Anti-carburizing painting capable of being removed through washing after quenching and preparation method thereof

A technology of anti-carburizing coatings and materials, applied in the field of anti-carburizing coatings, can solve problems such as low temperature resistance, affecting carburizing quality, interfering with carburizing atmosphere, etc., achieves strong acid resistance, excellent coating performance, and does not affect carburizing The effect of carbon atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An anti-carburization coating that can be washed and removed after quenching, consisting of 26% boric acid, 3% lithium-based bentonite, 5% kaolin, 8% titanium dioxide, 25% aluminum dihydrogen phosphate, 1% It is formulated with zinc chrome yellow and 32% water.

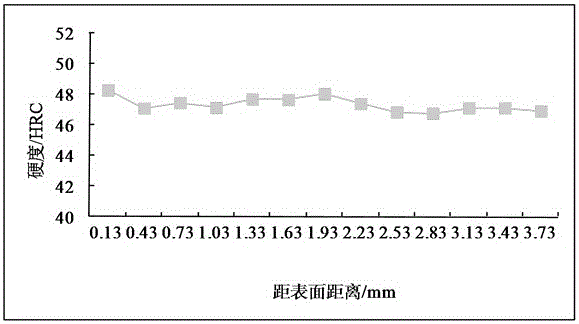

[0026] Use the anti-carburizing coating of embodiment 1 to carry out anti-carburizing treatment to the gear that material is 20CrNi2Mo, and carburizing process is 940 ℃ of heating 110h, and carburizing layer depth is 4.1-4.8mm, direct quenching after carburizing, the workpiece after quenching After soaking in water at 50°C for 3 hours, the anti-carburization coating on the surface of the workpiece peeled off completely. The structure of its surface after the anti-carburizing coating of embodiment 1 is brushed on the workpiece is as follows: figure 1 shown. Because the anti-carburizing coating of embodiment 1 has good anti-seepage effect, can effectively prevent carbon atoms from penetrating into the workpiece...

Embodiment 2

[0029] An anti-carburization coating that can be washed and removed after quenching, consisting of 25% boric acid, 5% lithium-based bentonite, 10% titanium dioxide, 15% aluminum dihydrogen phosphate, 5% chrome yellow and 40 % of water prepared.

Embodiment 3

[0031] An anti-carburizing coating that can be washed and removed after quenching, consisting of 35% boric acid, 3% lithium-based bentonite, 14% titanium dioxide, 16% aluminum dihydrogen phosphate, and 2% tetrabasic zinc Yellow and 30% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com