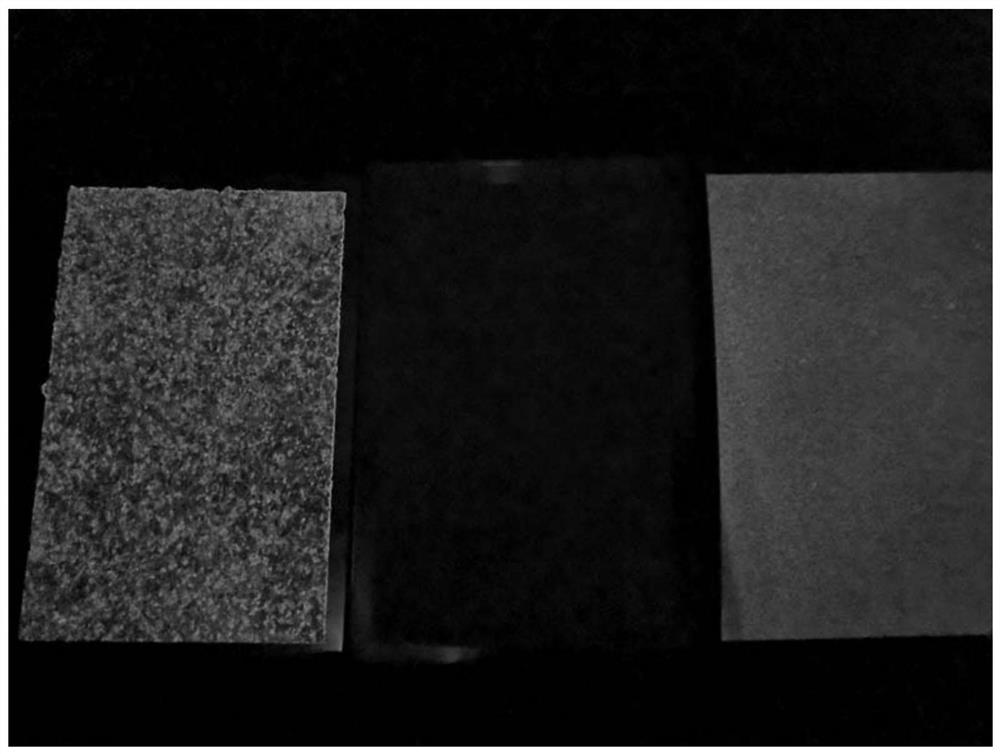

Water-based self-luminous reflective marking paint for rain night, preparation method thereof, and road marking and construction method thereof

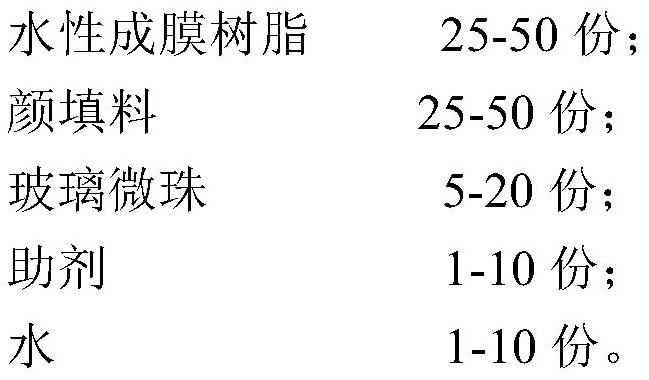

PendingCN112980266AImprove adhesionSimple and safe constructionTraffic signalsRoad signsWeather resistanceEngineering

The invention discloses a water-based self-luminous reflective marking coating for rain night. The water-based self-luminous reflective marking coating comprises a component A and a component B. The component A is a coating matrix, and the component B comprises high-reflection reflective beads used for being spread on the surface of the coating matrix. The coating matrix comprises the following components in parts by mass: 25-50 parts of water-based film-forming resin, 25-50 parts of pigment and filler, 5-20 parts of glass beads, 1-10 parts of an auxiliary agent and 1-10 parts of water. The marking paint is safe and environment-friendly, and has good wear resistance, weather resistance, rainwater resistance, acid and alkali resistance and good reflective property and luminous effect. The invention also discloses a preparation method of the marking paint, a road marking and a construction method of the road marking.

Owner:NIPPON PAINT CHINA

Communication cable connection box with waterproof device of elastic rubber shrinking pipe

ActiveUS8412016B2Highly ductileHighly flexibleCable installations in cable chambersOptical fibre/cable installationEngineeringMechanical engineering

A waterproof communication cable connection box includes a protective cover, a cable pass-through end surface, a hollow cylindrical pipe formed on the cable pass-through end surface, an elastic rubber shrinking pipe, and a flexible hard plastic strip provided on the inner wall of the elastic rubber shrinking pipe. The plastic strip will be removed after a cable passes through the cable connection box so that the elastic rubber shrinking pipe closely covers the hollow cylindrical pipe and the cable part exposing outside of the hollow cylindrical pipe.

Owner:KOREA AEROSPACE INDUSTRIES

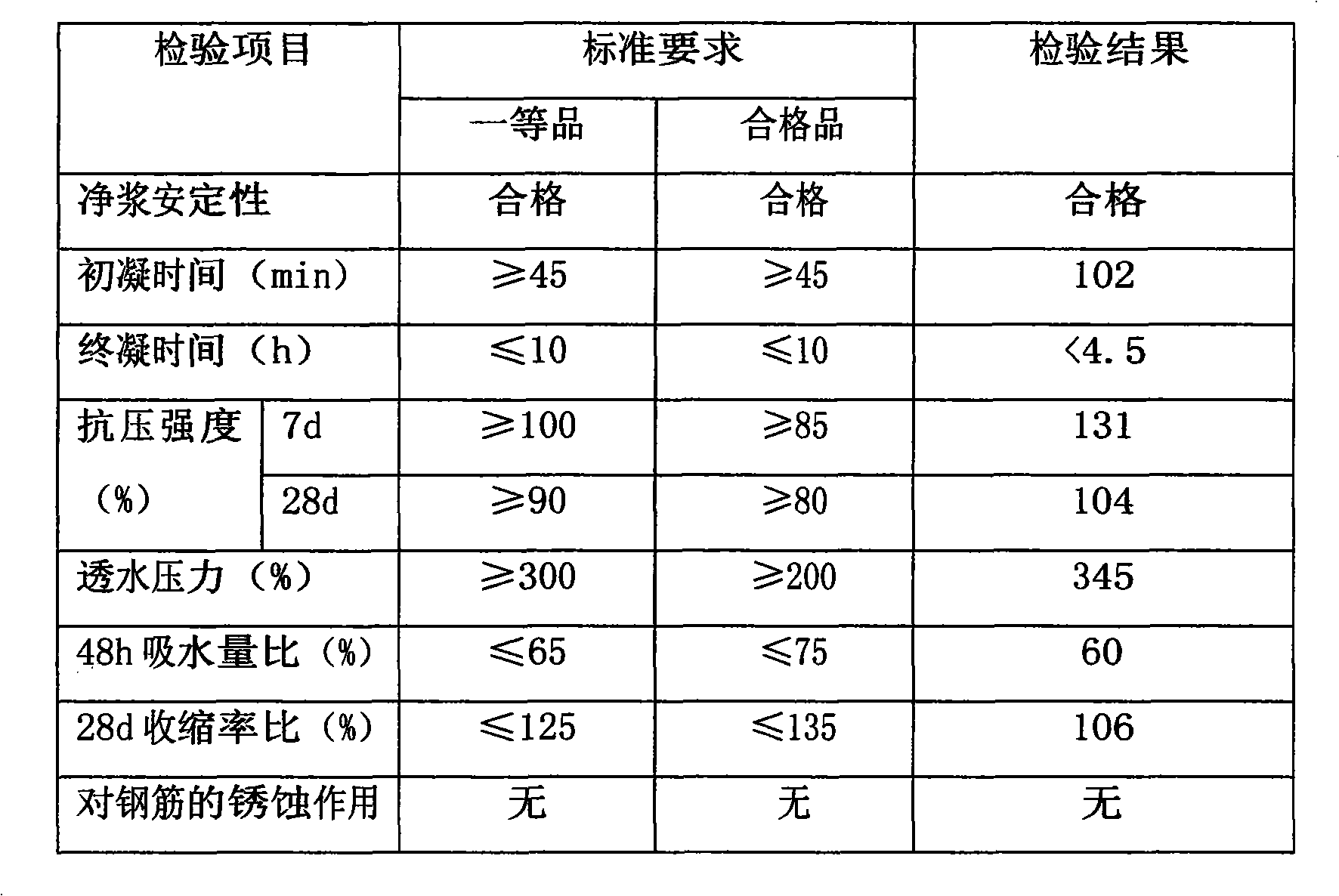

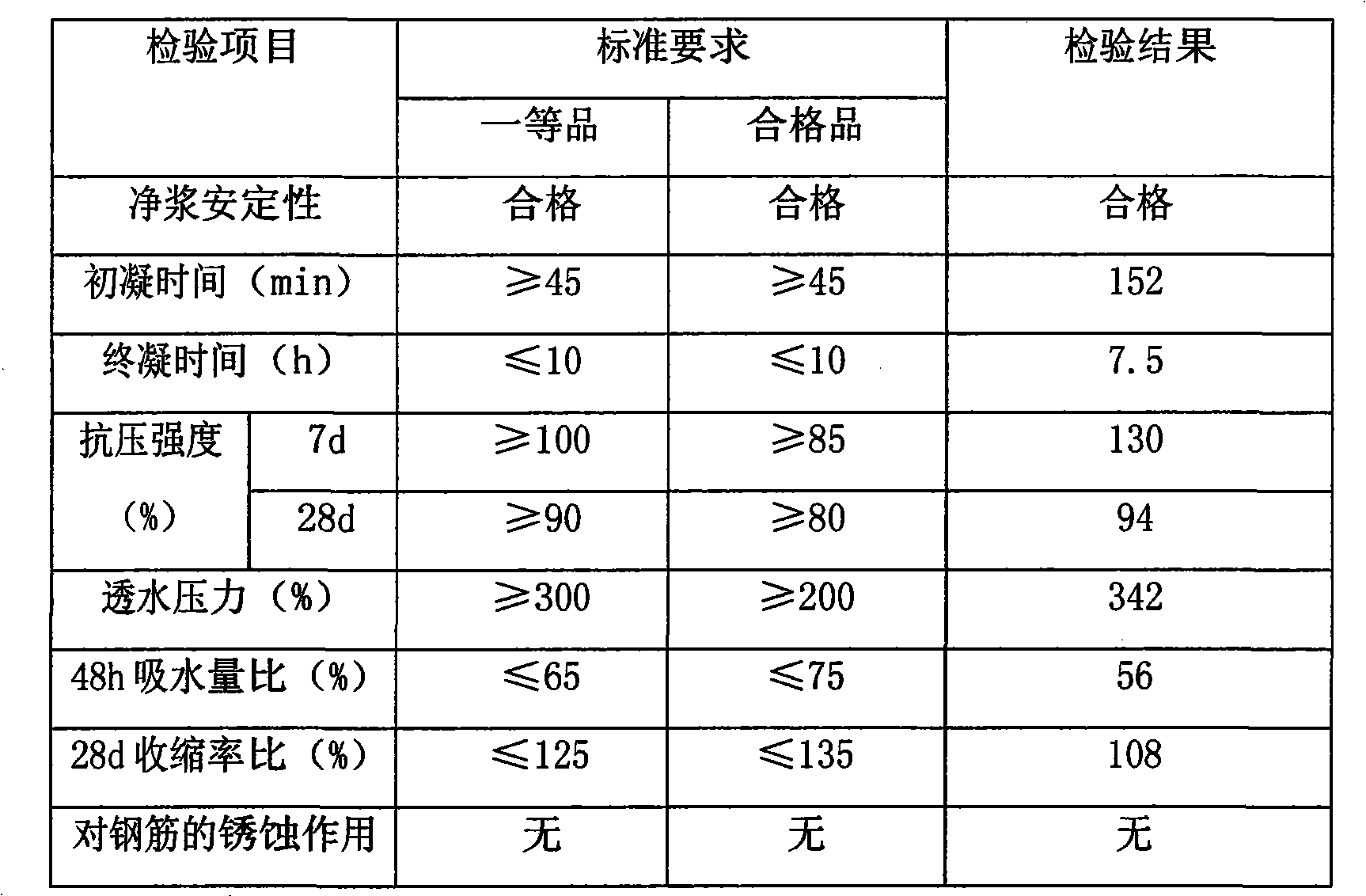

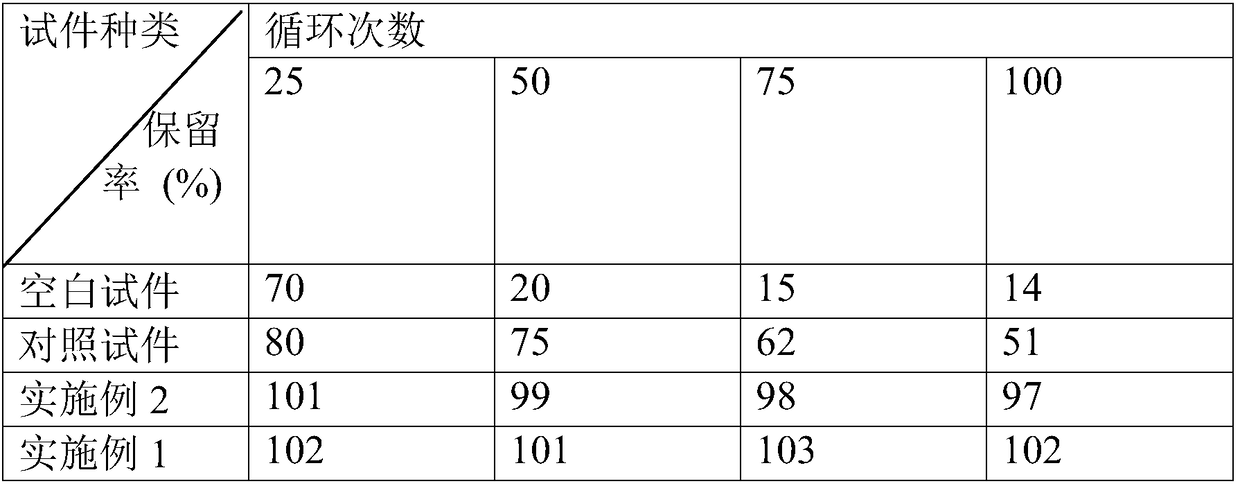

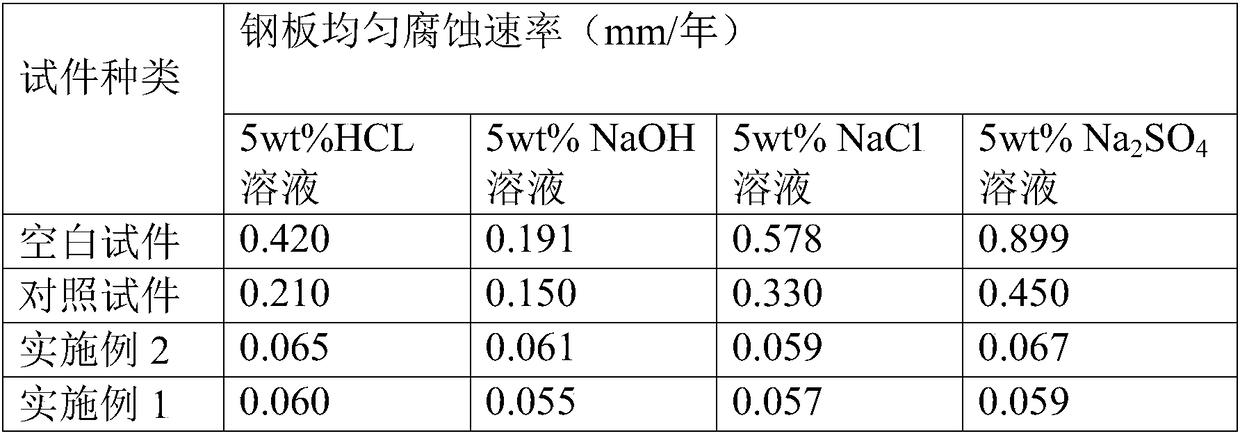

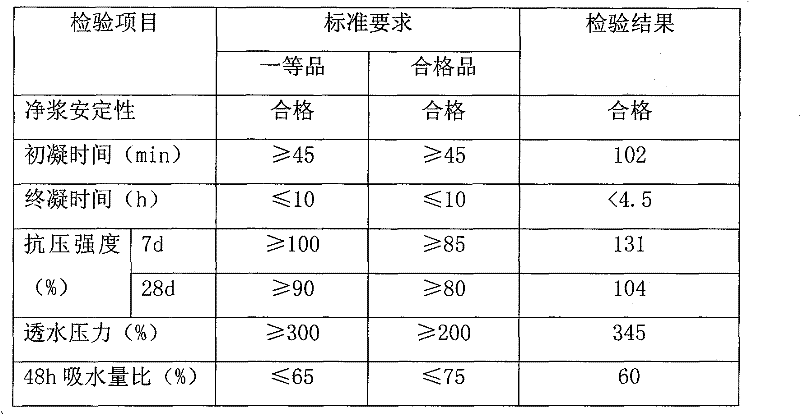

Cement-based composite anticorrosive coating

The invention belongs to the technical field of coatings, and particularly relates to a cement-based composite anticorrosive coating. The cement-based composite anticorrosive coating is a solid-liquidtwo-phase two-component composite material and is prepared by mixing a liquid-phase component and a solid-phase component; wherein the liquid-phase component is prepared from, by weight, 10%-30% of epoxy emulsion, 30%-40% of water and 1-5% of admixture; the solid-phase component is prepared from, by weight, 15%-30% of cement, 5%-15% of quartz sand, 1%-2% of cellulose, 0.5%-1. 5% of zinc powder and 0.5%-1. 5% of titanium oxide. The coating formed by mixing the solid phase and the liquid phase has anti-corrosion properties and the effects of impact resistance and environmental protection.

Owner:山东星火知识产权服务有限公司

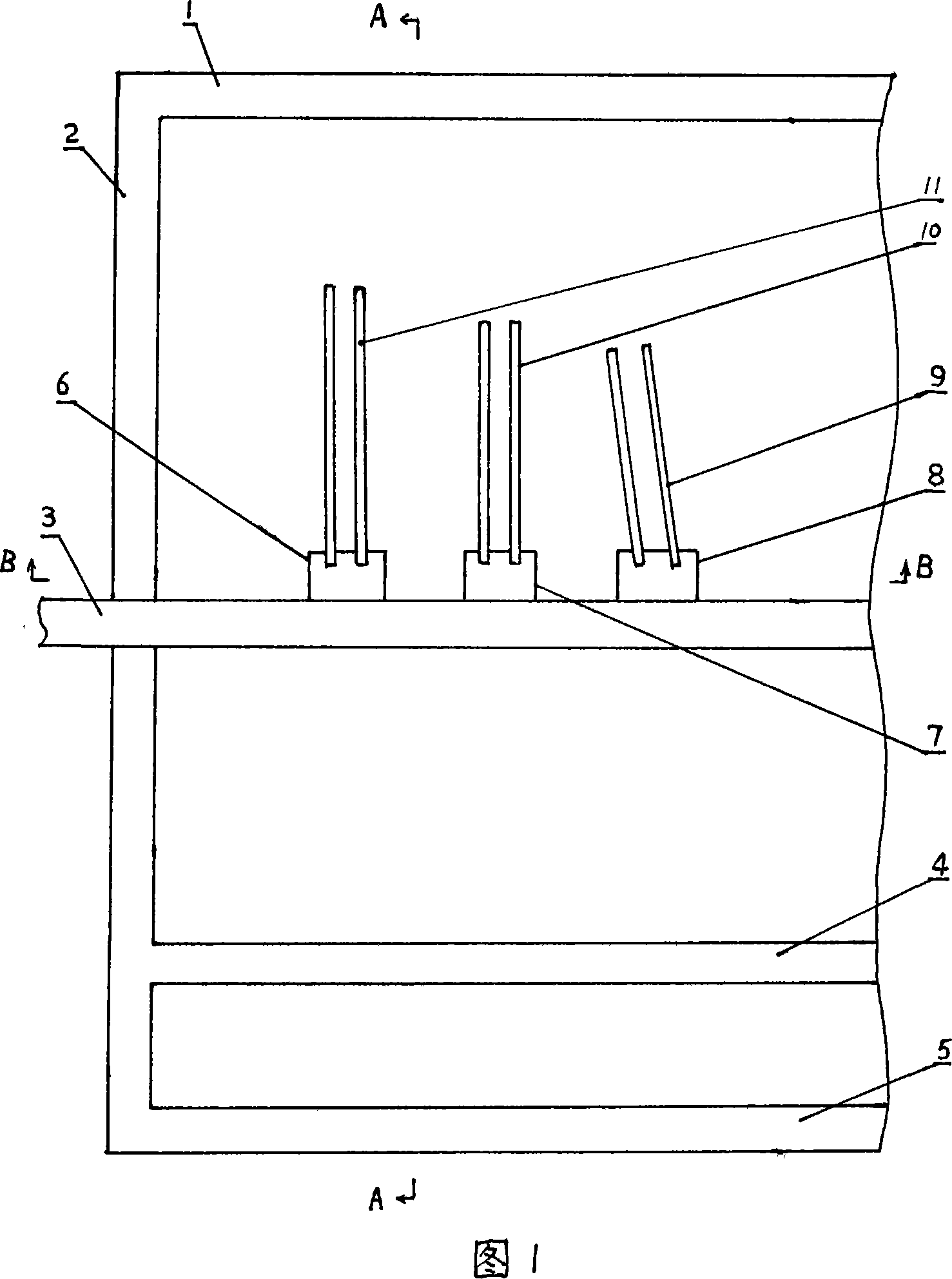

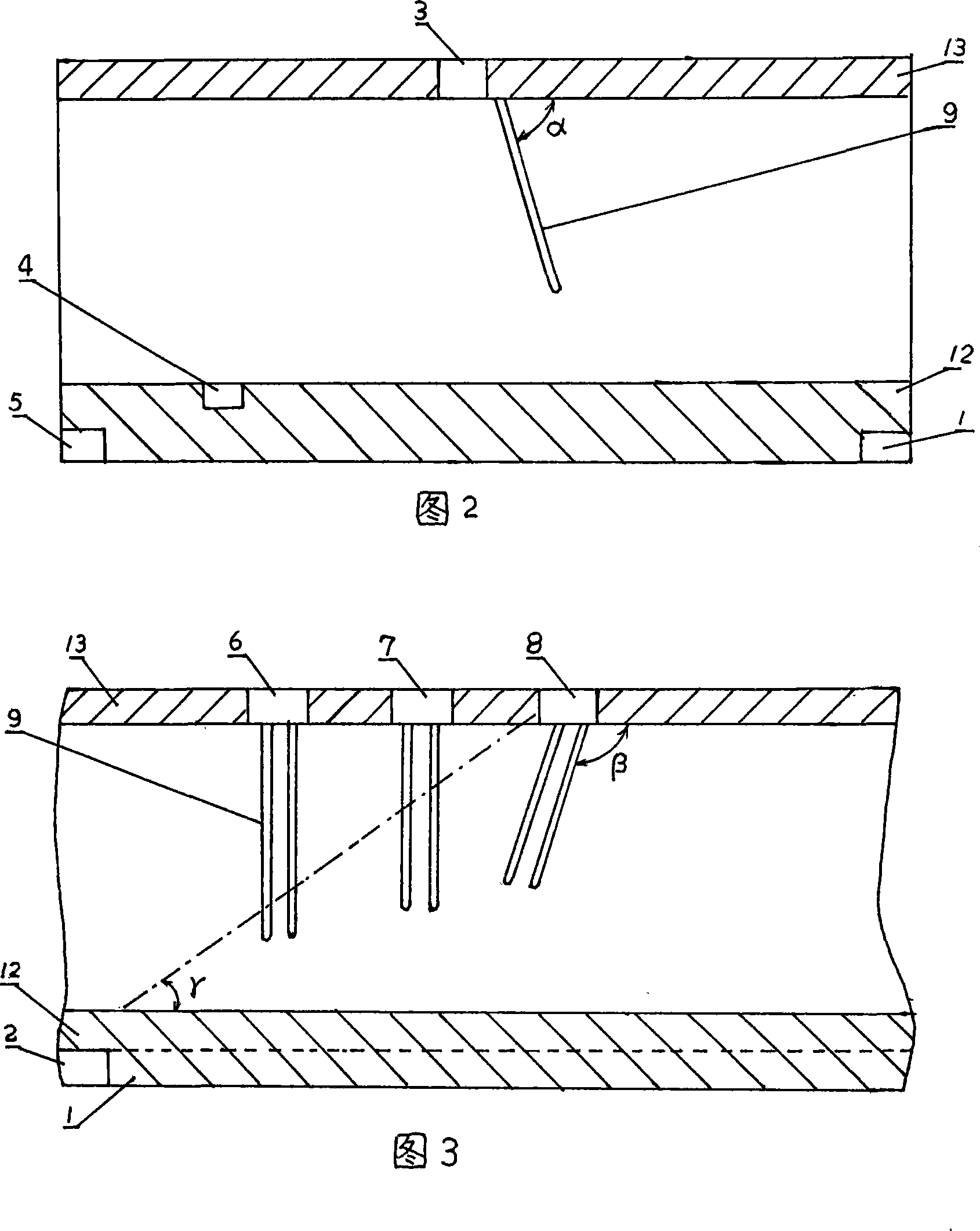

Skid resistance device for fractured rock mass and construction method thereof

ActiveCN104264695AIncreased shear strengthImprove stabilityClimate change adaptationExcavationsMaterial consumptionEngineering

The invention discloses a skid resistance device for fractured rock mass. The stability of an entire slope is improved by improving the shear strength of the device, the material consumption and the time consumption for piling are low, the device is unlikely to crack per se, the application condition is wide, the landslip state is unlikely to deteriorate, and the construction is safe, easy and convenient. The skid resistance device for the fractured rock mass comprises a plurality of grouting anti-skid piles, wherein each grouting anti-skid pile comprises a tower-section stone column and an anti-shear component; the anti-shear component comprises a seamless steel pipe and a high-strength anti-shear steel column; base rock is positioned below the fractured rock mass; the seamless steel pipe is inserted into the base rock through the fractured rock mass; the high-strength anti-shear steel column is attached to the seamless steel pipe; a part of the high-strength anti-shear steel column is positioned in the base rock, and the other part of the high-strength anti-shear steel column is positioned in the fractured rock mass; the tower-section stone column formed through multi-section filling, compacting and grouting is partially exposed out of the fractured rock mass or is completely positioned in the fractured rock mass. The invention also provides a construction method of the skid resistance device.

Owner:ZHONGSHUI FANGYUAN BEIJING ENG CONSULTING +2

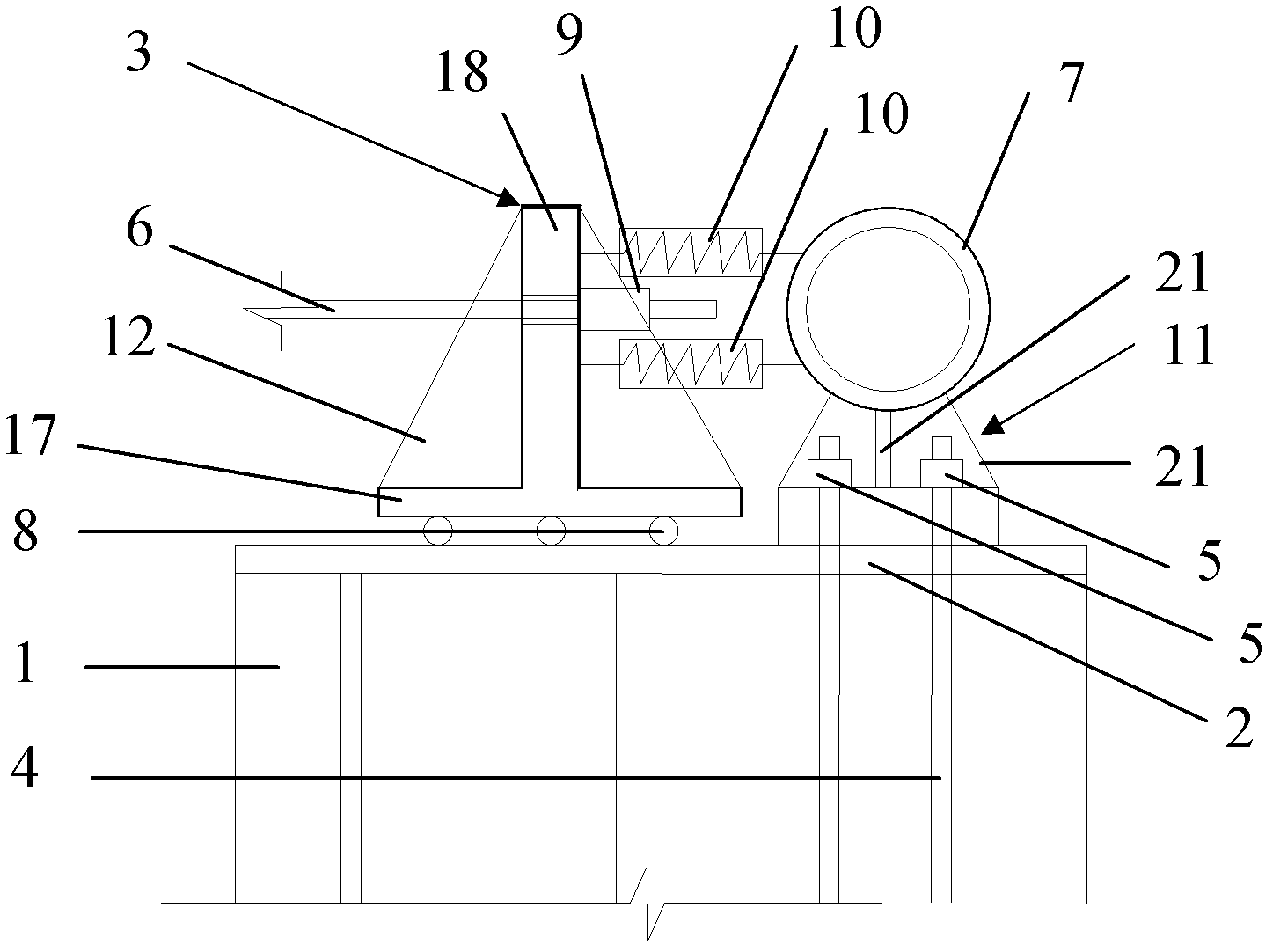

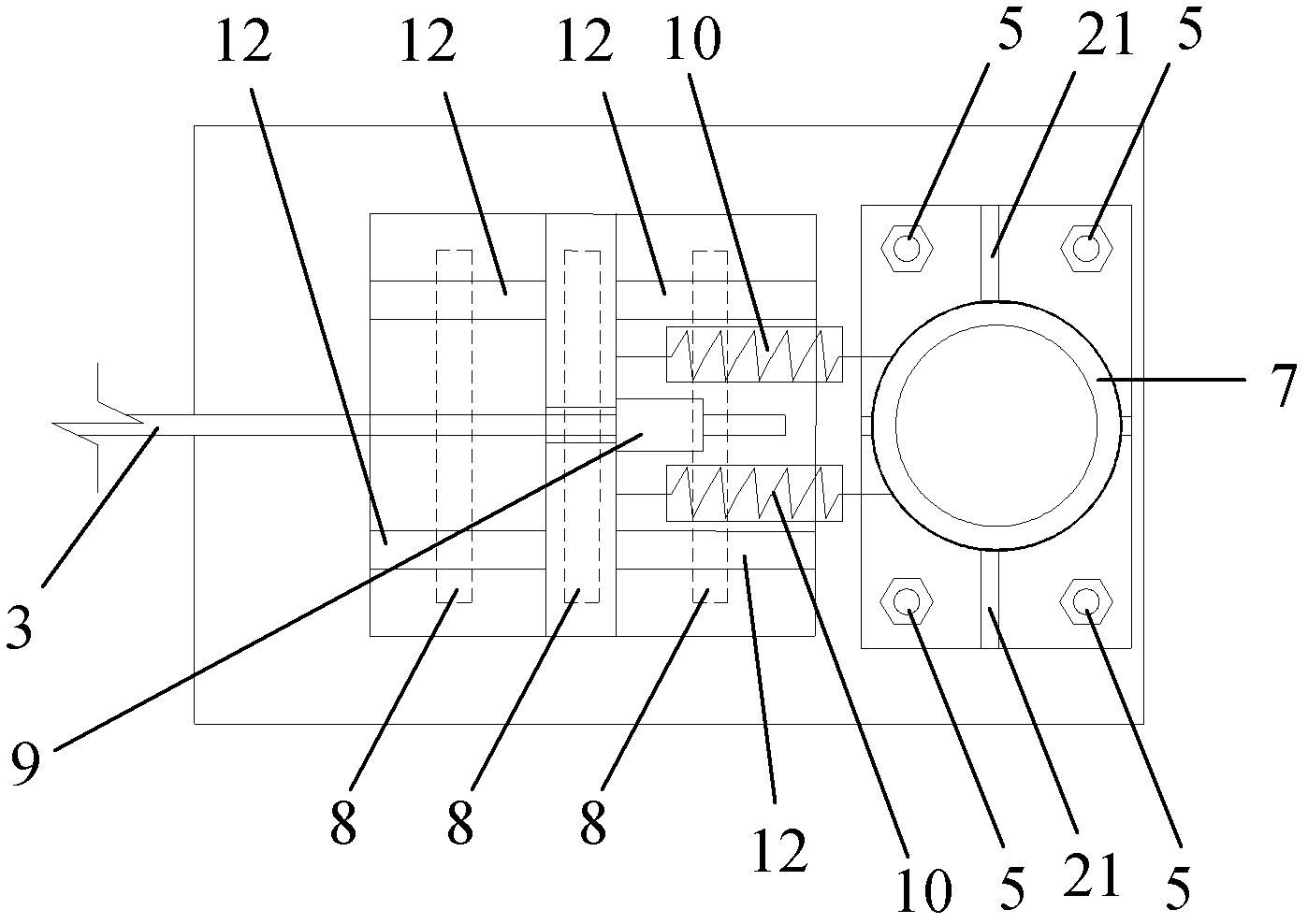

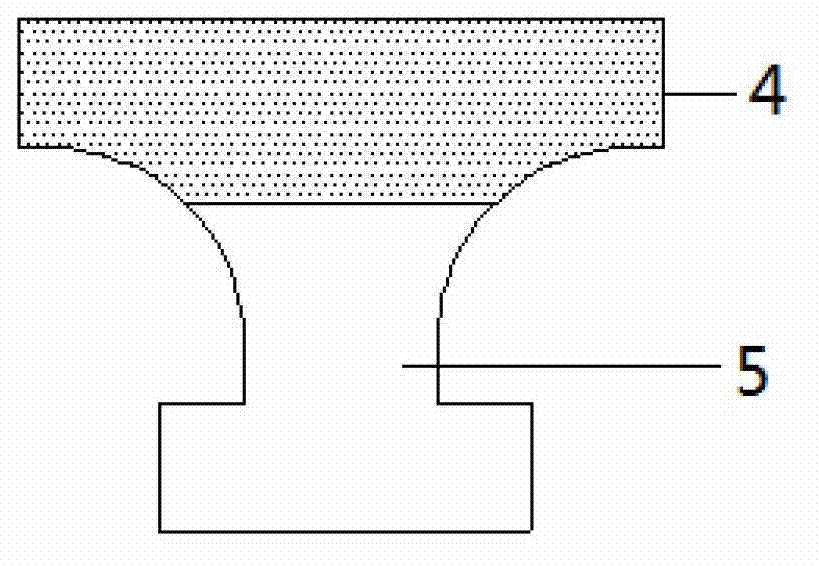

Sphere joint fixing support with effect of relieving internal force of stay rope

InactiveCN102561516ALittle change in internal forceFree from destructionShock proofingSlide plateInverted t

A sphere joint fixing support with an effect of relieving internal force of a stay rope comprises a lower supporting structure, an embedded cushion plate, an inverted-T-shaped sliding plate, a plurality of embedded reinforcing steel bars, a fixed sphere joint, a plurality of columnar rolling bearings, an anchorage device, a plurality of damper springs and a support. The sphere joint fixing support has the following advantages that material utilization rate is high, after the support is mounted, change of the internal force of the stay rope on a main structure is low, and the characteristic ofhigh tensile ability of the stay rope can be sufficiently realized; construction is safe, simple and convenient, and the stay rope is anchored after penetrating through the inverted-T-shaped sliding plate, and then can stretch; if ultra stretching is caused due to reasons in construction, the sphere joint fixing support can realize a load relieving effect in advance, and the main structure is protected against being damaged by means of increasing deformation degree; and safety is high, after a building comes into use, once the building is subjected to load of power catastrophe such as violentearthquake, typhoon and the like, stretching and retracting of the damper springs can guarantee that the stay rope cannot be broken when the deformation of the main structure is high, and the hidden danger that the main structure collapses due to breakage of the stay rope is eliminated.

Owner:CIVIL AVIATION UNIV OF CHINA

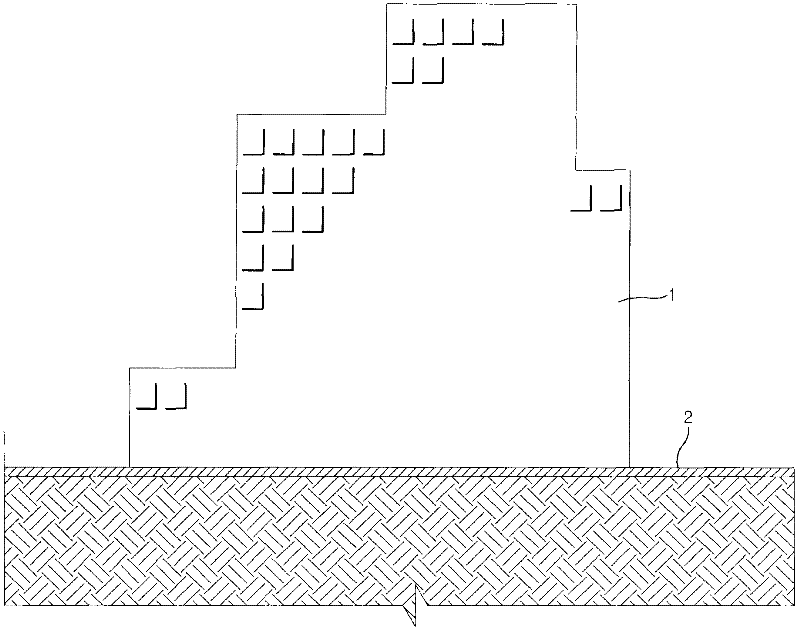

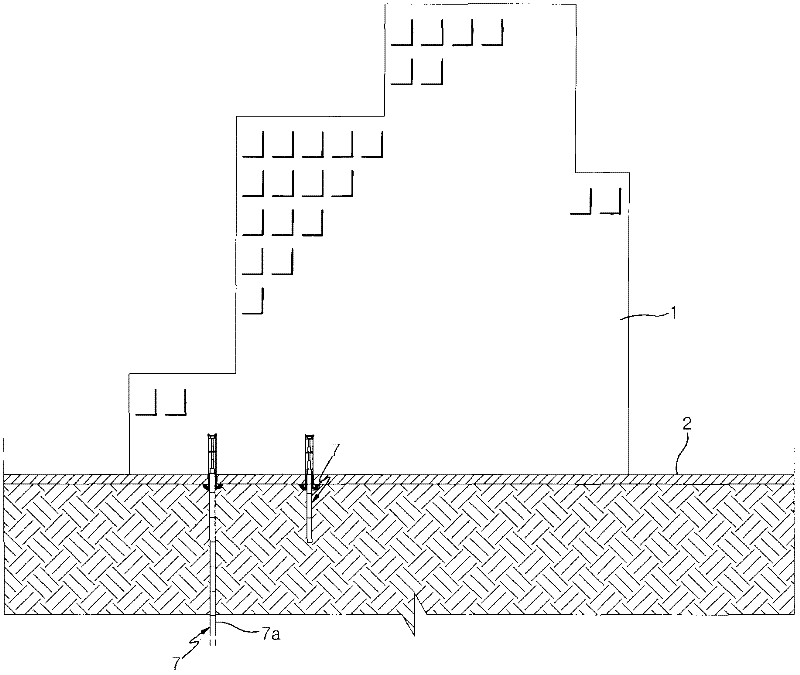

Construction method of cellar for building completed

InactiveCN102561391AReduce generationAvoid pollutionArtificial islandsUnderwater structuresBasementStructural engineering

Disclosed is a construction method of a cellar for a building completed. The construction method includes fixing supporting structures to bottom concrete of the building; installing a press-in machine on the supporting structures; inserting posts for supporting the building into the foundation under the building by inserting hollow piles into the holes to then insert the piles into the underground using the press-in machine, stacking new piles on the inserted piles, and sequentially inserting the piles using the press-in machine; excavating a foundation under the bottom concrete of the building to prepare an underground space when the building is supported by the posts; and placing the concrete on the horizontal and vertical faces of the underground space prepared by the excavating the bottom concrete of the building.

Owner:KOREA ENG & CONSULTANT +2

Water-based organic silicon waterproof agent

InactiveCN101580355BImprove waterproof performanceGood weather resistanceOther chemical processesWater basedBrick

Owner:郭元华

High-temperature-resistant plugging agent for heavy oil horizontal well and water plugging method

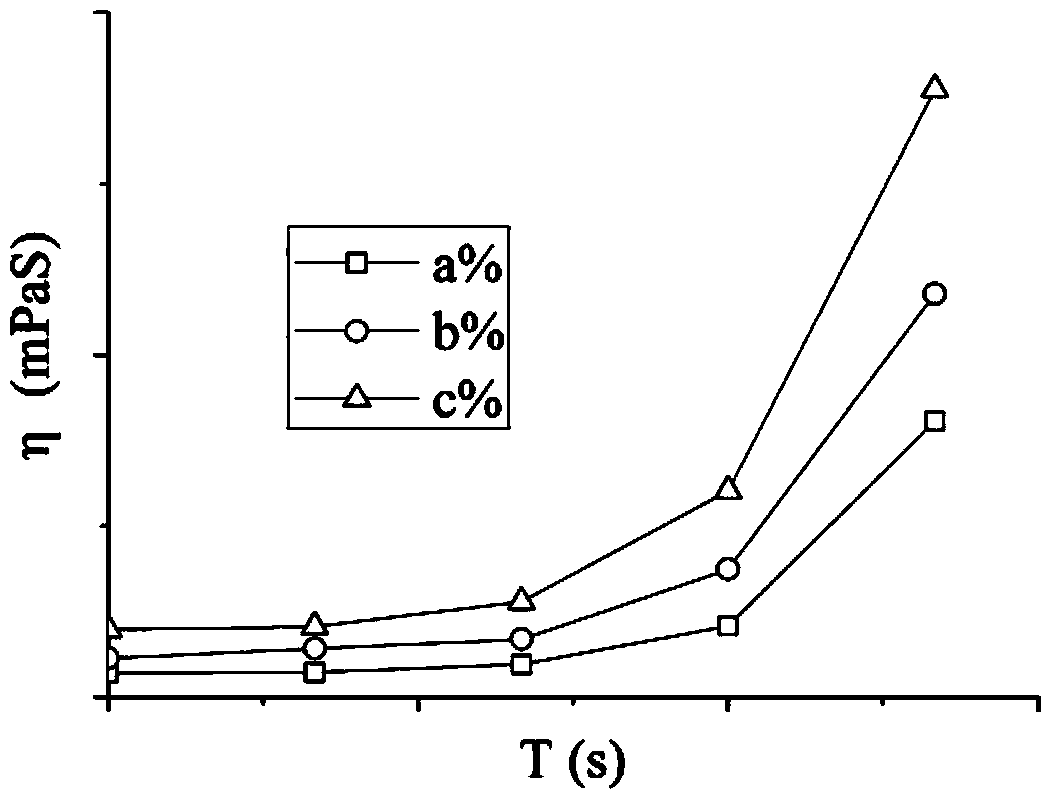

ActiveCN112852393AEnsure water blocking effectImprove seal strengthDrilling compositionSealing/packingHorizontal wellsNitrogen gas

The invention provides a high-temperature-resistant plugging agent for a heavy oil horizontal well and a water plugging method. The high-temperature-resistant plugging agent comprises water glass, urea and a filling agent, the volume ratio of the water glass to the urea is 1: (2-2.2), and the filling agent accounts for 20-25% of the total weight of the water glass and the urea. The residual plugging agent of the high-temperature-resistant plugging agent in a shaft can be treated through flushing operation, so that the construction safety is effectively ensured, and the construction process is simplified. The invention further provides a heavy oil horizontal well water plugging method, according to the method, the high-temperature-resistant plugging agent serves as a near-well section plug, a nitrogen foam gel plugging agent serves as a far-well section plug, and the water plugging effect of the horizontal well is guaranteed through cooperation of the two plugging agents. Compared with other water plugging methods of the high-temperature-resistant plugging agent, the high-temperature-resistant plugging agent and the water plugging method have the advantages of being wide in material source, safe and simple in construction, good in water plugging effect and wide in application prospect.

Owner:PETROCHINA CO LTD

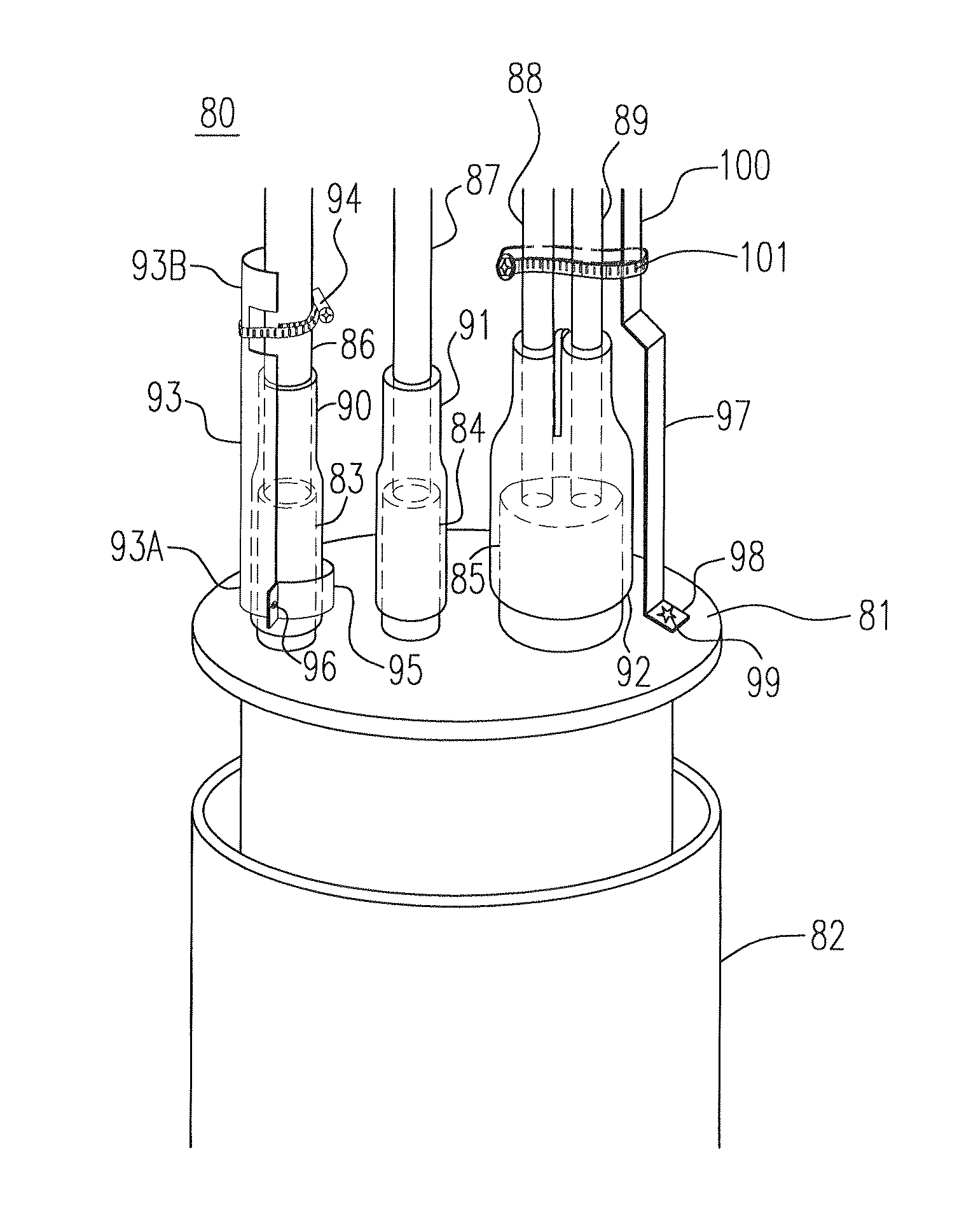

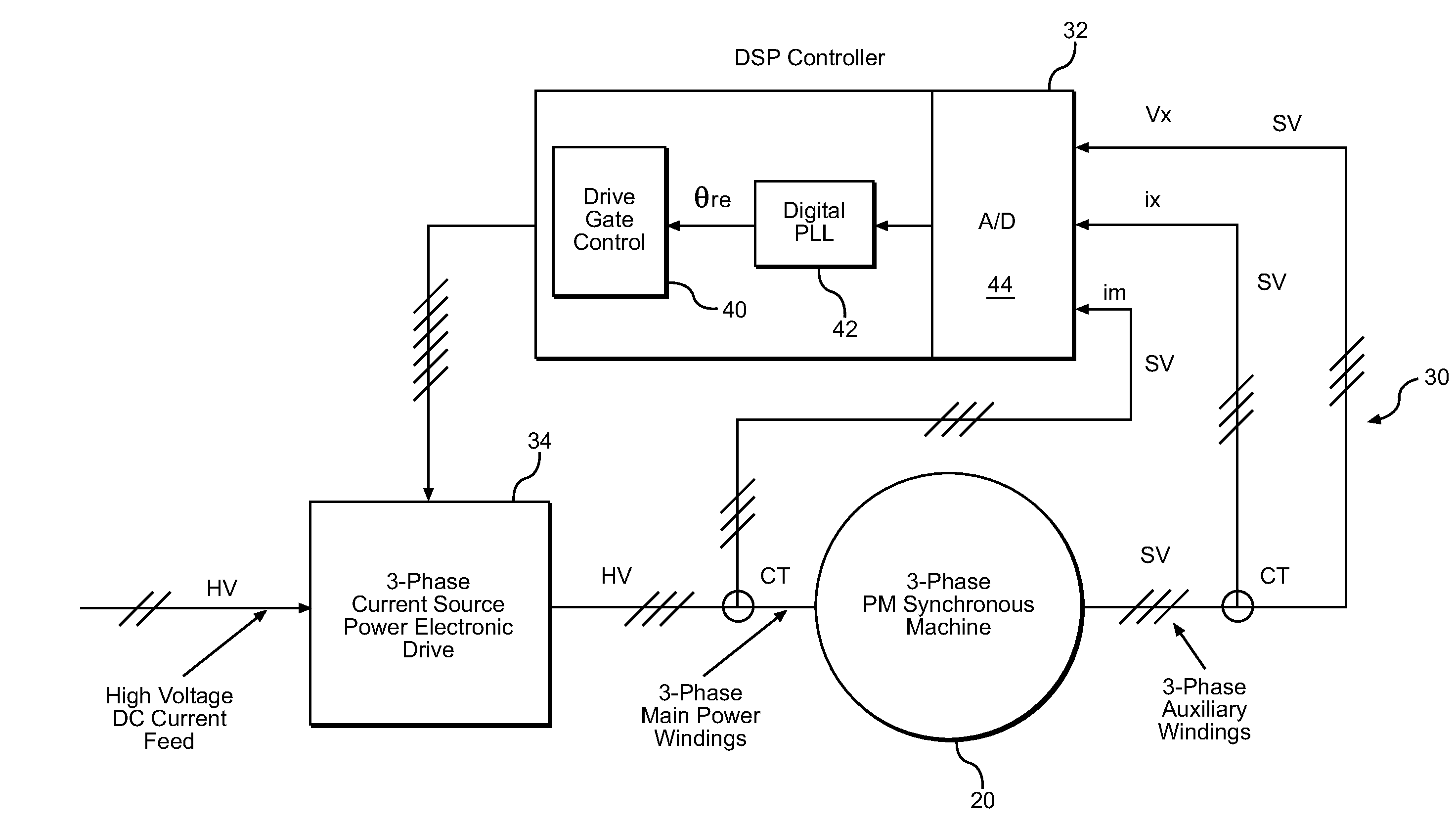

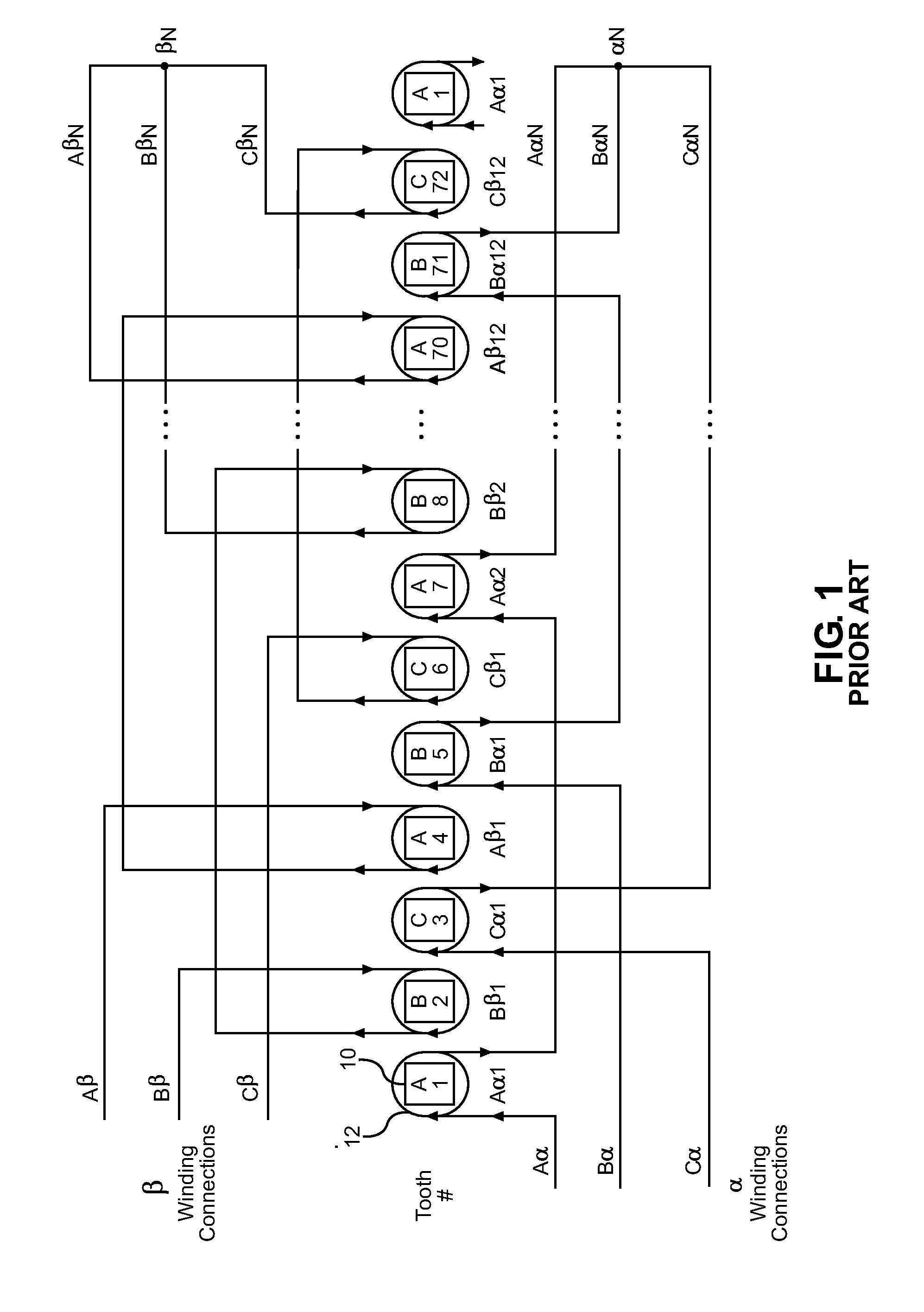

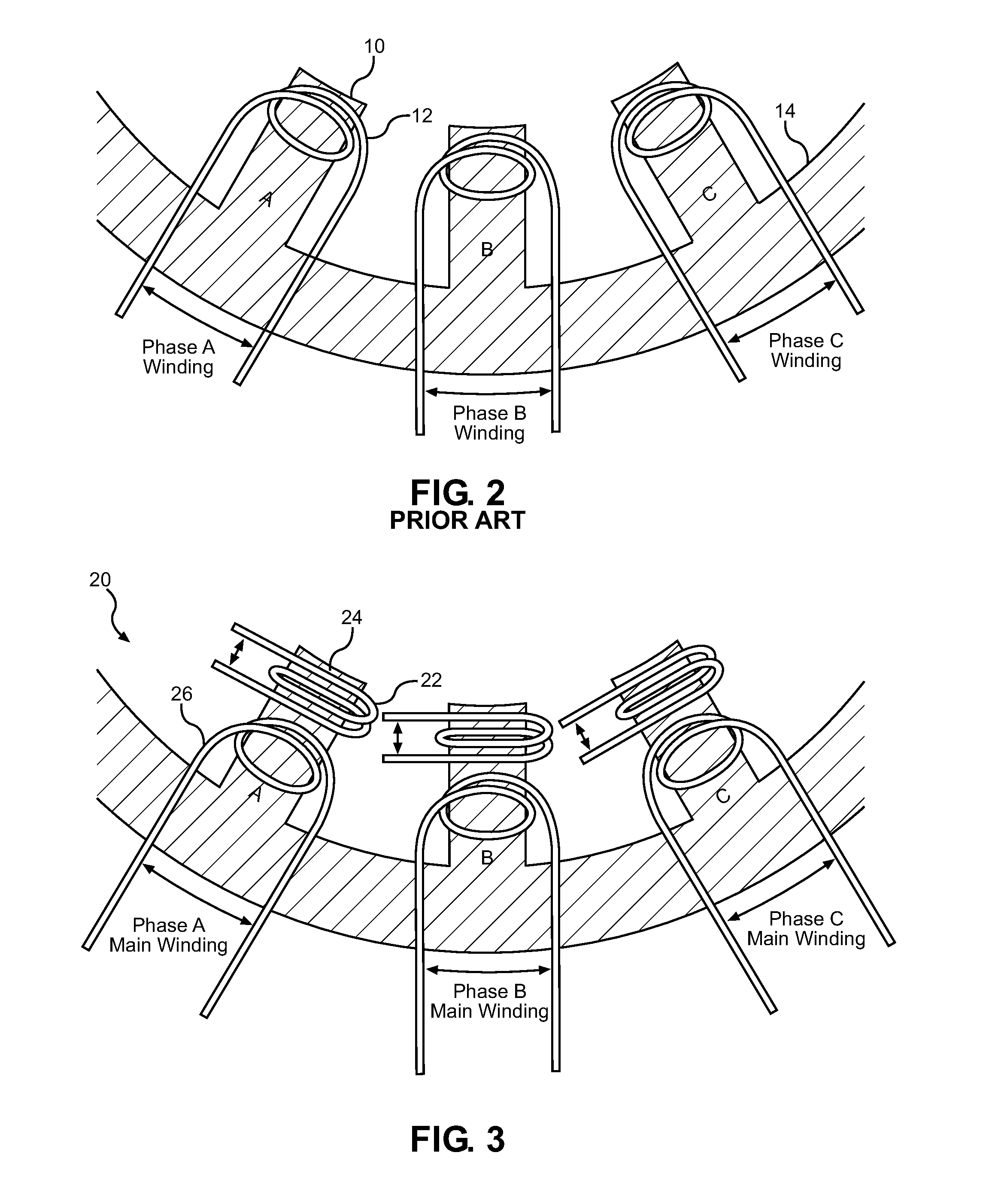

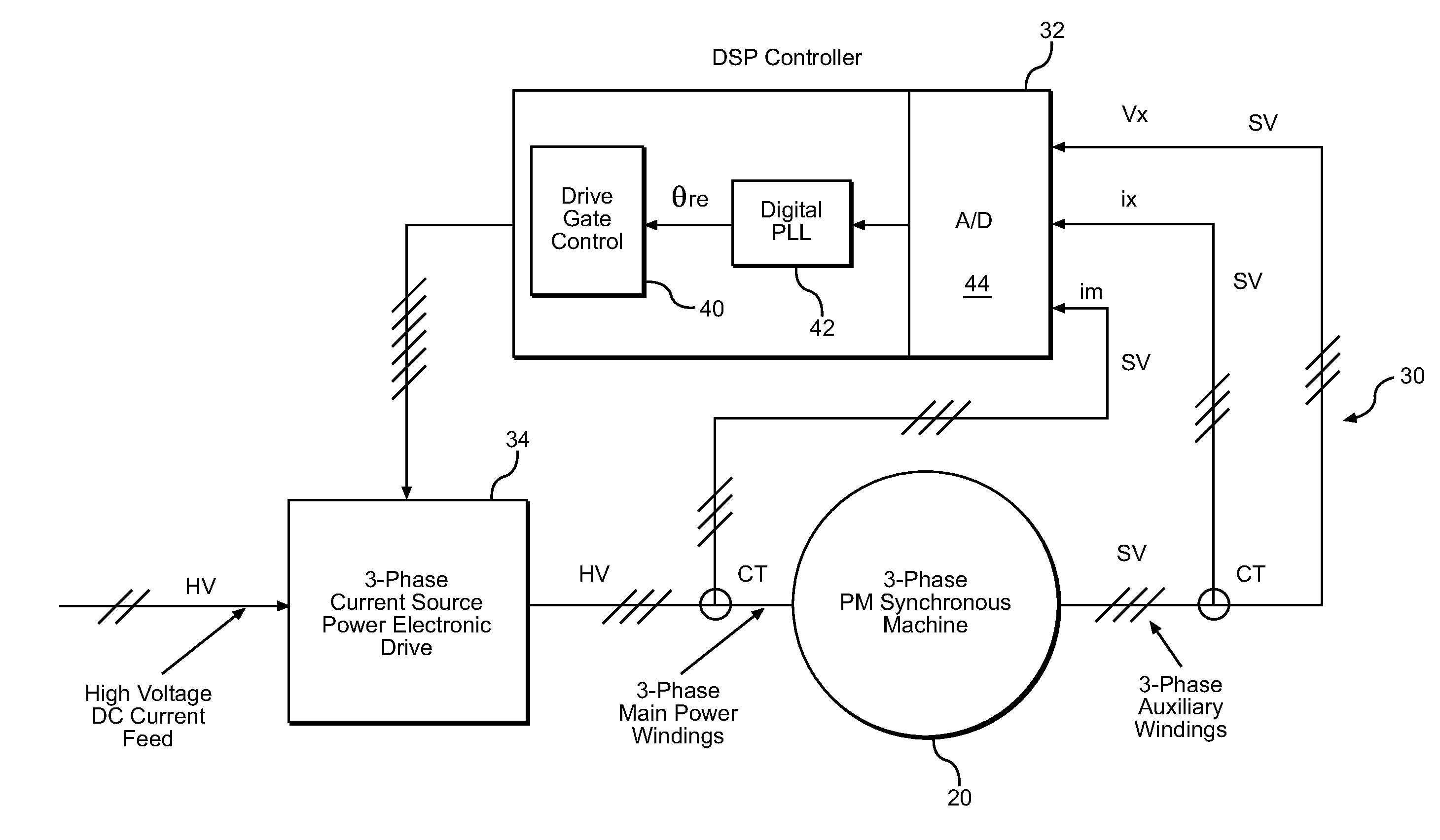

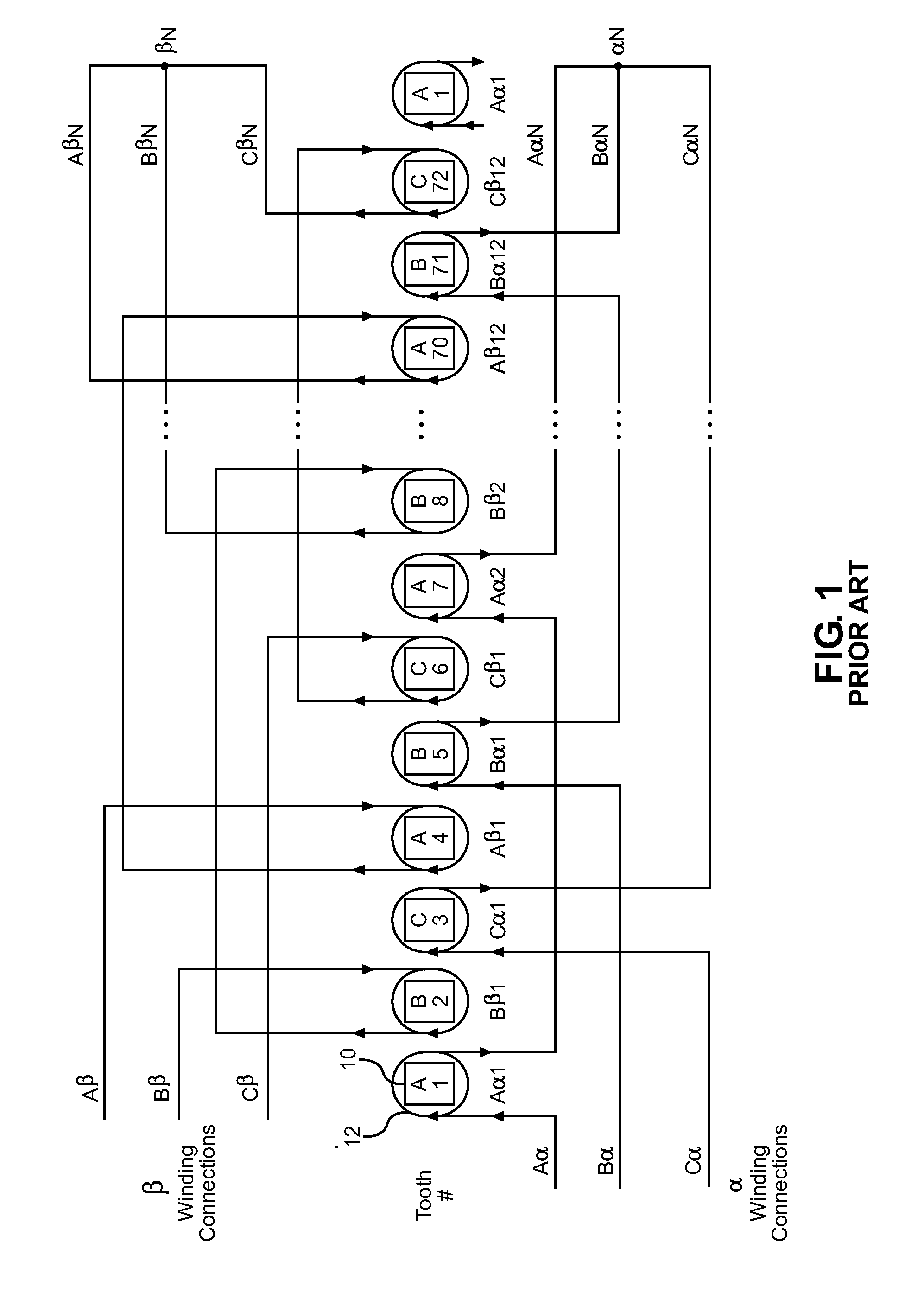

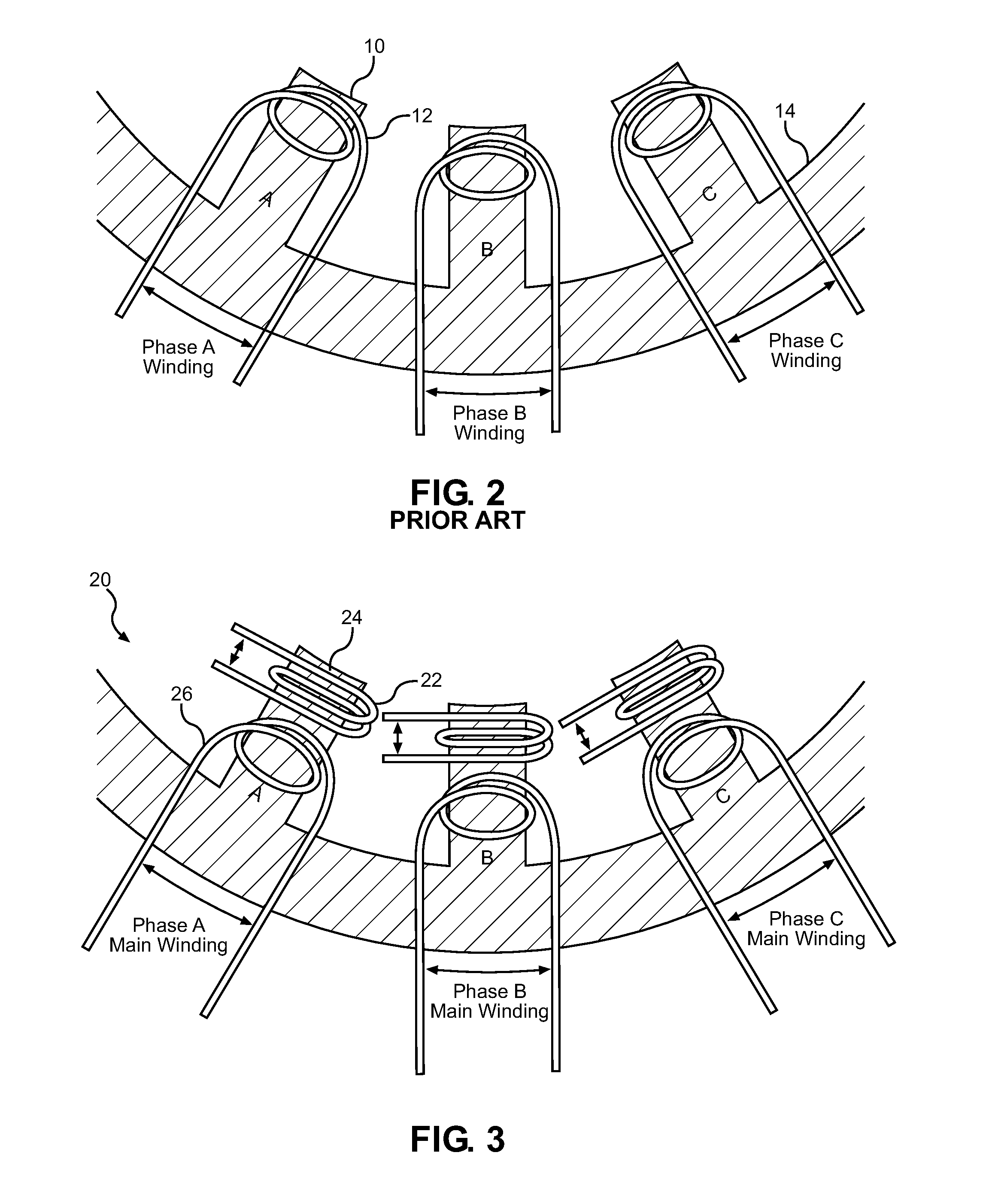

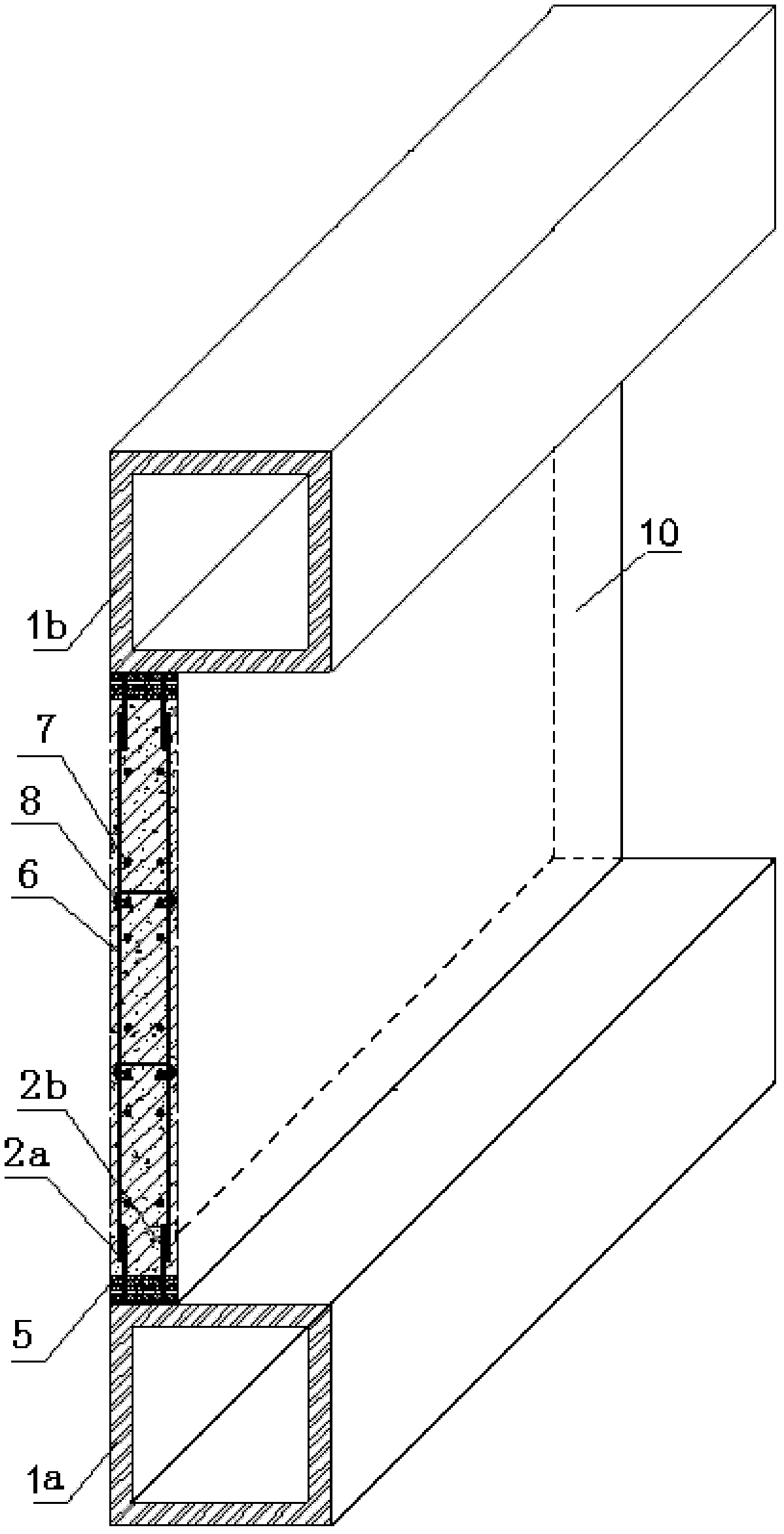

System and method for determining rotor shaft position of high voltage pm ac synchronous machines using auxiliary windings

ActiveUS20140265973A1Simple and safe and accurateSafe and easily manipulated signalMotor/generator/converter stoppersAC motor controlSynchronous motorConductor Coil

A system and method for determining rotor shaft position of high voltage permanent magnet AC synchronous machines using auxiliary windings utilizes a permanent magnet AC synchronous motor including a stator having a main set of coils and an auxiliary set of coils. A drive controller including a digital signal processor in communication with the motor utilizes a current and voltage measurements from the main and auxiliary coils to determine the position of the rotor shaft in a sensorless mode.

Owner:ADVERIO PHARMA +1

Interior wall self heat-insulation building block

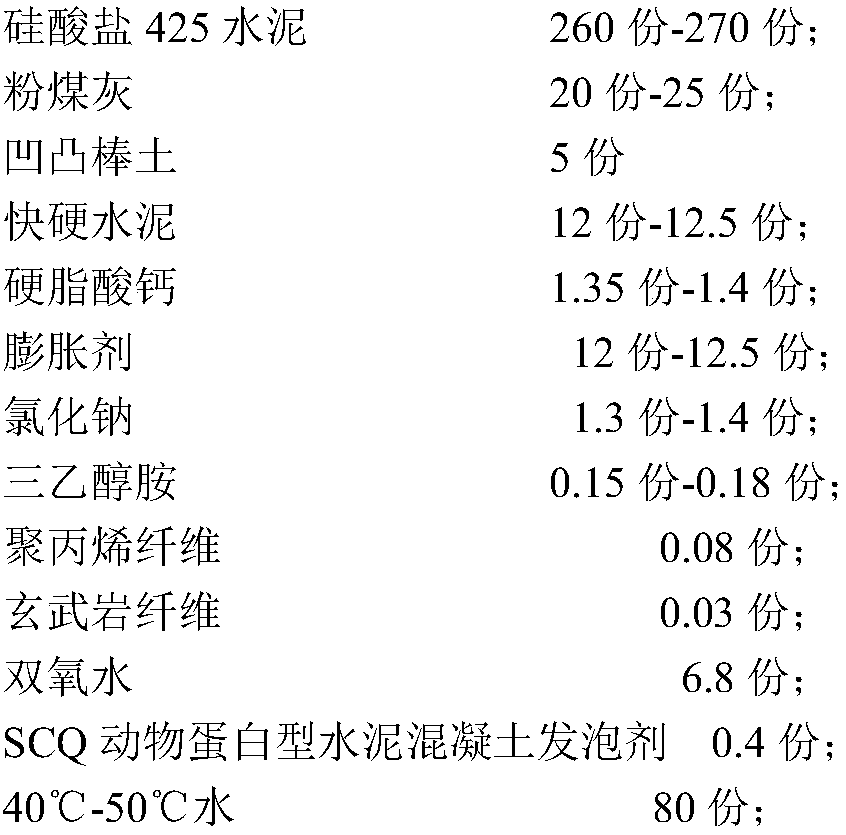

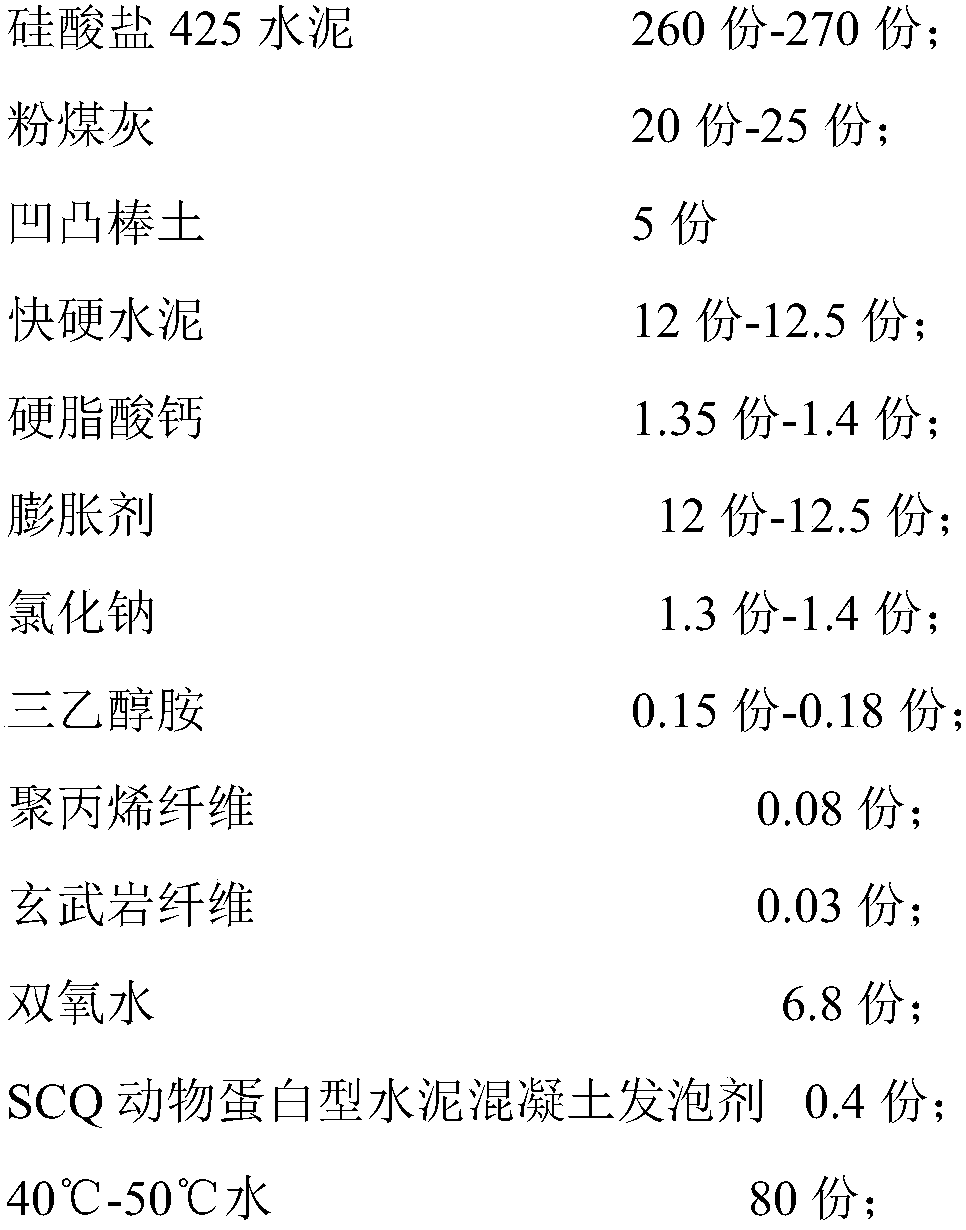

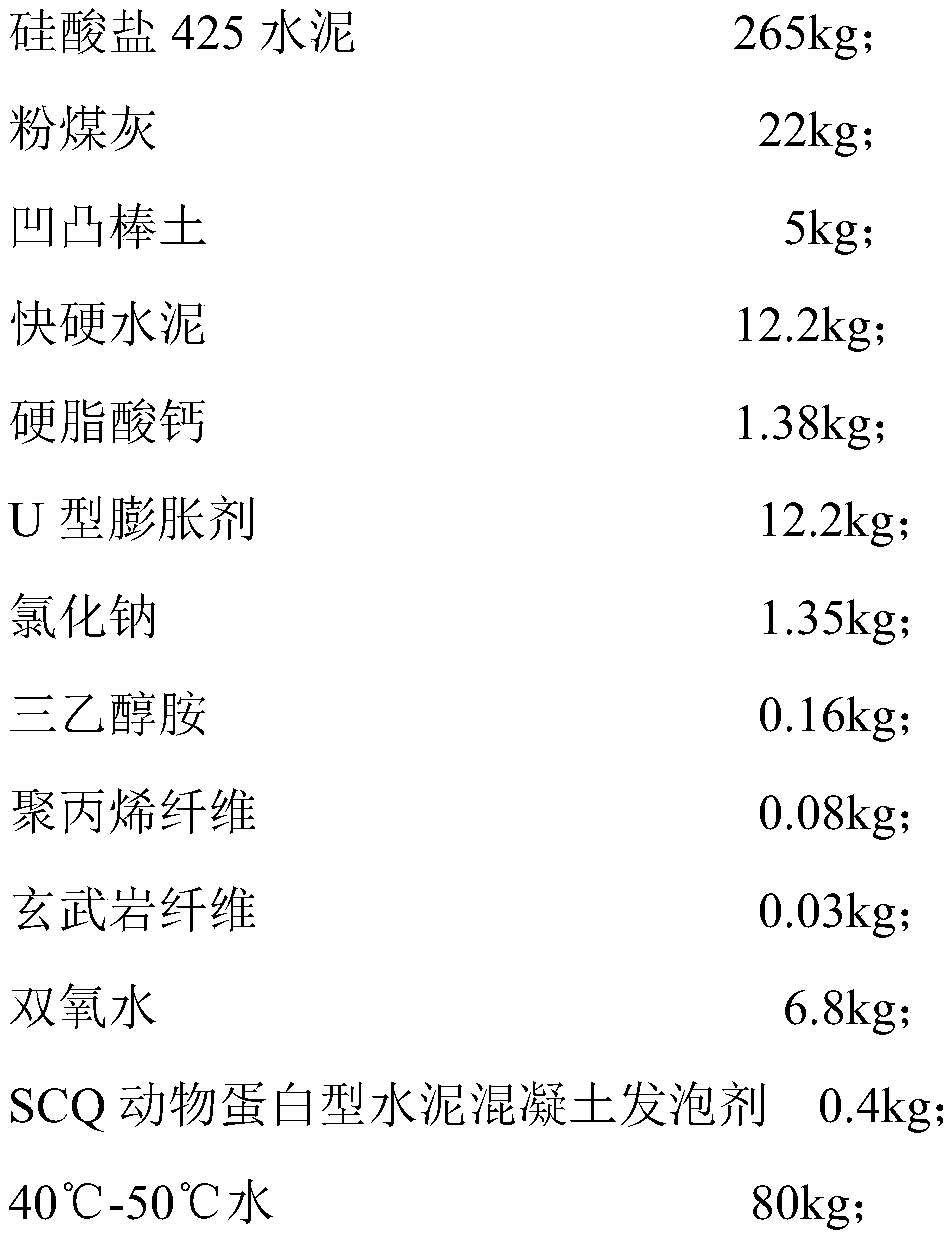

InactiveCN110759672AImprove mesostructureHigh compressive strengthCeramicwareFoam concreteCompressive resistance

The invention discloses an interior wall self heat-insulation building block. According to specific steps, attapulgite is soaked in water for use; an SCQ animal protein cement concrete foaming agent and water are mixed and made into foam through a foam machine; silicate 425 cement, ultrafine fly ash, II-grade fly ash, I-grade fly ash, quick hardening cement, calcium stearate, an expanding agent, sodium chloride, triethanolamine, polypropylene fibers, basalt fibers and the soaked attapulgite are added into water, mixed and stirred for 2 minutes, then the prepared foam is added and stirred for 10s, then hydrogen peroxide with the mass concentration of 5% is added, after 10s, and the formed paste is poured into a mold and is foamed and shaped in the mold to form a building block; and the surface of the building block is covered with plastic cloth, and after curing and drying, the foamed concrete self heat-insulation interior wall building block is obtained. The building block has the advantages that the process is simple, material blending is scientific and reasonable, the foaming agent has a good foaming effect, pores are uniform, and the product has excellent compressive strength and is suitable for a thermal-insulating interior wall.

Owner:锦州宇博保温建材有限公司

Anti-corrosion cement electricity pole

InactiveCN109535928ALess corrosiveExtended service lifeAnti-corrosive paintsEpoxy resin coatingsElectricityMaterials science

The invention relates to an anti-corrosion cement electricity pole including a pole body, wherein an anticorrosion layer is applied to the surface thereof. Corrosion on the cement electricity pole dueto acidic corrosive substances in soil is reduced, and service life of the cement electricity pole in soil is prolonged.

Owner:江苏荣辉电力设备制造有限公司

Fully mechanized coal face high suction tunnel lower-returning drilling primary mining gas drainage method

A gas drainage method for initial mining in a high-pumping working face under the back-drilling hole, the purpose of which is safe and convenient construction, improving the drainage rate, and effectively reducing the gas concentration of the working face; At a horizontal distance of 0 to 50 meters, excavate 2 to 3 drilling sites suitable for drilling rig construction, and drill 2 to 3 drilling holes in each drilling site; use drilling rigs to drill to the working face to replace the lower return of the back high pumping roadway Drilling, the drilling is drilled down from the high pumping roadway to the pressure relief zone just developed at the initial mining stage above the working face. ° within the angle line and within the rock stratum 4 to 5 times the mining height from the roof of the working face; during the initial mining of the working face, the high-level pumping roadway will be enclosed in the wall, and the iron pipe will be pressed to connect with the main pumping system to provide With high negative pressure, the gas that rises to the fracture zone is pumped to the high-level pumping lane through the down-return drilling, and then enters the drainage system to reach the ground.

Owner:HUAYANG NEW MATERIAL TECH GRP CO LTD

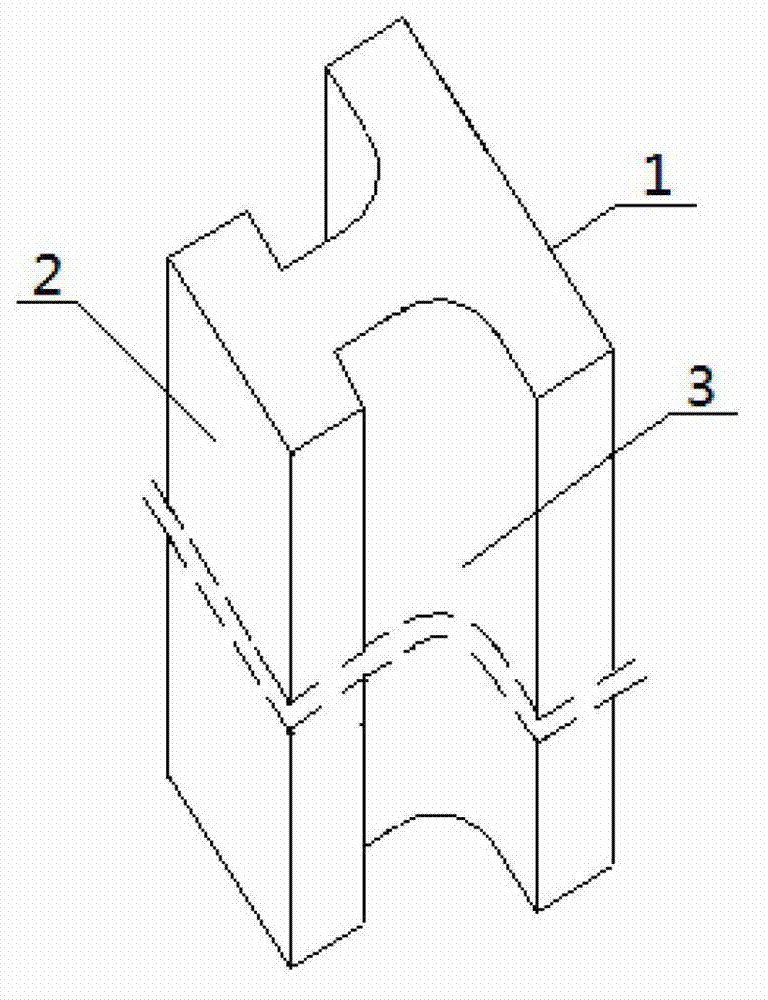

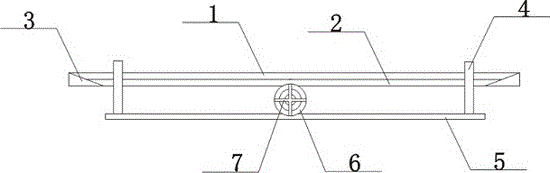

Anti-slide pile with I-shaped cross section

InactiveCN103046541AReduce in quantityReduce usageExcavationsBulkheads/pilesStress concentrationReinforced concrete

The invention relates to an anti-slide pile with an I-shaped cross section. The anti-slide pile with the I-shaped cross section is poured by reinforced concrete. Transverse width at the rear end of the anti-slide pile is larger than that of a common anti-slide pile with a rectangular cross section, so that post-pile soil arch effects are brought into full play, pile center distance between two adjacent anti-slide pile can be increased when the anti-slide piles are disposed on a plane, and the amount of the required anti-slide piles is reduced under the same landslide conditions to reduce cost. The rear end and the front end of the anti-slide pile are arc-shaped, stress concentration damaging the anti-slide pile is prevented from being generated at tips. The anti-slide pile can bear large slope pushing force has good bending resistance. The cross section area of the anti-slide pile is remarkably smaller that of the anti-slide pile with the rectangular cross section, so that concrete quantity and rebar quantity needed are reduced greatly, a large amount of concrete and rebar is saved, and cost is lowered. The anti-slide pile is small in construction section and simple and safe in construction, has promising popularization application prospect and facilitates mechanical construction.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

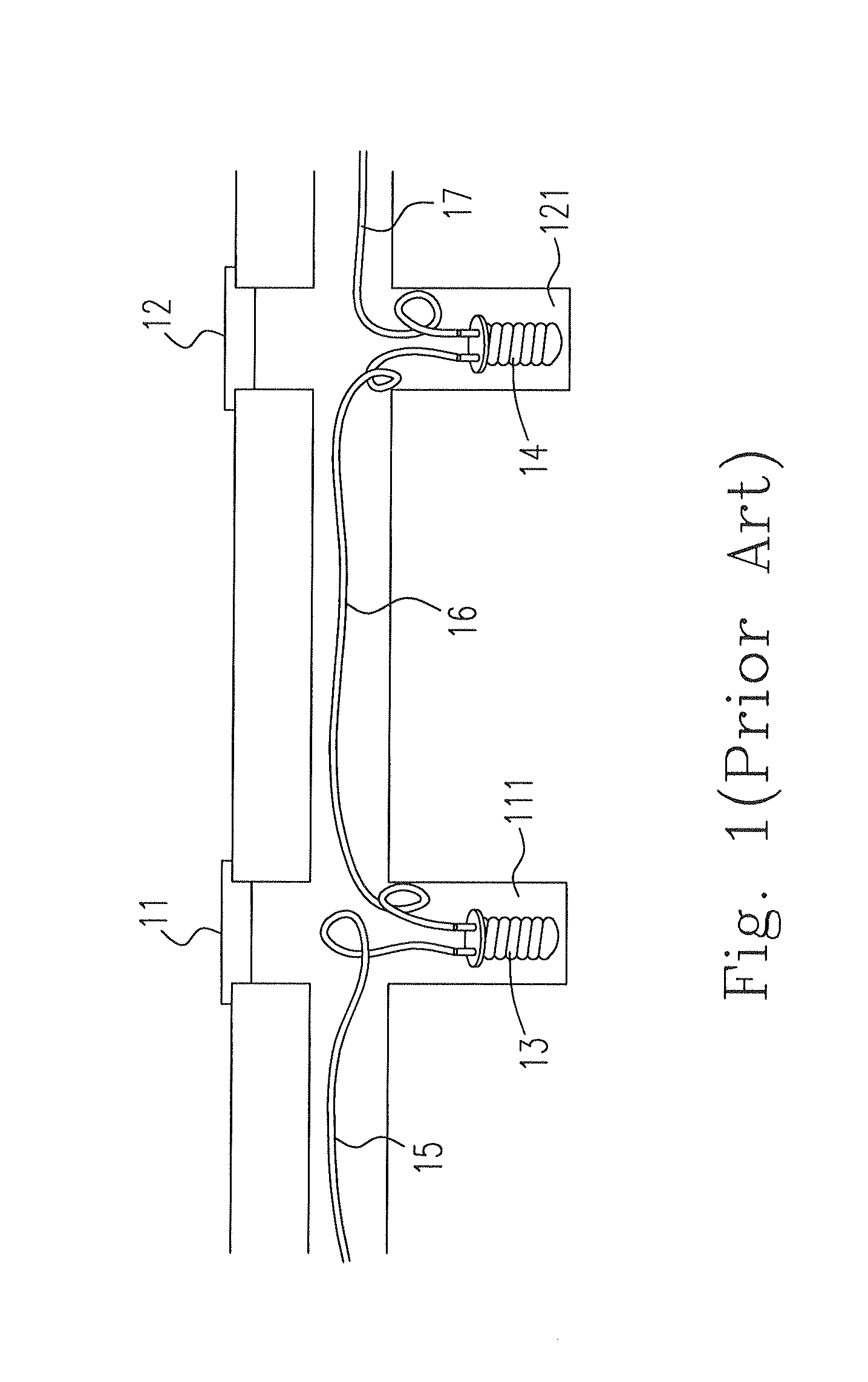

Compressive steel skeleton structure

ActiveCN104847043BSimple and safe constructionGuaranteed structural strengthWallsRight triangleSteel columns

The invention discloses a compression reinforcement skeleton structure which comprises a top steel plate and a bottom steel plate, wherein steel columns are vertically connected with the parts, close to the two ends, of the top steel plate and the bottom steel plate; the steel columns are integrally connected with the top steel plate and the bottom steel plate respectively; the tops of the steel columns penetrate through the upper surface of the top steel plate and extend to the outer side of the upper surface of the top steel plate; angle beads are arranged at parts, close to the two ends, in the top steel plate and are in right triangle structures; the two angle beads are arranged symmetrically; a steel protection plate is connected between the two angle beads; the two ends of the steel protection plate penetrate through the two angle beads respectively and are welded with the top steel plate; and the top steel plate and the bottom steel plate is provided with a reinforcement cage located between the two steel columns. The compression reinforcement skeleton structure is safe and simple in construct; the structural strength is ensured; the skeleton structure has low possibility of falling by utilizing a welding manner, has good compression resistance, and has low possibility of bending caused by excessive pressure; the compression strength of the skeleton structure is greatly improved; and the overall strength of the structure is further improved.

Owner:HEBEI ROAD & BRIDGE GROUP

System and method for determining rotor shaft position of high voltage PM AC synchronous machines using auxiliary windings

ActiveUS9287819B2Simple and safe constructionSimple and safe and accurate methodAC motor controlElectronic commutatorsSynchronous motorEngineering

A system and method for determining rotor shaft position of high voltage permanent magnet AC synchronous machines using auxiliary windings utilizes a permanent magnet AC synchronous motor including a stator having a main set of coils and an auxiliary set of coils. A drive controller including a digital signal processor in communication with the motor utilizes a current and voltage measurements from the main and auxiliary coils to determine the position of the rotor shaft in a sensorless mode.

Owner:ADVERIO PHARMA +1

Thin-wall cast-in-situ concrete enclosure structure and steel structure flexible connection and water stop treatment method

ActiveCN102322105BEffectively control the development of cracksEffective control of shrinkage cracksWallsBuilding insulationsStructural deformationCrack resistance

The invention discloses a thin-wall cast-in-situ concrete enclosure structure and steel structure flexible connection and water stop treatment method, which comprises the following steps of: A, performing surface treatment on a steel structure; B, welding a water stop steel plate; C, manufacturing a waterproof rock wool plate; D, installing the waterproof rock wool plate; E, welding horizontal and vertical steel bars; and F, closing concrete. By the method, the crack spreading of a concrete enclosure structure is effectively controlled, the condition that the concrete enclosure structure is deformed and cracked and then leaked because the concrete enclosure structure and the steel structure have a large linear expansion coefficient difference due to temperature change is avoided by utilizing flexible connection and the water stop steel plate on the surface of the steel surface in a projection area of a cast-in-situ concrete enclosure structure arranged at a joint, and the problem thata flexible connection material is non-fireproof in the welding process is solved by adopting the waterproof rock wool plate which is a non-combustible material. In addition, the method is simple in construction, and safe and feasible, the contraction crack of the concrete enclosure structure can be effectively controlled, a seepage path is blocked, the crack resistance and seepage resistance of the joint are improved, and the service life of the concrete enclosure structure is greatly prolonged.

Owner:WUHAN CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com