Solvent-type organic silicon stone protectant and preparation method thereof

A silicone and solvent-based technology, applied in the direction of coating, etc., can solve the problems that it is not suitable for industrial production and popularization, the effect of stone protective agent is good, and the cost cannot be connected with the market. It achieves good breathability, low price, and easy construction. Safe and Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

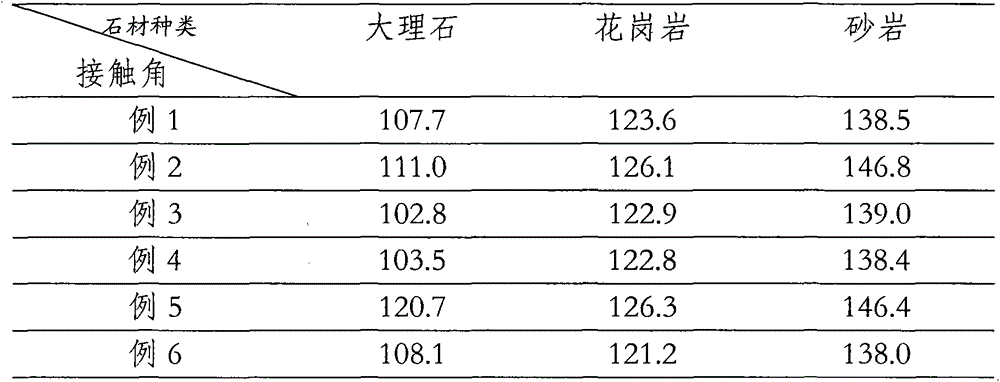

[0038] While stirring, first dissolve 50ml of methyltrimethoxysilane and 10ml of polymethylhydrogensiloxane in 200ml of D40 environment-friendly solvent oil. After 5 minutes, add 1m1 of tetra-n-butyl titanate, continue stirring for 15 minutes, and finally Add D40 environmentally friendly solvent oil to make up to 1000ml, and stir for 10 minutes. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 1.

Embodiment 2

[0040] While stirring, first dissolve 50ml of isobutyltriethoxysilane and 10ml of polymethylhydrogensiloxane in 200ml of D40 environment-friendly solvent oil. After 5 minutes, add 1ml of tetra-n-butyl titanate and continue stirring for 15 minutes. , and finally add D40 environmentally friendly solvent oil to make up to 1000ml, and stir for 10 minutes. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 2.

Embodiment 3

[0042] While stirring, first dissolve 50ml of dodecyltrimethoxysilane and 10ml of polymethylhydrogensiloxane in 200ml of D40 environment-friendly solvent oil. After 5min, add 1ml of tetra-n-butyl titanate and continue stirring for 15min. , and finally add D40 environmentally friendly solvent oil to make up to 1000ml, and stir for 10 minutes. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com