Mildew-proof antibacterial putty powder and using method

A technology of anti-mildew and antibacterial putty powder, which is applied in the direction of filling slurry, etc., can solve the problems of unsuitable market demand, poor water resistance and bonding strength of putty powder, and poor use effect, so as to inhibit the growth and spread, sticky High knot strength and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

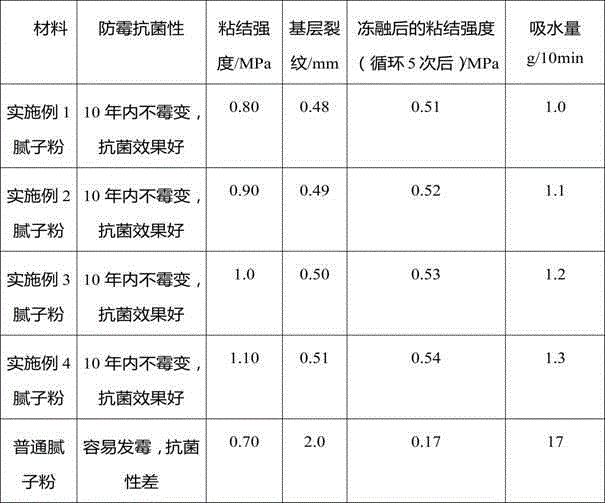

Examples

Embodiment 1

[0025] A mildew-proof and antibacterial putty powder and its application method

[0026] Composition of anti-mildew and anti-bacterial putty powder:

[0027] Main material: zinc fluorosilicate 1kg, quartz sand 20kg, gypsum powder 1kg, talc powder 1kg, kaolin 10kg, piezoelectric ceramic powder 1kg, marble powder 10kg, ferromagnesia tourmaline 1kg, terbium trioxide 3kg, dodecyl oxide Calcium fourteen aluminum 3kg.

[0028] Adhesive materials: sodium tripolyphosphate 1kg, hydroxyethyl cellulose 3kg, polypropylene fiber 3kg, starch ether 4kg, white cement 3kg, methyl cellulose ether 3kg.

[0029] Anti-mildew and anti-bacterial material: TiO 2 1kg, ZnO1kg, CdS3kg, WO 3 3kg, SnO 2 3kg, sodium diacetate 3kg, Fe 2 o 3 3kg.

[0030] Preparation and use method:

[0031] The main material, adhesive material and anti-mildew and anti-bacterial material are separately crushed before packaging, with a fineness of 50 μm, and packaged separately in a large putty powder package, and the...

Embodiment 2

[0033] A mildew-proof and antibacterial putty powder and its application method

[0034] Composition of anti-mildew and anti-bacterial putty powder:

[0035] Main material: zinc fluorosilicate 3kg, quartz sand 25kg, gypsum powder 4kg, talc powder 3kg, kaolin 15kg, piezoelectric ceramic powder 3kg, marble powder 20kg, ferromagnesia tourmaline 3kg, terbium trioxide 1kg, dodecyl oxide Calcium fourteen aluminum 1kg.

[0036] Adhesive materials: sodium tripolyphosphate 3kg, hydroxyethyl cellulose 3kg, polypropylene fiber 5kg, starch ether 5kg, white cement 5kg, methyl cellulose ether 5kg.

[0037] Anti-mildew and anti-bacterial material: TiO 26kg, ZnO6kg, CdS2.8kg, WO 3 2.8kg, SnO 2 2.8kg, sodium diacetate 2.8kg, Fe 2 o 3 2.8kg.

[0038] Preparation and use method:

[0039] The main material, adhesive material and anti-mildew and anti-bacterial material are separately crushed before packaging, with a fineness of 60 μm, and are individually packaged in a large package of put...

Embodiment 3

[0041] A mildew-proof and antibacterial putty powder and its application method

[0042] Composition of anti-mildew and anti-bacterial putty powder:

[0043] Main material: zinc fluorosilicate 1kg, quartz sand 25kg, gypsum powder 4kg, talc powder 1kg, kaolin 15kg, piezoelectric ceramic powder 1kg, marble powder 20kg, ferromagnesia tourmaline 3kg, tetraterbium heptoxide 3kg, twelve oxide Calcium fourteen aluminum 5kg.

[0044] Adhesive materials: sodium tripolyphosphate 2kg, hydroxyethyl cellulose 4kg, polypropylene fiber 4kg, starch ether 6kg, white cement 5kg, methyl cellulose ether 5kg.

[0045] Anti-mildew and anti-bacterial material: TiO 2 3kg, ZnO3kg, CdS3kg, WO 3 3kg, SnO 2 3kg, sodium diacetate 3kg, Fe 2 o 3 8kg.

[0046] Preparation and use method:

[0047] The main material, adhesive material and anti-mildew and anti-bacterial material are independently crushed before packaging, with a fineness of 70 μm, and are individually packaged in a large package of putt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com