Inorganic dry powder texture coating

A technology of texture coating and inorganic dry powder, which is applied in the fields of filling slurry, sustainable waste treatment, solid waste management, etc. It can solve the problems of difficult to make three-dimensional or texture, high flatness requirements of substrates, poor coating adhesion, etc. No problem, to achieve the effect of novel decorative effect, non-fading finish color, and non-peeling coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A kind of inorganic dry powder texture paint, take 325 mesh ash calcium powder 12kg, 200 mesh quartz powder 20kg, 120 mesh quartz sand 10kg, 325 mesh heavy calcium powder 30kg, hydroxypropyl methylcellulose HPMC 0.5kg, redispersible latex powder Put 1kg of DY-5030, 1kg of polyvinyl alcohol powder 24-88P and 0.3kg of wood fiber into a mixer and stir well to get the finished product.

Embodiment 2

[0016] A kind of inorganic dry powder texture coating, take 325 mesh ash calcium powder 15kg, 200 mesh quartz powder 30kg, 120 mesh quartz sand 15kg, 325 mesh heavy calcium powder 40kg, HPMC 0.6kg, redispersible latex powder DY-5030 2kg, polyethylene Put 2kg of alcohol powder 24-88P and 0.4kg of wood fiber into a blender and stir well to get the finished product.

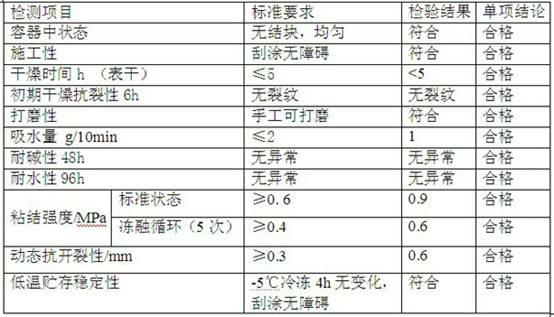

[0017] When using the inorganic dry powder texture coatings of Examples 1 and 2 of the present invention, add an appropriate amount of water and stir them evenly with an electric mixer. They can be directly applied on qualified substrates without a primer. Pigments can be added as needed, and they are suitable for Various construction tools can be sprayed, rolled, brushed, and can be wiped and pressed. After making the flexible anti-crack putty for the outer wall, the inspection data is shown in the table below:

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com