Thin-wall cast-in-situ concrete enclosure structure and steel structure flexible connection and water stop treatment method

A technology of enclosure structure and treatment method, which is applied to building components, building structures, building insulation materials, etc., can solve problems such as water blocking and free deformation, and achieve the effects of simple construction, prolonging service life, and blocking seepage paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

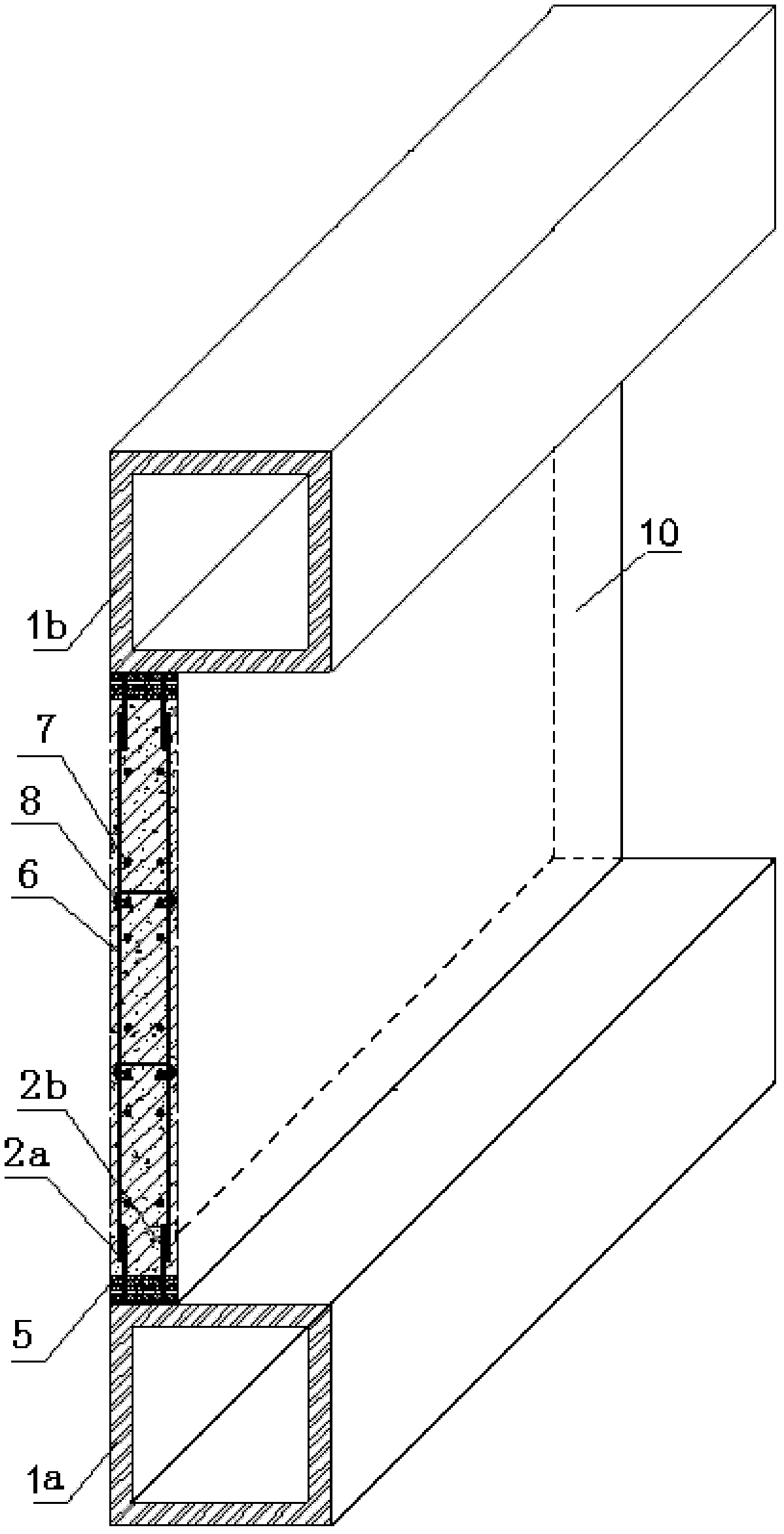

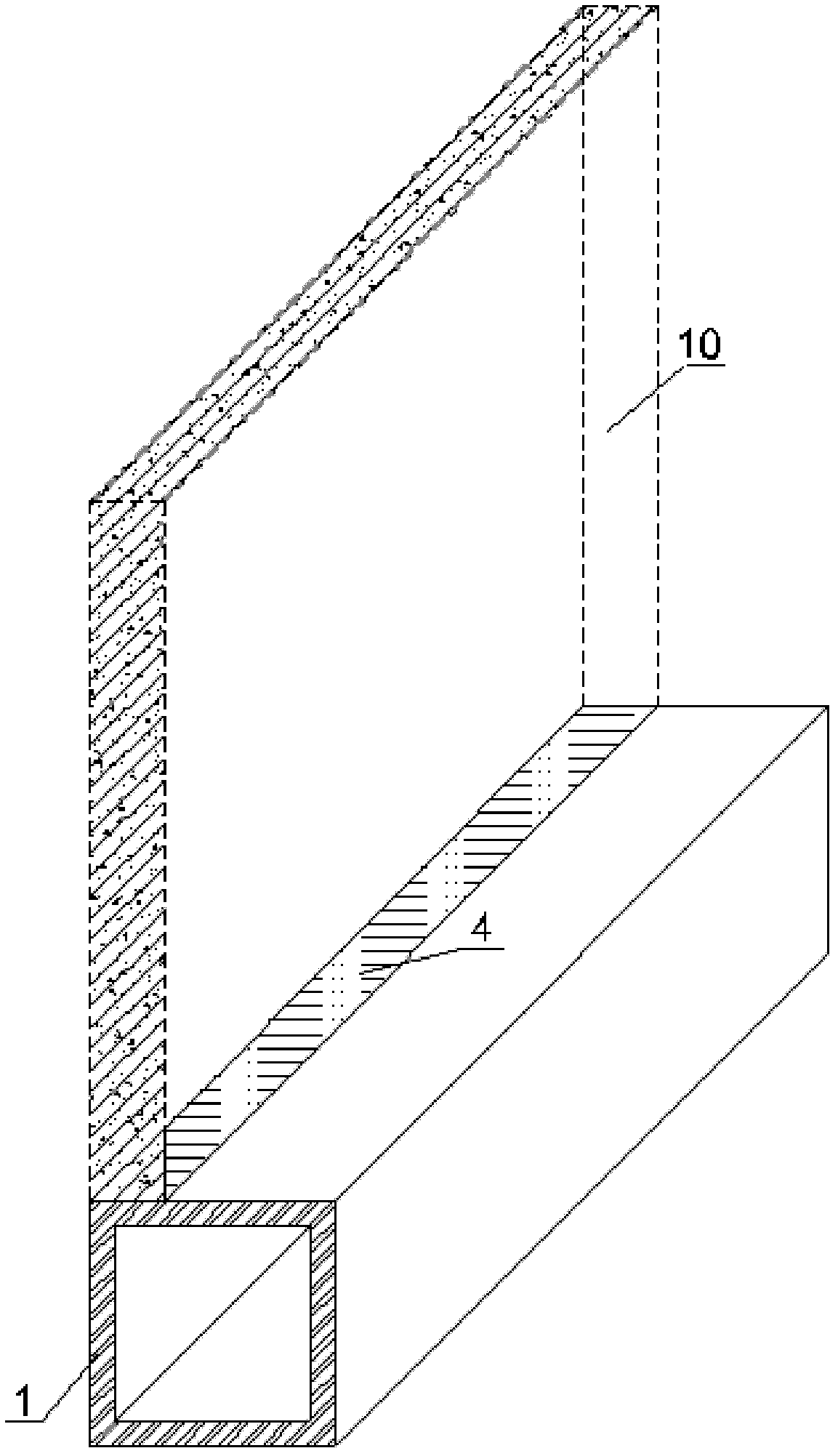

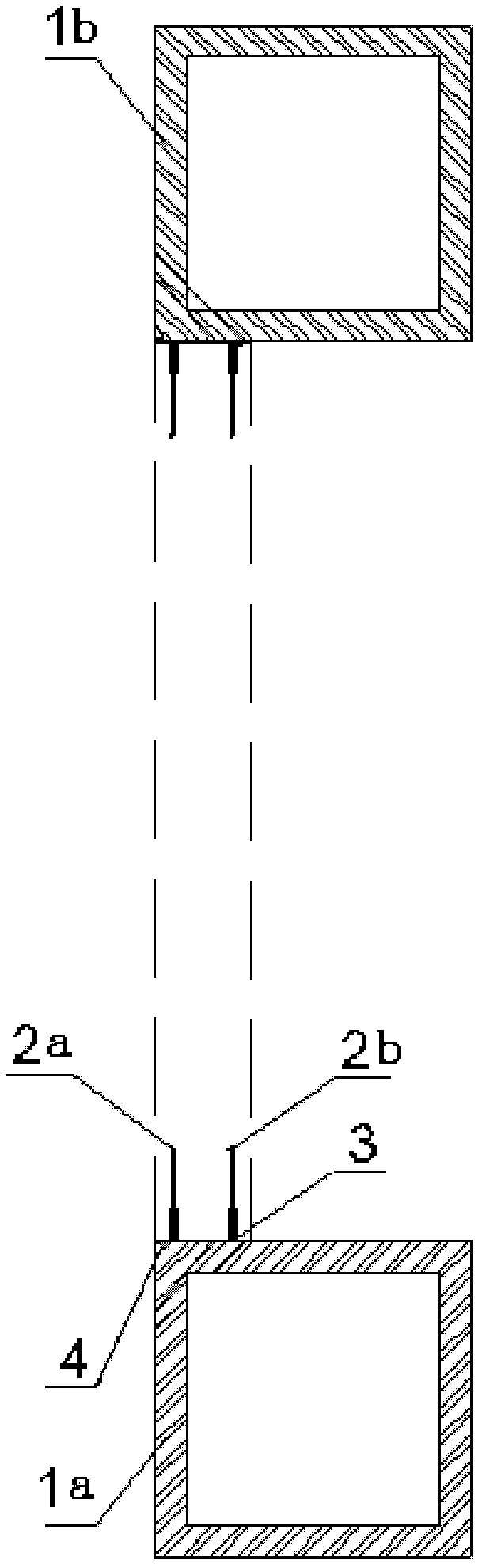

[0041] A flexible connection device between a thin-walled cast-in-place concrete enclosure structure and a steel structure, comprising a first steel structure 1a and a first water-stop steel plate 2a, characterized in that:

[0042] The first water-stop steel plate 2a and the second water-stop steel plate 2b are welded on the first steel structure 1a, and are arranged along the span direction of the first steel structure 1a; on the second steel structure 1b, two rows are welded in the same way as the first steel structure 1a The water-stop steel plate is symmetrical to the first steel structure 1a, and the connection between the water-stop steel plate and the steel structure or the water-stop steel plate is fully welded;

[0043] The waterproof rock wool board 5 is respectively pasted inside the first water-stop steel plate 1a and the second water-stop steel plate 1b through the adhesive glue 4, and pasted outside the first water-stop steel plate 1a and the second water-stop st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com