Epoxy seam gum and preparation method thereof

An epoxy, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of easy yellowing at the application site, affecting the bonding effect, affecting the construction efficiency, etc. The effect of large-scale production, convenient deployment and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In the preparation method of the above-mentioned epoxy joint adhesive, the raw materials of the A component are fully stirred and mixed in proportion, and the raw materials of the B component are fully stirred and mixed in proportion to obtain the A component and B components are stored separately for later use to obtain an epoxy joint adhesive.

[0075] The method of the invention has simple process, can effectively guarantee the comprehensive performance of the obtained epoxy joint adhesive, and is suitable for large-scale production.

[0076] Preferably, the preparation method of the A component comprises:

[0077] Weigh each raw material in proportion, first add benzyl alcohol, wetting agent and lubricant to the epoxy resin, stir and mix well; then add anti-sedimentation agent, stir and mix well; then add transparent powder and thixotropic agent, fully Stir evenly; finally add defoamer and stir well to obtain component A.

[0078] Preferably, the preparation of th...

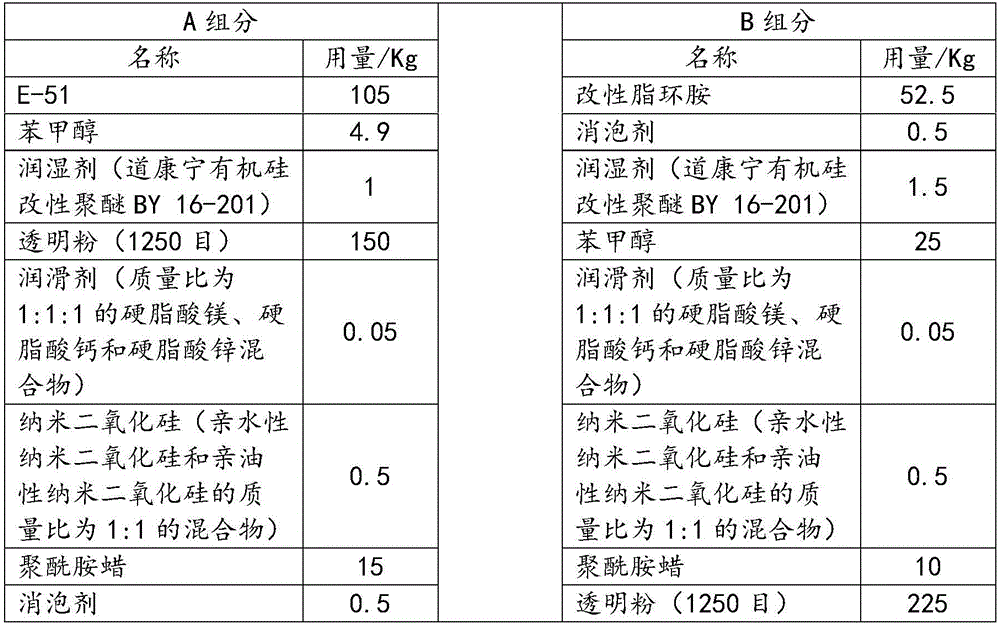

Embodiment 1

[0098] A preparation method of epoxy joint glue, comprising:

[0099] Preparation of component A: Pour the measured epoxy resin into the high-speed disperser, start the power supply and temperature control system of the disperser, control the speed at 1510±10r / min, control the temperature at 55-58°C, and stir in turn Add the measured benzyl alcohol, wetting agent and lubricant, and stir for 5 minutes; reduce the stirring speed to 510±10r / min, add the measured anti-settling agent, and after the anti-settling agent is fully wetted, adjust the stirring speed to 2510± Stir at 10r / min for 20min; add the measured transparent powder and thixotropic agent, and continue stirring for 40min; then reduce the speed to 510±10r / min, add the measured defoamer, stir for 10min, and discharge to obtain transparent epoxy Seam glue A component;

[0100] Preparation of component B: Pour the measured modified alicyclic amine curing agent into the high-speed disperser, start the power supply and tem...

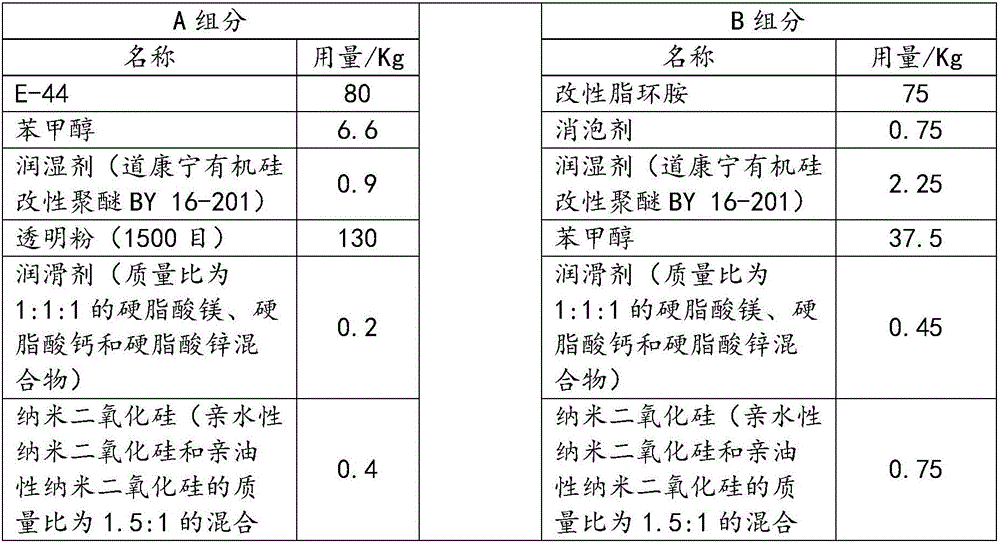

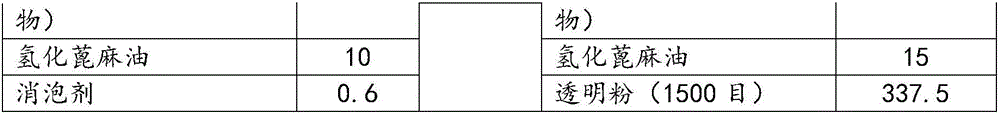

Embodiment 2

[0106] A preparation method of epoxy joint glue, comprising:

[0107] Preparation of component A: Pour the measured epoxy resin into the high-speed disperser, start the power supply and temperature control system of the disperser, control the rotation speed at 1910±10r / min, and control the temperature at 60-63°C, while stirring Add the measured benzyl alcohol, wetting agent and lubricant, and stir for 10 minutes; reduce the stirring speed to 610±10r / min, add the measured anti-settling agent, and after the anti-settling agent is fully wetted, adjust the stirring speed to 3010± 10r / min, stir for 30min; add the measured transparent powder and thixotropic agent, and continue to stir for 60min; then reduce the speed to 610±10r / min, add the measured defoamer, stir for 15min, and the transparent epoxy will be obtained after discharge Seam glue A component;

[0108] Preparation of component B: Pour the measured modified alicyclic amine curing agent into the high-speed disperser, star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com