Fully mechanized coal face high suction tunnel lower-returning drilling primary mining gas drainage method

A fully mechanized caving face and gas drainage technology, which is applied in gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of difficult ventilation management, potential safety hazards, easy gas accumulation, etc., so as to shorten the construction time and improve the Safety and Drainage, Easy to Manage Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

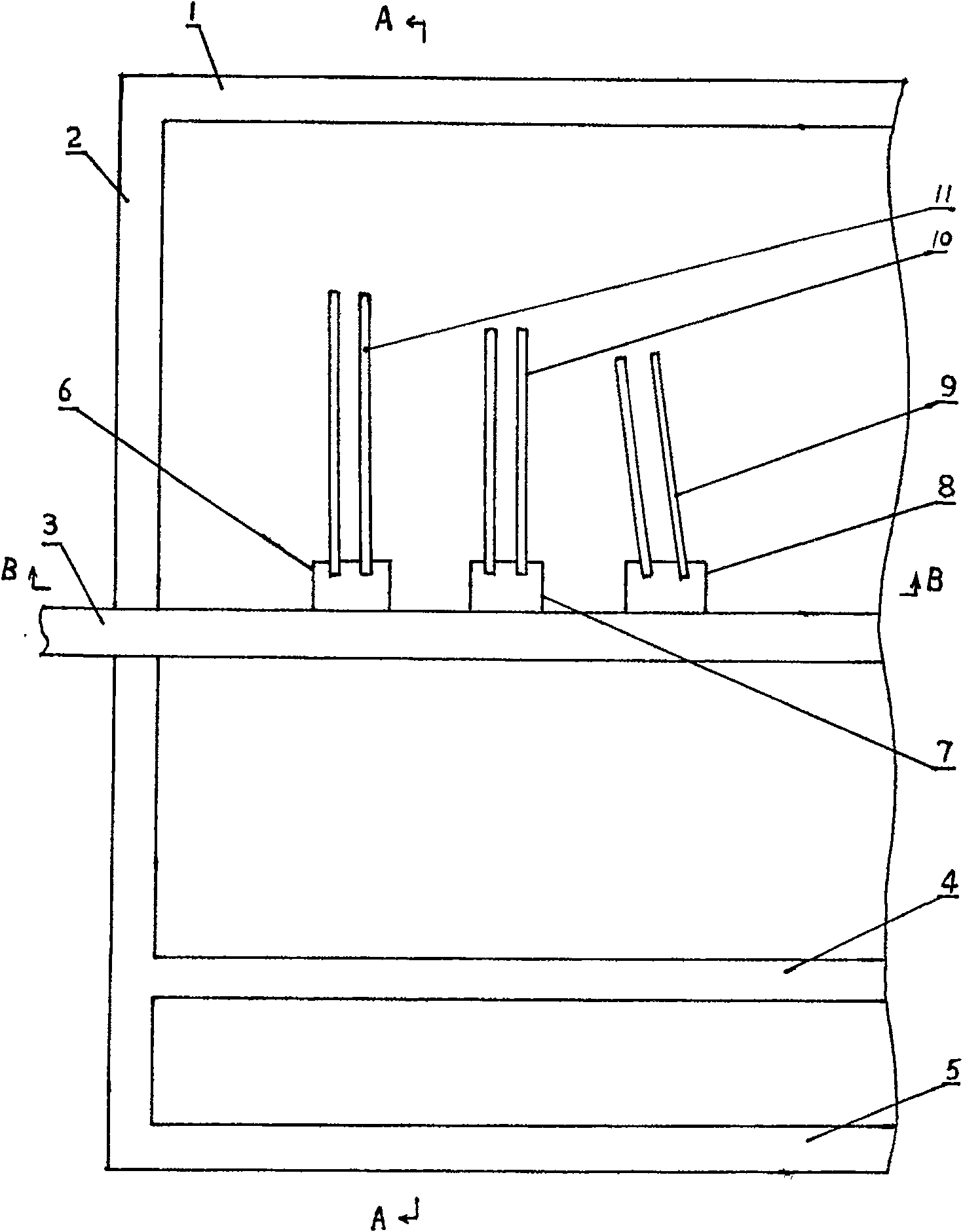

[0012] Xinjing Mine of Yangquan Coal Industry Group is located in the west of Yangquan City, with a field area of 86.3 square kilometers, a total reserve of 1.4 billion tons, and a shaft depth of more than 260 meters in the Fuli shaft. The minable coal seams are the third, twelfth and fifteenth layers, and the eighth layer is partially mineable. The coal seams are mined in order from top to bottom. The third coal seam with a thickness of 2.7 meters has been mined, the twelfth coal seam with an average thickness of 1.3 meters has been abandoned, and the other thin and unstable coal seams are not mined.

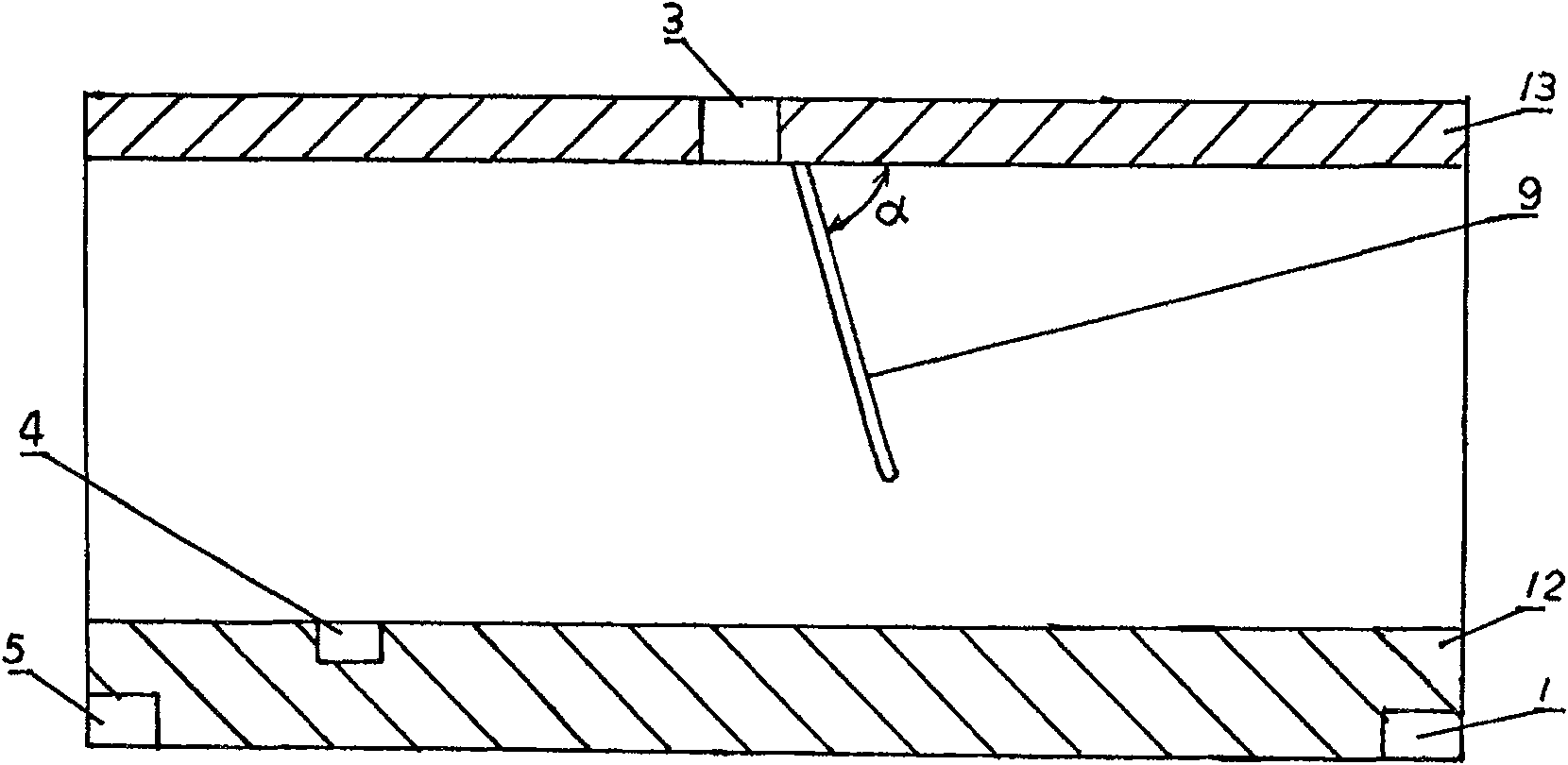

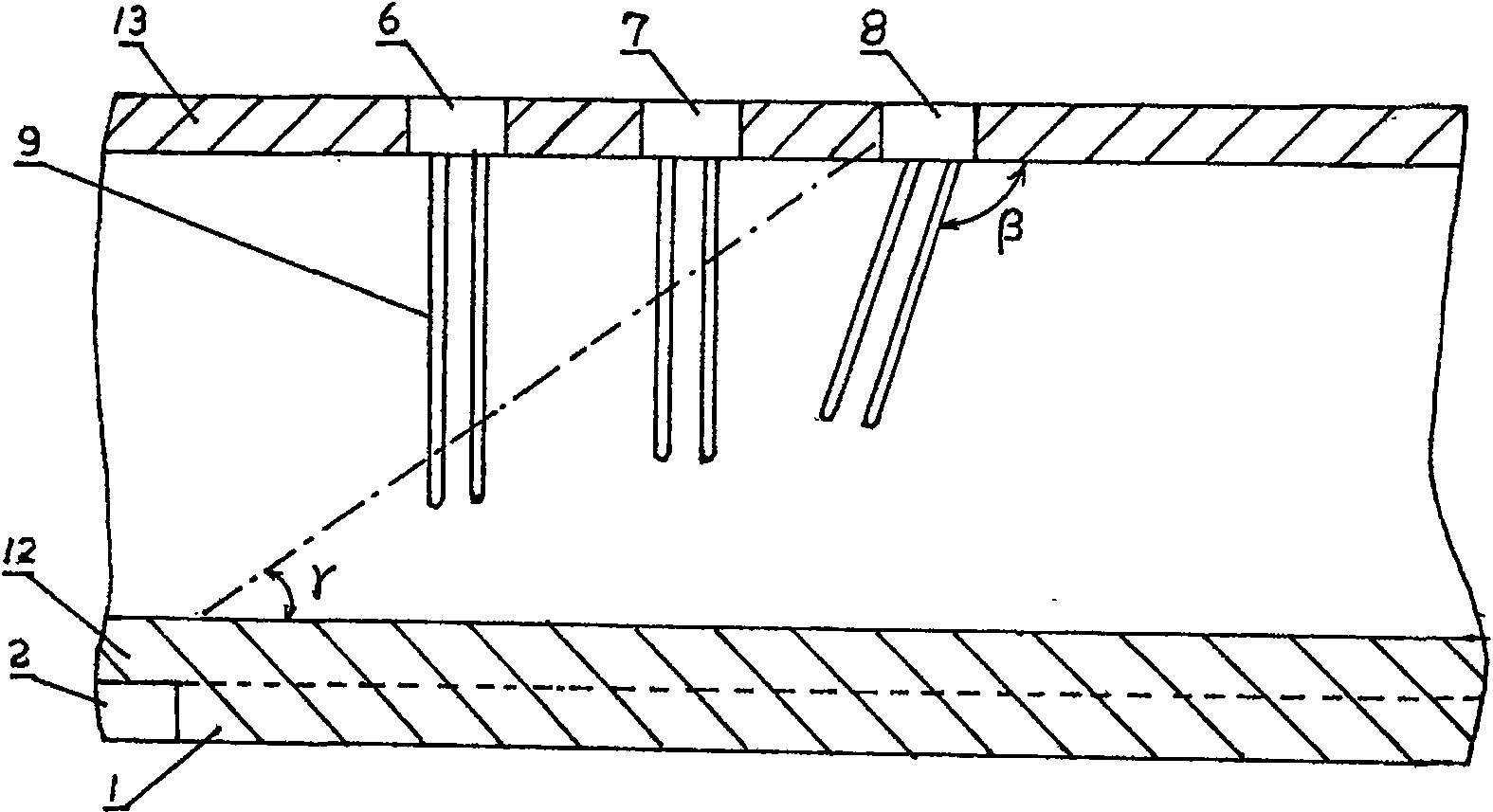

[0013] The coal seam (12) shown in the figure is the fifteenth layer, about 6.5 meters thick, is a thick coal seam, about 700 meters away from the ground, and adopts fully mechanized top coal mining. The upper coal seam (13) is the ninth layer, about 68 meters away from the coal seam (12) roof. Towards the high pumping roadway (3) is located in the upper coal seam (13).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com