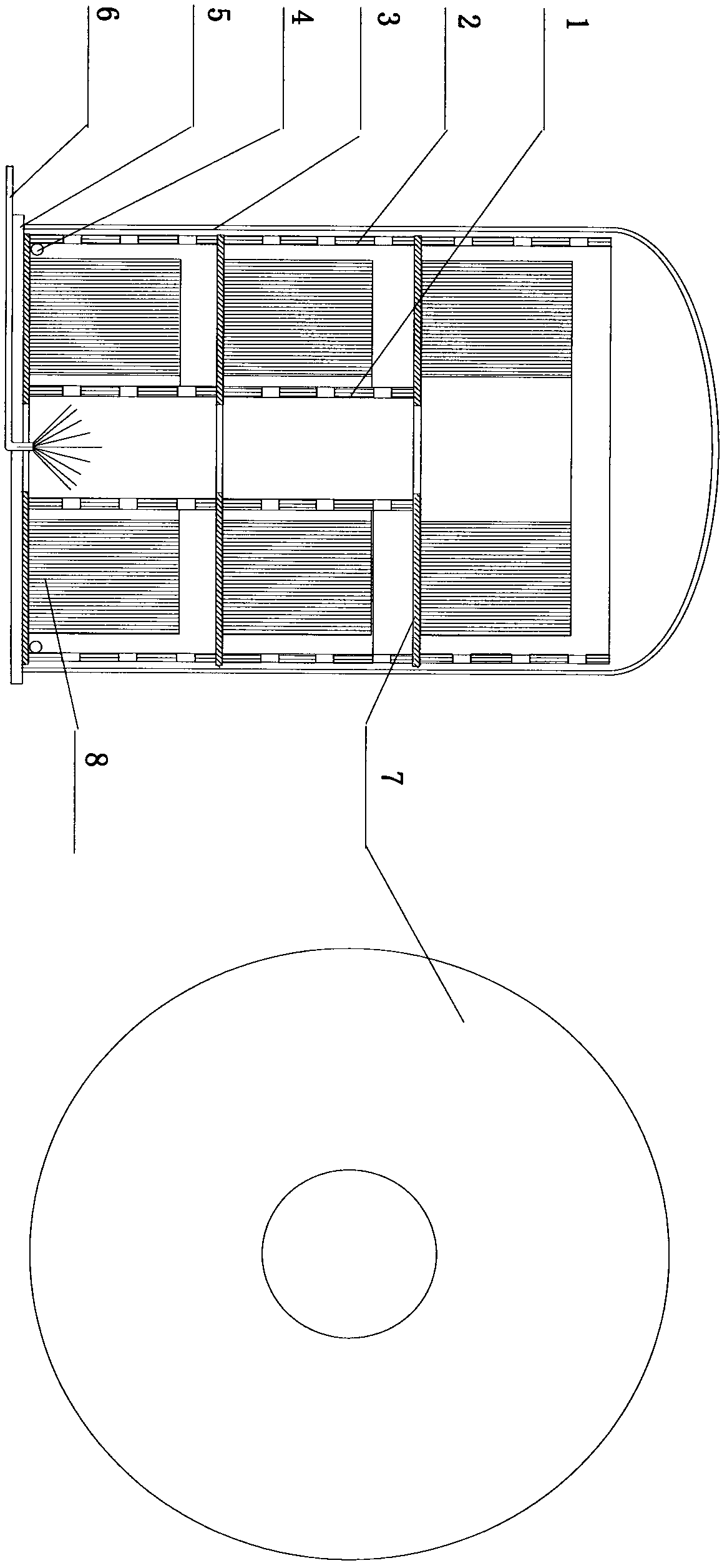

High temperature annealing air distribution system in orientation silicon steel strip coil bell type furnace

A technology of oriented silicon steel and high temperature annealing, applied in furnaces, heat treatment furnaces, furnace types, etc., it can solve problems such as safety risks, uneven temperature, and nitrogen specific gravity, so as to eliminate potential safety hazards, ensure product quality, and reduce oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

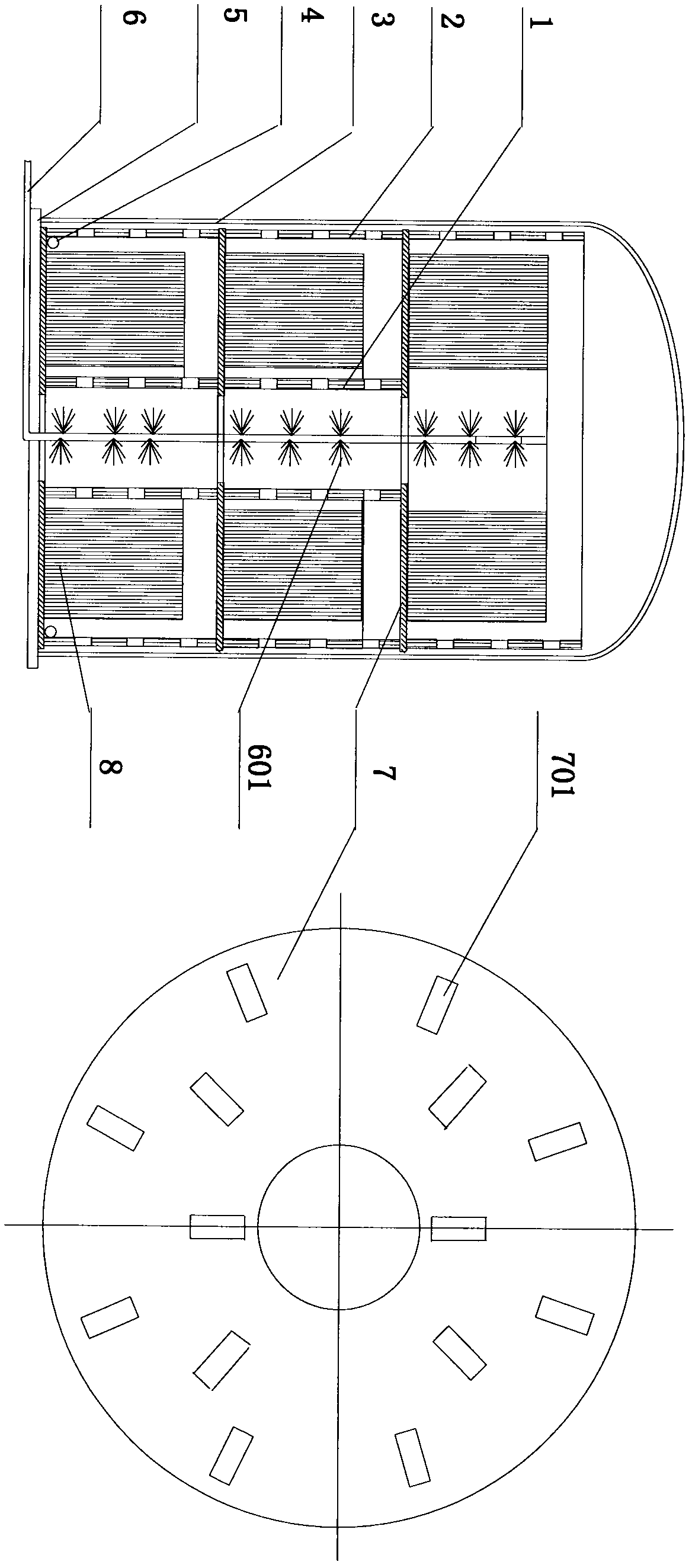

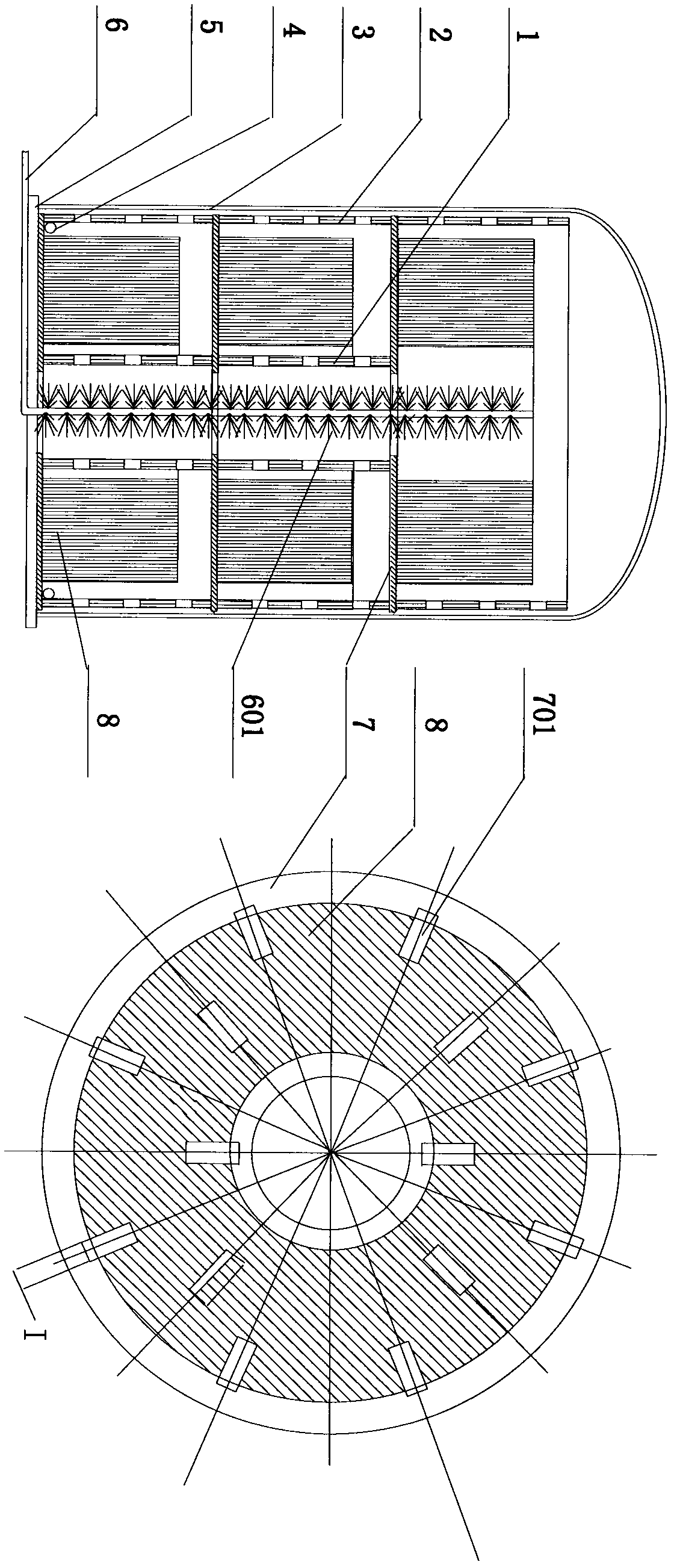

Method used

Image

Examples

Embodiment 1

[0060] Specifically, the following process steps are adopted:

[0061] (1) The loading capacity of the oriented silicon steel strip in the bell furnace is 3 coils.

[0062] (2) The total length of the gas supply pipeline for the furnace process atmosphere in the bell furnace is 2500mm.

[0063] (3) The material of the gas supply pipe for the process atmosphere in the bell furnace is Cr 25 Ni 35 .

[0064] (4) The specification of the gas supply pipe for the process atmosphere in the bell furnace is ¢25mm×2.0mm.

[0065] (5) The gas supply pipe for the process atmosphere in the bell-type furnace is provided with gas outlet channels at both ends of the same diameter direction every 100mm in the axial direction, and the radial angle between the upper and lower adjacent gas outlet channels in the axial direction is 180°C.

[0066] (6) The top of the gas supply pipe for the process atmosphere in the bell furnace is a blind hole.

[0067] (7) The gas outlet channel on the furna...

Embodiment 2

[0073] Specifically, the following process steps are adopted:

[0074] (1) The loading capacity of the oriented silicon steel strip in the bell furnace is 1 coil.

[0075] (2) The total length of the gas supply pipeline for the furnace process atmosphere in the bell furnace is 850mm.

[0076] (3) The material of the gas supply pipe for the process atmosphere in the bell furnace is Cr 25 Ni 35 .

[0077] (4) The specification of the gas supply pipe for the process atmosphere in the bell furnace is ¢8mm×1.0mm.

[0078] (5) The gas supply pipe for the process atmosphere in the bell-type furnace is provided with gas outlet channels at both ends of the same diameter direction at an axial interval of 30mm, and the radial angle between the upper and lower adjacent gas outlet channels in the axial direction is 180°C.

[0079] (6) The top of the gas supply pipe for the process atmosphere in the bell furnace is a blind hole.

[0080] (7) The gas outlet channel on the furnace proces...

Embodiment 3

[0086] Specifically, the following process steps are adopted:

[0087] (1) The loading capacity of oriented silicon steel strips in the bell furnace is 2 coils.

[0088] (2) The total length of the gas supply pipeline for the furnace process atmosphere in the bell furnace is 1300 mm.

[0089] (3) The material of the gas supply pipe for the process atmosphere in the bell furnace is Cr 25 Ni 35 .

[0090] (4) The specification of the gas supply pipe for the process atmosphere in the bell furnace is ¢12mm×2.0mm.

[0091] (5) The gas supply pipe for the process atmosphere in the bell-type furnace is provided with gas outlet channels at both ends of the same diameter direction every 65mm in the axial direction, and the radial angle between the upper and lower adjacent gas outlet channels in the axial direction is 180°C.

[0092] (6) The top of the gas supply pipe for the process atmosphere in the bell furnace is a blind hole.

[0093] (7) The gas outlet channel on the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com