Skid resistance device for fractured rock mass and construction method thereof

A construction method and rock mass technology, applied in excavation, foundation structure engineering, climate change adaptation, etc., can solve the problems of increasing the time consumption of pile body work, limited ability to resist landslides, and endangering the safety of reinforcement projects, etc. The effect of wide range of conditions, not easy to deteriorate, and safe and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

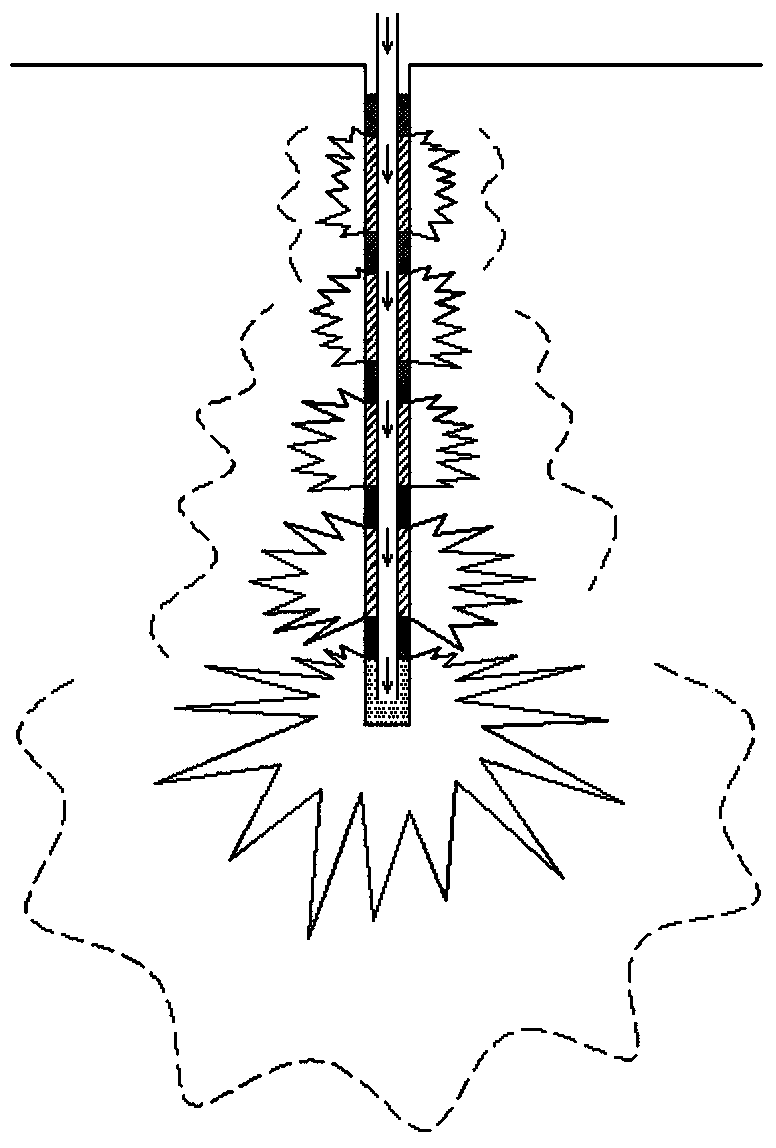

[0022] Such as Figure 5 As shown, the anti-slide device for broken rock mass includes a plurality of grouted anti-slide piles, each grouted anti-slide pile includes a tower-shaped stone column 1, and a shear assembly 2, and the shear assembly includes a seamless steel pipe 3 and the high-strength shear steel column 4, the bedrock 5 is below the broken rock mass 6, the seamless steel pipe 3 is inserted into the bedrock 5 through the broken rock mass 6, the high-strength shear steel column 4 is attached to the seamless steel tube 3, and the high-strength anti-shear A part of the shear steel column 4 is in the bedrock 5 and the other part is in the broken rock mass 6. The tower-shaped stone column 1 formed by multi-stage filling compaction grouting is partly exposed in the broken rock mass or completely in the broken rock mass. in the rock mass.

[0023] Since the shear assembly of the present invention can increase the shear strength of each grouted anti-slide pile, thereby im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com