Novel steel structure anchor increasing and grouting uplift pile and construction method thereof

A technology of uplift piles and steel structures, which is applied in basic structure engineering, sheet pile walls, protection devices, etc. Large degree, safe and simple construction, and the effect of improving the strength of the pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

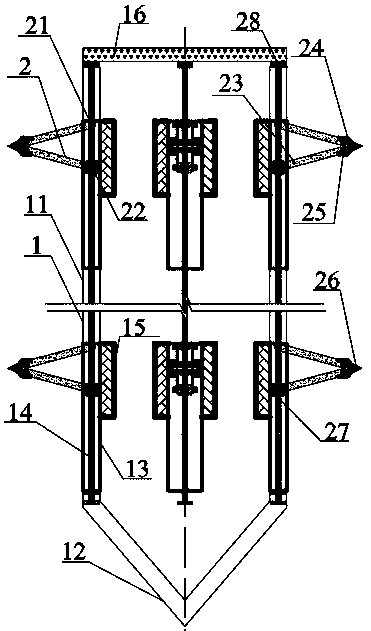

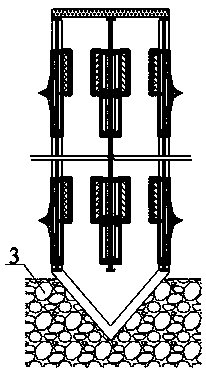

[0030] The present invention provides a new type of steel structure anchor-increased grouting uplift pile. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

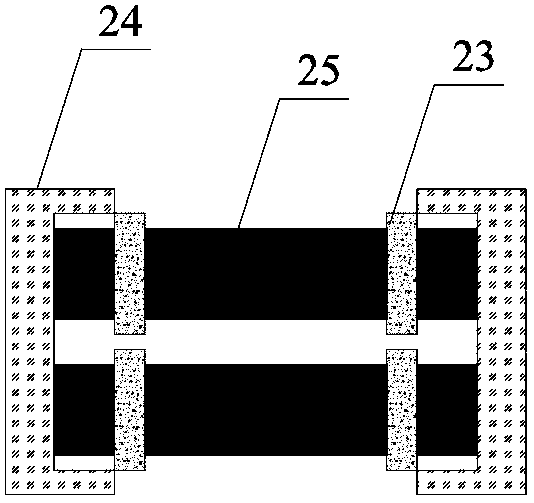

[0031] Such as figure 1 As shown, the present invention is a novel steel anchor-increasing cast-in-place uplift pile, which is mainly composed of a pile body 1 and an anchor-increasing deformation device 2. The pile body 1 is composed of a steel pile body 11, a tapered pile tip 12, and an anchor-increasing deformation hole. 13. Slide rail 14, T-shaped steel stiffening plate 15 and protective pile cap 16 are composed. Anchoring deformation device 2 is composed of upper rotating shaft 21, lower shaft 22, rotating arm 23, connecting box 24, connecting bearing 25, reinforcing cap 26, sliding thread Sleeve 27 and threaded rod 28 are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com