Cement-based composite anticorrosive coating

A kind of anti-corrosion coating, cement-based technology, applied in the field of coatings, can solve the problems of weak impact resistance, shortened life, high cost, etc., and achieve the effect of strong impact resistance, strong adhesion, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

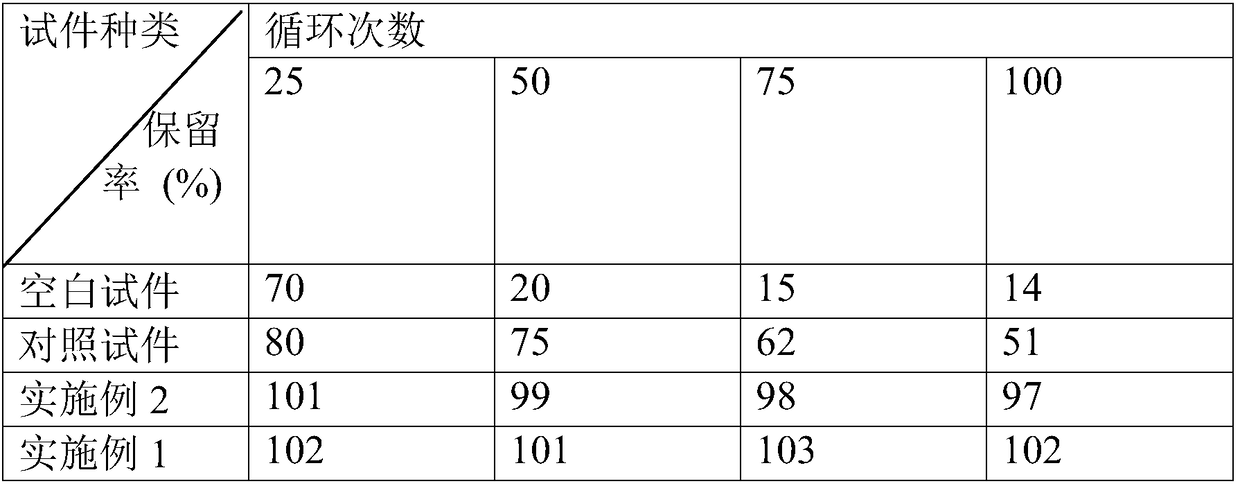

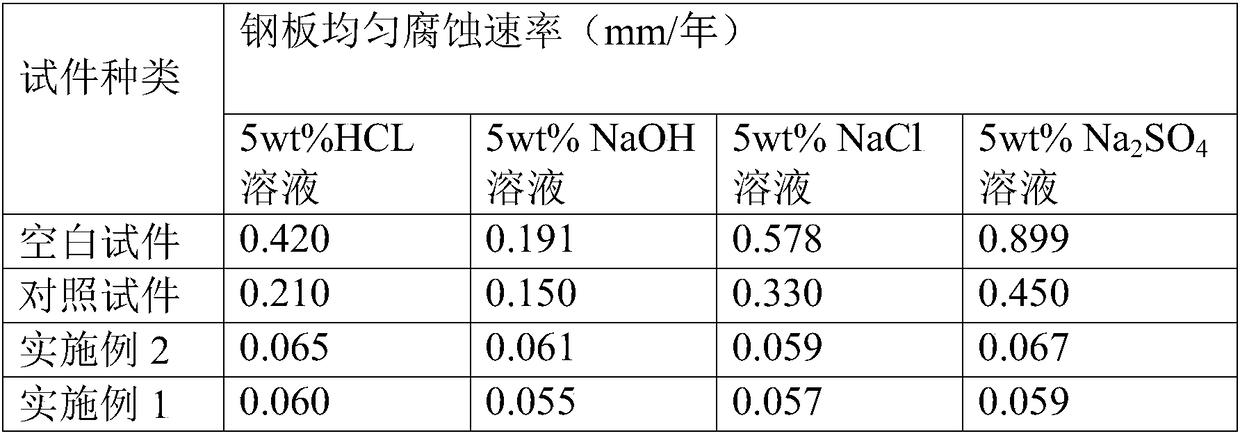

Examples

Embodiment 1

[0046] The coating is made by mixing the following materials by weight percentage, among which: liquid phase component: epoxy emulsion 20%; water 35%; admixture 2%; solid phase component: cement 30%; quartz sand 10%; fiber 1% element; 1% zinc powder; 1% titanium oxide. Wherein the admixture is a defoamer, and the fiber is a polyvinyl alcohol fiber.

[0047] The particle size of zinc powder in cement-based composite anti-corrosion coatings is 0.05-0.2 μm; the particle size of titanium oxide in cement-based composite anti-corrosion coatings is 0.02-0.3 μm; the cement in cement-based composite anti-corrosion coatings is sulphoaluminate cement, and the cement strength grade is ≥ 42.5; The particle size of the quartz sand in the cement-based composite anticorrosion coating of the present invention is 200-2000 μm.

[0048] First mix the liquid phase materials in proportion, then slowly pour the prepared solid phase powder into the liquid phase materials, and fully stir for 20 minut...

Embodiment 2

[0050] The coating is made by mixing the following materials by weight percentage, among which: liquid phase component: epoxy emulsion 20%; water 30%; admixture 2%; solid phase component: cement 28%; quartz sand 15%; fiber 2% plain; 1.5% zinc powder; 1.5% titanium oxide. Wherein the admixture is a defoamer, and the fiber is a polyvinyl alcohol fiber.

[0051] The particle size of zinc powder in cement-based composite anti-corrosion coatings is 0.05-0.2 μm; the particle size of titanium oxide in cement-based composite anti-corrosion coatings is 0.02-0.3 μm; the cement in cement-based composite anti-corrosion coatings is sulphoaluminate cement, and the cement strength grade is ≥ 42.5; The particle size of the quartz sand in the cement-based composite anticorrosion coating of the present invention is 200-2000 μm.

[0052] First mix the liquid phase materials in proportion, then slowly pour the prepared solid phase powder into the liquid phase materials, and fully stir for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com