Long-acting antirust grease and preparation method thereof

A grease and long-acting technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of difficult disassembly again, poor durability of anti-rust grease, etc., to reduce the cost of oiling, uniform and soft film quality, excellent physical and chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

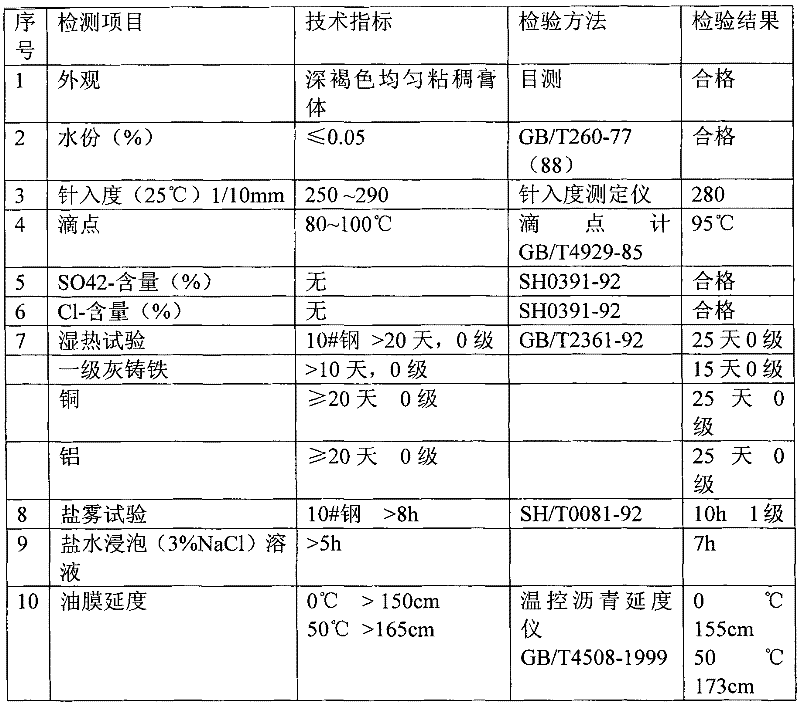

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of long-acting antirust grease:

[0031] 1. Formula (parts by weight): 5 parts of base oil N4685; 5 parts of calcium hydroxide; 4 parts of barium petroleum sulfonate; 1.5 parts of Span-80; 1 part of 746 antirust agent; 0.5 parts of butyl-4-methylphenol; 5 parts of n-bromopropane; 0.1 parts of 2.3-dibutanone.

[0032] 2. Process operation steps:

[0033] Add the formulated amount of phenolic modified resin, 2.3-dibutanone into the dissolution and dispersion kettle, after static swelling for 3 to 5 hours, add the formulated amount of n-bromopropane, stir for 3 hours to completely dissolve, the solution is brownish red transparent, add Anti-rust additives in the prescribed amount - a mixture of barium petroleum sulfonate, Span-80, and 746 anti-rust agents, stirred for 1 hour to completely dissolve. After complete dissolution, add 85 parts of base oil N468 of formula quantity.

[0034] Add the formulated amount of 2.6-di-tert-butyl-4-methylpheno...

Embodiment 2-9

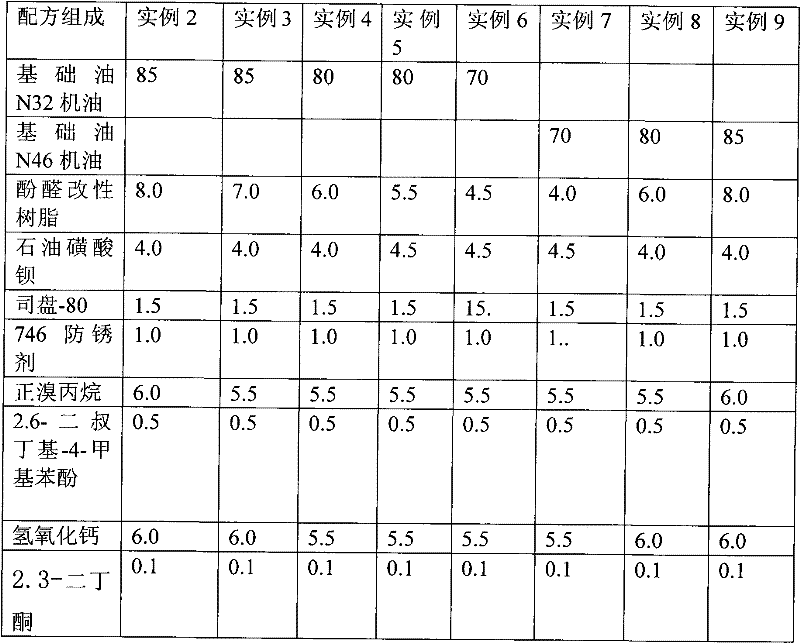

[0039] Embodiment 2-9: Preparation of long-acting antirust grease

[0040] 1. Formula (parts by weight)

[0041]

[0042] 2. Process operation steps: add 2.6-di-tert-butyl-4-methylphenol, 40°C for Examples 2-4, 45°C for Examples 5-6, and 50°C for Examples 7-9.

[0043] Add calcium hydroxide example 2~4 is 50 ℃, example 5~6 is 60 ℃, example 7~9 is 70 ℃.

[0044] Other technological operations are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com