Interior wall self heat-insulation building block

A self-insulating block and inner wall technology, which is applied in applications, household appliances, ceramic products, etc., can solve the problems that the performance indicators of blocks cannot meet the standard requirements, affect the strength of blocks, and have high compressive strength, etc. The structure is better, the effect is better, and the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

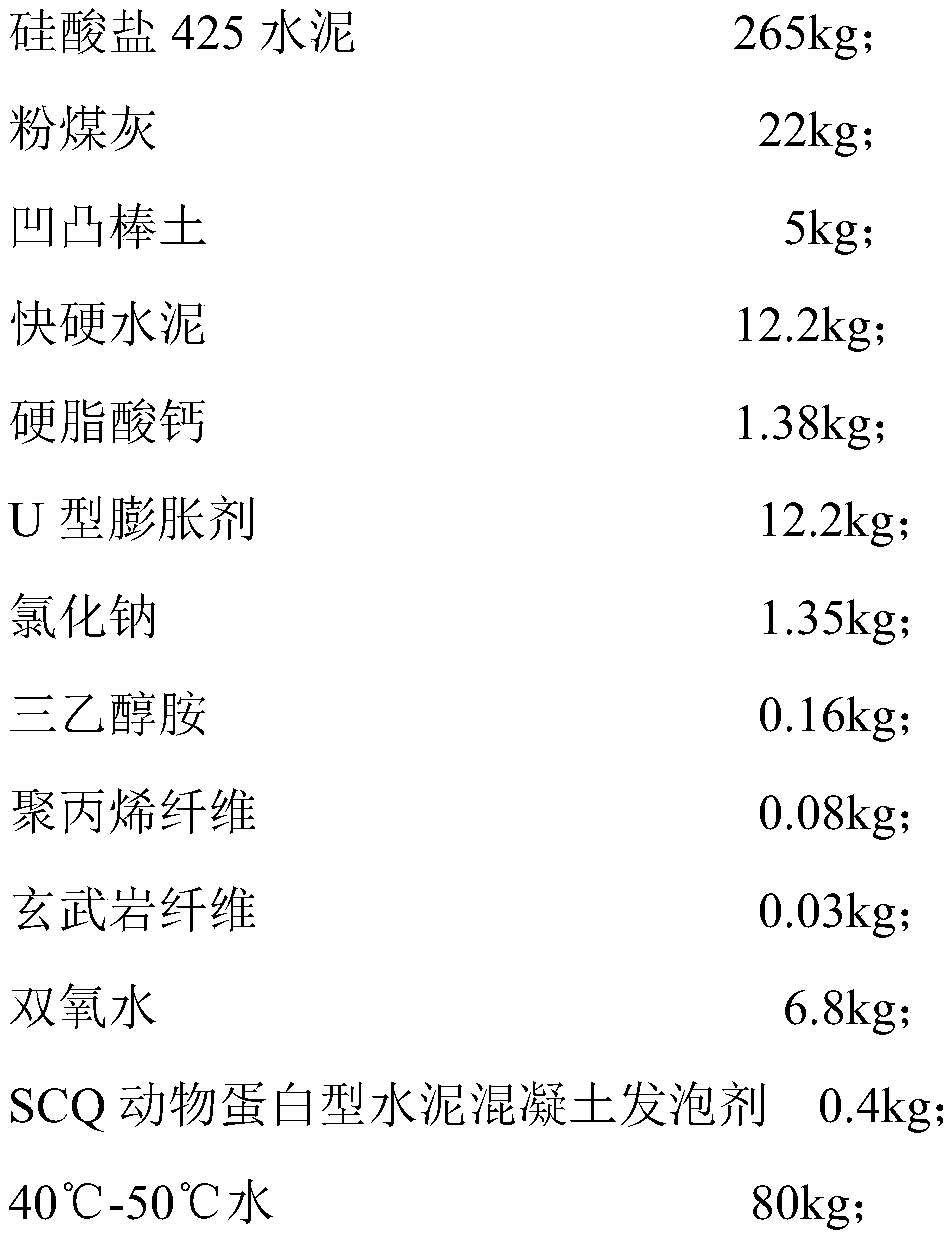

[0016]

[0017] The fly ash is composed of 6.6kg ultra-fine fly ash, 9.9kg class II fly ash and 5.5kg class I fly ash;

[0018] The specific steps are as follows:

[0019] (1) After soaking the attapulgite with 2 times the water for 3-5 minutes, set aside;

[0020] (2) 0.4kg SCQ animal protein type cement concrete foaming agent is mixed with 16kg water, and foam is made with a foam maker;

[0021] (3) 6.8kg hydrogen peroxide is mixed with the hydrogen peroxide that mass concentration is 5%;

[0022] (4) 265kg of Portland 425 cement, 6.6kg of superfine fly ash, 9.9kg of grade II fly ash, 5.5kg of grade I fly ash, 12.2kg of rapid hardening cement, 1.38kg of calcium stearate, and 12.2kg of U-type Expanding agent, 1.35kg sodium chloride, 0.16kg triethanolamine, 0.08kg polypropylene fiber, 0.03kg basalt fiber and the attapulgite soaked in step (1) were added to 40°C-50°C water and mixed for 2 minutes, then added The foam prepared in step (2) was stirred for 10 s, and then the...

Embodiment 2

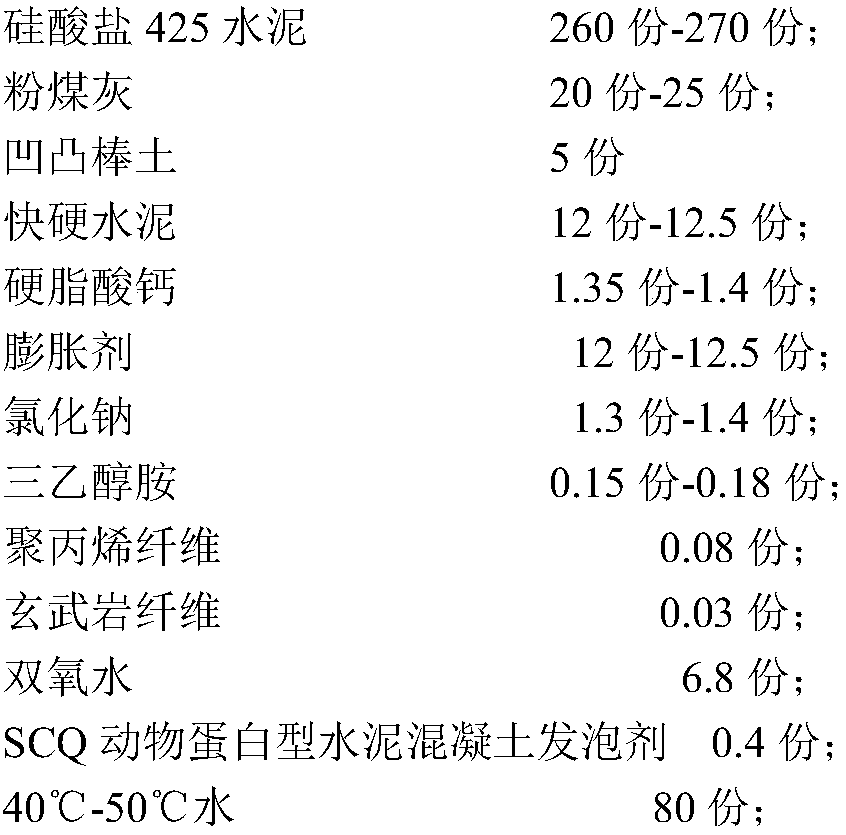

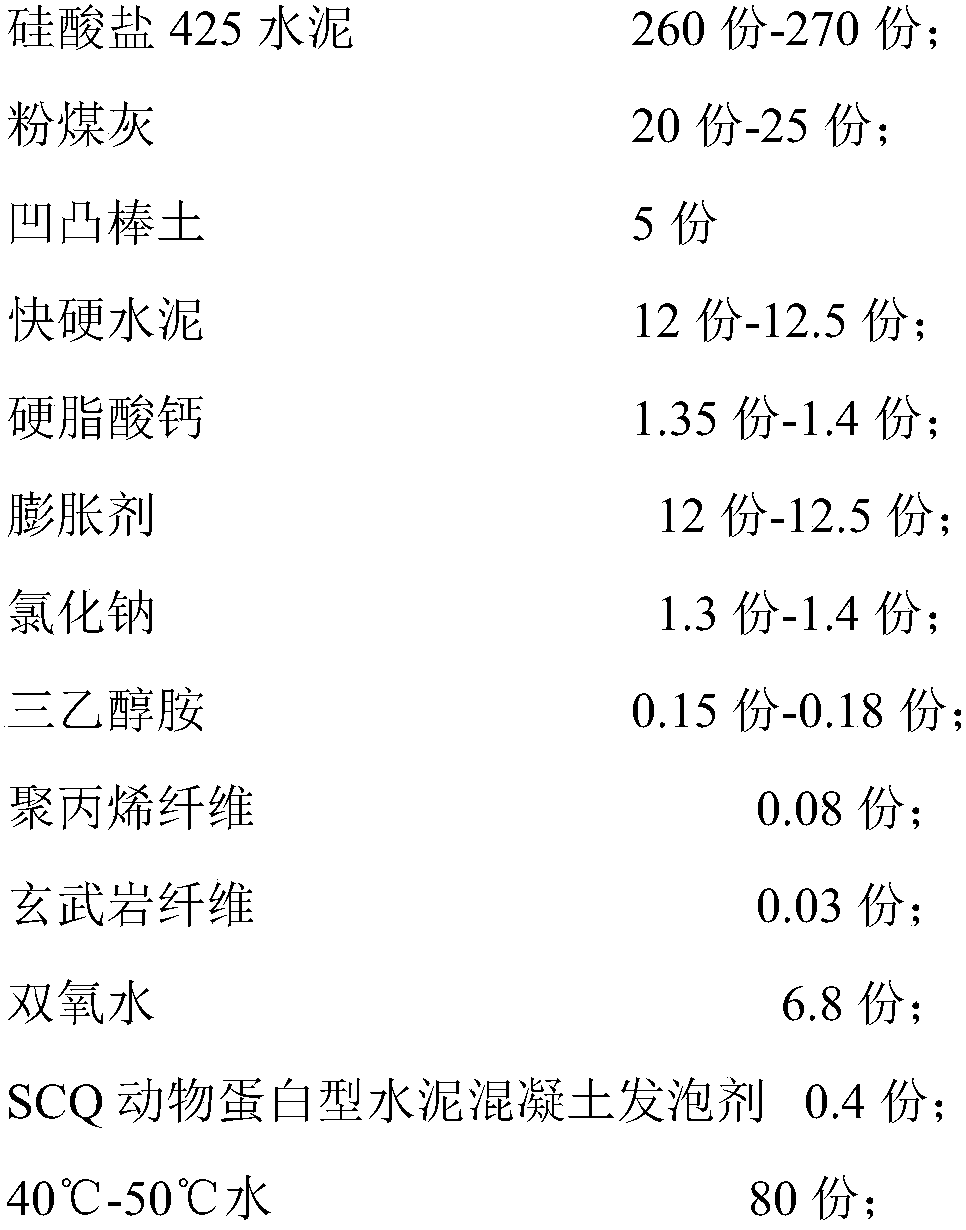

[0024]

[0025] The fly ash is composed of 30wt% superfine fly ash, 45wt% class II fly ash and 25wt% class I fly ash;

[0026] The specific steps are as follows:

[0027] (1) After soaking the attapulgite with 2 times the water for 3-5 minutes, set aside;

[0028] (2) Mix SCQ animal protein cement concrete foaming agent and water according to the mass ratio of 1:40, and make foam with a foam making machine;

[0029] (3) Portland 425 cement, superfine fly ash, class II fly ash, class I fly ash, rapid hardening cement, calcium stearate, U-type expansion agent, sodium chloride, triethanolamine, poly Propylene fiber, basalt fiber and attapulgite soaked in step (1) are added to 40°C-50°C water and mixed for 2 minutes, then the foam prepared in step (2) is added, stirred for 10s, and then added with a mass concentration of 5% After 10 seconds of hydrogen peroxide, it is poured into the mold, and the slurry is foamed in the mold to form a block. The surface of the block is cover...

Embodiment 3

[0031]

[0032] The fly ash is composed of 30wt% superfine fly ash, 45wt% class II fly ash and 25wt% class I fly ash;

[0033] The specific steps are as follows:

[0034] (1) After soaking the attapulgite with 2 times the water for 3-5 minutes, set aside;

[0035] (2) Mix SCQ animal protein cement concrete foaming agent and water according to the mass ratio of 1:40, and make foam with a foam making machine;

[0036] (3) Portland 425 cement, superfine fly ash, class II fly ash, class I fly ash, rapid hardening cement, calcium stearate, U-type expansion agent, sodium chloride, triethanolamine, poly Propylene fiber, basalt fiber and attapulgite soaked in step (1) are added to 40°C-50°C water and mixed for 2 minutes, then the foam prepared in step (2) is added, stirred for 10s, and then added with a mass concentration of 5% After 10 seconds of hydrogen peroxide, it is poured into the mold, and the slurry is foamed in the mold to form a block. The surface of the block is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com