Trial four-linking technology

A quadruple, technical technology, applied in the direction of production fluid, measurement, wellbore/well components, etc., can solve the problems of complex pipe string, affecting the determination of fluidity, and low precision of mechanical pressure gauge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

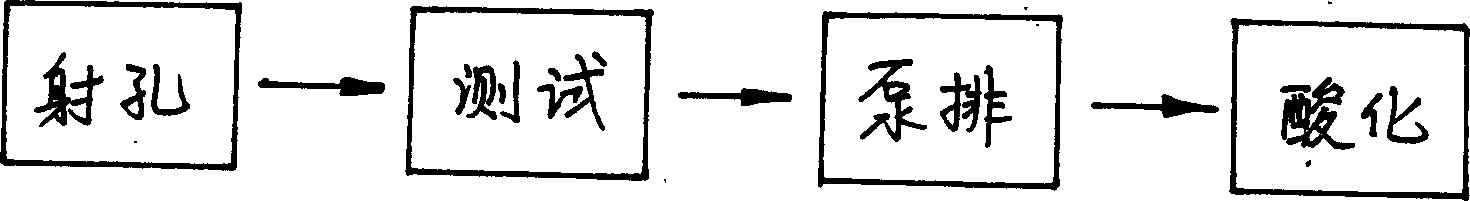

[0011] see figure 1 As shown, the oil testing quadruple operation technology refers to the completion of perforating, testing, pumping, and acidizing measures in one string. Its basic working principle: run perforating guns, fishable test devices, hydraulic pumps and other tools into the well together with the pipe string, cast rods to perforate after positioning, measure liquid level or surface self-spraying for production, shut down and measure Pressure recovery, if pumping is required, pumping is carried out for production, and if measures such as acidification and plugging removal are required, construction is carried out without moving the pipe string.

[0012] The depth error of the perforation process is ±20cm. For perforating bullets, there are basically no special restrictions, as long as they are suitable for the casing size, but try to avoid using booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com